Asymmetric V-shaped groove and double-point unlocking type rigid wrapping tape for interstage line type separation device

A separation device and asymmetric technology, applied in the direction of weapon types, projectiles, self-propelled projectiles, etc., can solve the problems of weak tape rigidity, poor tape restraint, uneven contact stress distribution, etc., to achieve preload and limit The effect of increased bearing capacity, uniform distribution of contact stress and preload, and uniform stress distribution of the tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

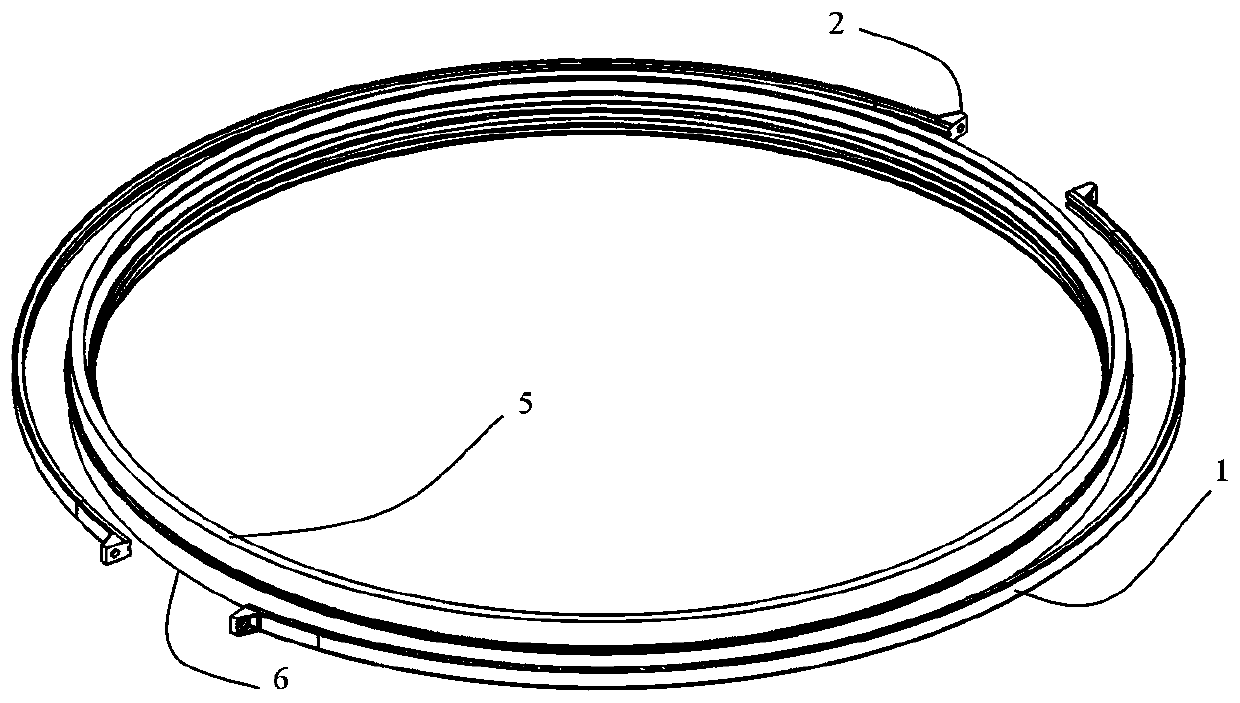

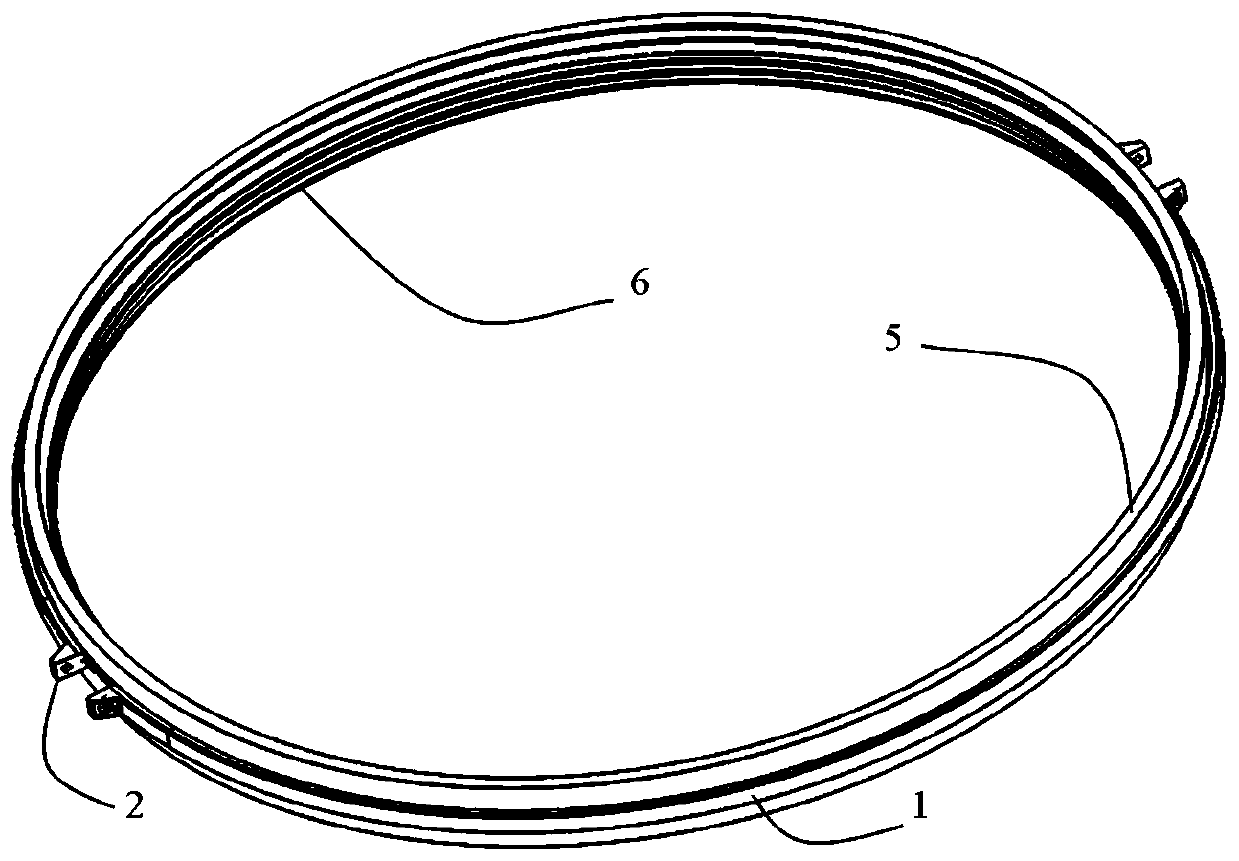

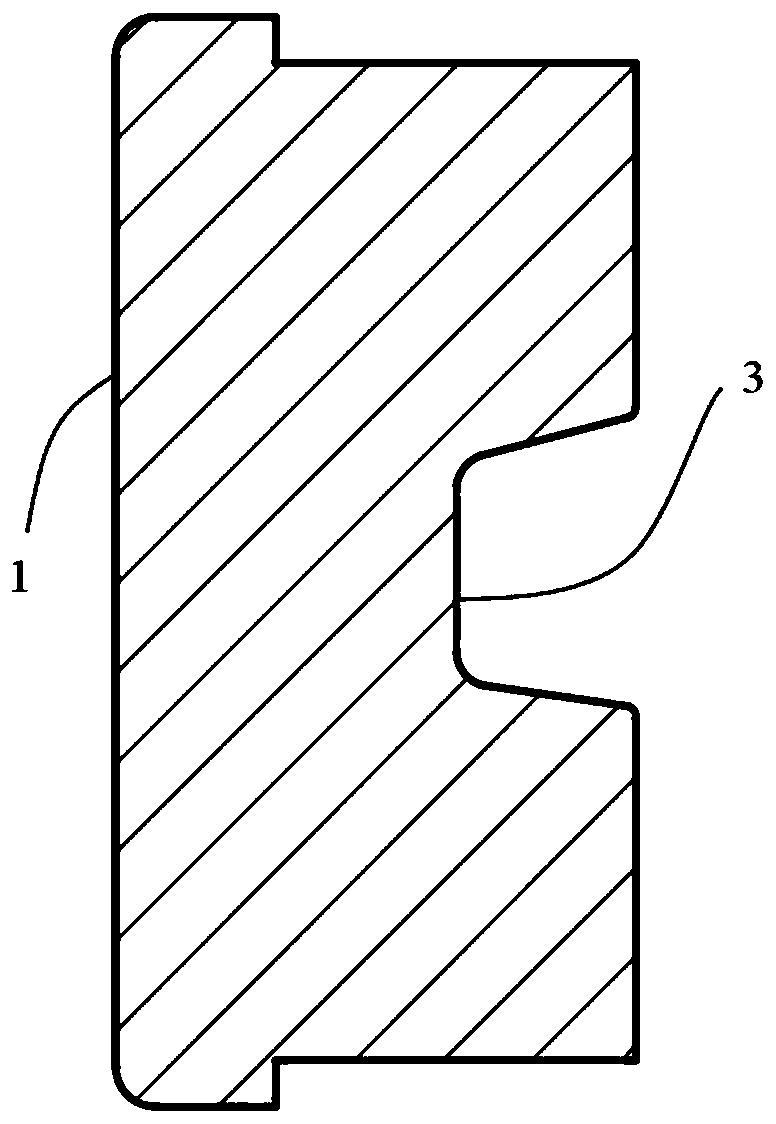

[0019] Such as Figure 1-5 As shown, the present invention provides an asymmetrical V-groove and double-point unlocking rigid tape for the inter-stage line separation device, and its features include a rigid tape 1, a tape end 2, an asymmetric V-shaped Groove 3 and bolt hole 4; the inner surface of the rigid tape 1 is processed to form an asymmetric V-shaped groove 3; the end of the tape 2 is provided with bolt holes 4; the lower end surface of the upper separation body 5 is separated from the lower wedge-shaped flange 7 The wedge-shaped flange 70 on the upper end surface of the body 6 is butted to form an asymmetric V-shaped flange 8 embedded in the asymmetric V-shaped groove 3 on the inner surface of the rigid tape 1, thereby realizing the connection function.

[0020] Rigid tape 1 is manufactured by rolling and bending process of thick aluminum plate with high rigidity. It is a split structure with double openings. The uniform preload can also greatly improve the ultimate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com