Novel soluble ball seat structure suitable for unconventional oil and gas exploitation

A technology of oil and gas exploitation and soluble ball seat, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve the problems of slip anchoring failure, fracturing operation failure, and large energy loss of fracturing fluid To achieve uniform distribution of contact stress, avoid insufficient sealing performance, and improve anchorage pressure-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

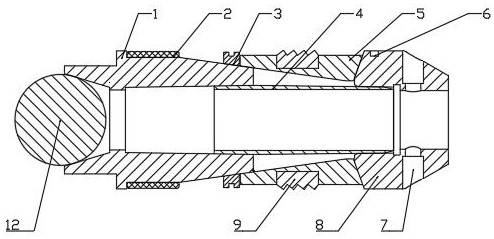

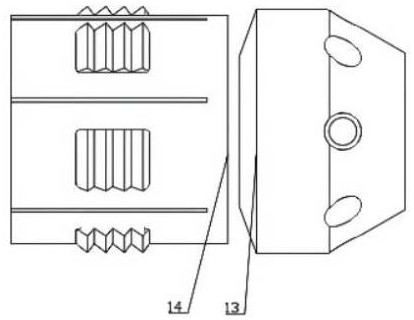

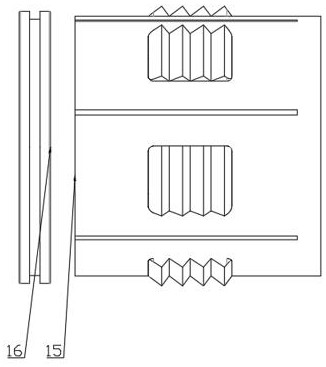

[0029] see figure 1 , 5 As shown in and 6, a new type of soluble ball seat structure suitable for unconventional oil and gas exploitation, including cone 1, metal sealing ring 3, locking ring 4, slip body 5 and anti-collision ring 9 from top to bottom , the outer ring surface of the locking ring 4 is matched with the inner ring surface of the cone 1; the outer surface of the cone 1 is sequentially covered with a rubber sealing rubber 2 and a metal sealing ring 3, and the slip body 5 is axially installed with a slip block 9, and the slip block 9 is a helical tooth, and the cusp of the slip block 9 faces the bottom of the ball seat during assembly.

[0030] The length of the rubber sealing rubber 2 is short. After the soluble ball seat is assembled, the length is less than 300mm, the outer diameter is 98mm, and the inner diameter is 35mm. The overall length of the ball seat is short and the amount of rubber used is small.

[0031] The rubber sealing rubber 2 interacts with the...

Embodiment 2

[0038] This embodiment is further optimized on the basis of Embodiment 1, refer to figure 1 and image 3 , the slip body 5 is in contact with the metal sealing ring 6, which can ensure the effective separation of the slip during the sealing process of the ball seat, and can ensure that the slip body 5 is evenly opened along the slit. 5 "C" type opening, which can effectively improve the anchoring ability of slips.

Embodiment 3

[0040] This embodiment is further optimized on the basis of Embodiment 1, refer to figure 1 , the anti-collision ring 8 is evenly installed with anti-wear teeth 6 in the circumferential direction; the anti-wear teeth 6 are installed in the circumferential anti-wear tooth holes of the anti-collision ring 8 to prevent the ball seat from being worn during the process of entering the ball seat into the well and ensure that the ball The role of the outer diameter of the seat.

[0041] After the ball seat is set, the slips crawl along the inclined surface of the cone 1 to the inner wall of the anchoring sleeve, and the resilience of the metal sealing ring 3 itself provides a pulling force for the slips, which cooperates with the inclined surface of the cone 1 to form a balance and promotes the The shoe body 5 is fitted to the inner wall of the casing, which can solve the problem of slip falling back in the single-slip structure.

[0042] After the ball seat is set, the slip body 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com