Water-based diamond polishing solution and preparation method thereof

A technology of diamond and polishing liquid, applied in the field of polishing liquid, can solve the problems of easy precipitation, poor stability of polishing liquid system, limited application of diamond polishing liquid, etc., and achieve the effect of high polishing efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

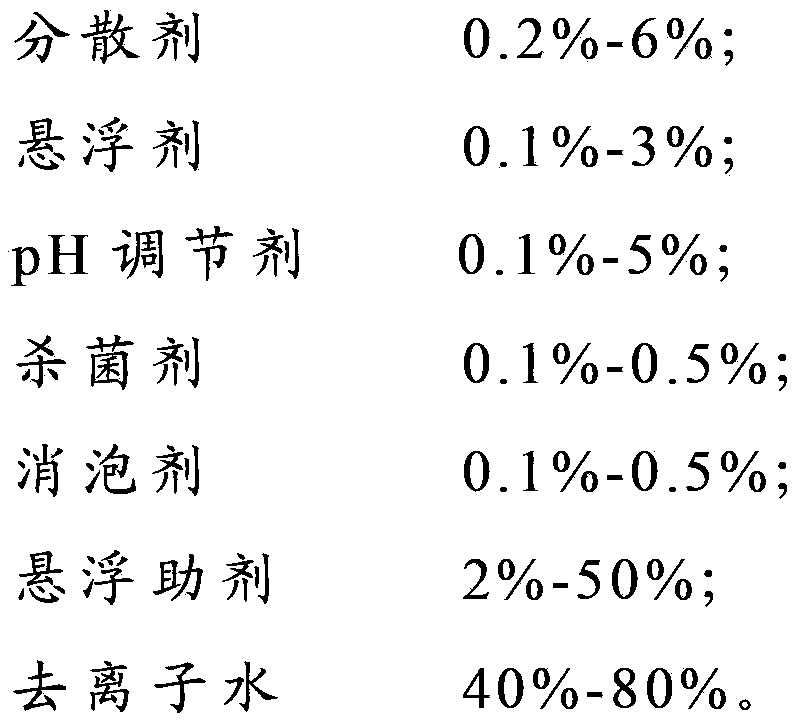

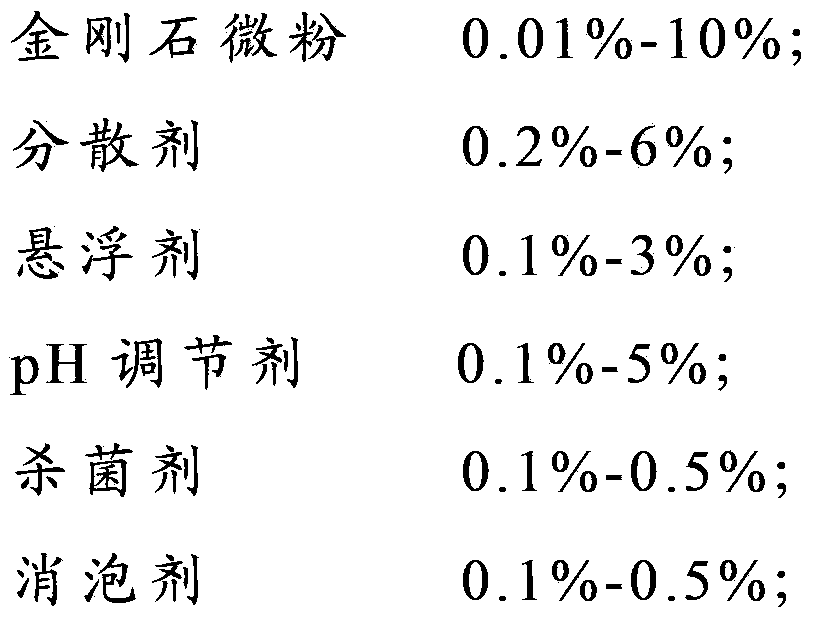

preparation example Construction

[0023] The preparation method of above-mentioned aqueous diamond polishing fluid, comprises the steps:

[0024] After mixing deionized water, dispersant, suspension aid and diamond micropowder, disperse into a diamond micropowder solution with loose precipitation. The dispersion method can adopt one or more combinations of mechanical stirring, ultrasonic oscillation, and mechanical ball milling. The dispersion time is preferably 1-2 hours.

[0025] Add the suspending agent into the diamond micropowder solution, and continue to disperse to obtain a suspended and stable water-based diamond polishing liquid. The dispersion method can adopt one or more combinations of mechanical stirring, ultrasonic oscillation, and mechanical ball milling. The dispersion time is preferably 1-2 hours.

[0026] Finally, add a bactericide, a defoamer and a pH regulator, and adjust the pH value of the water-based diamond polishing solution as required, and the adjustment range is 2-12.

[0027] T...

Embodiment 1

[0030] Take a beaker, add 80wt% deionized water, 0.5wt% polyvinyl alcohol, 2wt% polyethylene glycol, 2wt% single crystal diamond powder with a median particle size D50 of 6.065 μm, and ultrasonically oscillate for 2 hours , to obtain a diamond micropowder solution dispersed into loose precipitates. Then add 1.5wt% magnesium aluminum silicate, continue magnetic stirring for 1 hour, finally add 0.2wt% sodium benzoate and 0.2wt% simethicone, adjust the pH value to 9 with sodium carbonate, and make up the remaining deionized water. A diamond polishing liquid with a weight ratio of 2wt% in stable suspension was prepared.

[0031] Use the polishing liquid prepared above to polish stainless steel on an automatic polishing machine. The surface roughness of the workpiece before polishing is about 3 μm. The polishing pressure is 3.0kPa, the rotational speed is 150rpm, the flow rate of the polishing liquid is 5mL / min, and the polishing time is 5min. After polishing, the surface roughnes...

Embodiment 2

[0033] Take a beaker, add 80wt% deionized water, 1wt% sodium hexametaphosphate, 4wt% ethylenediamine, 2wt% single crystal diamond micropowder with a median particle diameter D50 of 3.516 μm, and ultrasonically vibrate for 2 hours. A diamond micropowder solution dispersed into loose precipitates is obtained. Then add 1.5wt% bentonite, continue magnetic stirring for 1 hour, finally add 0.2wt% sodium benzoate and 0.2wt% simethicone, adjust the pH value to 8 with phosphoric acid, and make up the remaining deionized water to obtain a stable suspension The weight ratio is the diamond polishing liquid of 2wt%.

[0034] Use the polishing liquid prepared above to polish stainless steel on an automatic polishing machine. The surface roughness of the workpiece before polishing is about 2 μm. The polishing pressure is 3.0kPa, the rotational speed is 150rpm, the flow rate of the polishing liquid is 5mL / min, and the polishing time is 5min. After polishing, the surface roughness of the stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com