Constant loading device for testing durability of reinforced concrete

A durability test, concrete technology, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, using a stable bending force to test the strength of materials, etc., can solve the problem of not being able to comprehensively and objectively reflect the durability of reinforced concrete, Affect the stability and service life of reinforced concrete components, and cannot guarantee the long-term stability of the load, etc., to achieve good observability, good corrosion resistance, and a large loading range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

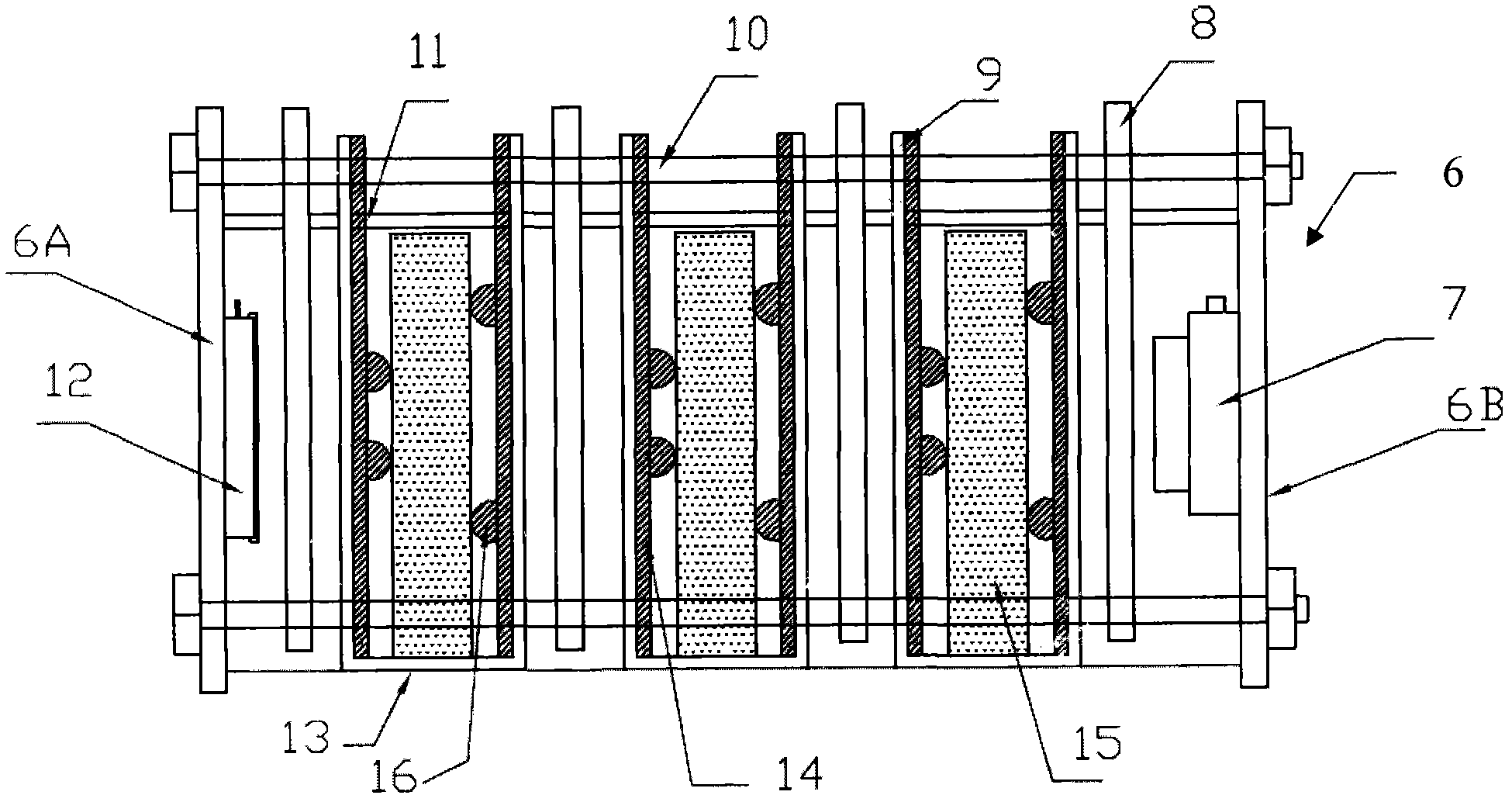

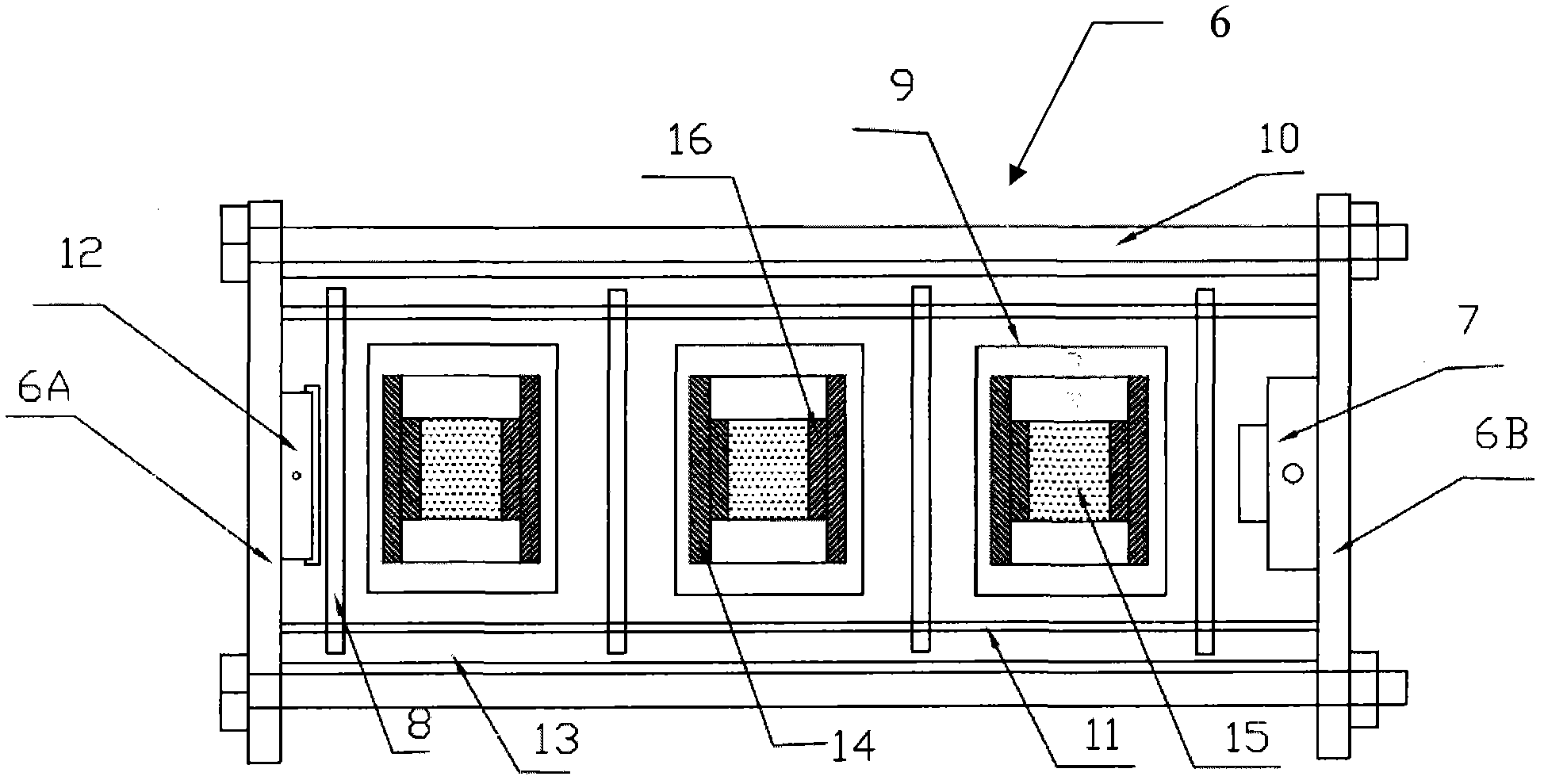

[0023] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

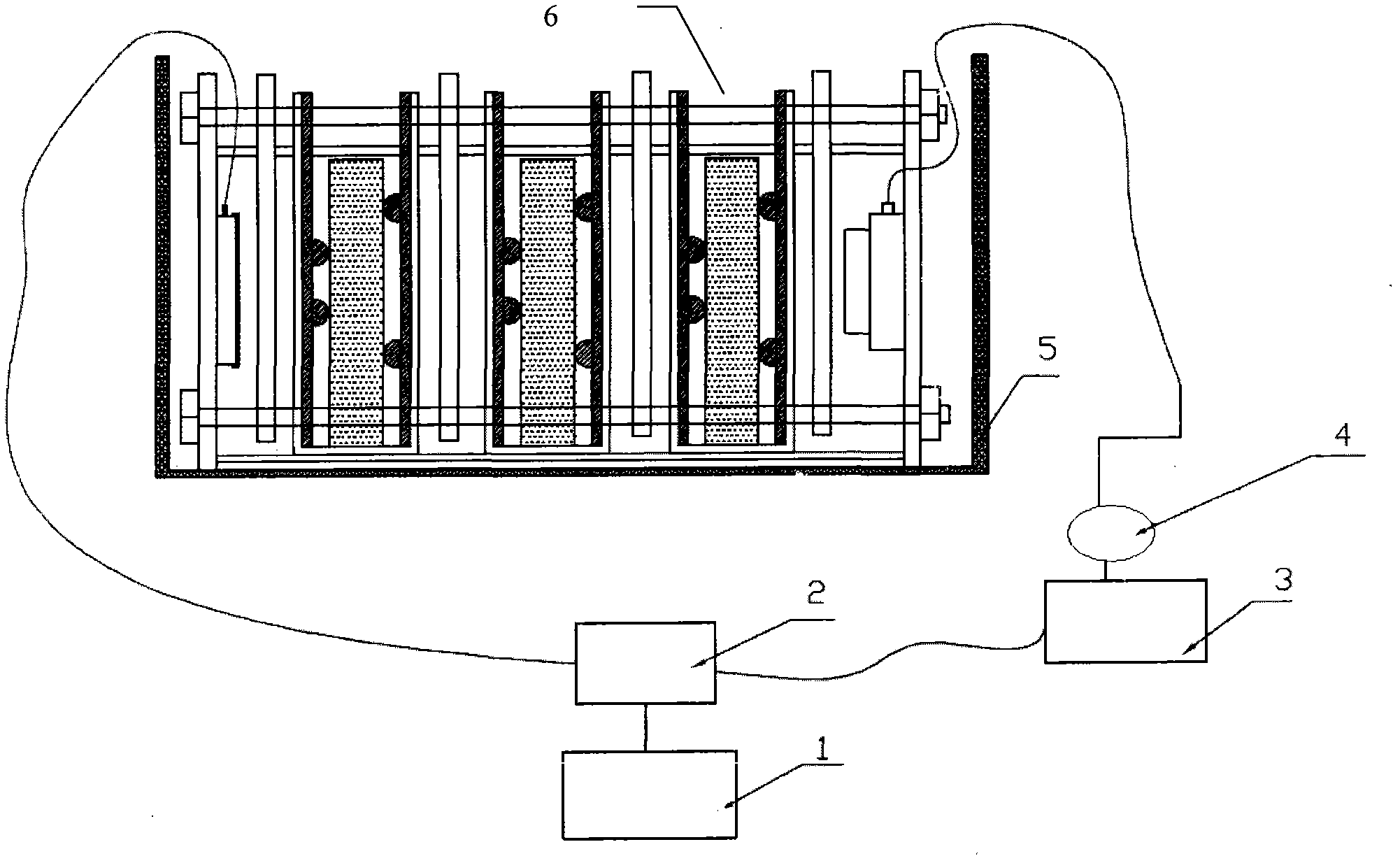

[0024] see figure 1 As shown, the constant loading device for reinforced concrete durability test of the present invention includes a touch screen 1 , a controller 2 , an electric hydraulic pump 3 , an energy storage tank 4 , a fast freeze-thaw cycler box 5 and a loading assembly 6 . in:

[0025] The touch screen 1 is a man-machine dialogue interface, which is connected with the controller 2 through a data line, through which the target setting value of the test can be input into the programmable controller PLC 2, and the change of the load can be observed at any time during the test Condition;

[0026] The controller 2 is a programmable logic controller PLC, which is the computing center of the whole device, and is responsible for collecting pressure sensors 12 from the loading assembly 6 (see figure 2 and image 3 ) to receive the signal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com