Verification tooling for rear cushion with cradle

A technology of cradle and tooling, which is applied in the field of motorcycle test tooling, can solve the problems of no verification tooling, rust, and damaged bearings, etc., and achieve the effect of authenticity, reliability and good durability of verification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

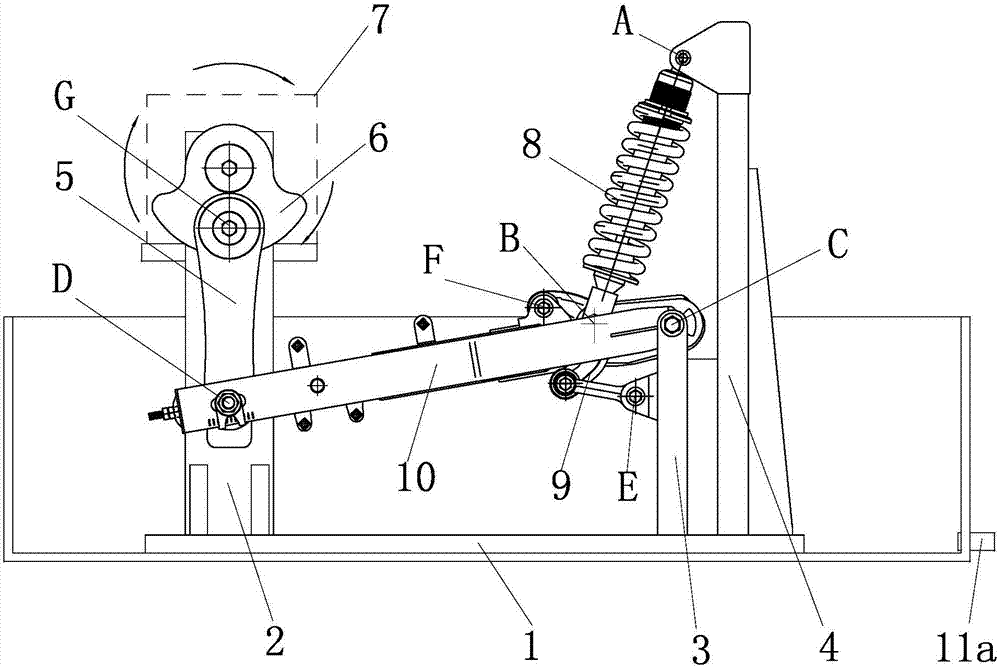

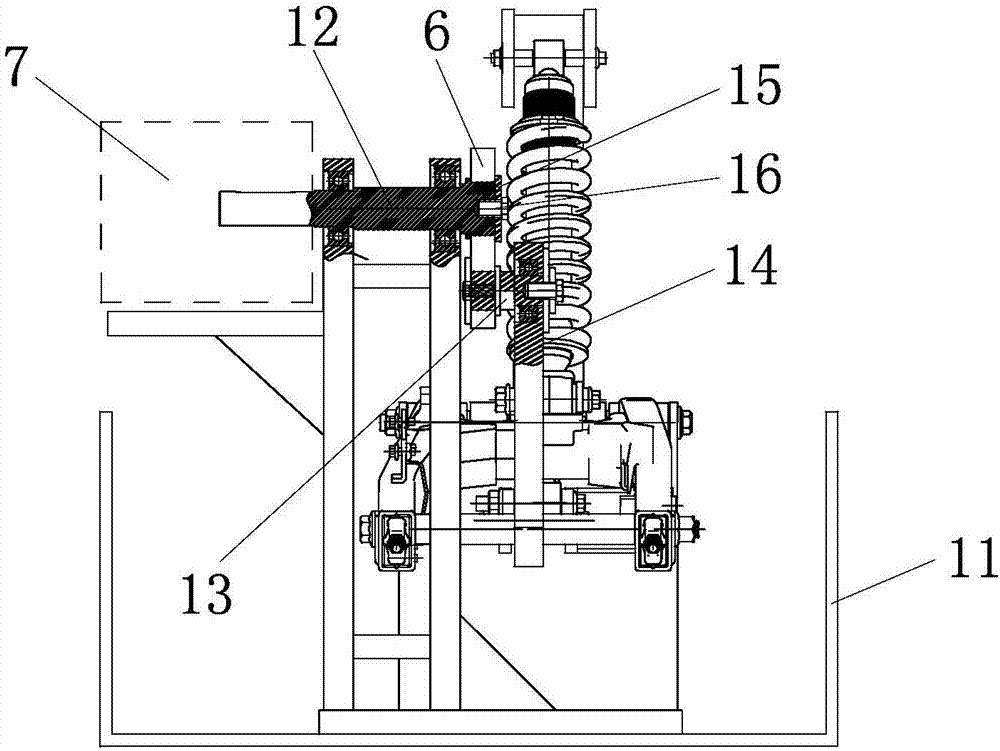

[0013] combine figure 1 , figure 2 As shown, a rear shock absorption verification tool with a cradle is mainly composed of a base 1, a rocker cam mounting seat 2, a rear chainstay assembly mounting seat 3, a rear shock absorbing assembly mounting seat 4, a rocker arm 5, and a rocker Arm cam 6, motor 7, water storage tank 11, motor connection pin 12, spline shaft 13, bearing 14, anti-off cover plate 15 and fastening screw 16 form. The rear shock absorber assembly 8, the cradle assembly 9 and the rear chainstay assembly 10 are the rear shock absorber assembly with the cradle to be verified.

[0014] A rocker cam mounting seat 2, a rear chain fork assembly mounting seat 3 and a rear shock absorber assembly mounting seat 4 are sequentially installed on the base 1 from left to right.

[0015] The upper end of the rear shock absorber assembly 8 is hinged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com