Evaluation method for ice and snow removing effects of coating type anti-freezing road surface

An evaluation method and technology of ice and snow, applied in the direction of surface/boundary effects, measuring devices, instruments, etc., can solve the problems of time-consuming, limited, labor-consuming, etc., and achieve the effect of good durability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0017] A method for evaluating the deicing effect of a coating type antifreeze pavement, comprising the following steps:

[0018] Step (1): Test piece preparation

[0019] First, prepare the specimen 1 of the asphalt mastic macadam mixture (SMA-13), the specimen size is 300mm*50mm*50mm (length*width*height); and then coat a certain amount of deicing snow on its upper surface The surface coating material is applied in 3 times, with an interval of 30 minutes between each time, and a total of 0.75kg / m2 is applied on the surface of the test piece. 2 Surface coating materials for snow and ice removal;

[0020] Step (2): Accelerated loading wear test

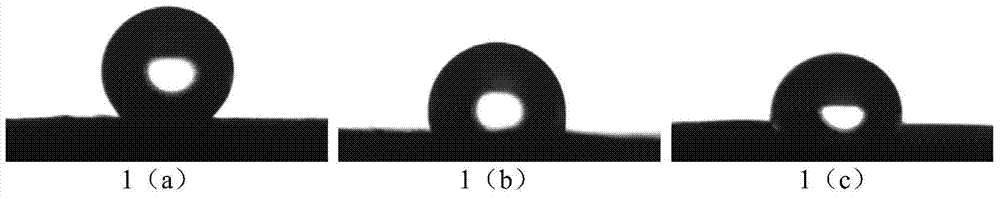

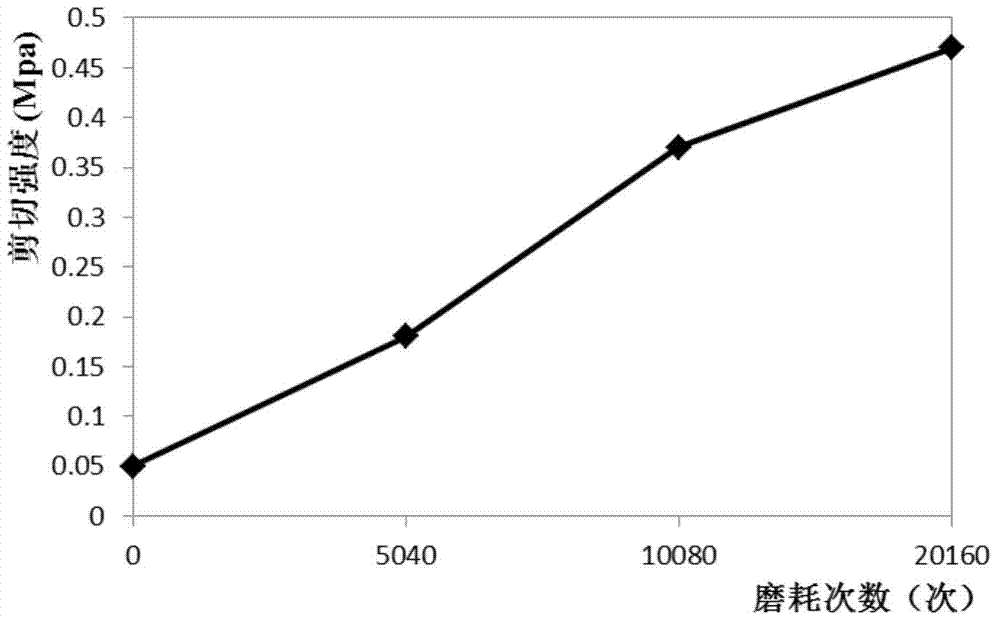

[0021] The upper surface of the test piece coated with the snow and ice removal surface coating material obtained in step (1) is not worn on the accelerated loading abrasion instrument (asphalt mixture rutting instrument), so as to simulate the road just coated with the snow and ice removal surface coating material Road conditions;...

specific Embodiment 2

[0024] A method for evaluating the deicing effect of a coating type antifreeze pavement, comprising the following steps:

[0025] Step (1): Test piece preparation

[0026] First, prepare the specimen 1 of the asphalt mastic macadam mixture (SMA-13), the specimen size is 300mm*50mm*50mm (length*width*height); and then coat a certain amount of deicing snow on its upper surface The surface coating material is applied in 3 times, with an interval of 30 minutes between each time, and a total of 0.75kg / m2 is applied on the surface of the test piece. 2 Surface coating materials for snow and ice removal;

[0027] Step (2): Accelerated loading wear test

[0028] The upper surface of the test piece coated with the deicing surface coating material obtained in step (1) is subjected to 2520 abrasions on the accelerated loading abrasion instrument (asphalt mixture rutting instrument) to simulate the wear and tear of the driving wheel on the road. Condition;

[0029] Step (3): Contact an...

specific Embodiment 3

[0031] A method for evaluating the deicing effect of a coating type antifreeze pavement, comprising the following steps:

[0032] Step (1): Test piece preparation

[0033] First, prepare the specimen 1 of the asphalt mastic macadam mixture (SMA-13), the specimen size is 300mm*50mm*50mm (length*width*height); and then coat a certain amount of deicing snow on its upper surface The surface coating material is applied in 3 times, with an interval of 30 minutes between each time, and a total of 0.75kg / m2 is applied on the surface of the test piece. 2 Surface coating materials for snow and ice removal;

[0034] Step (2): Accelerated loading wear test

[0035] The upper surface of the test piece coated with the deicing surface coating material obtained in step (1) is subjected to 5040 wears on the accelerated loading wear tester (asphalt mixture rutting tester), so as to simulate the wear and tear of the driving wheel of the road on the road. Condition;

[0036] Step (3): Contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com