Window glass abrasion-resistance experimental device

A kind of technology of experimental device and car window glass, applied in the direction of measuring device, testing wear resistance, instrument, etc., to achieve the effect of shortening the time of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

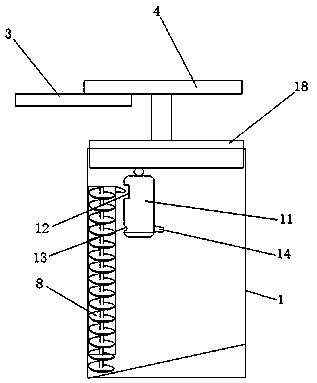

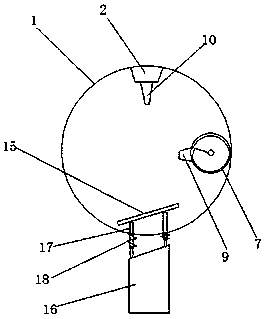

[0024] like figure 1 (The blower 2 and the glass sample 15 are omitted), a vehicle window glass wear resistance experimental device of the present invention includes a rotating drive mechanism, an experimental chamber 1, a sand injection device, and a blower 2, and the experimental chamber 1 is an upper part of The open barrel structure, the rotating drive mechanism is located in the upper part of the opening of the experimental chamber 1, the sand injection device and the blower 2 are located inside the experimental chamber 1, and the bottom of the experimental chamber 1 is filled with sand; the interior of the experimental chamber 1 is also provided with a glass sample 15.

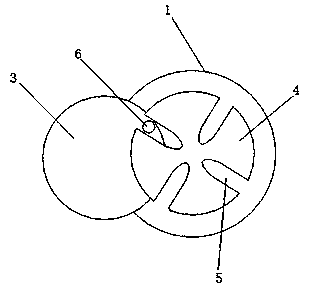

[0025] like figure 2 , the rotating drive mechanism includes a horizontal drive disk 3 and a rotating disk 4, the drive disk 3 and the rotating disk 4 have ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com