Method For Reducing Or Eliminating Residue In A Glass Container And A Glass Container Made In Accordance Therewith

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

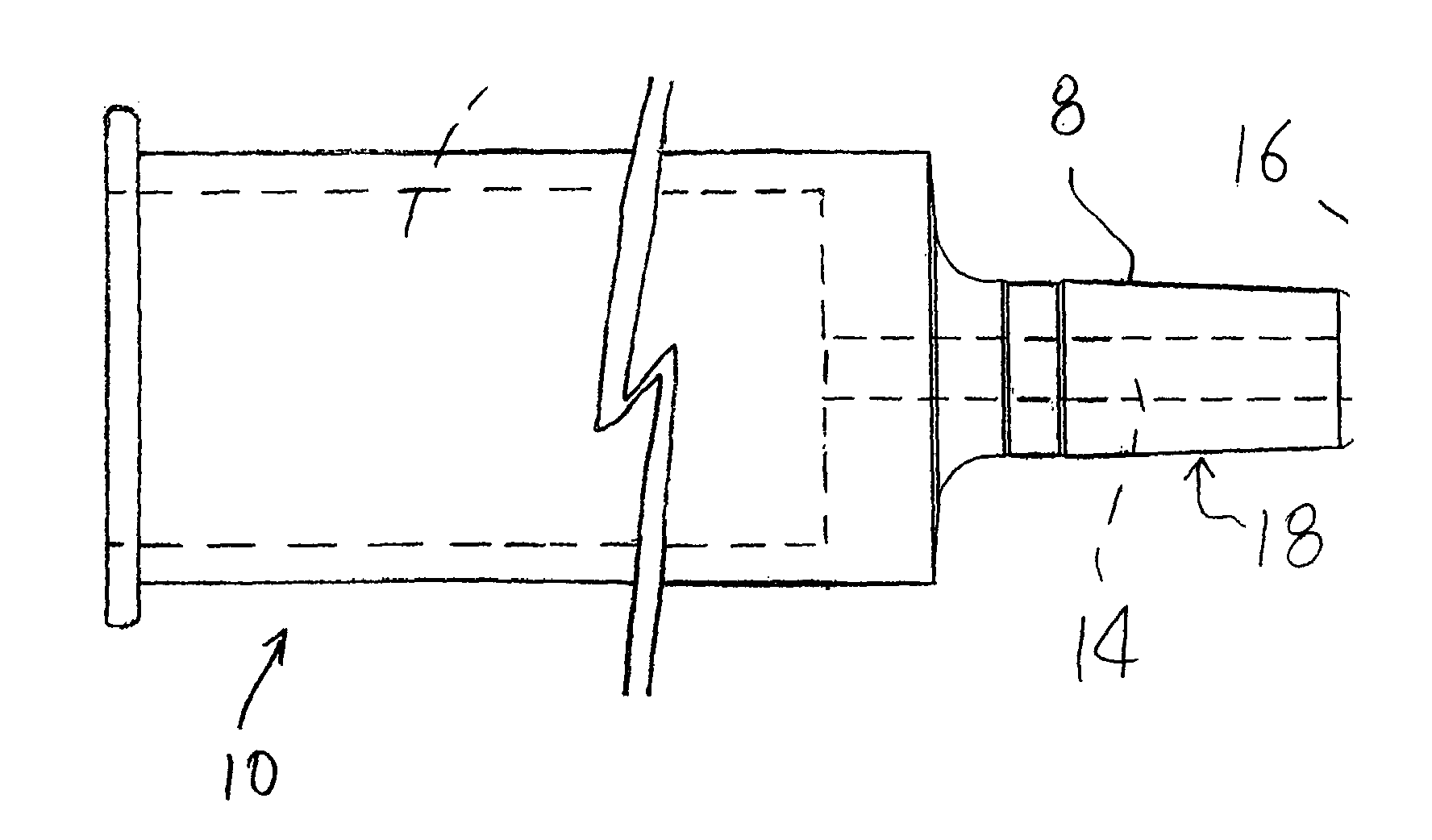

[0012]With the subject invention, a method is provided for substantially reducing or altogether eliminating tungsten or derivatives thereof from a glass container without the need for additional annealing, sterilization or washing steps after the container has been completely formed. The method is particularly well-suited for use in forming glass medical containers. For illustrative purposes, an exemplary glass medical container 10 is shown and described which is in the form of a glass syringe barrel. As can be appreciated by those skilled in the art and from the disclosure provided herein, the glass medical container 10 can be any glass body used for containing or storing a liquid and / or dry substance, including, but not limited to glass syringe barrels, glass vials, and glass drug cartridge bodies.

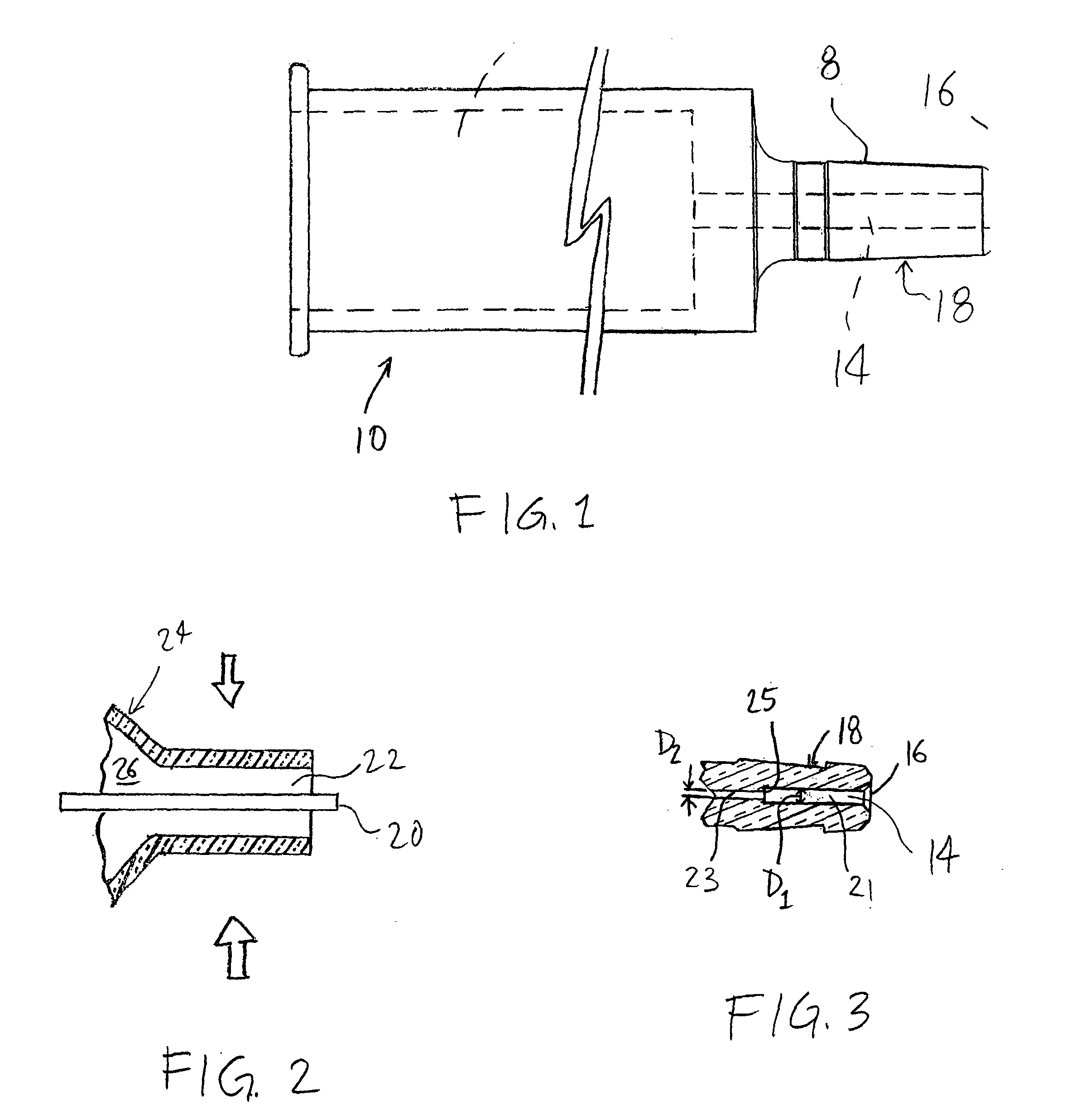

[0013]With reference to FIG. 1, the glass medical container 10 defines a reservoir 12 and has a hub 8 with a channel 14 defined therethrough and in communication with the reservoir 12. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com