Mould for processing glass container

A technology for processing glass and containers, which is applied in glass forming, manufacturing tools, glass manufacturing equipment, etc. It can solve problems such as bottle scrapping, large seam gap, and affecting the appearance quality of bottles, so as to suppress deformation and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

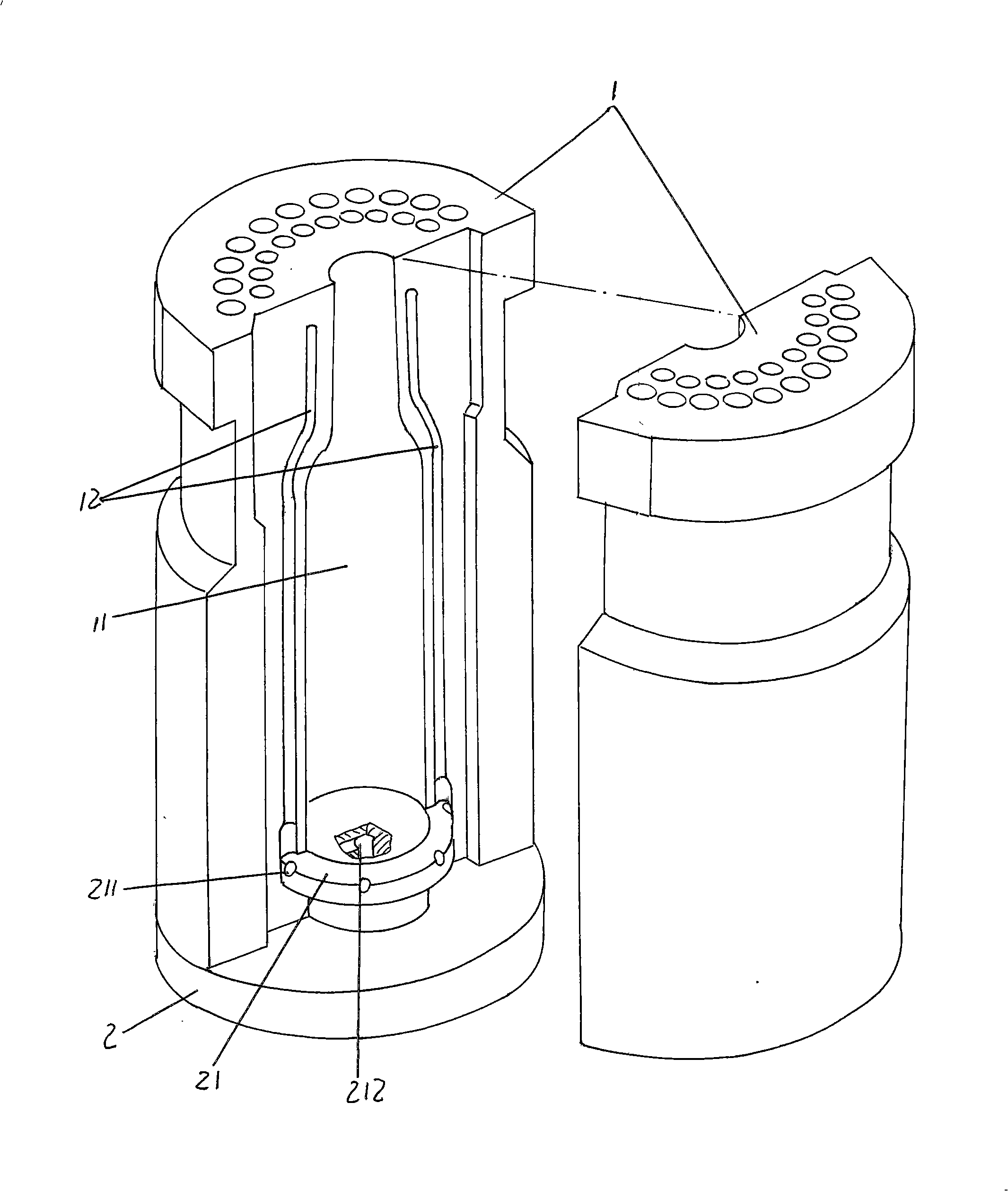

[0007] Please refer to the accompanying drawings, a pair of half-molds 1 identical in shape and consistent in structure are provided. Because the glass container mentioned in the present embodiment is a beer bottle, it is useful for forming in the middle area of the height direction of a pair of half-molds 1. The mold cavity 11 of the beer bottle is provided with a bottom mold 2 in an inlaid manner at the bottom of a pair of mold halves 1 . As the technical point of the present invention, the side portions of each (two) mold cavities 11 of a pair of half molds 1 are all processed with a vacuuming groove 12, and the height of the vacuuming groove 12 is substantially consistent with the height of the mold cavity 11. . The bottom of each vacuum chamber 12 communicates with the vent hole 211 provided on the bottom mold core 21 of the bottom mold 2 , and the vent hole 211 also communicates with the central hole 212 at the center of the bottom mold core 21 . When the central hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com