Borosilicate glass-spherical alumina low temperature co-fired ceramic green tape and preparation method thereof

A technology of borosilicate glass and low-temperature co-fired ceramics, which is applied in the field of low-temperature co-fired ceramic materials in multiphase glass-ceramic systems, can solve problems such as anisotropy, and achieve the effect of smooth surface and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

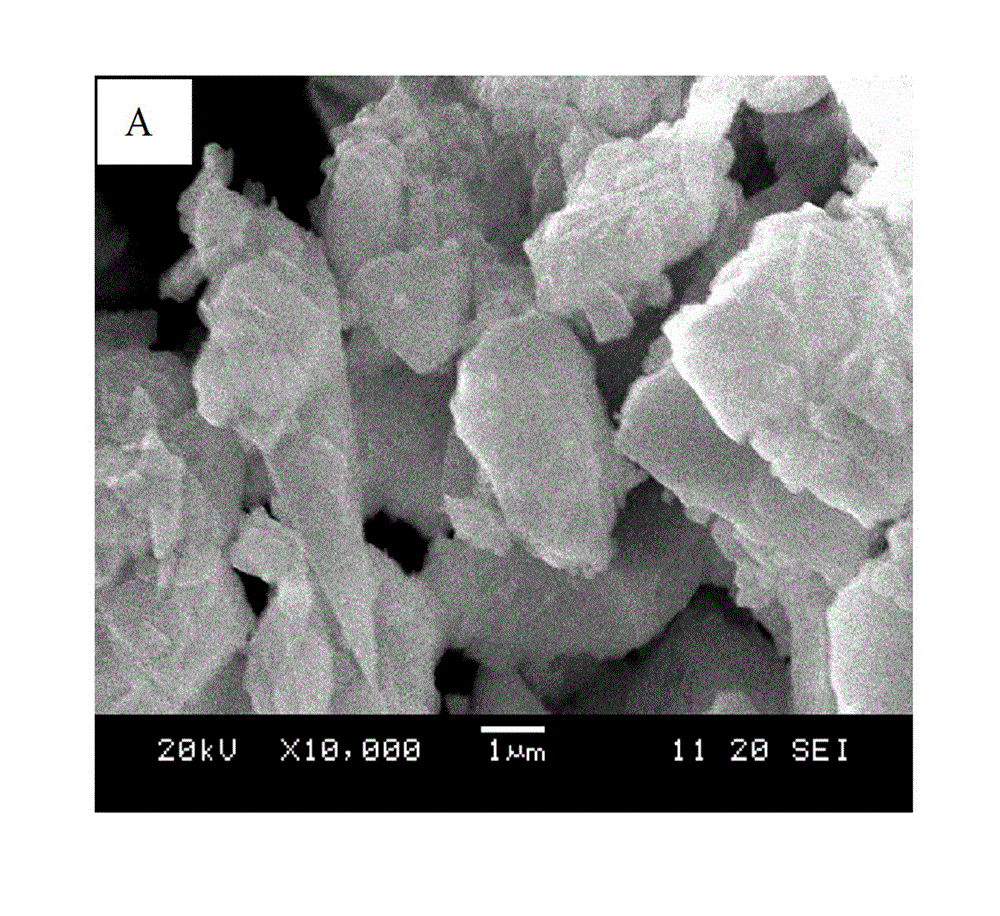

[0030] Select non-spheroidized alumina powder (3~5um) as the ceramic filling phase in the inorganic powder contained in the green ceramic tape, select polyvinyl butyral as the binder in the organic casting system, and make Compared:

[0031] According to the ratio of parts by weight, weigh B 2 o 3 18kg, SiO 2 65kg, Al 2 o 3 8kg, MgO 5kg, K 2 O 2kg, Na 2 O 2kg, mixed for 12 hours, placed in a platinum crucible, kept at 1500~1600°C for 3 hours, poured into deionized water to obtain transparent and uniform borosilicate glass shards.

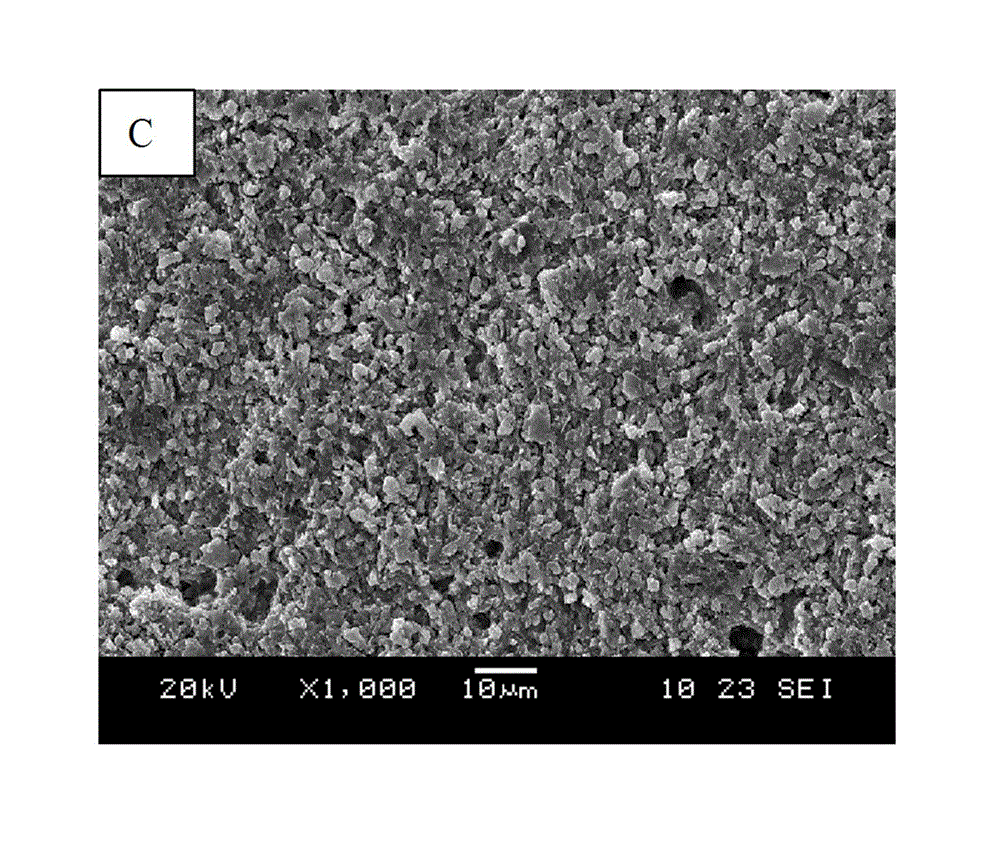

[0032] Use corundum counter-rollers to crush the prepared glass fragments to obtain coarse glass powder with an average particle size of 0.5~1mm. Mix the coarse glass powder with deionized water, and use zirconia balls as the ball milling medium. According to the material: ball: water = 1 : 3:0.8 ratio of ball milling for 8 hours, placed in an oven at 120°C for 4 hours to obtain borosilicate glass powder with an average particle size of 0.5...

Embodiment 2

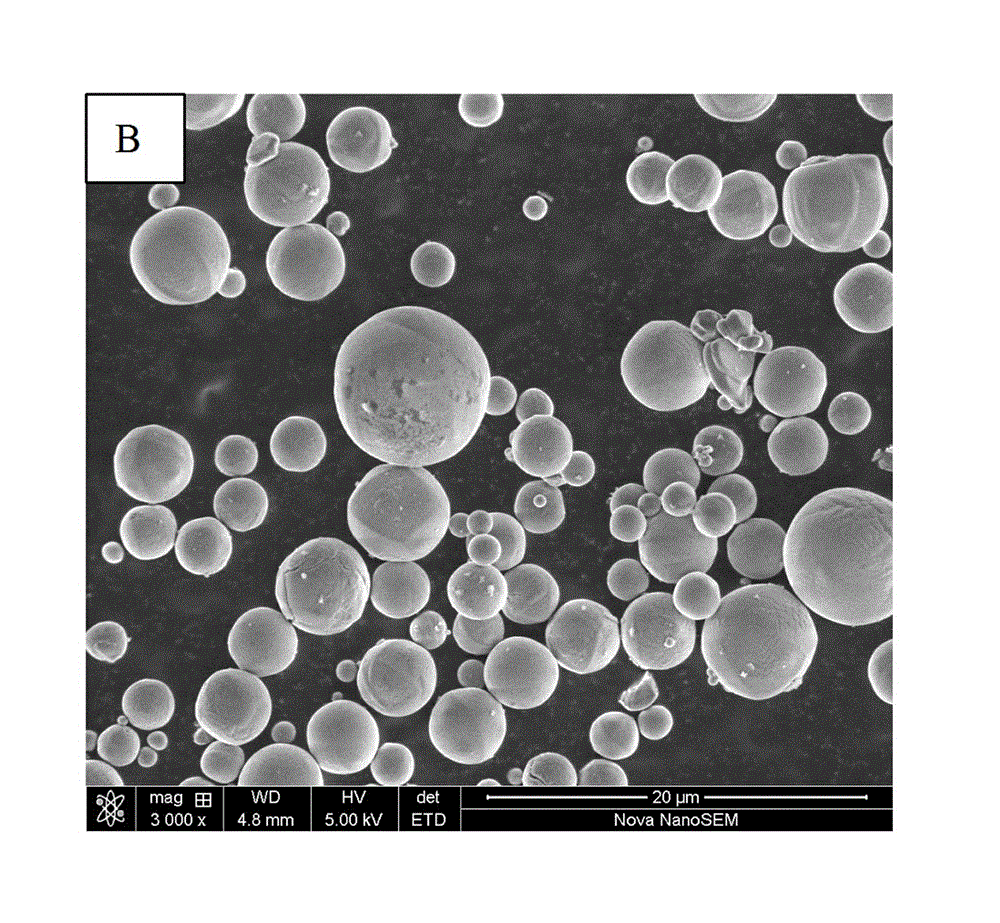

[0043] Select 1# non-spherical alumina powder (3~5um) and 2# spherical alumina powder (3~6um) as the ceramic filling phase in the inorganic powder contained in the green ceramic belt, and choose ethyl methacrylate, methyl Acrylic acid is used as the binder in the organic casting medium. The preparation method of the green porcelain tape is the same as in Example 1. The formula of the green porcelain tape and the performance of the sintered porcelain body are shown in Table 3 and Table 4 (ceramic in the inorganic powder contained in the 1# sample Phases are non-spherical alumina, 2# is spherical alumina);

[0044] Table 3 Contents of each component of borosilicate glass-alumina low temperature co-fired ceramic green tape2

[0045]

[0046] Table 4 Sintering and dielectric properties of borosilicate glass-alumina low temperature co-fired ceramic green tape 2

[0047]

[0048] Comparing Example 1 and Example 2, under the condition that the viscosity of the slurry is guaran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com