Silicon-glass micro pressure sensor chip of island membrane self-packaging structure and manufacturing method

A pressure sensor, self-encapsulation technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, instruments, force measurement, etc., can solve the problem of increasing manufacturing costs, affecting the output characteristics and stability of pressure sensors, and expanding or shrinking silicone and other issues to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

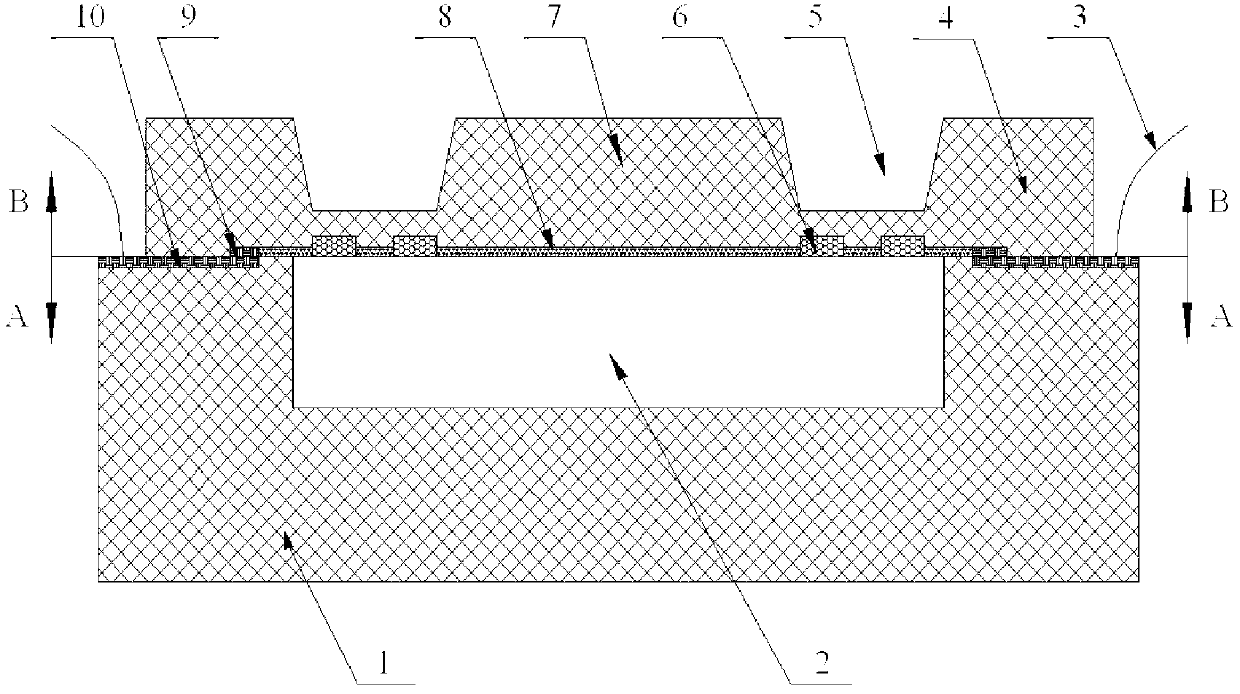

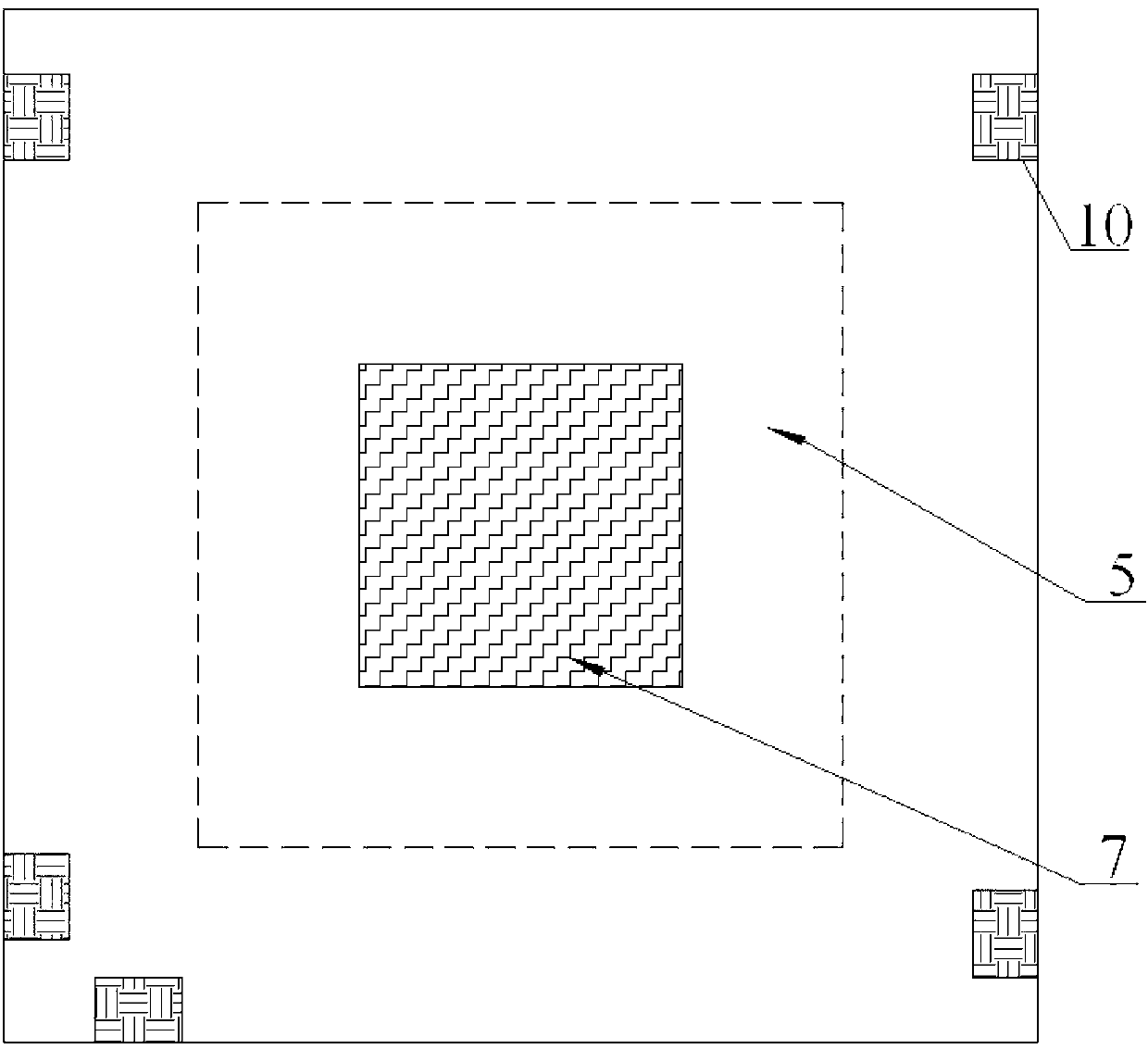

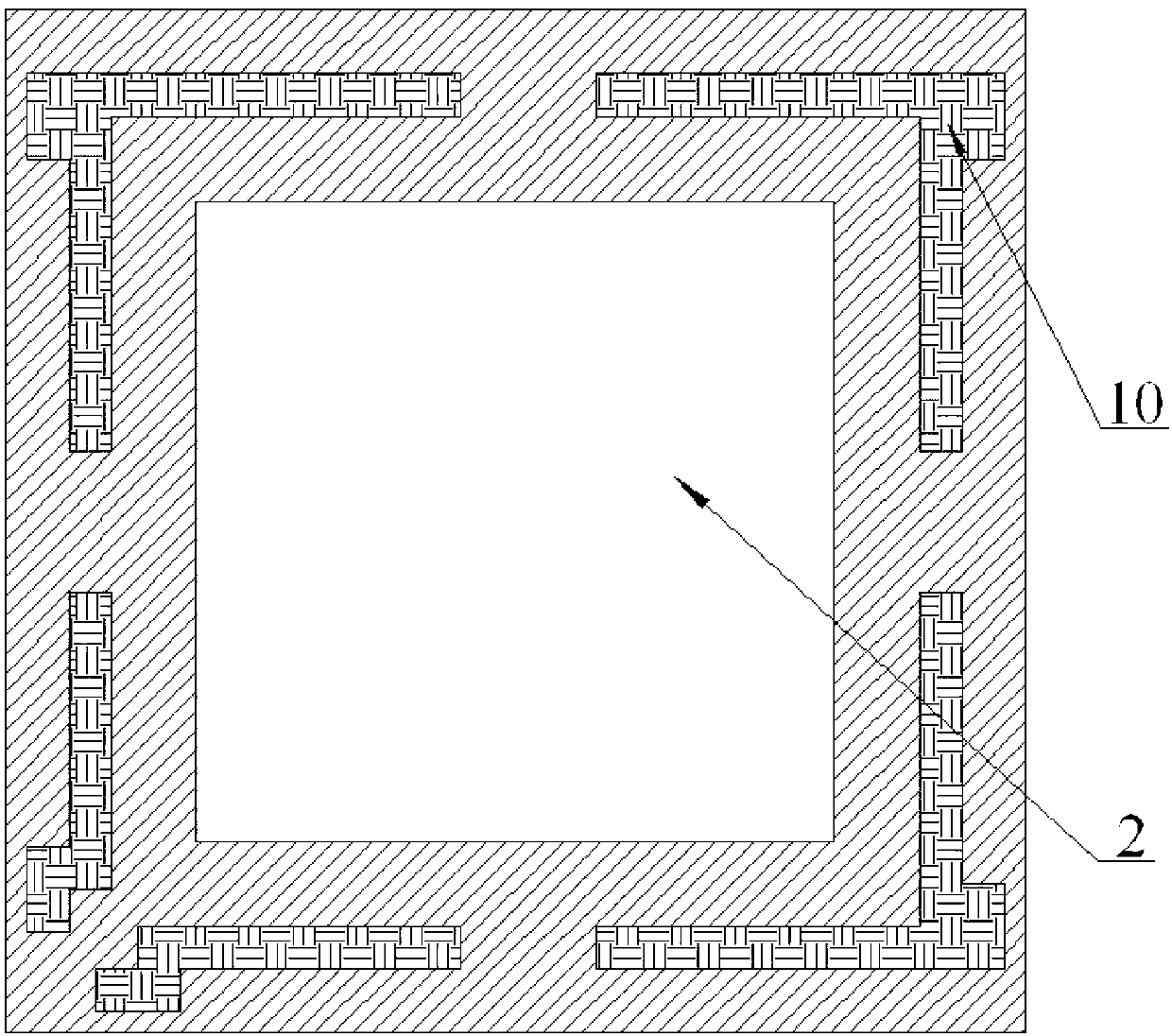

[0053] see Figure 1~4 , the silicon-glass micro pressure sensor chip embodiment of the island membrane self-encapsulation structure of the present invention is provided with a pressure sensitive film 4 and a base 1 with a cavity 2; the pressure sensitive film 4 is a front island membrane composite structure, The stress-concentrated area of the film composite structure is provided with four piezoresistors 6, and the four piezoresistors 6 form a Wheatstone bridge through metal electrodes, and the Wheatstone bridge is formed by using a silicon-glass anode bonding process. Sealed in an airtight absolute pressure chamber, the Wheatstone bridge connects the interface preset electrodes with external testing equipment through metal leads to form a complete pressure sensing and measuring system.

[0054] The pressure sensitive film 4 is provided with a raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com