High temperature anodic bonding apparatus

an anodic bonding and high temperature technology, applied in the field of anodic bonding apparatus, can solve the problems that the process does not generally work with glass or glass-ceramic substrates, and the conventional techniques for anodic bonding of a semiconductor layer to a glass or glass-ceramic substrate do not adequately address the above process variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

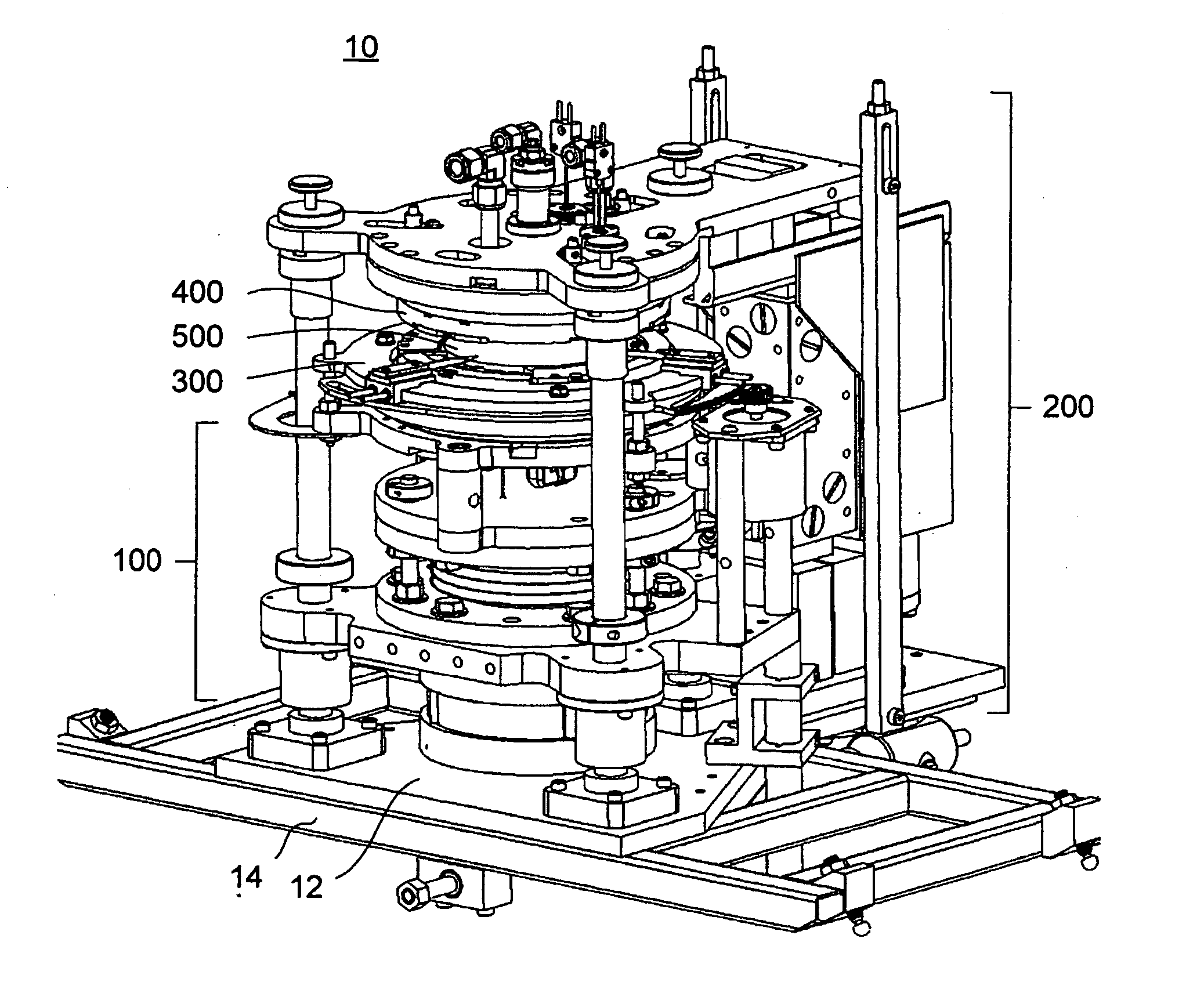

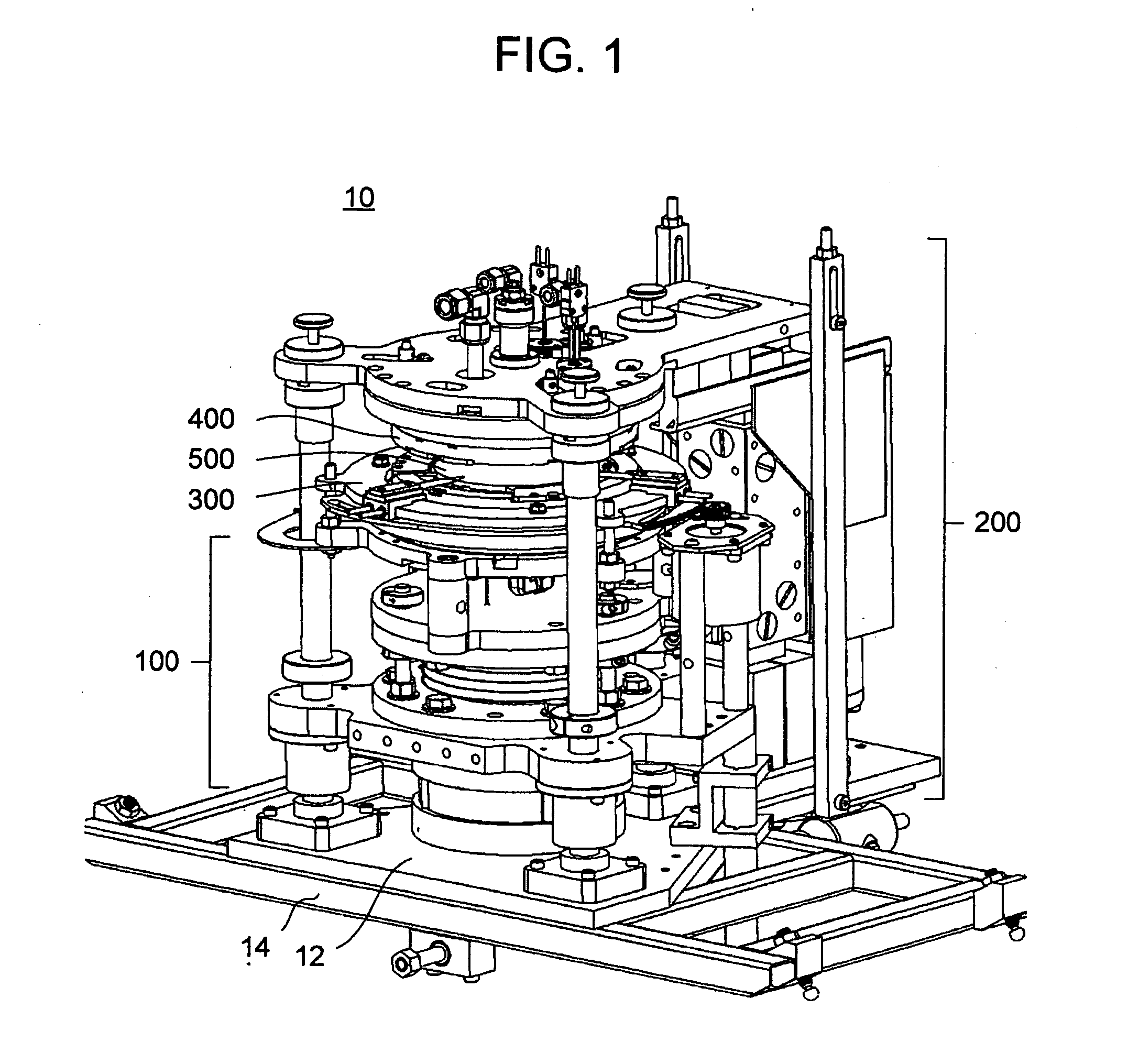

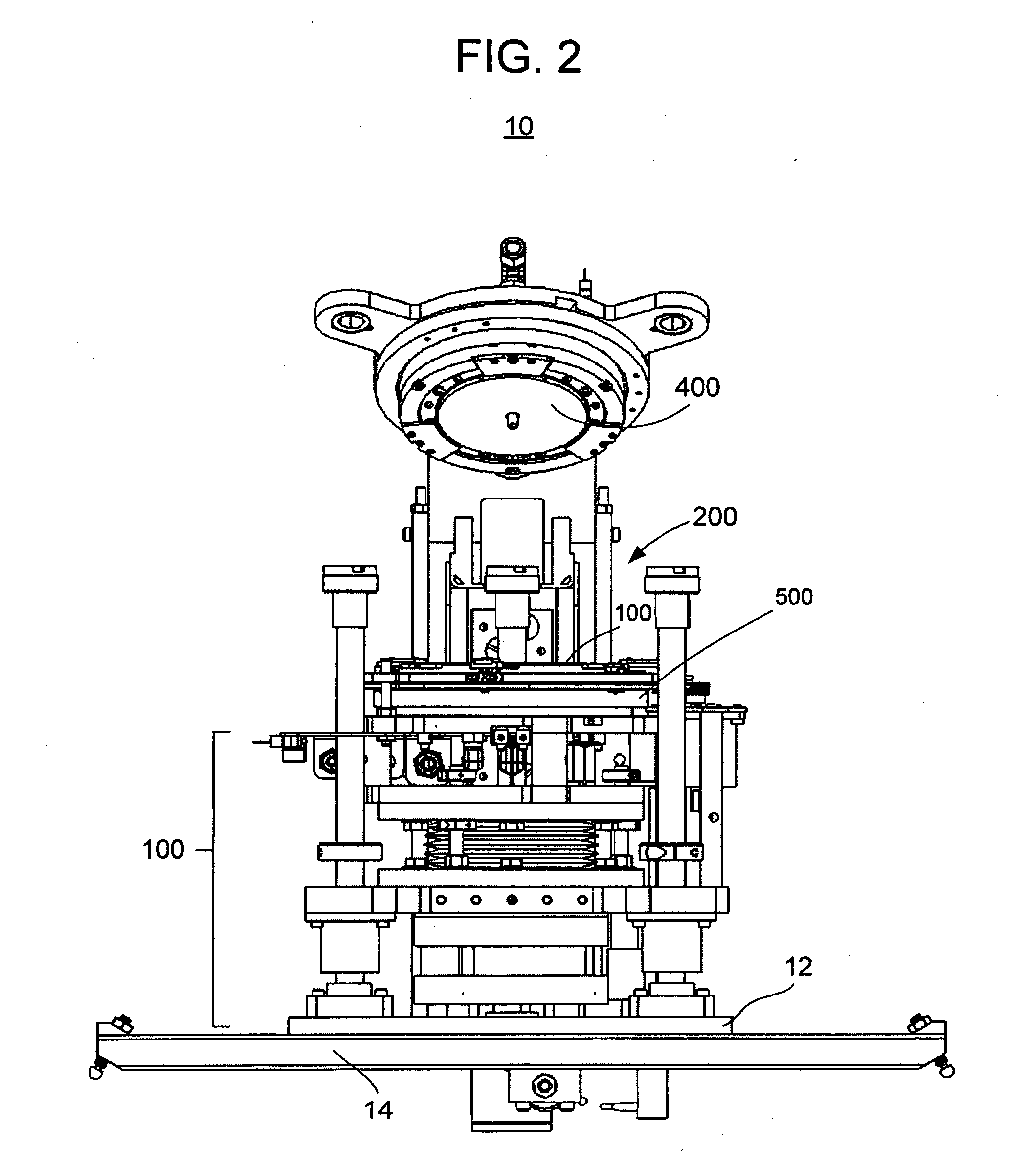

[0054] With reference to the drawings, wherein like numerals indicate like elements, there is shown in FIG. 1 a perspective view of a bonding apparatus 10 in accordance with one or more embodiments of the present invention. In this embodiment, the bonding apparatus is an integrated processing system capable of anodically bonding two material sheets of an SOI structure at temperatures above conventional bonding temperatures, e.g., above 600° C. and approaching and / or exceeding 1000° C. (It is noted that the bonding apparatus 10 is also capable of anodic bonding at conventional temperatures.) For purposes of illustration (but not limitation), an SOI structure will be described herein as a suitable work piece upon which the bonding apparatus 10 operates (e.g., in producing the SOI structure). Also for purposes of discussion (but not limitation), the particular SOI structure discussed hereinbelow as a work piece will be an SOG structure formed by bonding a semiconductor donor wafer (suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com