Novel modified asphalt waterproof coiled material and preparation method thereof

A technology of modified asphalt and waterproof membranes, which is applied to roofs, building insulation materials, and building components using flexible materials. Scope of application and effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

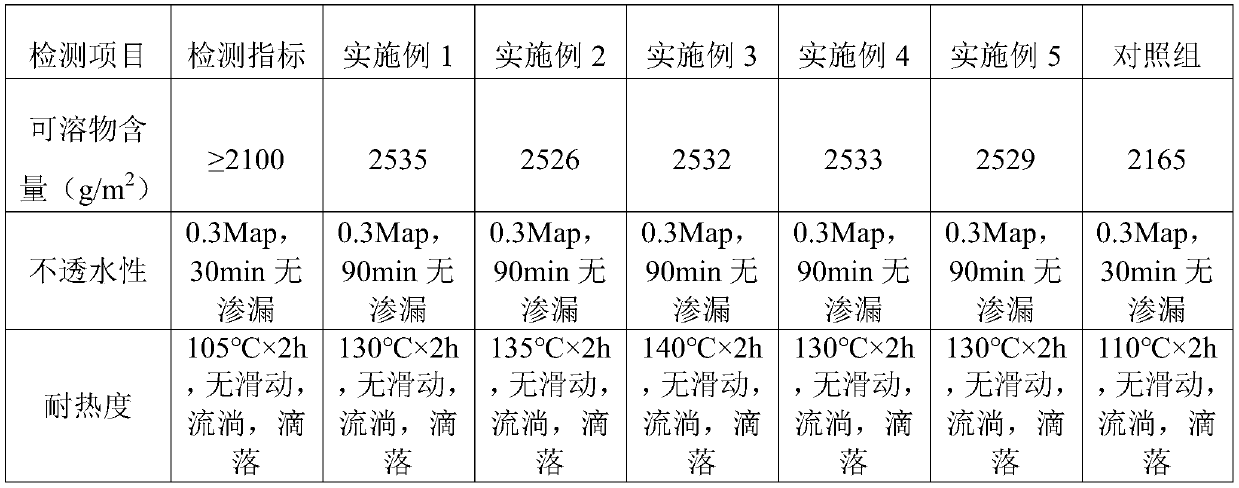

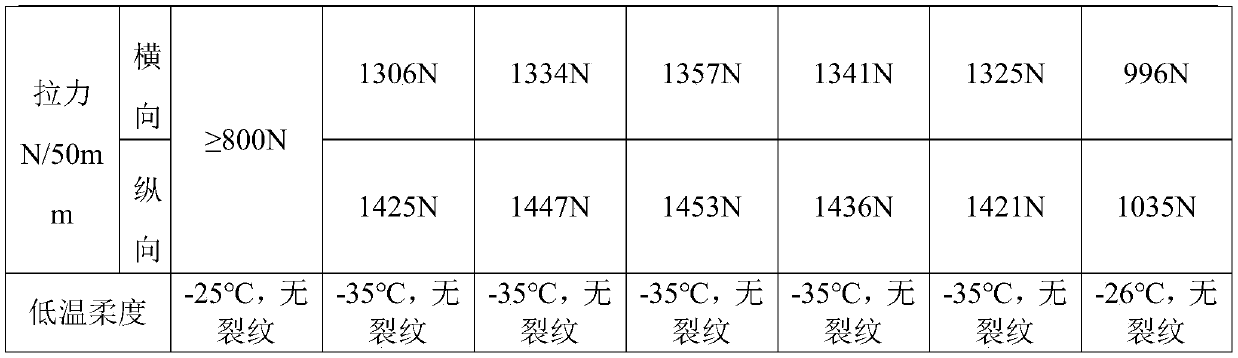

Examples

Embodiment 1

[0026] A preparation method of a new type of modified bitumen waterproofing membrane includes the following steps:

[0027] S1. According to the formula of the following parts by weight, weigh each component for use: 5 parts of 10# asphalt, 40 parts of 90# asphalt, 6 parts of softening oil, 4 parts of rubber powder, 3 parts of SBS, 2 parts of high-density polyethylene, three parts 0.2 parts of allyl isocyanurate, 0.6 parts of dicumyl peroxide, 10 parts of light calcium;

[0028] S2. Pour 10# bitumen and 90# bitumen into the batching tank, add softened oil when the temperature rises to 160±5°C, heat up to 180±5°C, and stir for 30 minutes until the mixture is uniform;

[0029] S3. Control the temperature at 180~190℃, then add the tire rubber powder, stir for 60 minutes until the mixture is uniform, turn on the colloid mill and perform the first grinding to make the rubber powder and oil completely blend in;

[0030] S4. After the first grinding is completed, add SBS, stir for 30 minutes...

Embodiment 2

[0035] A preparation method of a new type of modified bitumen waterproofing membrane includes the following steps:

[0036] S1. According to the following formula, weigh each component for use: 6 parts of 10# asphalt, 43 parts of 90# asphalt, 8 parts of softening oil, 5 parts of rubber powder, 4 parts of SBS, 3 parts of high-density polyethylene, three parts 0.3 parts of allyl isocyanurate, 1.0 part of dicumyl peroxide, 13 parts of light calcium;

[0037] S2. Pour 10# bitumen and 90# bitumen into the batching tank, add softened oil when the temperature rises to 160±5°C, heat up to 180±5°C, and stir for 30 minutes until the mixture is uniform;

[0038] S3. Control the temperature at 180~190℃, then add the tire rubber powder, stir for 60 minutes until the mixture is uniform, turn on the colloid mill and perform the first grinding to make the rubber powder and oil completely blend in;

[0039] S4. After the first grinding is completed, add SBS, stir for 30 minutes until the mixture is un...

Embodiment 3

[0044] A preparation method of a new type of modified bitumen waterproofing membrane includes the following steps:

[0045] S1. Weigh each component according to the following formula in parts by weight: 7 parts of 10# asphalt, 45 parts of 90# asphalt, 9 parts of softening oil, 5 parts of rubber powder, 4 parts of SBS, 3 parts of high-density polyethylene, three parts 0.4 parts of allyl isocyanurate, 1.2 parts of dicumyl peroxide, 15 parts of fly ash;

[0046] S2. Pour 10# bitumen, 90# or 100# bitumen into the batching tank, add softened oil when the temperature rises to 160±5°C, heat up to 180±5°C, stir for 30 minutes until the mixture is uniform;

[0047] S3. Control the temperature at 180~190℃, then add the tire rubber powder, stir for 60 minutes until the mixture is uniform, turn on the colloid mill and perform the first grinding to make the rubber powder and oil completely blend in;

[0048] S4. After the first grinding is completed, add SBS, stir for 30 minutes until the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com