Thermal storage and insulation microcapsule for building material and preparation method thereof

A technology of microcapsules and heat storage, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of low mechanical strength of microcapsules, complicated preparation process, poor thermal conductivity, etc., and achieve easy industrial promotion and preparation The effect of simple process and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0028] The following operations and examples will help to understand the present invention, but do not limit the content of the present invention. The preparation of embodiment 1~4 double-layer microcapsule of the present invention

[0029] Take the organic phase change core material, add a certain amount of 400-800 mesh graphite, and heat together until the core material melts;

[0030] a. Control the temperature at 30~40℃, add bath I (modified core material, toluene diisocyanate, polyethylene glycol mass ratio is 1:0.48~1.11:0.16~0.37) into bath II (distilled water and emulsifier mass ratio Ratio of 1:0.02~0.3), high-speed homogenization at 10000~13000rpm, stirring at 350~500rpm for 0.5~1h, to polymerize the inner wall material.

[0031] b. Add 1% to 1.4% of the total mass of chain extender 1,4-butanediol to a, raise the temperature to 50-60°C, and add bath III (distilled water and diethylenetriamine 1:0.06~ 0.28), keep warm for 1 to 2 hours, and polymerize the outer wall ...

Embodiment 5 Embodiment 1

[0039] Embodiment 5 Embodiment 1 double-layer microcapsule performance test

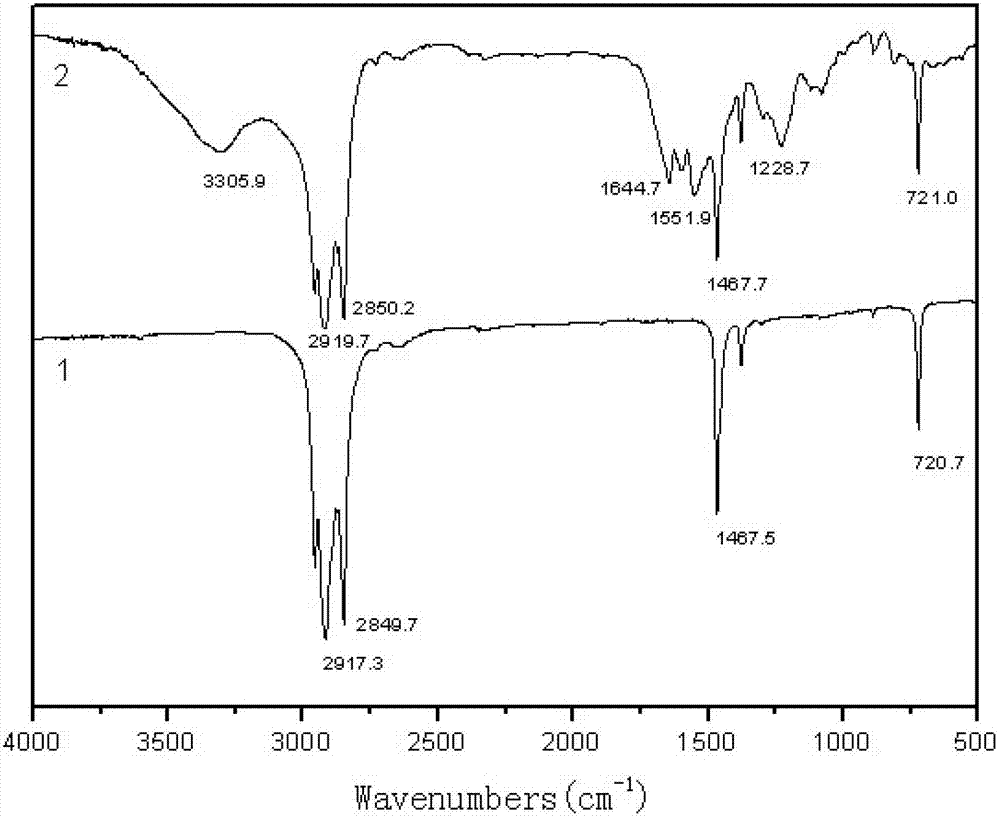

[0040] 1. Use a Fourier transform infrared spectrometer (Nicolet Company, USA) to test the characteristics of paraffin and paraffin heat storage and heat preservation microcapsules, see figure 1 .

[0041] Depend on figure 1It can be seen that the strong absorption peak at 2917.3cm-1 in curve 1 corresponds to the stretching vibration peak of the C-H bond in the fatty chain, 1467.5cm-1 is the scissor bending vibration absorption peak of CH2, and the absorption peak at 720.7cm-1 is the CH2 The in-plane rocking vibration absorption peak is characterized by having more than 4 CH2 long-chain alkanes. Comparing curve 1, it can be seen that the strong absorption peak at 3305.9cm-1 of curve 2 corresponds to the stretching vibration peak of the secondary amino group N-H, and the absorption peak at 1644.7cm-1 corresponds to the stretching vibration of the carbonyl in polyurea, 1551.9cm-1 The absorption peak...

Embodiment 1

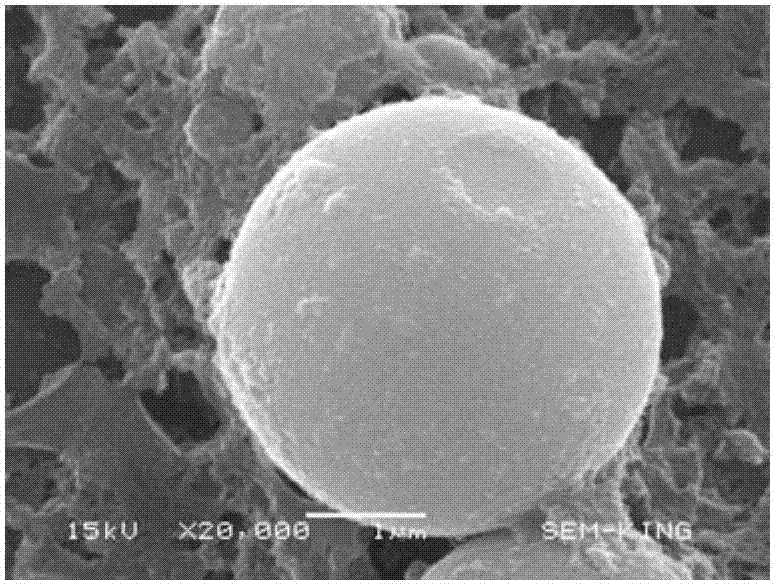

[0051] The coated microcapsules in Example 1 were neatly arranged and had a smooth surface. The microcapsules were broken when the temperature was lower than 30°C, and the microcapsules were bonded when the temperature was higher than 40°C.

[0052] The mechanical strength of the microcapsules prepared at different temperatures was compared by using the pump circulation method. The lower the damage rate, the better the mechanical strength. It is characterized by the damage rate:

[0053] table 3

[0054]

[0055] The results in Table 3 show that outside the range of 30-40°C, even if the temperature changes only slightly, the damage rate increases significantly, and the mechanical strength of the product obtained at 30-40°C is obviously better.

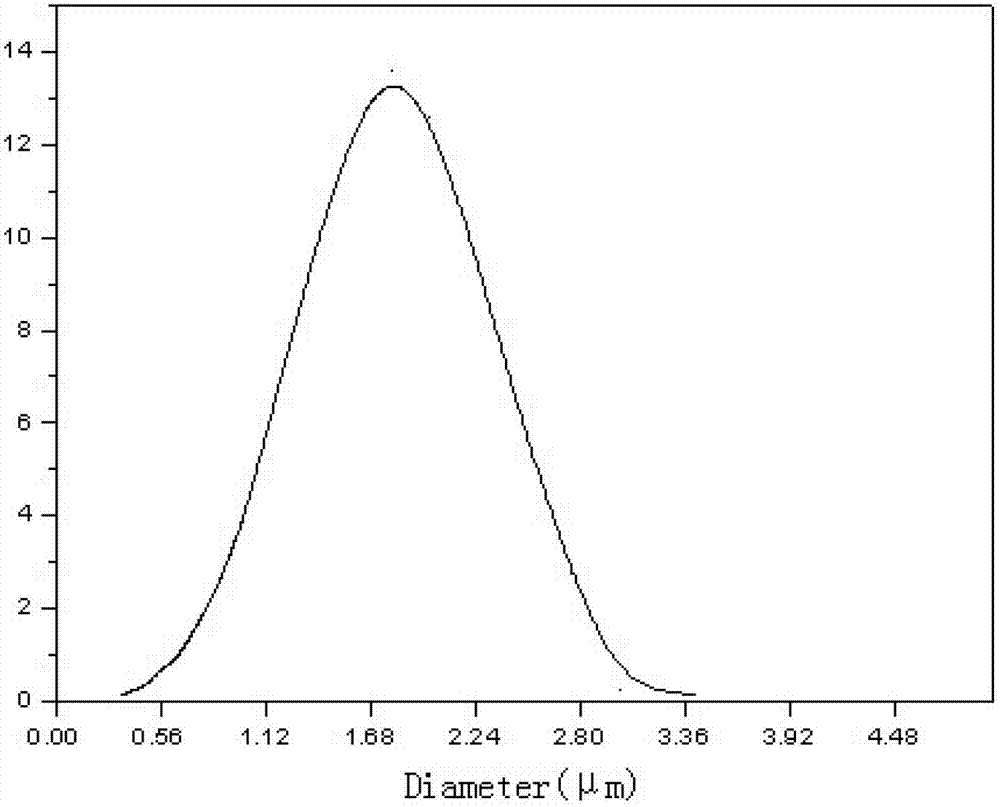

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com