Hydrophilic trauma dressing made from polyurethane and its preparation method

A technology of hydrophilic polyurethane and wound dressings, applied in viscous dressings, dressings, medical science, etc., can solve the problems of non-absorbent foam layer and matrix material preparation introduction, etc., achieve good adhesion, no foreign body reaction, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

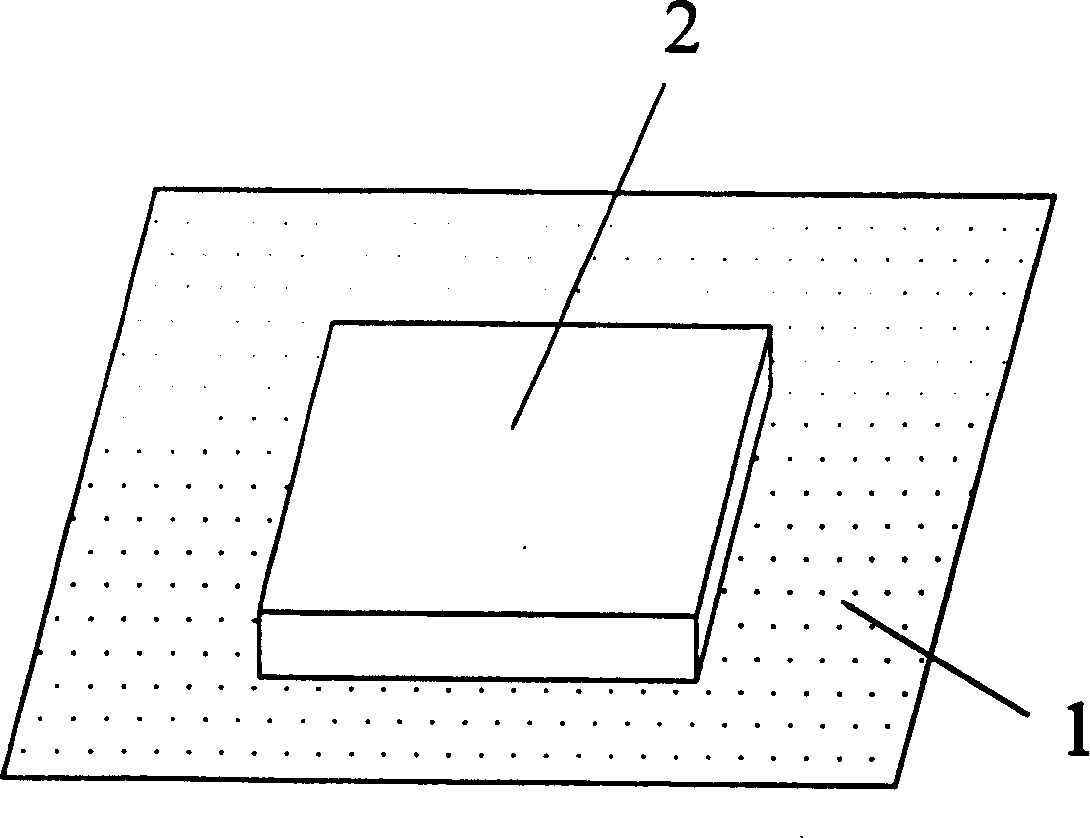

[0047] The structure of polyurethane wound dressing in the present embodiment is as figure 1 As shown, the outer layer 1 and the inner layer 2 are compounded by pressure-sensitive adhesive, the inner layer is polyurethane soft foam slices, and the outer layer is polyurethane film. The preparation method is as follows:

[0048] 1. Preparation of polyurethane soft foam slices

[0049] Raw material formula:

[0050] Polyethylene glycol (molecular weight 1000) 47.25%

[0051] Toluene diisocyanate (TDI-80) 29.04%

[0052] Glycerol 1.97%

[0053]Polyether N210 17.39%

[0054] Stannous octoate 0.87%

[0055] Triethylenediamine 1.16%

[0056] Styrene / acrylonitrile graft polyether alcohol 0.29%

[0057] L-580 Silicone 0.87%

[0058] Deionized water 1.16%

[0059] The above percentages are percentages by weight.

[0060] Technological process: Stir the polyethylene glycol, toluene diisocyanate (TDI-80) and glycerol evenly at room temperature, then heat up to 80°C and react fo...

Embodiment 2

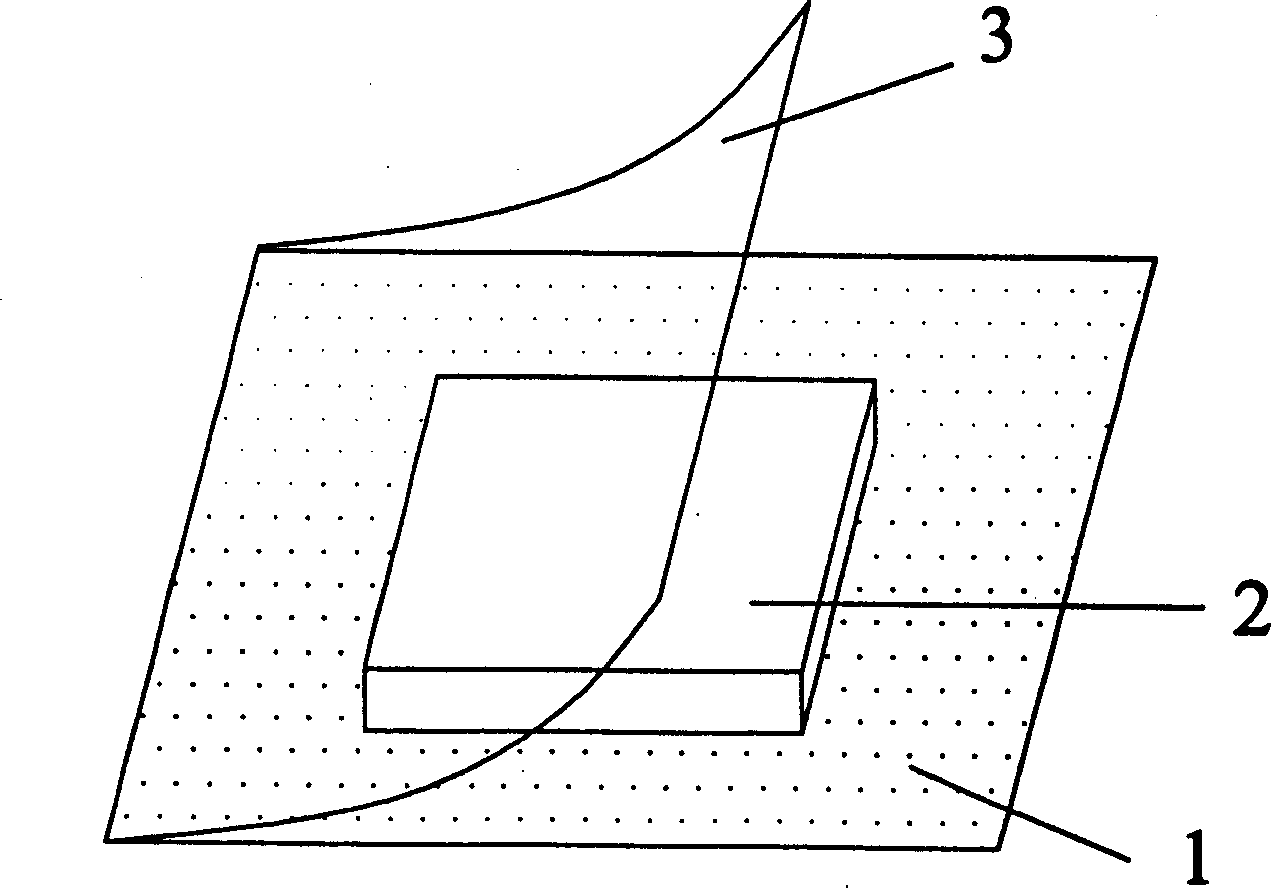

[0071] The structure of polyurethane wound dressing in the present embodiment is as figure 2 As shown, the outer layer 1, the inner layer 2, and the peeling paper 3 are compounded by pressure-sensitive adhesive, the inner layer is a polyurethane soft foam slice, and the outer layer is a polyurethane film. The preparation method is as follows:

[0072] 1. Preparation of polyurethane soft foam slices

[0073] Raw material formula:

[0074] Polyethylene glycol (molecular weight 2000) 49.85%

[0075] Toluene diisocyanate (TDI-80) 27.81%

[0076] Glycerol 2.71%

[0077] Polyether N3010 14.57%

[0078] Stannous octoate 1.19%

[0079] Triethylenediamine 1.19%

[0080] Polybutadiene diol 0.30%

[0081] L-580 Silicone 0.89%

[0082] Deionized water 1.49%

[0083] The above percentages are percentages by weight.

[0084] Process flow: Stir the above polyethylene glycol, toluene diisocyanate (TDI-80) and glycerol at room temperature, then raise the temperature to 85°C and rea...

Embodiment 3

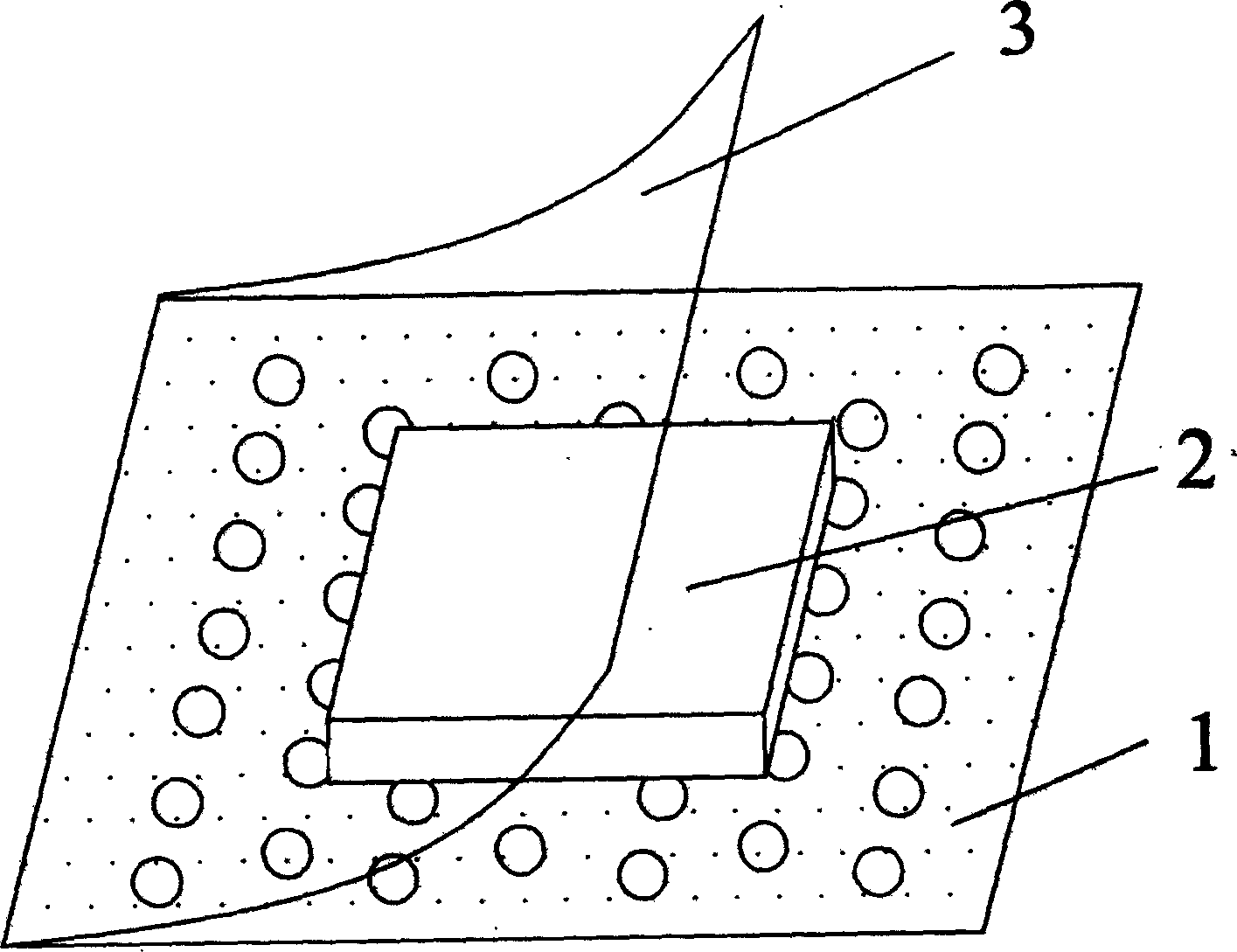

[0097] The structure of polyurethane wound dressing in the present embodiment is as image 3 As shown, the outer layer 1, the inner layer 2, and the release paper 3 are bonded and compounded. The inner layer is polyurethane soft foam slices, and the outer layer is medical adhesive tape or medical non-woven fabric with air holes. The preparation method is as follows:

[0098] 1. Preparation of polyurethane soft foam slices

[0099] Raw material formula:

[0100] Polyethylene glycol (molecular weight 1500) 45.44%

[0101] Toluene diisocyanate (TDI-80) 34.53%

[0102] Glycerol 2.10%

[0103] Polyether N210 12.16%

[0104] Stannous octoate 0.61%

[0105] Triethylenediamine 0.91%

[0106] Polybutadiene diol 0.91%

[0107] L-580 Silicone 1.52%

[0108] Deionized water 1.82%

[0109] The above percentages are percentages by weight.

[0110] Process flow: Stir the above polyethylene glycol, toluene diisocyanate (TDI-80) and glycerin at room temperature, then raise the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com