Flexible polyurethane foam and production process

A technology of flexible polyurethane and foamed plastics, applied in the field of flexible polyurethane foamed plastics, can solve problems such as deformation and unsatisfactory service life, and achieve the effects of good opening, high elasticity and bearing capacity, and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

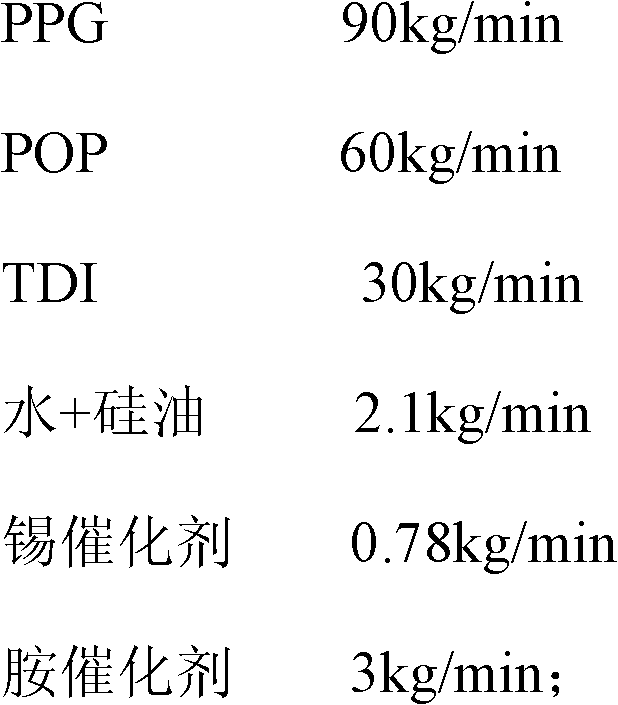

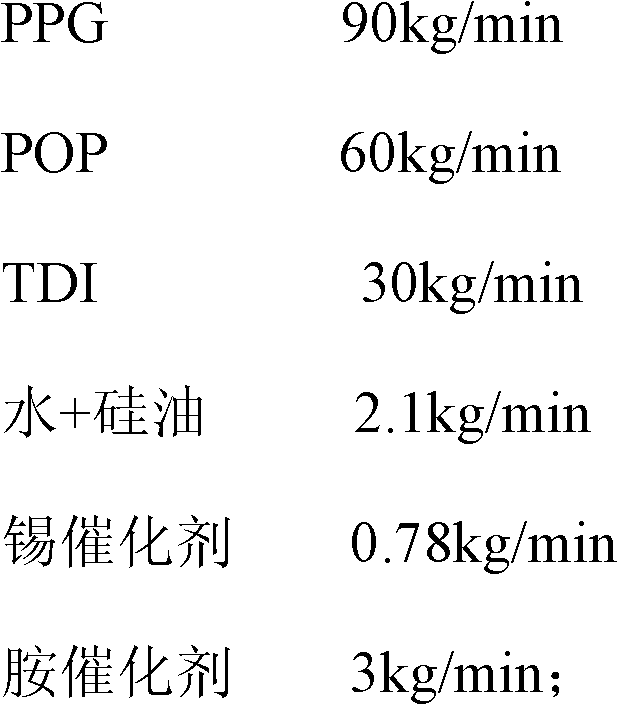

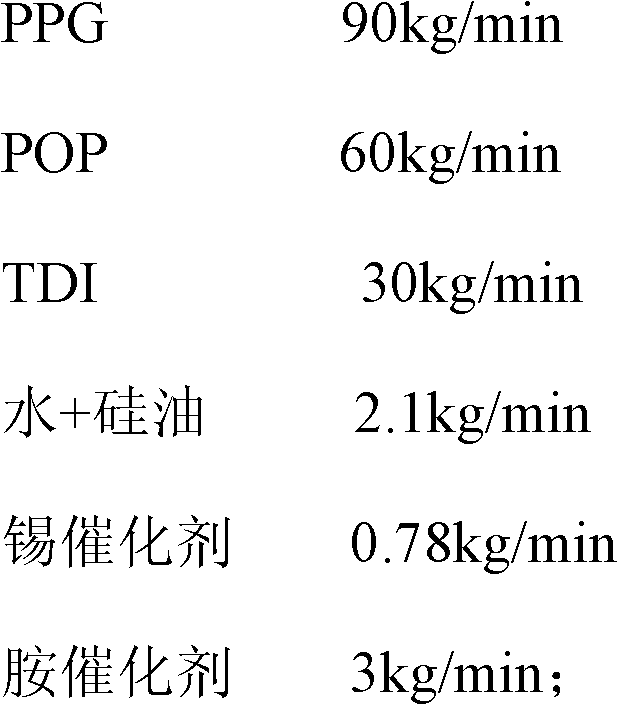

[0026] A kind of soft polyurethane foam plastics, the mixture of raw material polyether, isocyanate, water, catalyst, foam stabilizer is formed by one-step continuous foaming process reaction, and described polyether is made of PPG (polyether polyol) POP (polymer polyol), the isomer ratio of the isocyanate TDI 2,4-TDI:2,6-TDI is 75-85:15-25. The catalyst is composed of an amine catalyst and a tin catalyst, wherein the amine catalyst is a delayed catalyst, the model is KE-9727, the tin catalyst model is T-9, the foam stabilizer is ordinary silicone oil or flame retardant silicone oil, and the TDI isotropic The conformation ratio 2,4-TDI:2,6-TDI is 80:20. A coloring material is also added to the raw material mixture, and the coloring material changes accordingly according to different color requirements. The weight percentage of PPG in the polyether is 50%-60%, and the POP is 40%-50%. Based on the weight of 100 parts of the sum of PPG and POP, the weight percentage of other com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com