High-barrier-property photovoltaic backboard of multilayer structure

A photovoltaic backplane and multi-layer structure technology, applied in photovoltaic power generation, coating, layered products, etc., can solve the problems of yellowing, backplane barrier adhesion and insufficient thermal conductivity, etc., to achieve good adhesion , Reduce the production process and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

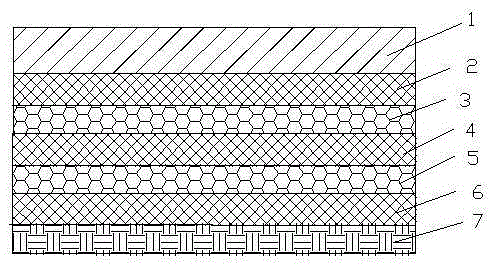

[0029] The present invention discloses a high-barrier multi-layer structure photovoltaic backsheet. The photovoltaic backsheet is composed of a weather-resistant outer layer, a first barrier coating, a first base layer, a second barrier coating, and a second barrier coating from top to bottom. Base layer, third barrier coat and inner layer.

[0030] Among them, the weather-resistant layer adopts a polyvinyl fluoride film with a thickness of 20um; the first barrier coating, the second barrier coating and the third barrier coating adopt a two-component polyurethane system with a thickness of 5um, and the A component is composed of 15 parts of fluororesin , 20 parts of polypropylene oxide polyol, 1 part of defoamer, 0.5 part of catalyst, 5 parts of inorganic filler, 20 parts of organic solvent, component B is trimethyl 1,6-hexamethylene diisocyanate curing agent , and NCO / OH=0.5 in components A and B; the first base layer and the second base layer use a weather-resistant PET film...

Embodiment 2

[0032] The present invention discloses a high-barrier multi-layer structure photovoltaic backsheet. The photovoltaic backsheet is composed of a weather-resistant outer layer, a first barrier coating, a first base layer, a second barrier coating, and a second barrier coating from top to bottom. Base layer, third barrier coat and inner layer.

[0033] Among them, the weather-resistant layer adopts a polyvinylidene fluoride film with a thickness of 22.5um; the first barrier coating, the second barrier coating and the third barrier coating adopt a two-component polyurethane system with a thickness of 18um, and the A component consists of 20 parts Fluorine resin, 30 parts of polypropylene oxide polyol, 1.5 parts of defoamer, 0.8 parts of catalyst, 8 parts of inorganic filler, 10 parts of organic solvent, component B is isophorone diisocyanate curing agent, and component A and NCO / OH=0.8 in component B; the first base layer and the second base layer use a weather-resistant PET film ...

Embodiment 3

[0035] The present invention discloses a high-barrier multi-layer structure photovoltaic backsheet. The photovoltaic backsheet is composed of a weather-resistant outer layer, a first barrier coating, a first base layer, a second barrier coating, and a second barrier coating from top to bottom. Base layer, third barrier coat and inner layer.

[0036] Among them, the weather-resistant layer adopts a polyvinylidene fluoride film with a thickness of 40um; the first barrier coating, the second barrier coating and the third barrier coating adopt a two-component polyurethane system with a thickness of 20um, and the A component is composed of 25 parts of fluorine Resin, 40 parts of polypropylene oxide polyol, 2 parts of defoamer, 1 part of catalyst, 10 parts of inorganic filler, 30 parts of organic solvent, B component is toluene diisocyanate curing agent, and A component and B component Medium NCO / OH=1.1; the first base layer and the second base layer use a weather-resistant PET film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com