Patents

Literature

84 results about "Poly(propylene oxide)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

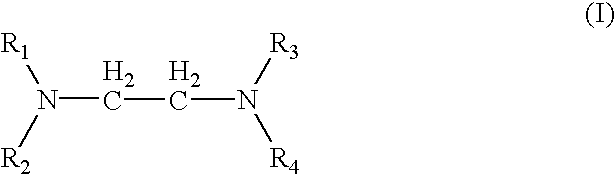

Membrane which comprises a blend of a polysulphone or a polyether sulphone and polyethylene oxide/polypropylene oxide substituted ethylene diamine

A membrane which can be used in membrane filtration processes and which has a reduced tendency to fouling is a polysulphone or a plyether sulphone and a polyethylene oxide / polypropylene oxide substituted diamine and can be made by a phase inversion process in the presence of pore modifying agents such as an alcohol, glycerol or glycol to give a membrane which has a pore size of 0.1.mu. to 1 micron and is hydrophilic.

Owner:HYDRANAUTICS

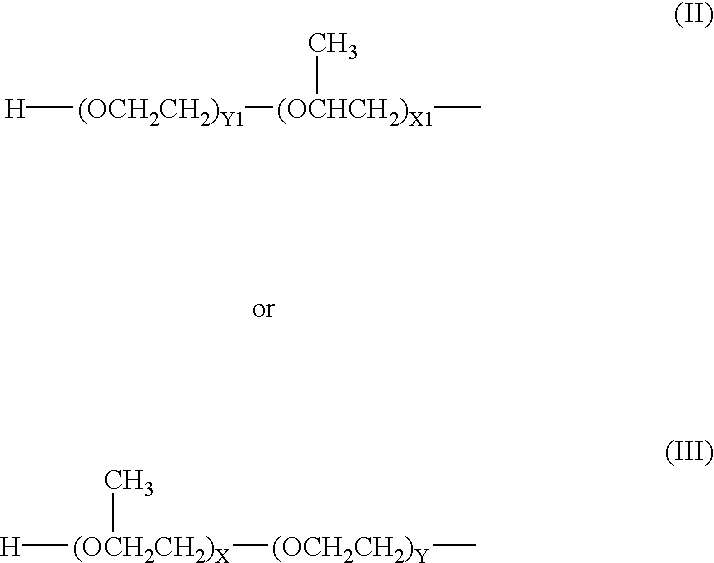

Cleaning compositions with amphiphilic water-soluble polyalkylenimines having an inner polyethylene oxide block and an outer polypropylene oxide block

Laundry detergent and cleaning compositions comprising amphiphilic water-soluble alkoxylated polyalkylenimine polymer having an inner polyethylene oxide block comprising 20 to 50 polyethylene oxide units and an outer polypropylene oxide block comprising 10 to 50 polyethylene oxide units and especially to such alkoxylated polyalkylenimines wherein the ratio of polyethylene oxide units and polypropylene oxide units is proportionally related to the square root of the number of polyalkylenimine units present in the backbone.

Owner:THE PROCTER & GAMBLE COMPANY

Thermosensitive polymers and thermoreversible gels obtained from these polymers

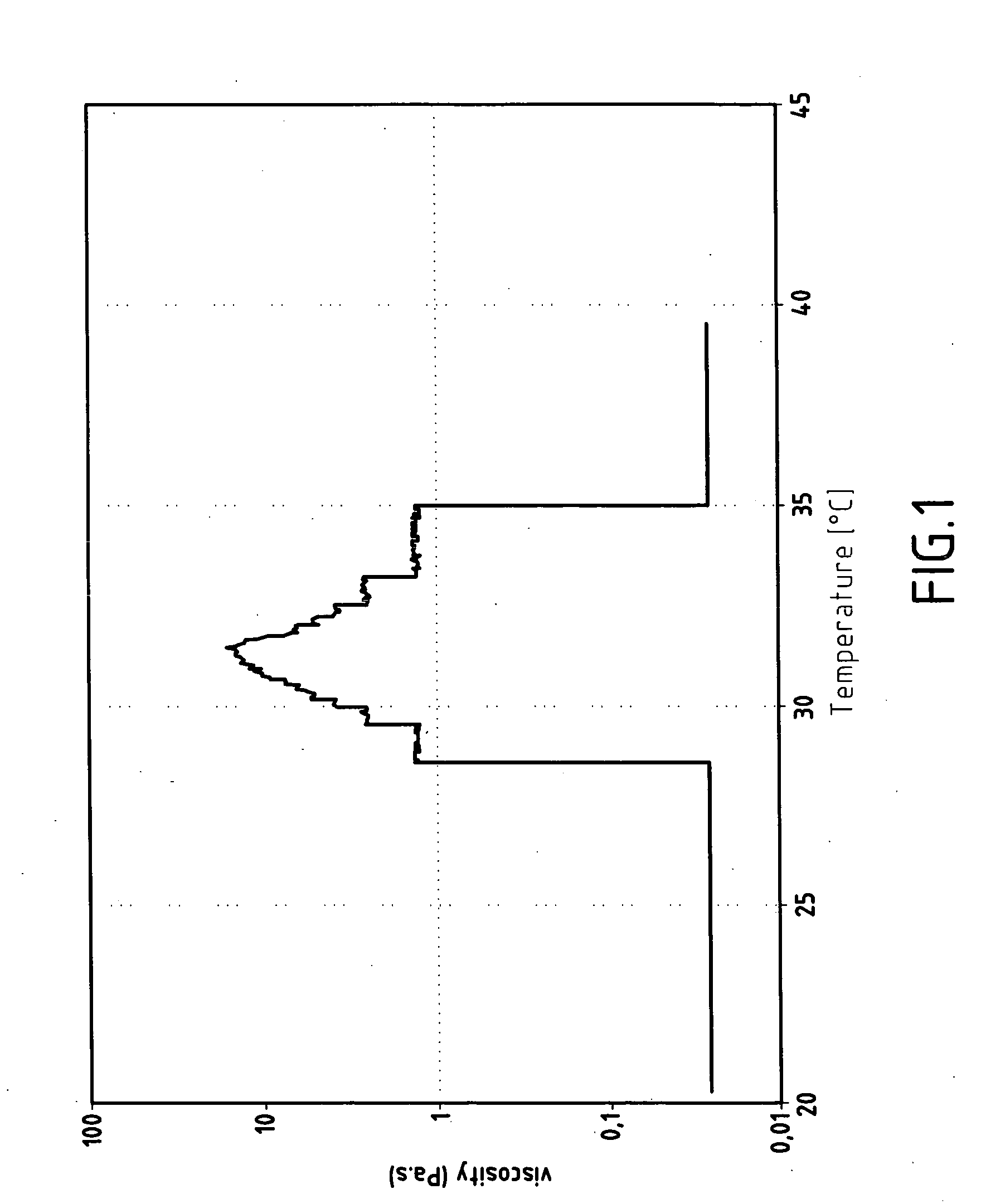

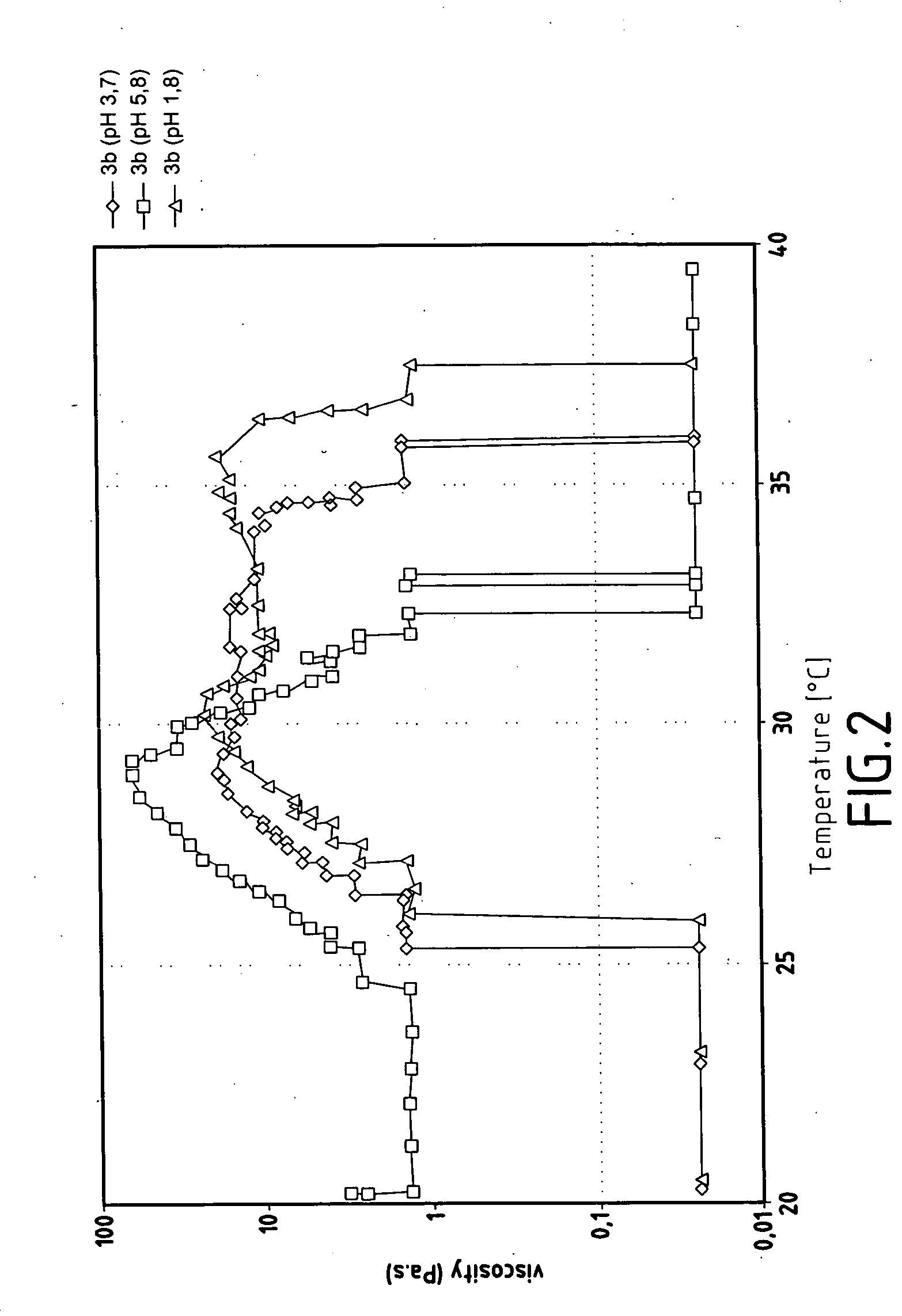

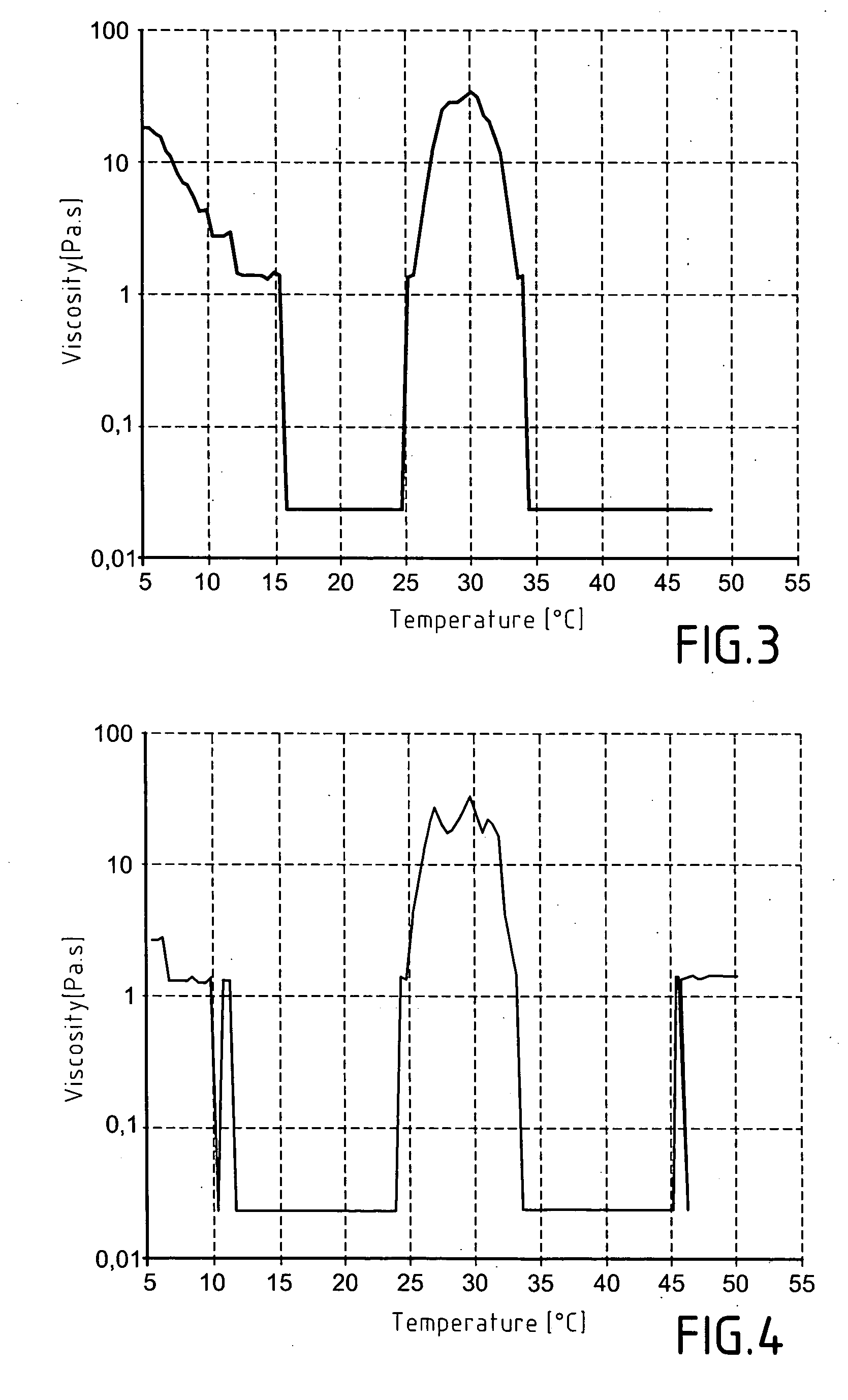

InactiveUS20050175573A1Improve propertiesHigh viscosity indexCosmetic preparationsSenses disorderAllophanePolymer science

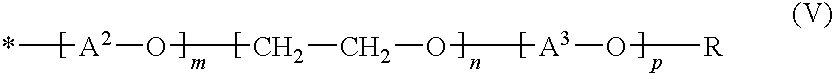

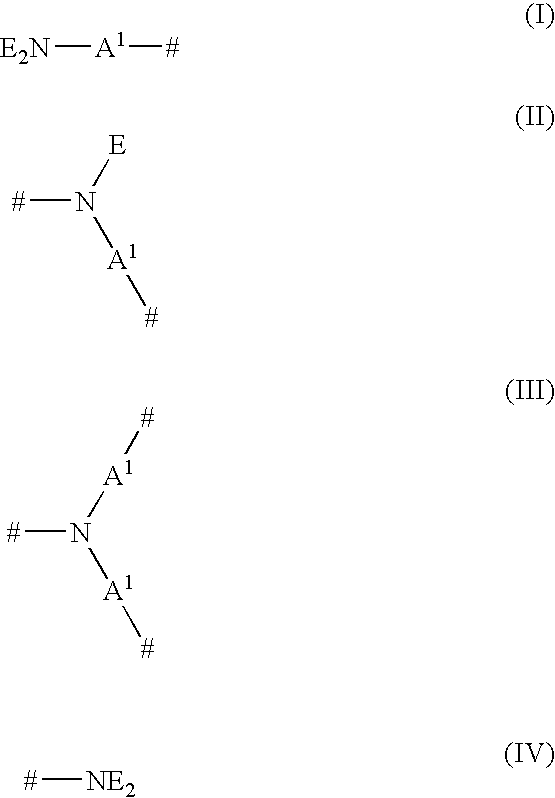

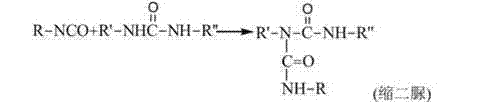

Polymers which comprise polymer chains of terpolymer type which are constituted by poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) of PEO-PPO-PEO form, which are modified at their termini by groups which can essentially be other chains of PEO-PPO-PEO, acid segments, amine groups or PEOs, these chains being linked to the terpolymer chains via chemical bridges which are constituted by urethane bridges, urea bridges, allophanate bridges and biuret bridges, and which comprise more than 80% by weight of said PEO-PPO-PEO. Thermoreversible physical gels of high viscosification index, which contain these polymers, and their uses. Preparation of these polymers and of these gels.

Owner:POLYMEREXPERT

Rapid mold stripping urethane elastomer compoistion and use method thereof

The invention relates to a fast-demoulding casting type PU elastomer compound; two component systems are adopted; one is a prepolymer component; vulcabond is reacted with polylol for obtaining a prepolymer with NCO percent is equal to 9 to 15 percent (weight); polypropylene oxide ether polylol with molecular weight of 1000 to 3000 and a functionality of 2 to 3 is adopted as the polylol; the second is a polymer component which consists of the polypropylene oxide ether polylol with a molecular weight of 1000 to 3000 and a functionality of 2 to 3, an aromatic diamine firming agent and a catalyst. The prepolymer component and the polymer component are mixed according to a weight ratio of 1: 1, cast, vulcanized and shaped; a product can be demoulded in ten minutes without post-vulcanization, thus obtaining the fast-demoulding casting type PU elastomer with a product rigidity of shoreA80 to 97 and excellent mechanical properties. The fast-demoulding casting type PU elastomer compound is mainly used for manufacturing the products of PU elastomer such as polyurethane rubber wheel, polyurethane plank stuff and rubber roller, etc.

Owner:SHANDONG INOV POLYURETHANE

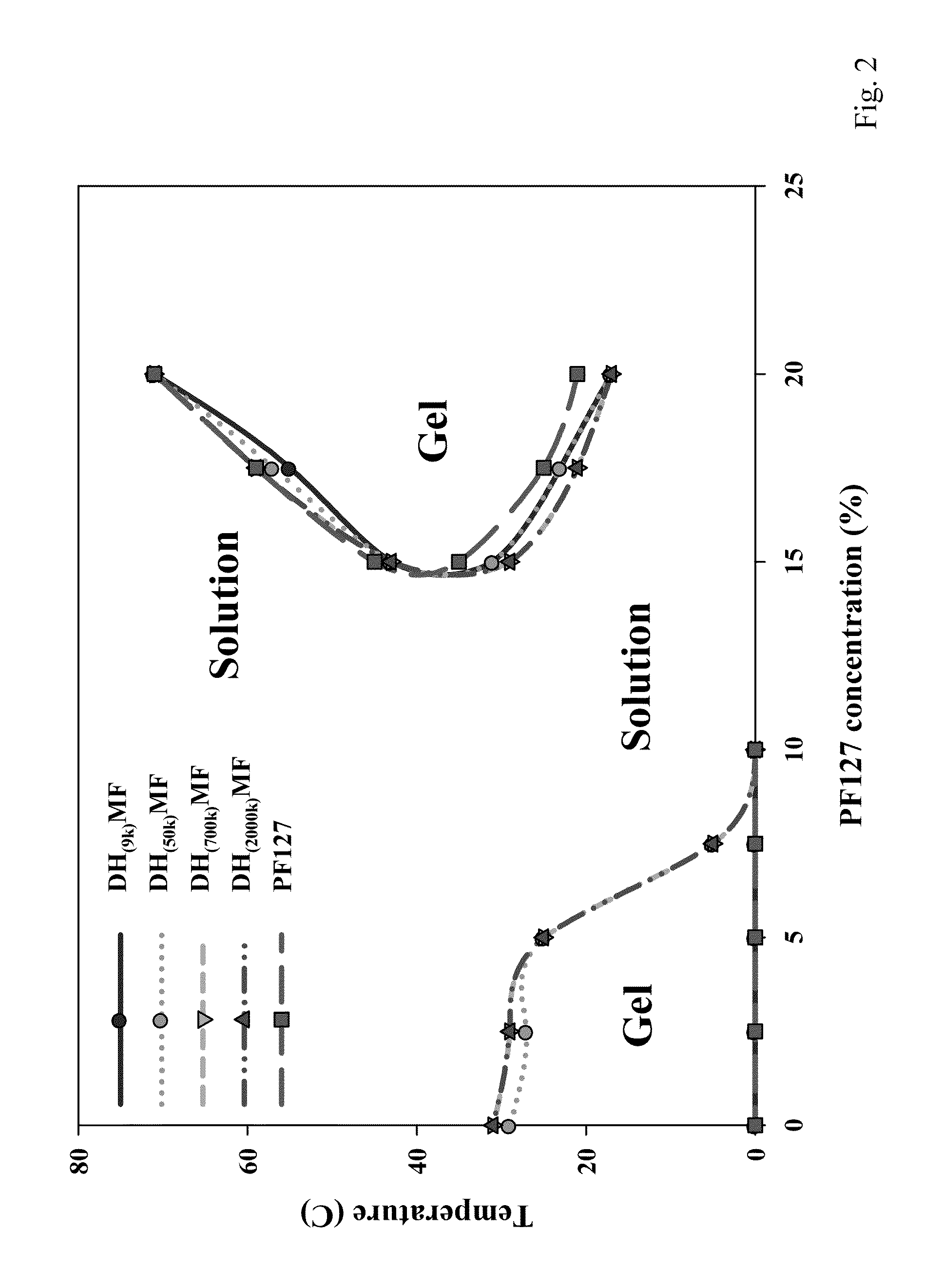

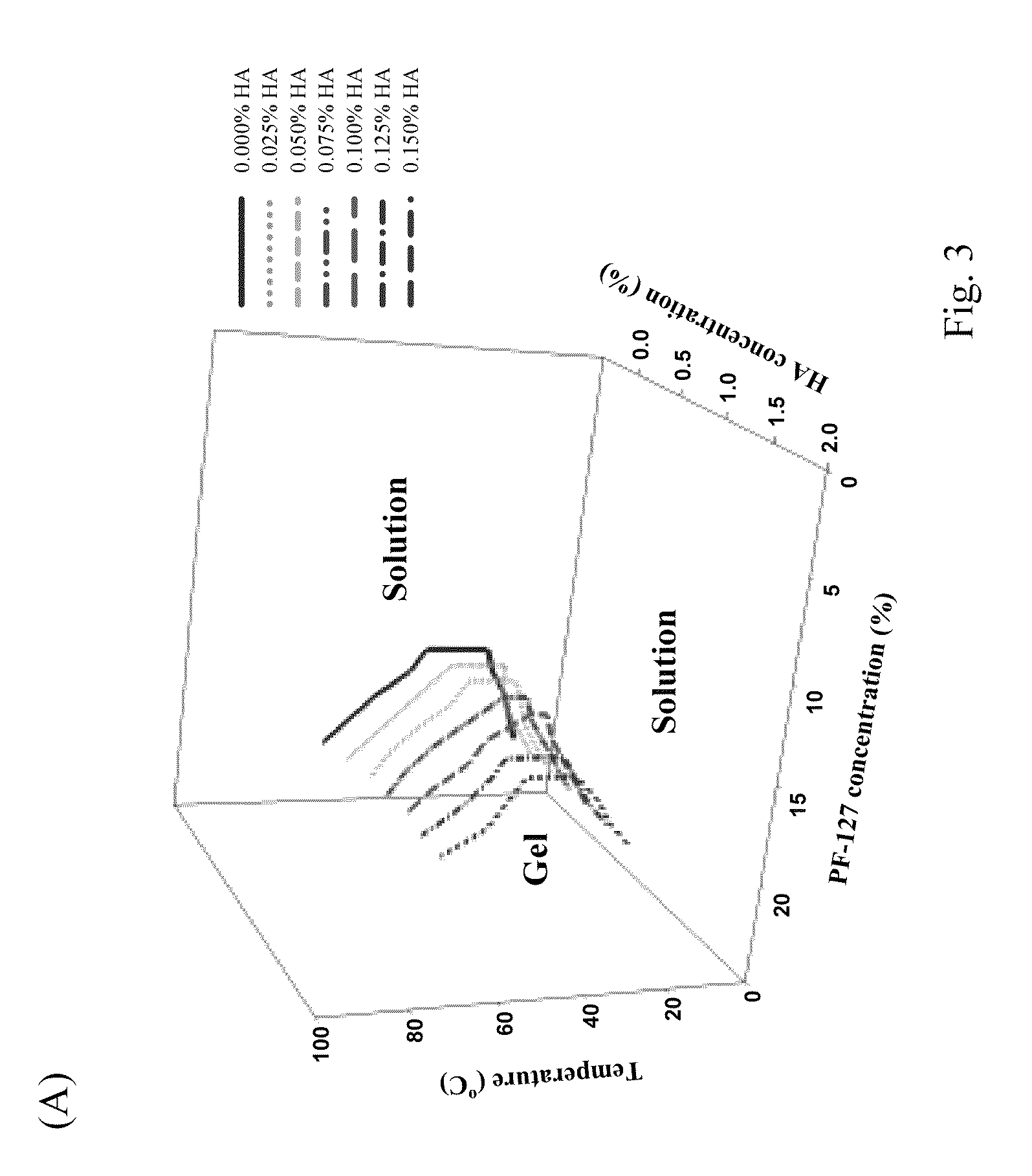

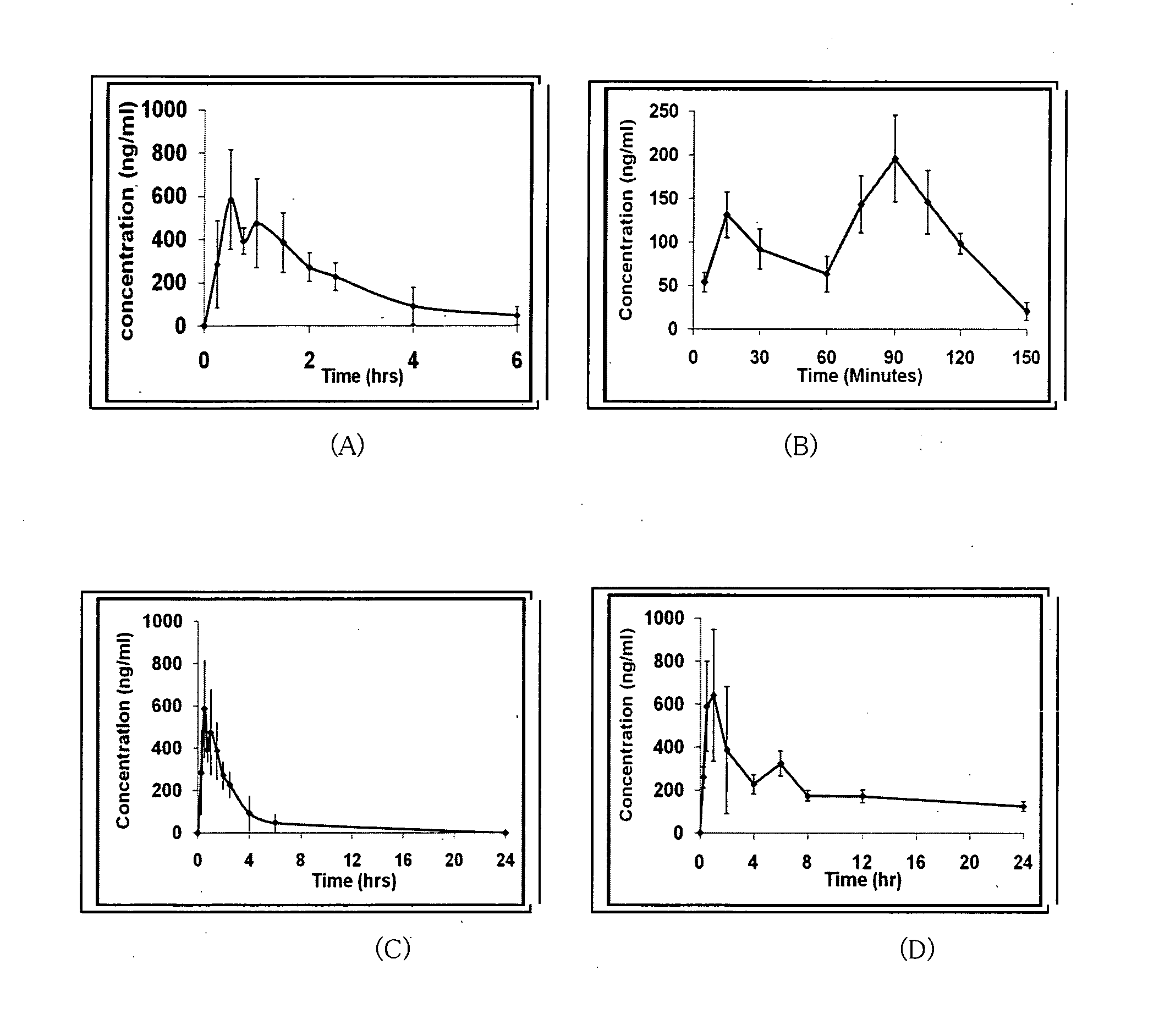

Thermosensitive injectable hydrogel for drug delivery

ActiveUS9364545B2Efficient Growth InhibitionGood curative effectOrganic active ingredientsAerosol deliveryPolyethylene oxideMedicine

The invention develops a developed a thermosensitive injectable hydrogel based on HA and a copolymer of polyethylene oxide (PEO) and polypropylene oxide (PPO), which has a gel formation temperature from 30° C. to 37° C. The thermosensitive injectable hydrogel of the invention provides a potential drug delivery system that can increase therapeutic efficacy of the drug.

Owner:TAIPEI MEDICAL UNIV

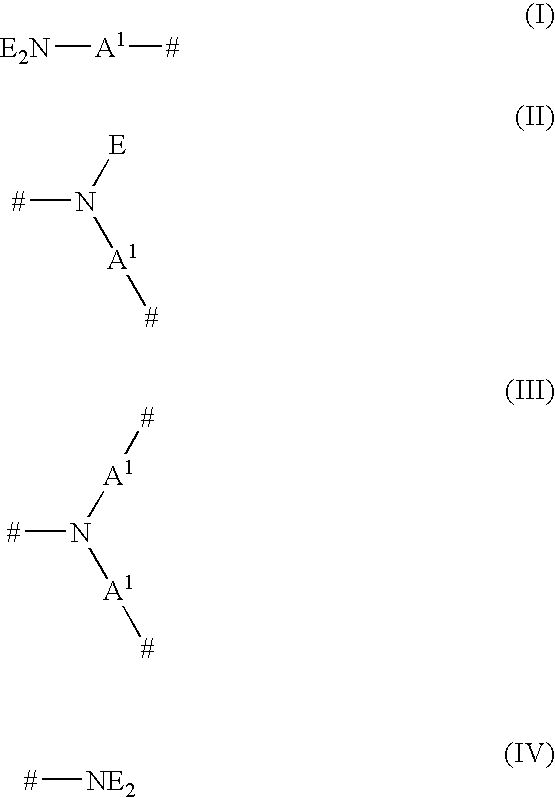

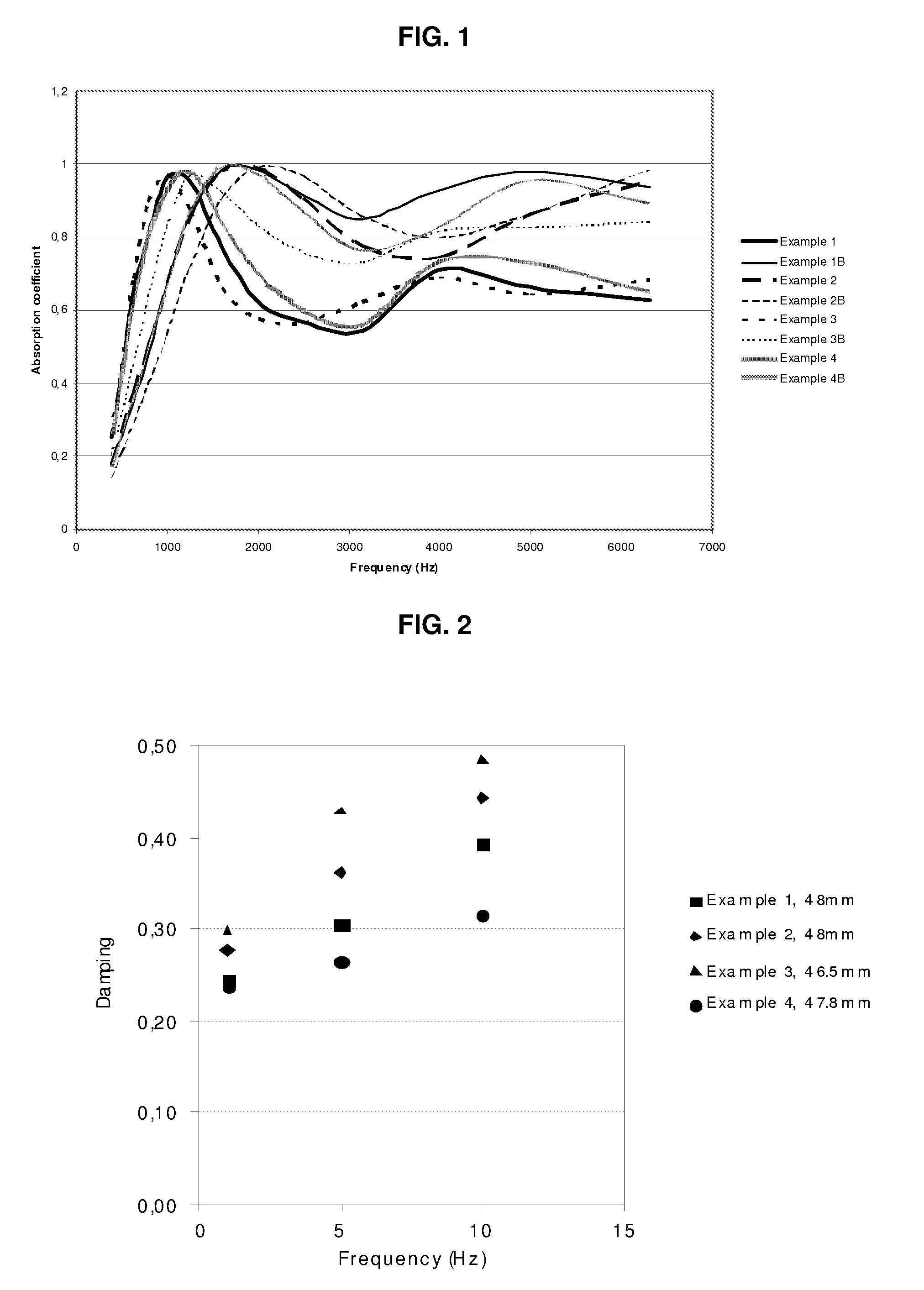

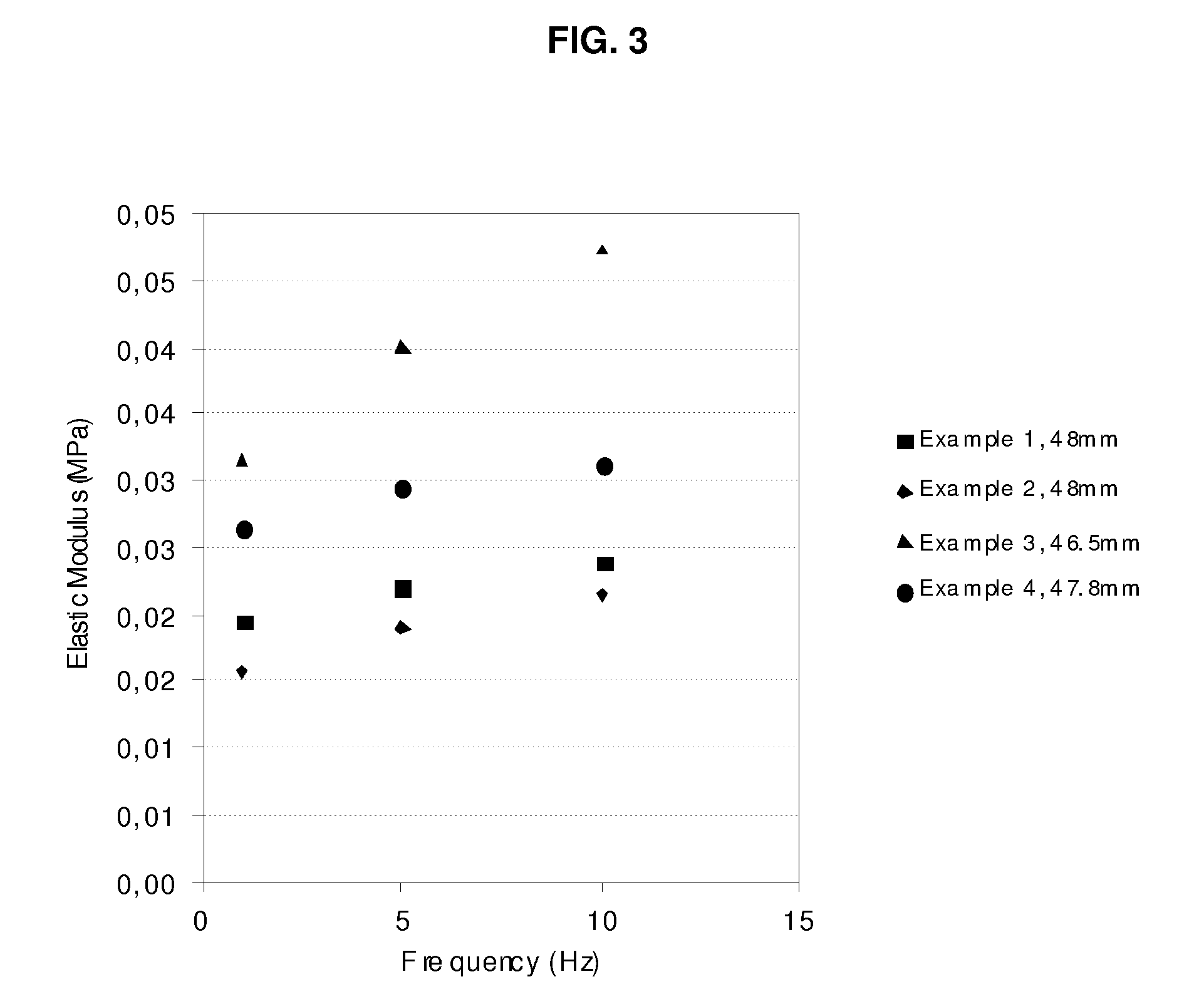

Process for making low density high resiliency flexible polyurethane foam

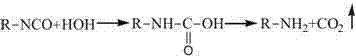

A process for producing resilient, flexible polyurethane foams that function well in noise and vibration absorption applications for vehicle applications that are made from a blend of polyols (i) and an isocyanate (ii), wherein the blend of polyols (i) comprises a mixture of polyether polyols (i.a) that each has a hydroxyl equivalent weight of from 1200 to 3000 and at least 70% primary hydroxyl groups, from 5 to 80% by weight of the ethylene oxide-capped polypropylene oxides are nominally difunctional, from 0.5 to 20% by weight of the ethylene oxide-capped polypropylene oxides have a nominal functionality of four or higher, and the balance of the ethylene oxide-capped polypropylene oxides, but not less than 1.5% by weight thereof, are nominally trifunctional; an autocatalytic polyol (i.b) having a functionality in the range of 2 to 8 and a hydroxyl number in the range of 15 to 200, wherein said autocatalytic polyol compound comprising at least one tertiary amine group; and a low unsaturation polyol (i.c) having a functionality equal to or greater than 2, a hydroxyl equivalent weight of from 1800 to 2800, and a total unsaturation value of equal to or less than 0.06 meq / g.

Owner:DOW GLOBAL TECH LLC

Flame-retardant rigid polyurethane foaming plastic composite material and preparation method thereof

The invention relates to a flame-retardant rigid polyurethane foaming plastic composite material and a preparation method thereof. The flame-retardant rigid polyurethane foaming plastic composite material is prepared from the following raw materials in parts by weight: 27-40 parts of modified nanometer magnesium hydrate, 10-13 parts of microencapsulation red phosphorus, 30-50 parts of polypropylene oxide, 30-45 parts of isocyanate, 5-15 parts of foaming agent and 0.5-2 parts of dibutyltin dilaurate. Through synergism of the inorganic particle nanometer magnesium hydrate and the microencapsulation red phosphorus, the flame resistance of the composite material is improved, the oxygen index of the composite material is improved to 31%, the horizontal firing level of the composite material reaches HB40, and the vertical firing level of the composite material reaches V-0.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Controlled release micro-capsule for osteogenic action

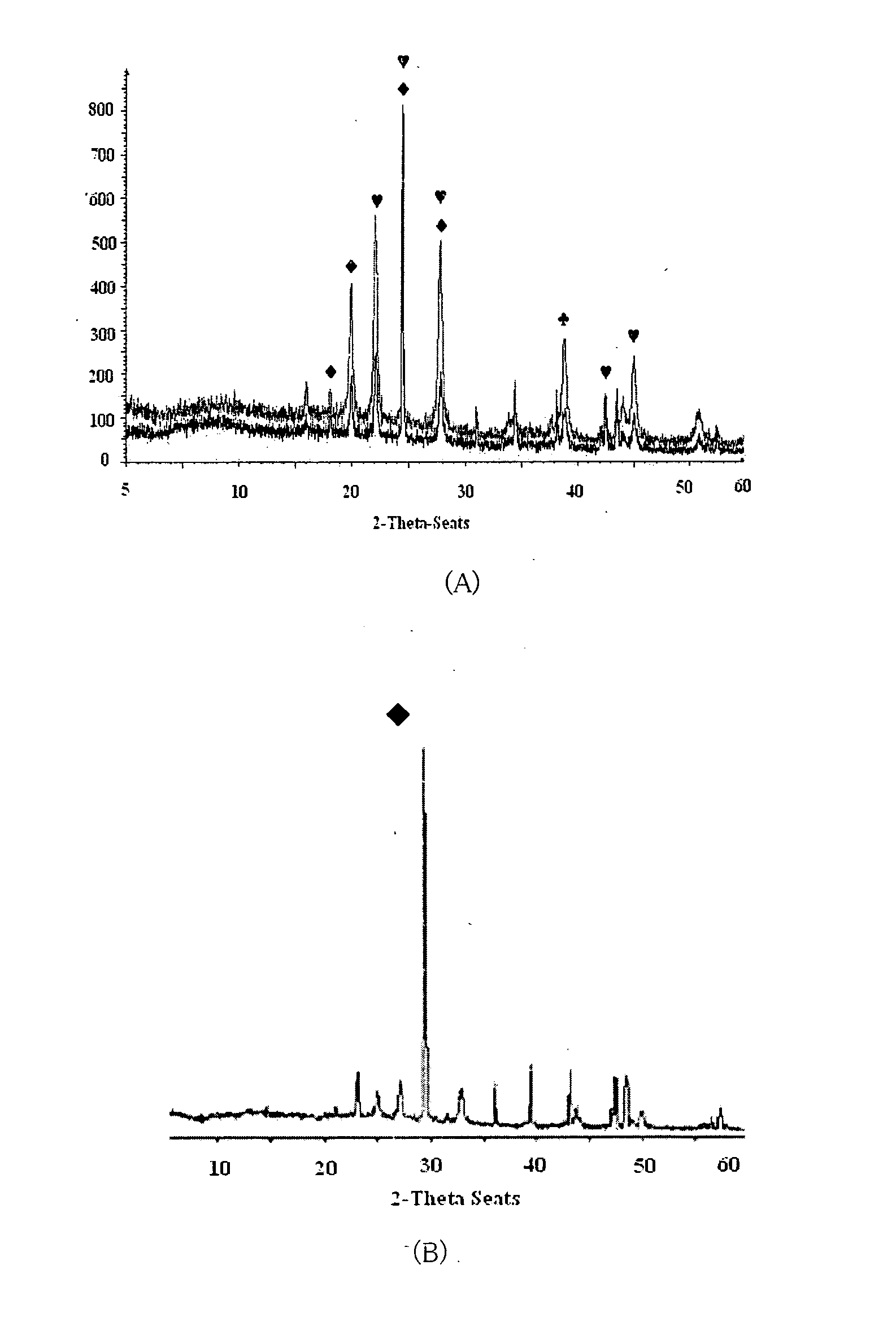

ActiveUS20110305754A1Improve actionHigh drug loadingBiocidePretreated surfacesPluronic F68Controlled release

The present invention relates to a microcapsule for controlled release of flavanoid compound and a process for preparation thereof. The microcapsule comprising a core particle consisting of a calcium salt, Pluronic F68 [poly (ethylene oxide-co-polypropylene co-polypropylene oxide), block poly oxyethylene-polypropylene block copolymer], loaded with a flavanoid compound, the resulting core particle having a plurality of alternate layers of cationic and anionic polyelectrolytes adsorbed thereon and an outer layer formed by a bile salt, wherein the flavanoid is ranging between 10 to 96% by weight.

Owner:COUNCIL OF SCI & IND RES

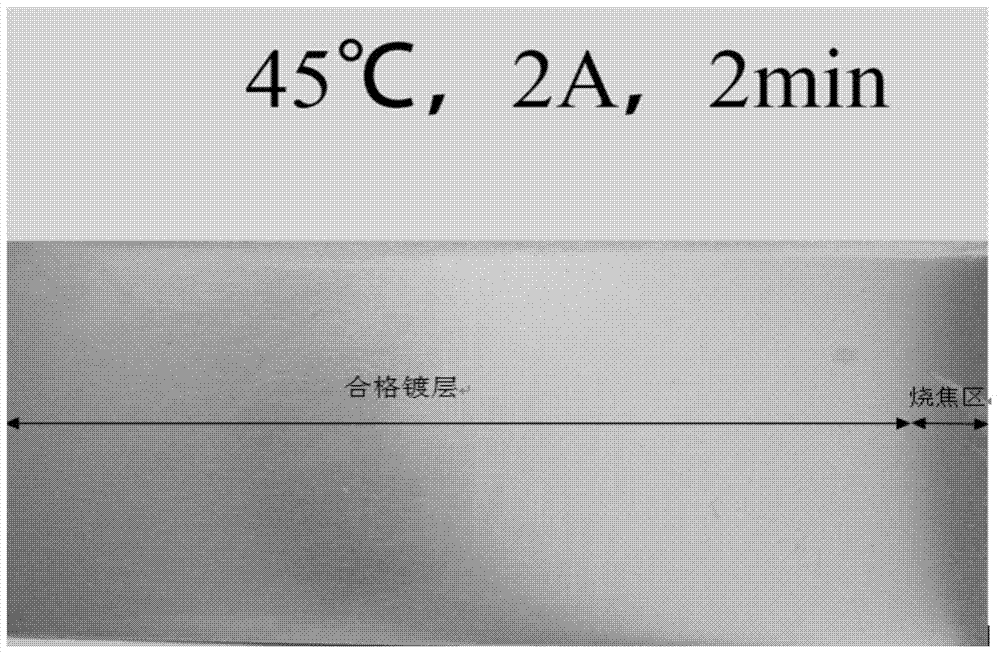

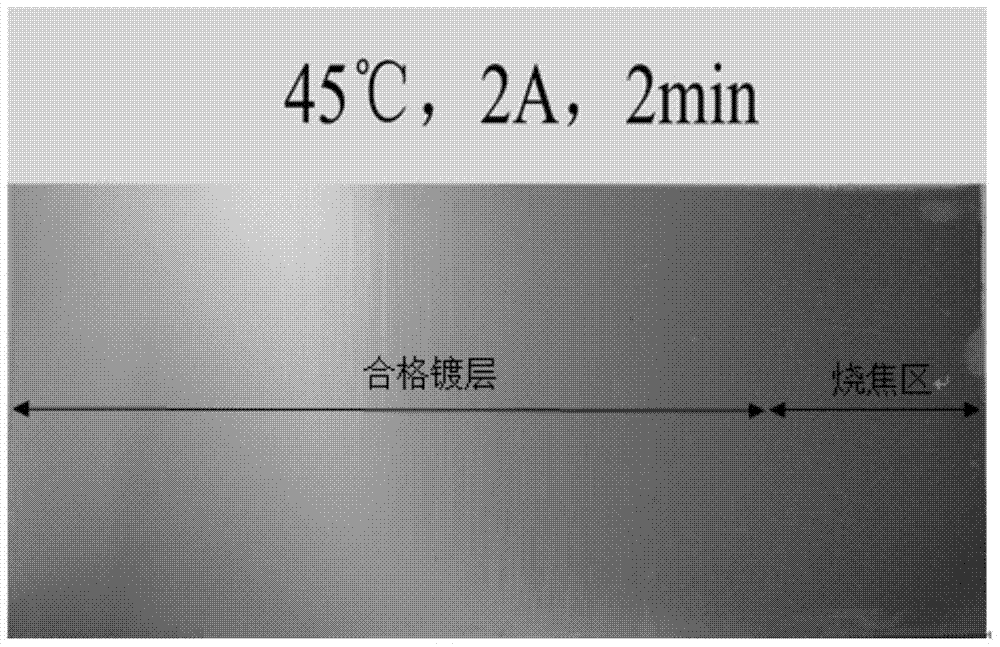

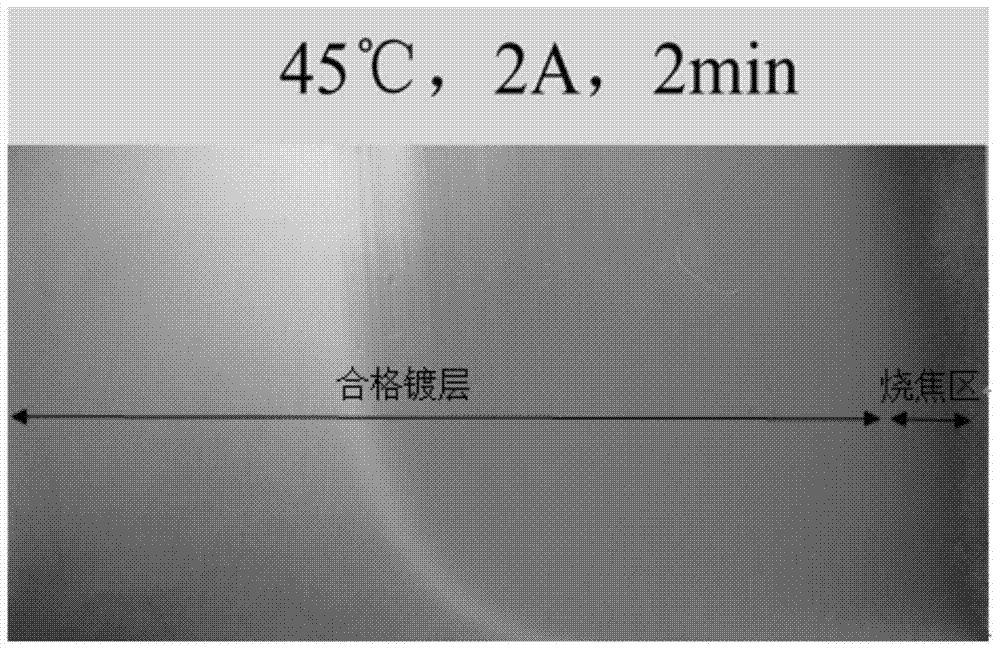

All-sulfate tin electroplating additive and plating solution thereof

The invention discloses an all-sulfate tin electroplating additive and a plating solution thereof. The additive comprises 0.1-200 mg / L defoaming agent, 0.1-50 g / L fine crystal agent, 0.01-20 g / L leveling agent and 0.1-40 g / L antioxidant. The plating solution comprises 5-100 g / L stannous sulfate, 0.1-100 ml / L sulfuric acid, and 0.1-200 mg / L defoaming agent, 0.1-50 g / L fine crystal agent, 0.01-20 g / L leveling agent and 0.1-40 g / L antioxidant used as the additive. The additive disclosed by the invention is free of anionic, cationic and amphoteric surfactants, polyformaldehyde, polyethylene oxide, polypropylene oxide homopolymer, aldehydes, heterocyclic ring compounds, amine compounds, polyaminocarboxylic acid, sulfur amino acids and any organic solvent. The plating solution can be used for obtaining a matte plating with fine crystals and uniform coverage at the on-line speed of 0-800 m / minute.

Owner:HARBIN INST OF TECH

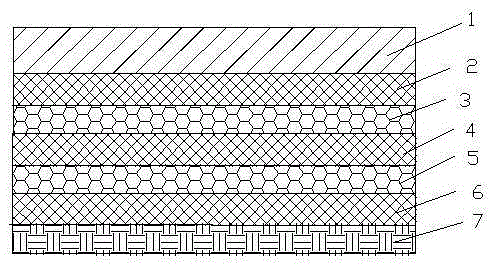

High-barrier-property photovoltaic backboard of multilayer structure

ActiveCN105419617AImprove barrier propertiesImprove insulation performanceSynthetic resin layered productsPolyurea/polyurethane coatingsPtru catalystMoisture barrier

The invention discloses a high-barrier-property photovoltaic backboard of a multilayer structure. The photovoltaic backboard sequentially comprises a weather-proof outer layer, a first obstruction coating, a first base layer, a second obstruction coating, a second base layer, a third obstruction coating and an inner layer from top to bottom. The first obstruction coating, the second obstruction coating and the third obstruction coating are all double-component polyurethane systems. A component A is prepared from 15-25 parts of fluorine resin, 20-40 parts of polypropylene oxide polyhydric alcohols, 1-2 parts of defoaming agent, 0.5-1 part of catalyst, 5-10 parts of inorganic filler and 10-30 parts of organic solvent. A component B is a mixture containing one or two of toluene diisocynate, isophorone diisocyanate and trimethyl 1,6-hexamethylene diisocyanate. The component A and the component B are mixed according to the ratio NCO / OH=0.5-1.1. According to the high-barrier-property photovoltaic backboard, by designing the two base layers and the three obstruction coatings, the moisture barrier property and the insulativity of the backboard are effectively improved.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

Process for making low density high resiliency flexible polyurethane foam

Owner:DOW GLOBAL TECH LLC

Cross-linked anti-fatigue and anti-wear polyurethane rubber

The invention discloses a method for preparing cross-linked anti-fatigue and anti-wear polyurethane rubber. The cross-linked anti-fatigue and anti-wear polyurethane rubber comprises the following components in percentage by mass: 65-70% of polytetramethylene glycol, 6-10% of cyclic polypropylene oxide ether triatomic alcohol, 14-20% of toluene diisocyanate, 5-8% of 1,5-naphthalene diisocyanate, 1-3% of di-o-chlorodiphenylamine methane, 0.5-1.5% of trimethylolpropane, 0-0.5% of carbon black and 1-2% of molybdenum disulfide. The rubber has the advantages of high wear resistance, good resilience, good low-temperature resistance, high tensile strength, predominant hydrolysis resistance, good adhesion to metal, shock resistance and relatively good anti-fatigue performance.

Owner:JIANGSU GUANGDING PIPE IND TECH CO LTD

Solvent-free single-component moisture-curable polyurethane adhesive suitable for wood and preparation method thereof

The invention relates to a solvent-free single-component moisture-curable polyurethane adhesive suitable for wood and a preparation method thereof. A raw material formula of the polyurethane adhesivecomprises the following components in percentage by mass: 45.6 to 58% of isocyanate, 18.7 to 30% of polyether polyol, 20 to 27% of polyester polyol, 0.1 to 0.3% of a catalyst and 0.1 to 0.3% of an auxiliary agent, wherein the polyether polyol is a mixture of polypropylene oxide ether polyol with a functionality of 3 and a number-average molecular weight of 5000-6000, random copolymerization polyether polyol of ethylene oxide and propylene oxide, and polytetrahydrofuran ether polyol with a functionality of 2 and a number-average molecular weight of 1000-2000. According to the single-component moisture-curable polyurethane adhesive disclosed by the invention, the polyol in the formula adopts blending of specific polyether polyol and polyester polyol; and the prepared polyurethane adhesive isused for bonding wood, the compression-shear strength of the wood is high after bonding, and the wood is durable in use.

Owner:XUCHUAN CHEM SUZHOU

Ultralow-hardness polyurethane elastomer and preparation method thereof

The invention relates to an ultralow-hardness polyurethane elastomer which comprises three components: a component A is diphenylmethane diisocyanate or a prepolymer thereof, wherein the prepolymer is formed by polymerizing the diphenylmethane diisocyanate and a modifier thereof with polypropylene oxide ether polyol with the functionality of 2-3 and the number-average molecular weight of 1000-8000; a component B consists of polymer polyol, a catalyst and an antiaging agent; and a component C is polymer linear monoalcohol with the number-average molecular weight of 1000-4000. When the component A is the prepolymer, the mass ratio of the component A to the component B is 1:(0.8-1.3). When the component A is the diphenylmethane diisocyanate, the mass ratio of the component A to the component B is 1:(19-27). The mass ratio of the component B to the component C is 1:(0-0.3). The invention also provides a preparation method of the ultralow-hardness polyurethane elastomer material, which is simple to formulate and easy for manufacturing; and the obtained product is environment-friendly and safe, has favorable buffering performance and compression resisting performance, the Shore hardness ranging between 0 and 15, and smooth surface or extremely low viscosity, and is used for manufacturing shoe products for buffering, resisting wearing, and the like.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Cross-linked polyether reverse demulsifier and preparation method thereof

ActiveCN112300379AFast water purificationImprove water qualityWaste water treatment from quariesDewatering/demulsification with chemical meansPolyethylene oxidePtru catalyst

The invention discloses a cross-linked polyether reverse demulsifier and a preparation method thereof. The preparation method comprises the following step of: by taking polypropylene oxide-polyethylene oxide-polypropylene oxide triblock polyether taking pyridinol as an initiator and epoxy chloropropane as raw materials, reacting under the action of a basic catalyst to obtain the water-soluble cross-linked polyether reverse demulsifier. The water-soluble cross-linked polyether reverse demulsifier can be used for treating high-water-content crude oil produced liquid, and has the characteristicsof high water purification speed and clear dehydrated water.

Owner:中海油(天津)油田化工有限公司 +2

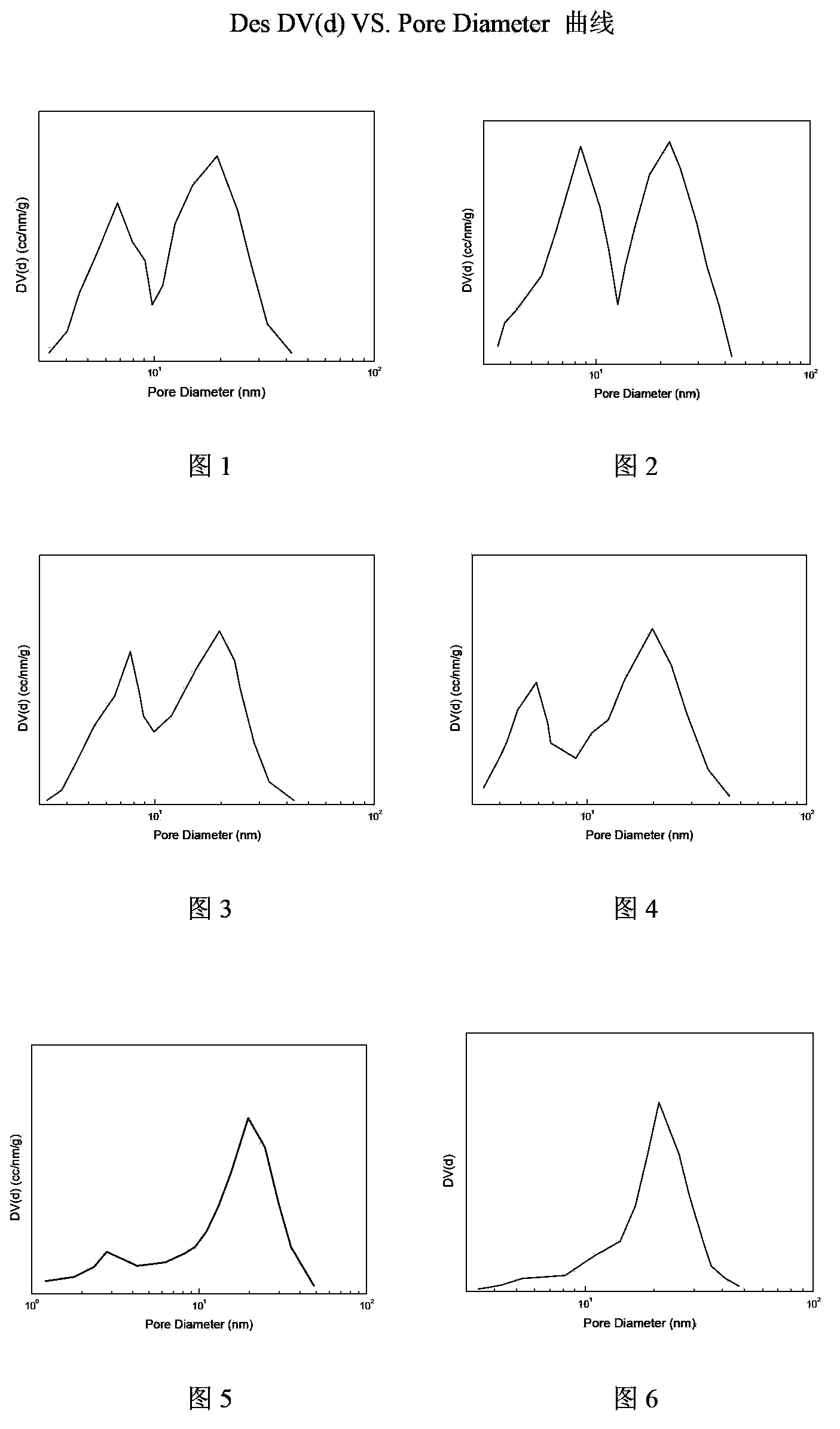

High-elasticity silane-terminated polypropylene oxide sealant and preparation method thereof

ActiveCN105238320AIncrease elasticityHigh tensile strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEndcappingPolymer science

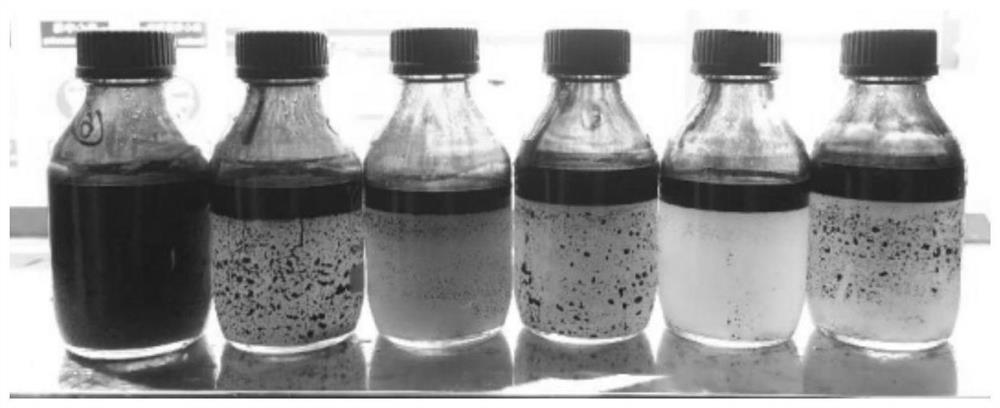

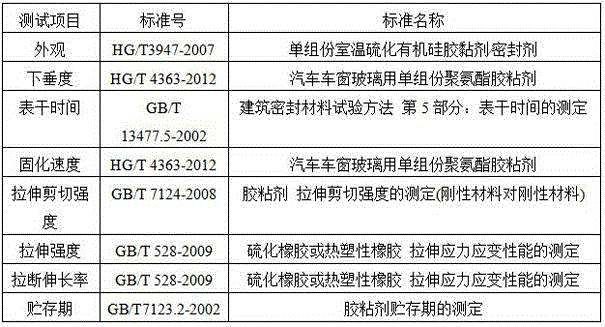

The invention discloses a high-elasticity silane-terminated polypropylene oxide sealant and a preparation method thereof. The sealant is prepared from the raw materials of silane-terminated polypropylene oxide polymer, a diluting agent, calcium carbonate, carbon black, a thixotropic agent, a light stabilizer, an antioxidant, a dehydrating agent, an adhesion promoter, and a catalyst. The preparation method of the high-elasticity silane-terminated polypropylene oxide sealant comprises the following steps: (1) the silane-terminated polypropylene oxide polymer, the diluting agent, calcium carbonate, carbon black, the thixotropic agent, the light stabilizer and the antioxidant are well mixed under a temperature of 80-120 DEG C and a vacuum degree of 0.085-0.095MPa; and the above mixing conditions are maintained for 2-6h; (2) the temperature of the mixed material obtained in the above step is reduced to below 50 DEG C; the diluting agent, the adhesion promoter and the catalyst are added; the materials are well mixed under a protective gas atmosphere; and (3) the obtained material is discharged and packaged in a sealed manner according to certain specifications. The sealant provided by the invention has good performances. The preparation process is simple and environment-friendly.

Owner:GUANGZHOU MECHANICAL ENG RES INST

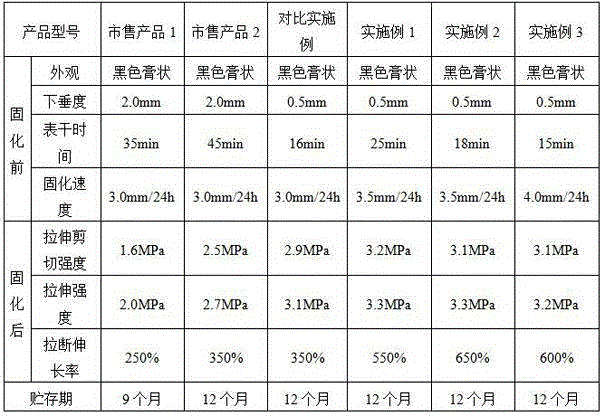

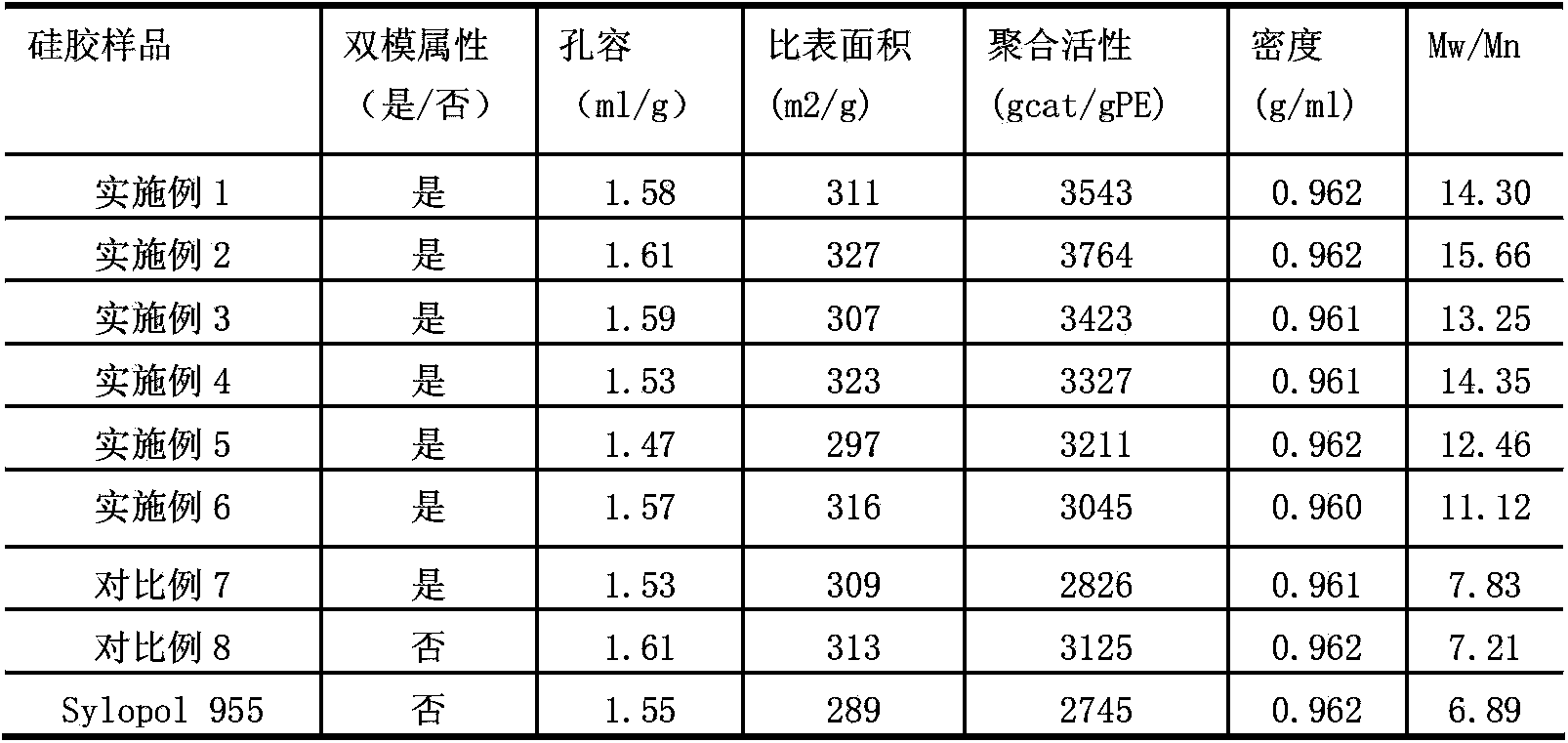

Method for preparing silica gel carrier with dual-mode pore size distribution

Disclosed is a method for preparing silica gel with dual-mode pore size distribution by taking an inorganic silicate and an inorganic acid as raw materials and through two stages of gel reaction. In the first stage, silica gel with the pore size distribution of between 50 angstroms and 500 angstroms is prepared by adopting a sol-gel process and adjusting the pH value, the reaction temperature and the aging time; and in the second stage, the second-stage silica gel pore size is adjusted and controlled by adding polyethylene oxide or polypropylene oxide as a template reagent, the second-stage pore size distribution is between 20 angstroms and 150 angstroms, and the silica gel carrier having a difference between the average pore sizes of the two stages being greater than 50 angstroms is prepared. A catalyst prepared from the obtained carrier is polymerized to obtain an olefin polymer with wide molecular weight distribution.

Owner:PETROCHINA CO LTD

Copper electroplating additive and preparation method thereof

The invention discloses a copper electroplating additive and a preparation method of the copper electroplating additive. The copper electroplating additive is prepared from, by weight, 5-10kg of 50% sulfuric acid, 1-5kg of copper sulfate, 1-6kg of bis-(sodium sulfopropyl)-disulfide, 1-6kg of propane pyridinium sulfonate salt, 1-5kg of alkyl dimethyl ammonium chloride and sulfur dioxide polymerizedquaternary ammonium salt, 80-150kg of polyoxycyclohexane-polypropylene oxide monobutyl ether and 1-8kg of PEG. The preparation method comprises the specific steps that 1.1, about 85 L of pure water is added, and stirring is started; 1.2, sulfuric acid is added and stirred till being completely dissolved; 1.3, copper sulfate is added and stirred till being completely dissolved; 1.4, bis-(sodium sulfopropyl)-disulfide is added and stirred till being completely dissolved; 1.5, propane pyridinium sulfonate salt is added and stirred till being completely dissolved; 1.6, alkyl dimethyl ammonium chloride and sulfur dioxide polymerized quaternary ammonium salt are added and stirred till being completely dissolved; 1.7, polyoxycyclohexane-polypropylene oxide monobutyl ether is added and stirred till being completely dissolved; and 1.8, PEG8000 is added and stirred till being completely dissolved. Brightness of an electroplated copper layer can be ensured, plate burning is prevented, anode slime is reduced, and the electroplating Tp value is high.

Owner:南通赛可特电子有限公司

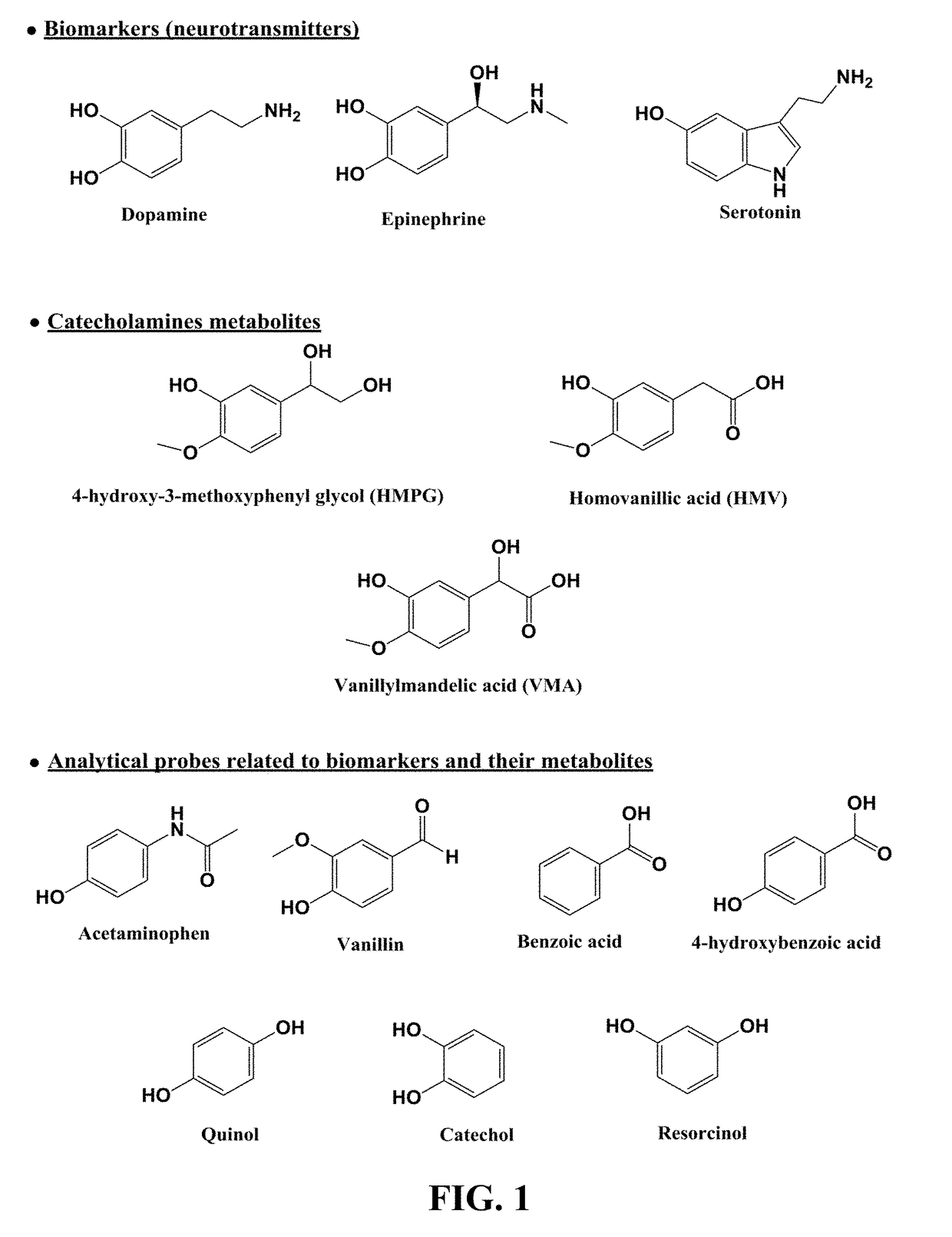

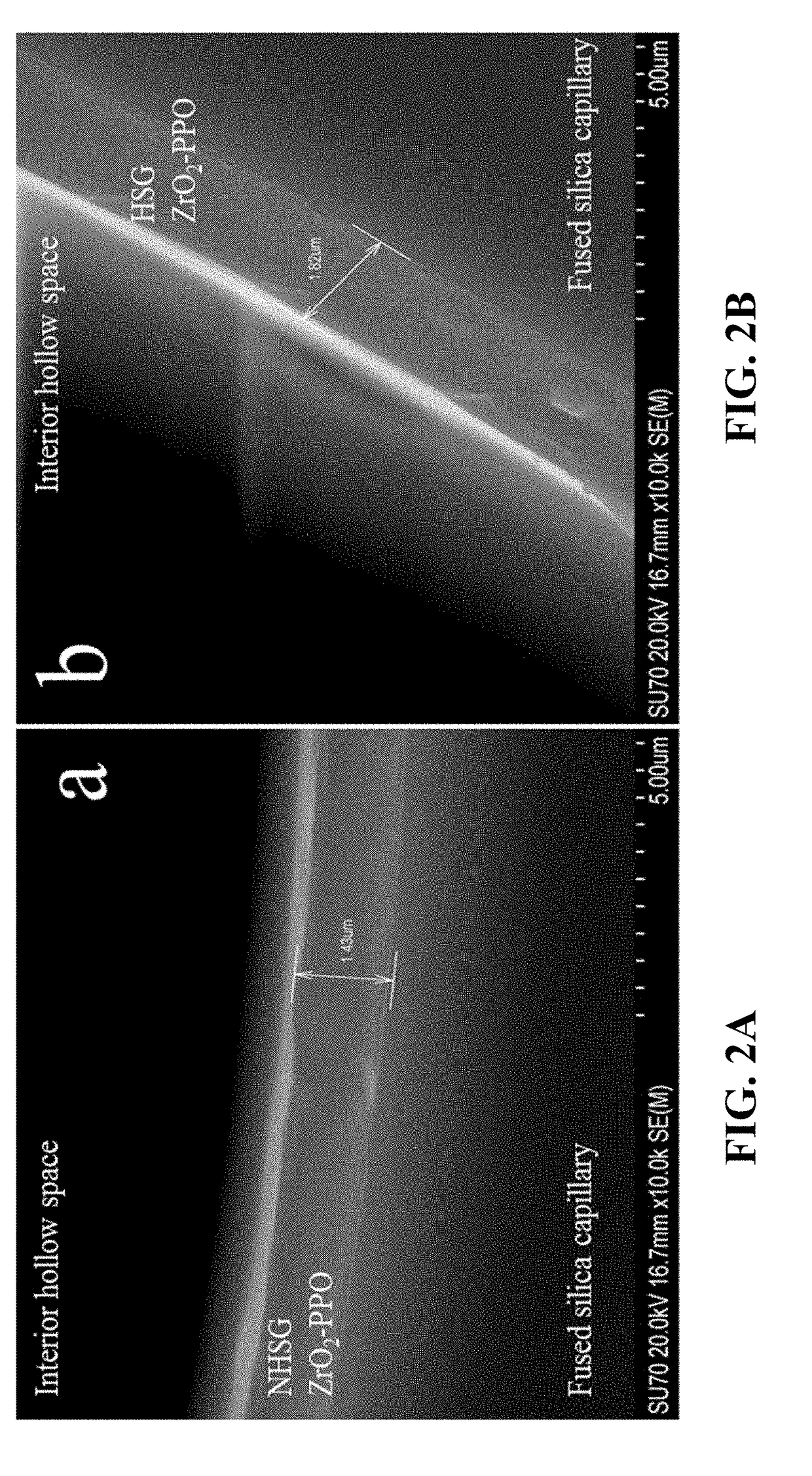

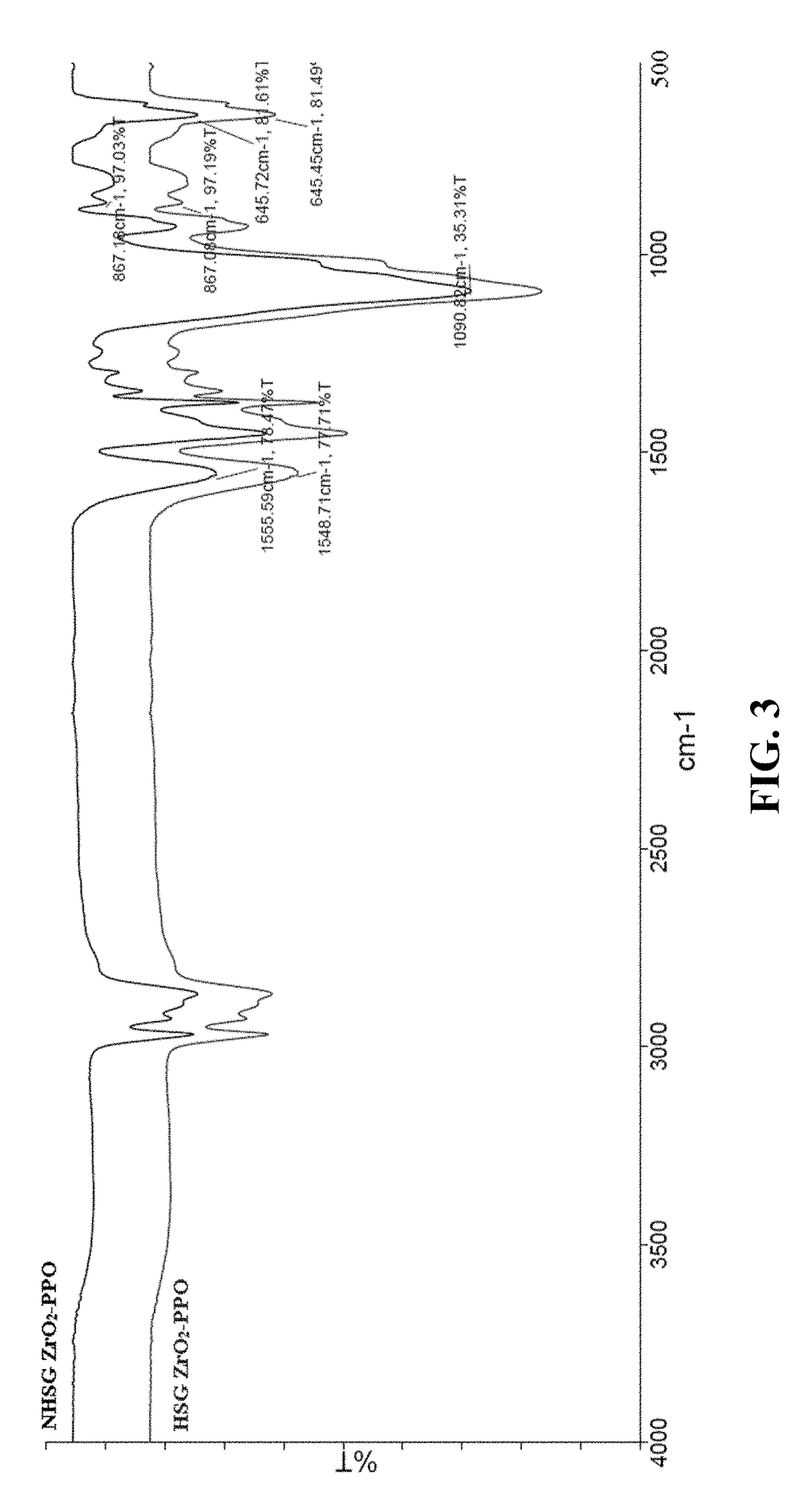

Metal oxide-based biocompatible hybrid sorbent for the extraction and enrichment of catecholamine neurotransmitters and related compounds, and method of synthesis

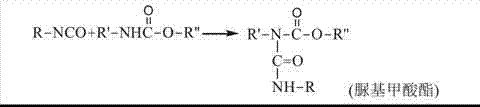

The subject invention concerns metal or metalloid oxide-based sol-gel hybrid sorbent and methods of synthesis. In one embodiment, the sorbent is a ZrO2 polypropylene oxide based sol-gel. The subject invention also concerns a hollow tube or capillary internally coated with a sorbent of the invention. Sorbent coated tubes and capillaries of the invention can be used in extraction and / or enrichment of samples to be analyzed for catecholamines and related compounds.

Owner:UNIV OF SOUTH FLORIDA

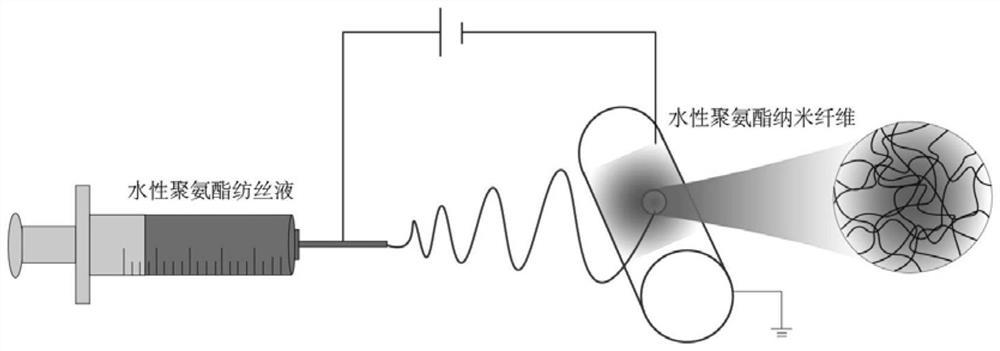

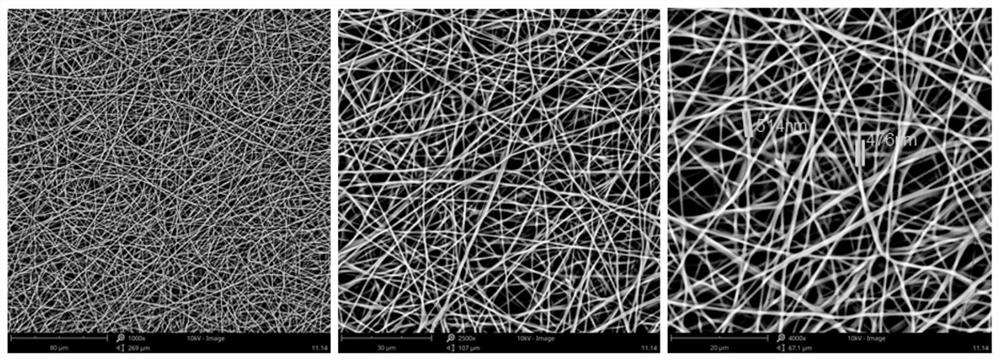

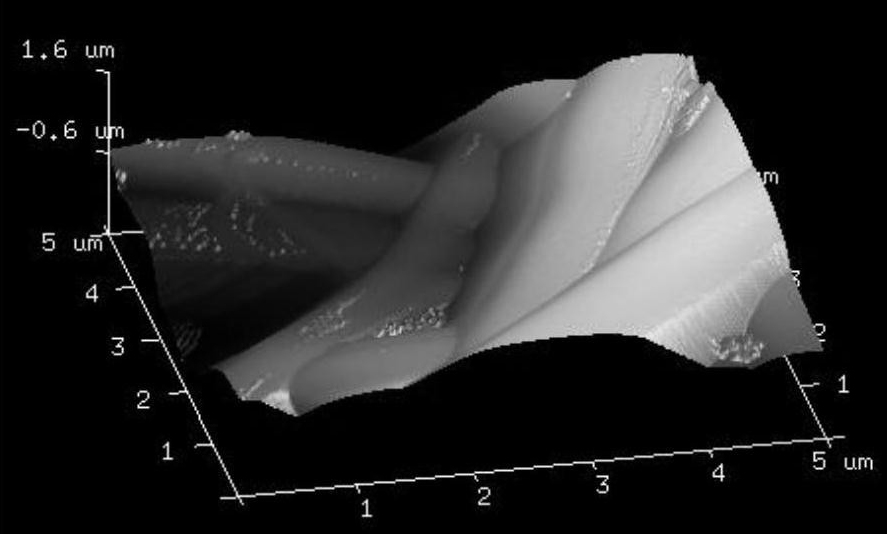

Preparation method of green and environment-friendly waterborne polyurethane nanofibers

ActiveCN112921414AGood fibrillationAvoid harmMonocomponent polyurethanes artificial filamentElectro-spinningFiberPolymer science

The invention discloses a preparation method of green and environment-friendly waterborne polyurethane nanofibers. The preparation method includes the following steps: mixing 50-80 parts of polypropylene oxide glycol, 10-30 parts of isophorone diisocyanate and 1-8 parts of a front chain extender; adding 0.5-1 part of a catalyst, heating to 80-90 DEG C, and reacting for 4-6 hours; then adding 3-10 parts of acetone, cooling to 50-70 DEG C, and adding 2-12 parts of triethylamine to react for 10-20 minutes to obtain a polyurethane prepolymer; dispersing the polyurethane prepolymer in water added with a post-chain extender at high speed to obtain a waterborne polyurethane spinning solution with the solid content of 15-30%; and using the waterborne polyurethane spinning solution as a raw material, and carrying out electrostatic spinning to prepare the waterborne polyurethane nanofibers. The prepared waterborne polyurethane spinning solution can be independently applied to an electrostatic spinning technology to prepare the nanofibers, and has good fiber forming property, the diameter range is 100-1500 nm, the defect that the nanofibers can be prepared from the waterborne polyurethane only by means of other spinnable high polymers is overcome, water serves as a solvent, damage of organic solvents to human bodies and the environment is avoided, and the preparation method is green and environmentally friendly.

Owner:QILU UNIV OF TECH

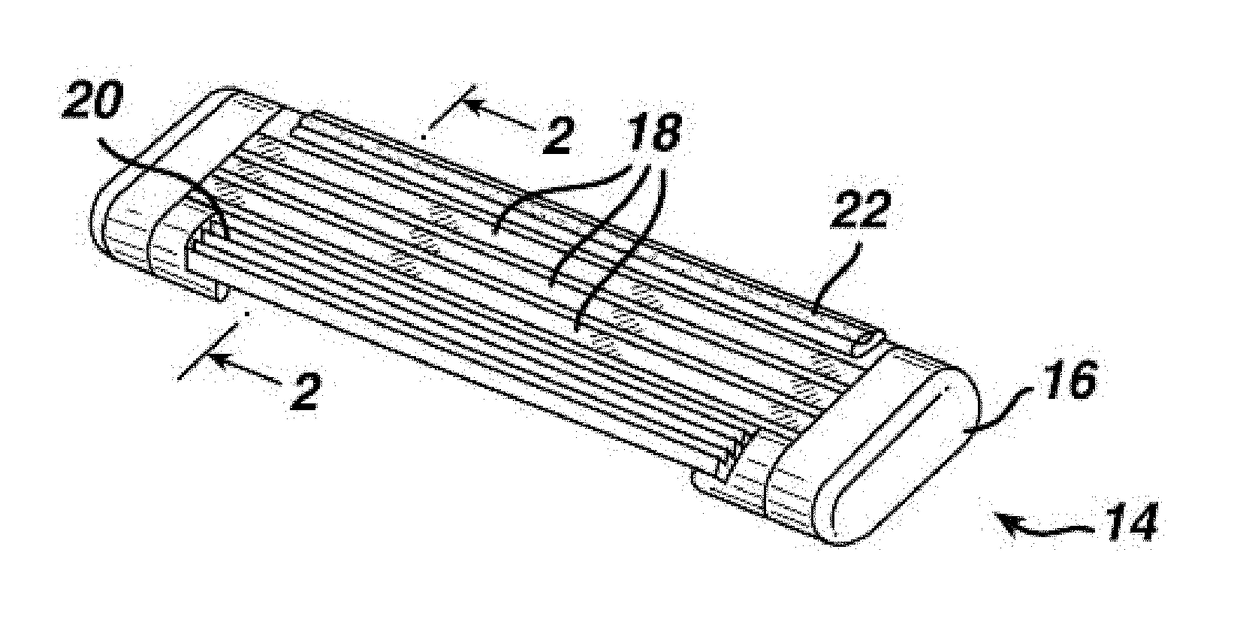

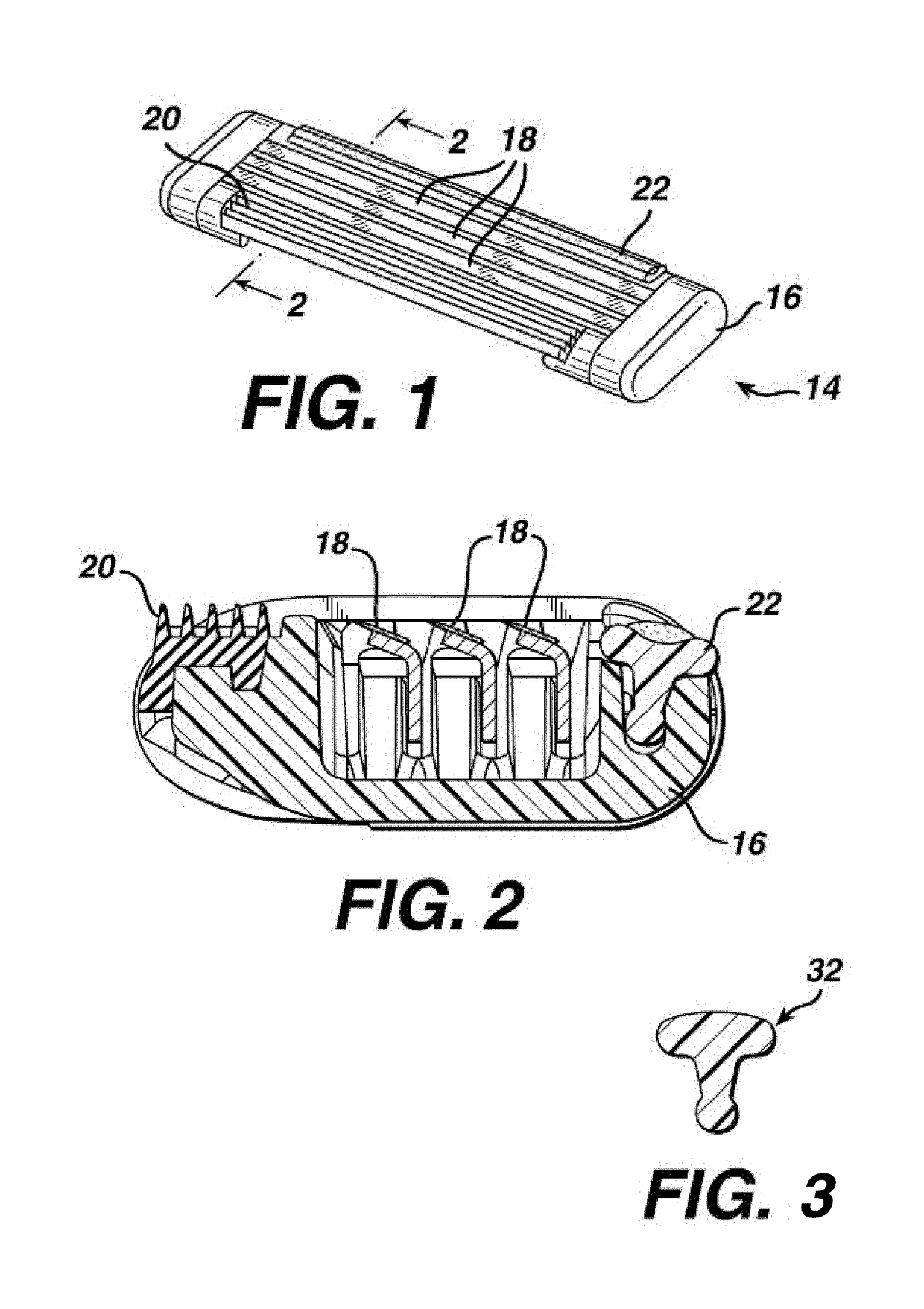

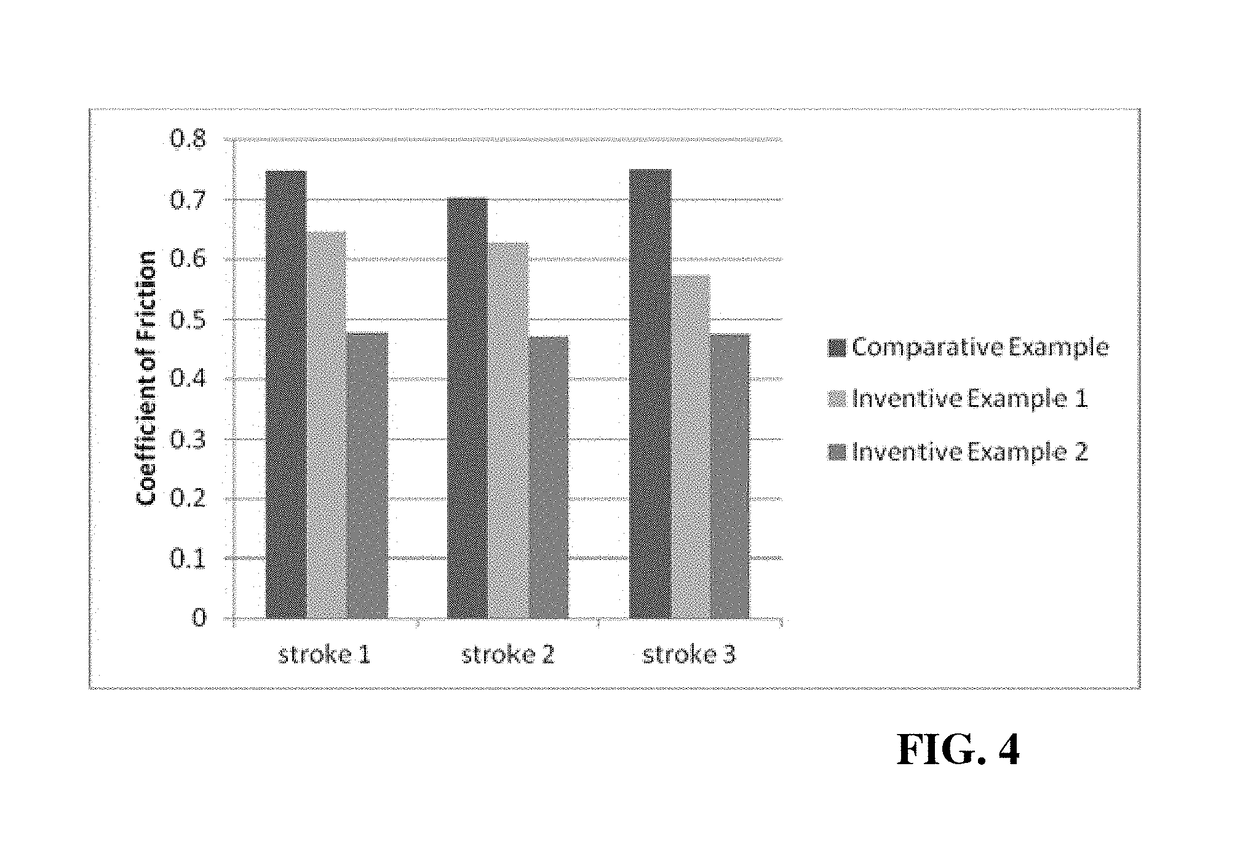

Lubricating shaving aid member

A shaving aid member comprising a lubricating material, the lubricating material comprising a water soluble polymer having an average molecular weight of at least 5,000, and a copolymer of polyethylene oxide and polypropylene oxide.

Owner:THE GILLETTE CO

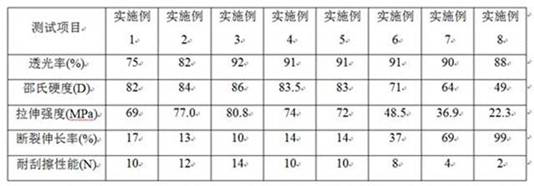

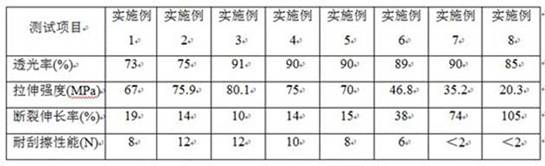

Ultrahigh-hardness transparent two-component aliphatic polyurethane coating and preparation method thereof

ActiveCN114149733AGood UV aging resistanceImprove scratch resistancePolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to an ultrahigh-hardness transparent two-component aliphatic polyurethane coating and a preparation method thereof, the ultrahigh-hardness transparent two-component aliphatic polyurethane coating comprises a polyol component and an isocyanate prepolymer, the polyol component comprises the following raw materials by weight: 20-55% of polyester polyol and / or polyether polyol, 40-55% of a first chain extender, 0.2-2% of an organic metal catalyst, and 0.5-3% of an anti-ultraviolet aging agent; 1-4% of an anti-hydrolysis agent; the polyester polyol is one or more of adipic acid polyesters with the hydroxyl value of 100 to 180 mgKOH / g; the polyether polyol is one or more of polypropylene oxide polyether polyol with the hydroxyl value of 100 to 180 mgKOH / g; the isocyanate prepolymer is formed by prepolymerizing a second chain extender and aliphatic isocyanate, and the NCO content of the prepolymer is 15-35%. The coating is prepared from a polyol component and an isocyanate prepolymer through a transparent coating injection molding process, has excellent ultraviolet aging resistance, scratch resistance and light transmittance, and can be widely applied to the surfaces of decorative parts, household appliance shells, furniture parts and the like in the interior and the exterior of an automobile.

Owner:LIMING RES INST OF CHEM IND

Skin care cosmetic compositions and methods for microemulsification of sebum on contact

InactiveUS20050048025A1Deep deliveryEnhance (1) deep pore cleansing of skinCosmetic preparationsOrganic active ingredientsEmulsionAlcohol

A combination of a non-ionic tri-block poly-propylene-oxide, poly-ethylene-oxide alcohol ether surfactant coupled with block polymer poly(Butadiene-b-Ethylene Oxide) is an excellent surfactant phase to micro-emulsify sebum on contact. A method of micro-emulsification of sebum on contact with inventive compositions according to the present invention will form micro-emulsions which can enhance (1) deep pore cleansing of skin and (2) delivery of skin benefit actives into the skin.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

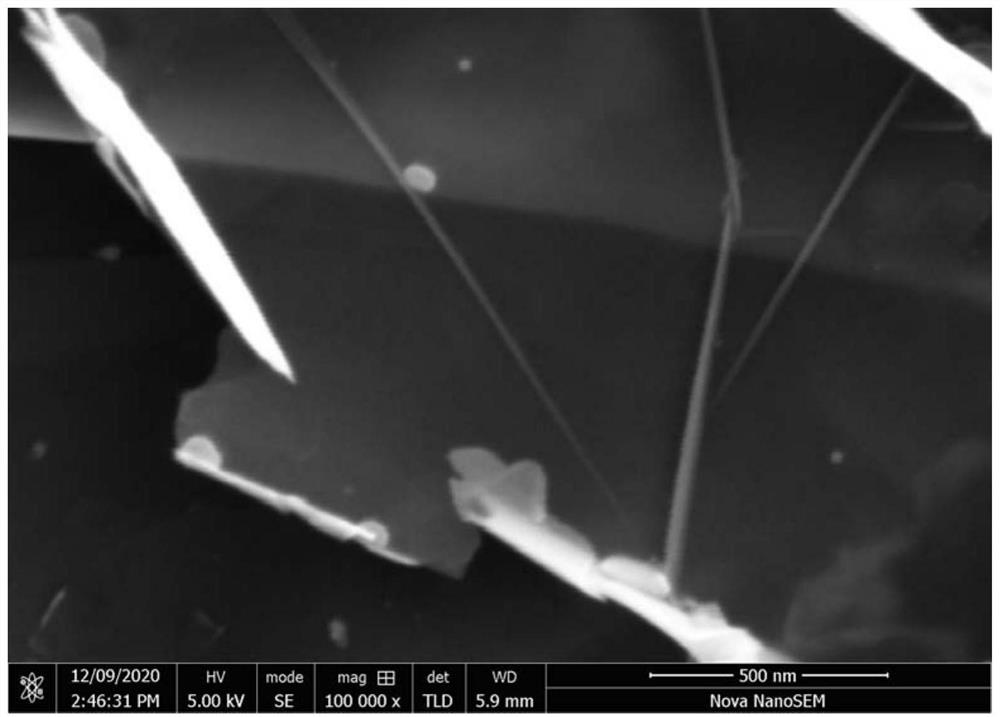

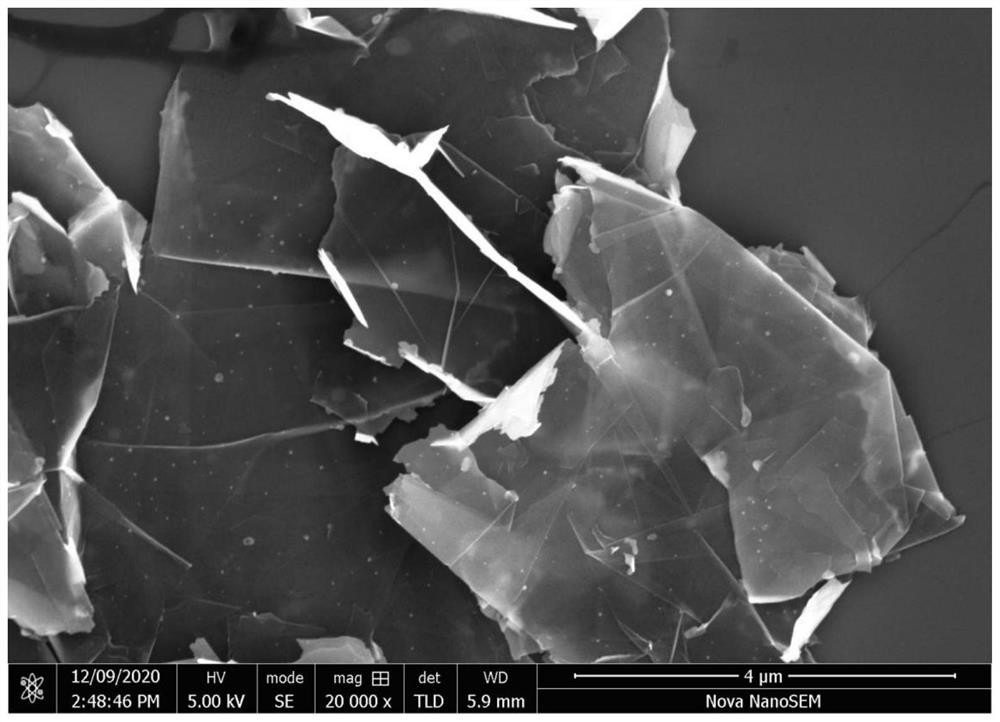

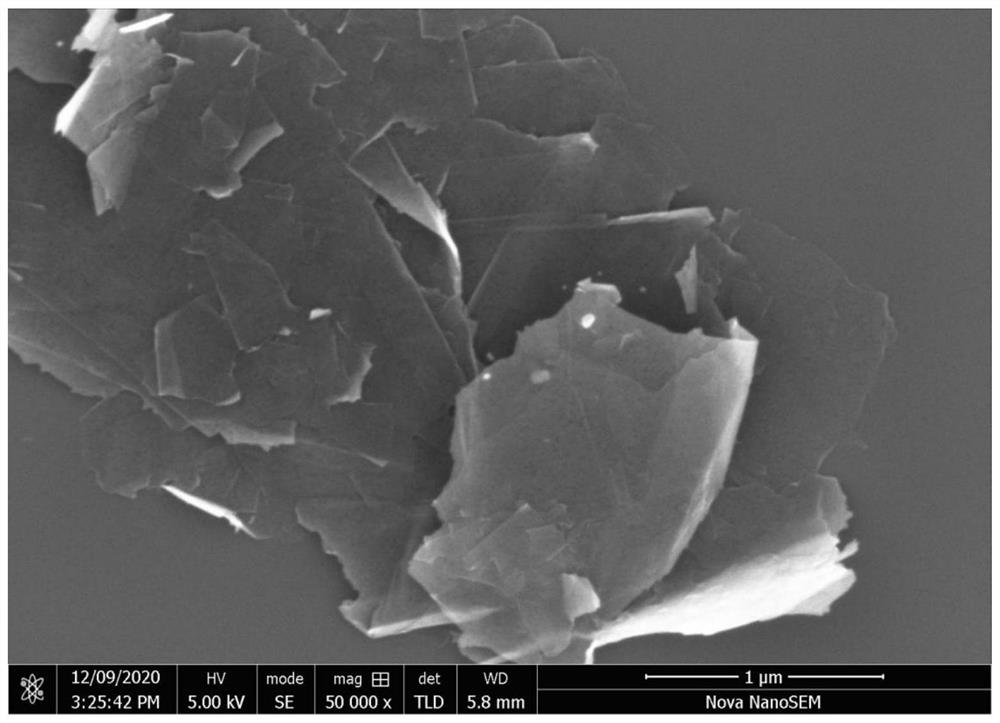

Preparation method and application of two-dimensional MXene/polydopamine composite desalination electrode material

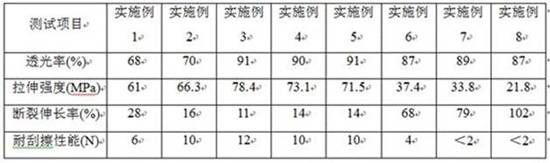

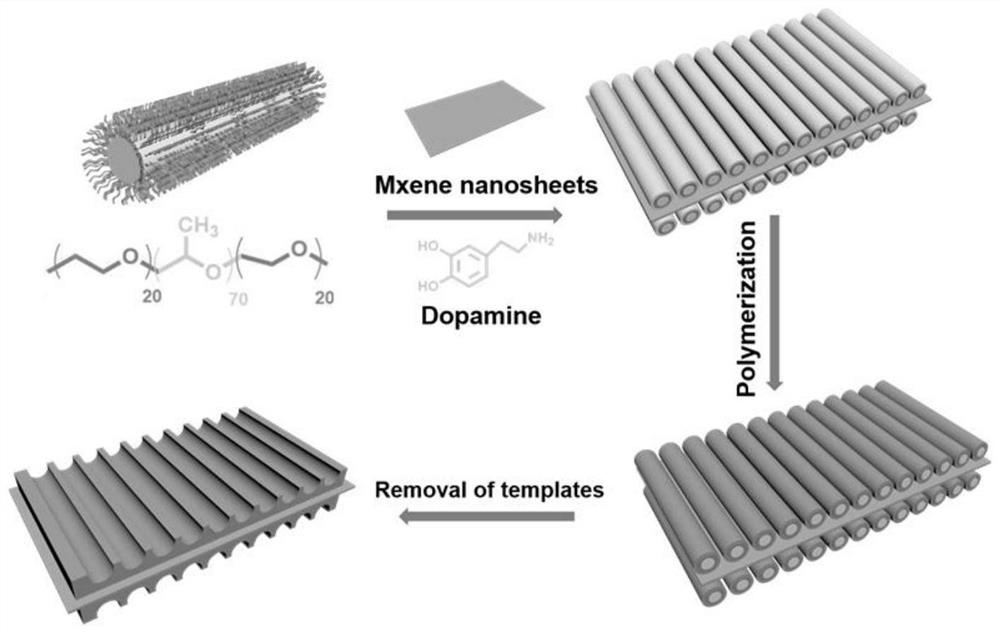

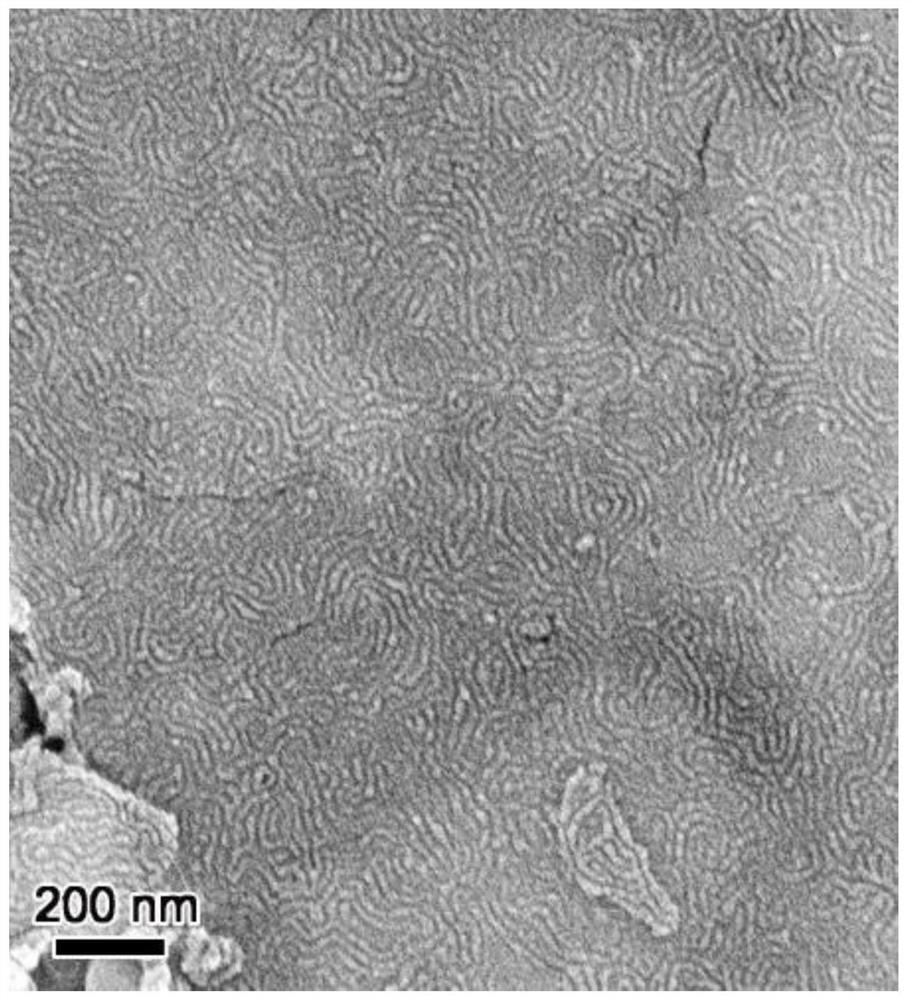

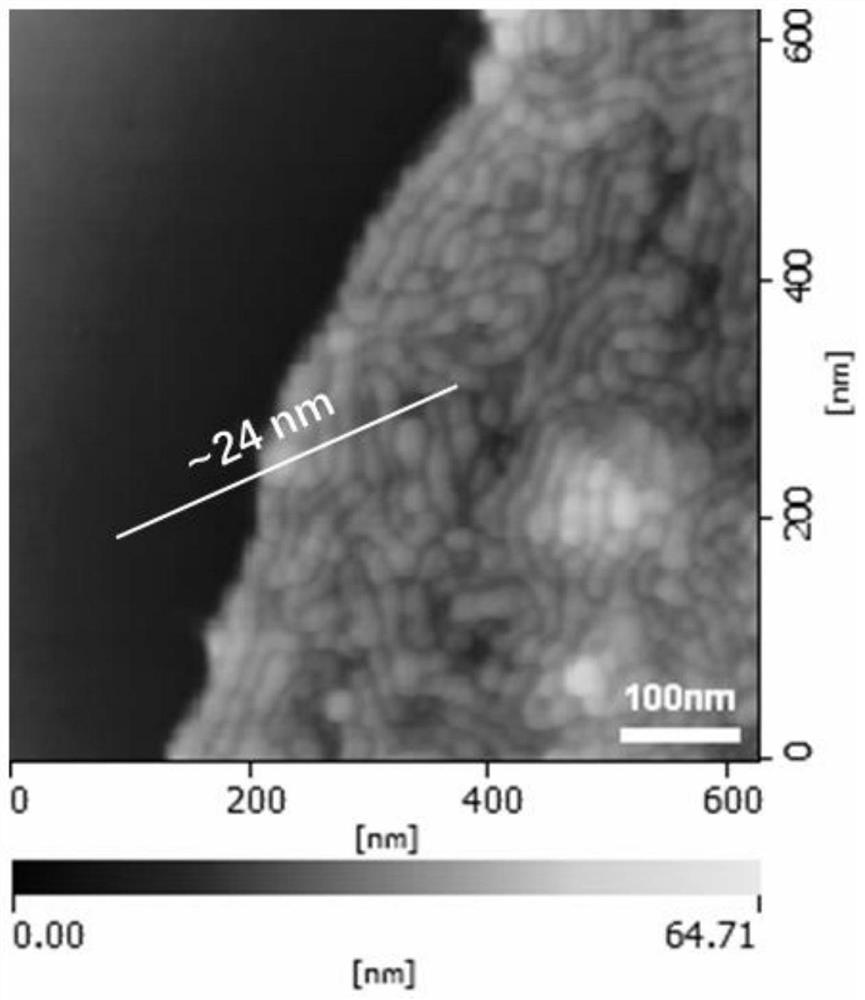

ActiveCN113881040AImproved low desalination capacityIncreased desalination capacityGeneral water supply conservationDispersed particle separationCapacitancePolyethylene oxide

The invention discloses a preparation method of a two-dimensional MXene / polydopamine composite desalination electrode material, wherein the preparation method is characterized by comprising the following steps: (1) self-assembly of a block polymer: firstly, carrying out self-assembly on a polyethylene oxide-block-polypropylene oxide-block-polyethylene oxide PEO20-b-PPO70-b-PEO20 triblock polymer in a solution to form columnar micelles, and taking the columnar micelles as a mesoporous soft template; and (2) preparing the columnar mesoporous MXene / polydopamine two-dimensional composite nanosheet (mPDA / MXene). The invention also provides an application of the two-dimensional MXene / polydopamine composite desalination electrode material in a CDI battery. According to the invention, P123 is used as a soft template, and mesoporous channels are introduced to two sides of MXene, so that the material has a larger internal active specific surface area and ion transmission channels, the electrochemical performance is expected to be improved, and the application prospect of capacitive deionization is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Purification of propylene oxide

InactiveUS6906209B2Increases filtration and sorption efficiencyImprove abilitiesOrganic chemistryActivated carbonSorbent

A process for purifying propylene oxide containing an unacceptable quantity of a poly (propylene oxide) polymer contaminant having a number average molecular weight of at least 50,000 and precursors having a number average molecular weight below 50,000. The process comprises contacting the propylene oxide with a sorbent selected from activated carbon, charcoal, and attapulgite for a time and under conditions sufficient to reduce the amount of the contaminant to acceptable levels, and thereafter recovering the purified propylene oxide product, wherein the propylene oxide is contacted with the sorbent at a temperature below 10° C.

Owner:HUNTSMAN INT LLC

Graphene water-based slurry and preparation method thereof

The invention provides a preparation method of graphene water-based slurry, which comprises the steps of placing an expanded graphite aqueous solution containing a dispersing agent in liquid phase stripping equipment, and carrying out liquid phase stripping on the expanded graphite to prepare the graphene water-based slurry, wherein the dispersing agent is a segmented copolymer of polyethylene oxide and polypropylene oxide, and in the segmented copolymer, the molar ratio of an ethylene oxide monomer unit to a polypropylene oxide monomer unit is 1: 9 to 4: 6. According to the preparation method of the graphene water-based slurry, the wettability of graphene and water can be effectively improved, efficient stripping of a graphene liquid phase is achieved, and the dispersity and conductivity of the slurry can be improved.

Owner:江苏杉元科技有限公司

Prothioconazole intelligent microcapsule suspending agent and preparation method thereof

The invention belongs to the technical field of bactericides. The invention relates to a prothioconazole intelligent microcapsule suspending agent and a preparation method thereof. The suspending agent comprises the following components in percentage by weight: 1-5% of polypropylene oxide, 1-3% of an emulsifier, 2-40% of prothioconazole, 2-8% of caprylic / capric triglyceride, 2-8% of isopropyl myristate, 1-5% of polyacrylic acid, 1-3% of a surfactant, 0.1-0.3% of xanthan gum, 3-5% of glycerin, 0.1-0.3% of Kathon, 0.5-2% of magnesium aluminum silicate, 1-2% of hydrochloric acid and the balance of water. The preparation method comprises the following steps: preparing an oil phase, preparing a water phase, emulsifying, adjusting a pH value, microencapsulating and preparing the suspending agent. The microcapsule suspending agent disclosed by the invention has self-assembly, self-repair and high pH sensitivity, and meanwhile, the lasting period can be prolonged by slow release, and the use frequency is reduced, so that the use amount of pesticides is reduced. The method is simple in process and capable of effectively achieving mass production, and therefore the method has a high application value.

Owner:利民化学有限责任公司

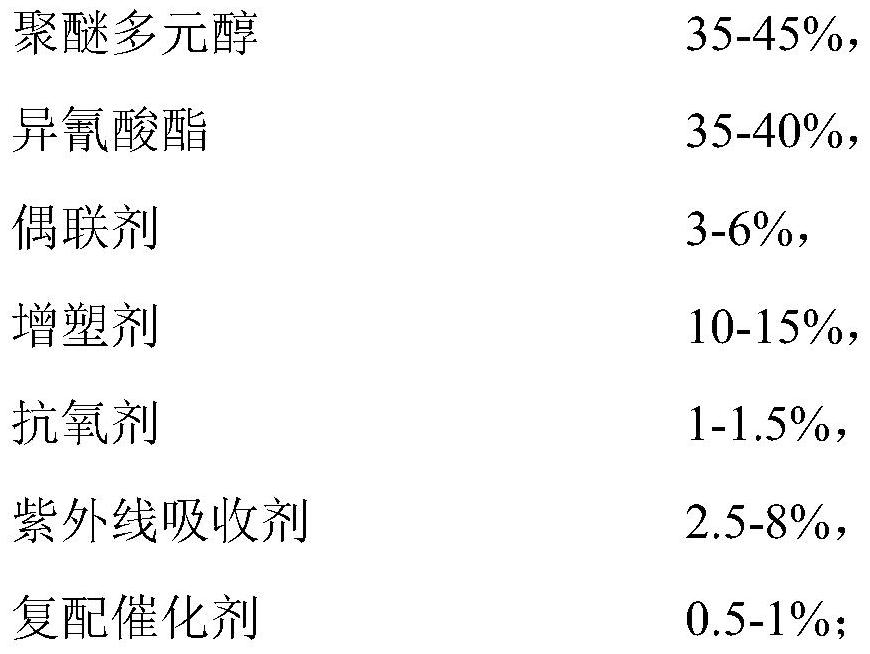

Low-temperature rapidly-vulcanized polyurethane high-temperature adhesive as well as preparation method and application thereof

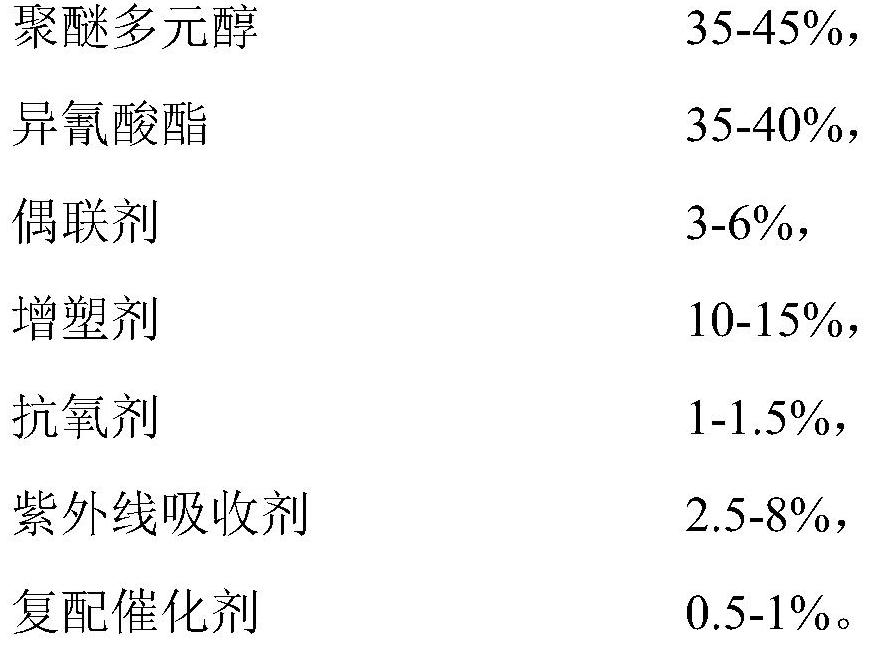

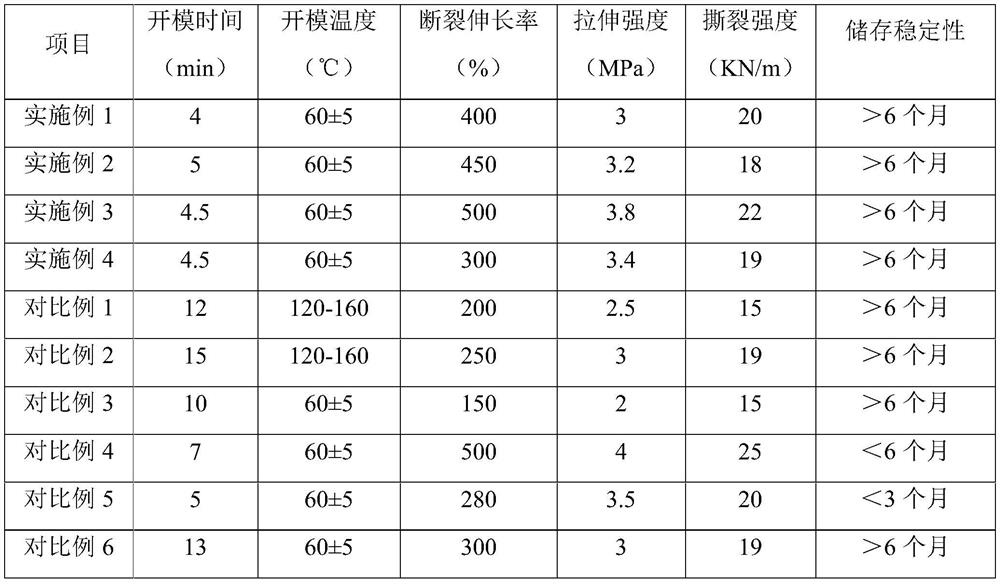

PendingCN113717680AHigh activityGuaranteed opening timePolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to the technical field of polyurethane adhesives, and in particular, relates to a low-temperature rapidly-vulcanized polyurethane high-temperature adhesive as well as a preparation method and application thereof. The low-temperature rapidly-vulcanized polyurethane high-temperature adhesive comprises the following raw materials in percentage by mass: 35-45% of polyether polyol, 35-40% of isocyanate, 3-6% of a coupling agent, 10-15% of a plasticizer, 1-1.5% of an antioxidant, 2.5-8% of an ultraviolet light absorber and 0.5-1% of a compound catalyst; and the polyether polyol is a mixture of polyethylene oxide polyol and polypropylene oxide polyol, and the compound catalyst is a compound of an organic tin catalyst and an amine catalyst. The low-temperature rapidly-vulcanized polyurethane high-temperature adhesive has the advantages of energy conservation and consumption reduction in the process of preparing a rubber floor mat, no harm to the environment and human bodies, and excellent mechanical properties.

Owner:SHANDONG INOV POLYURETHANE

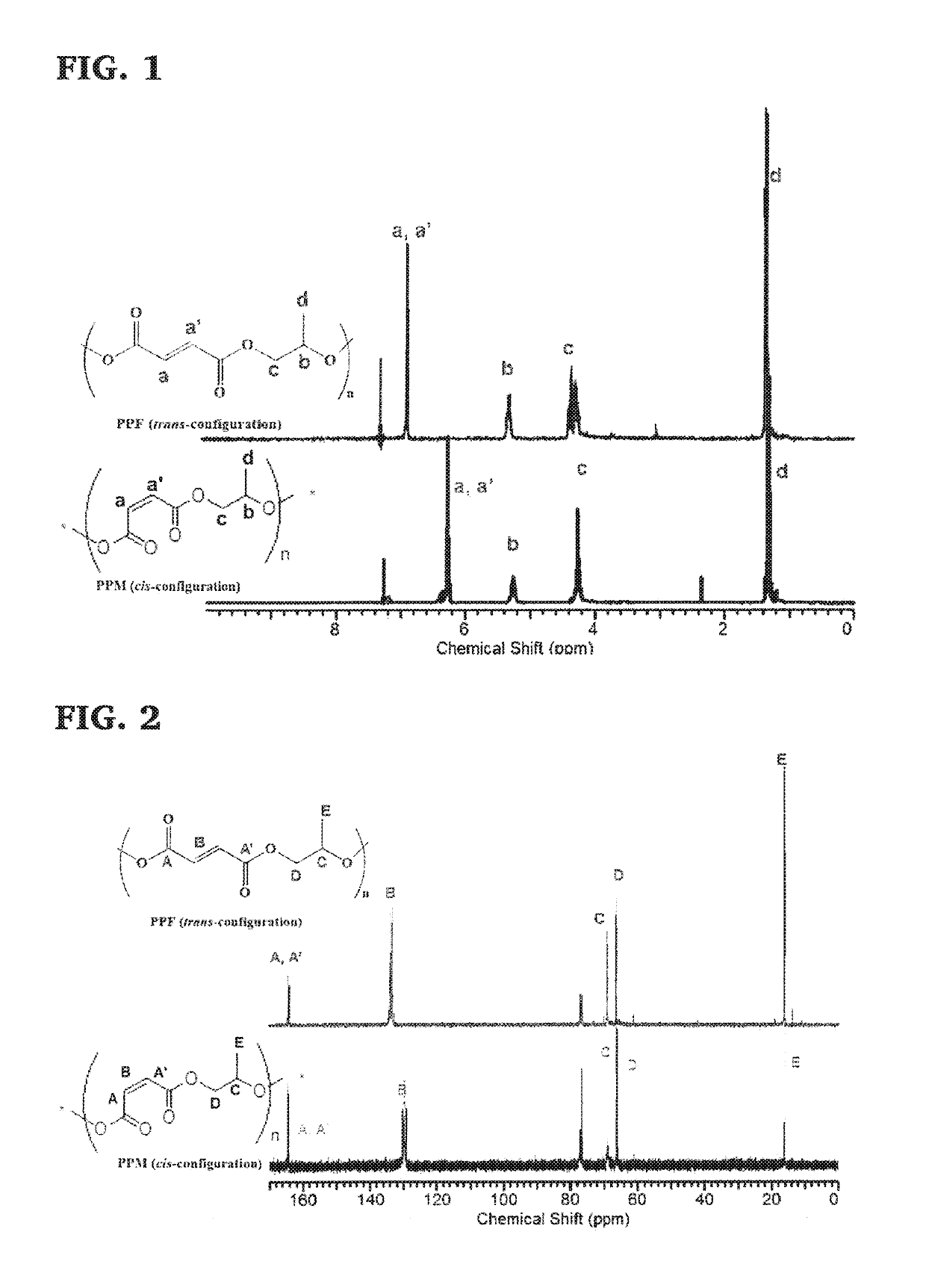

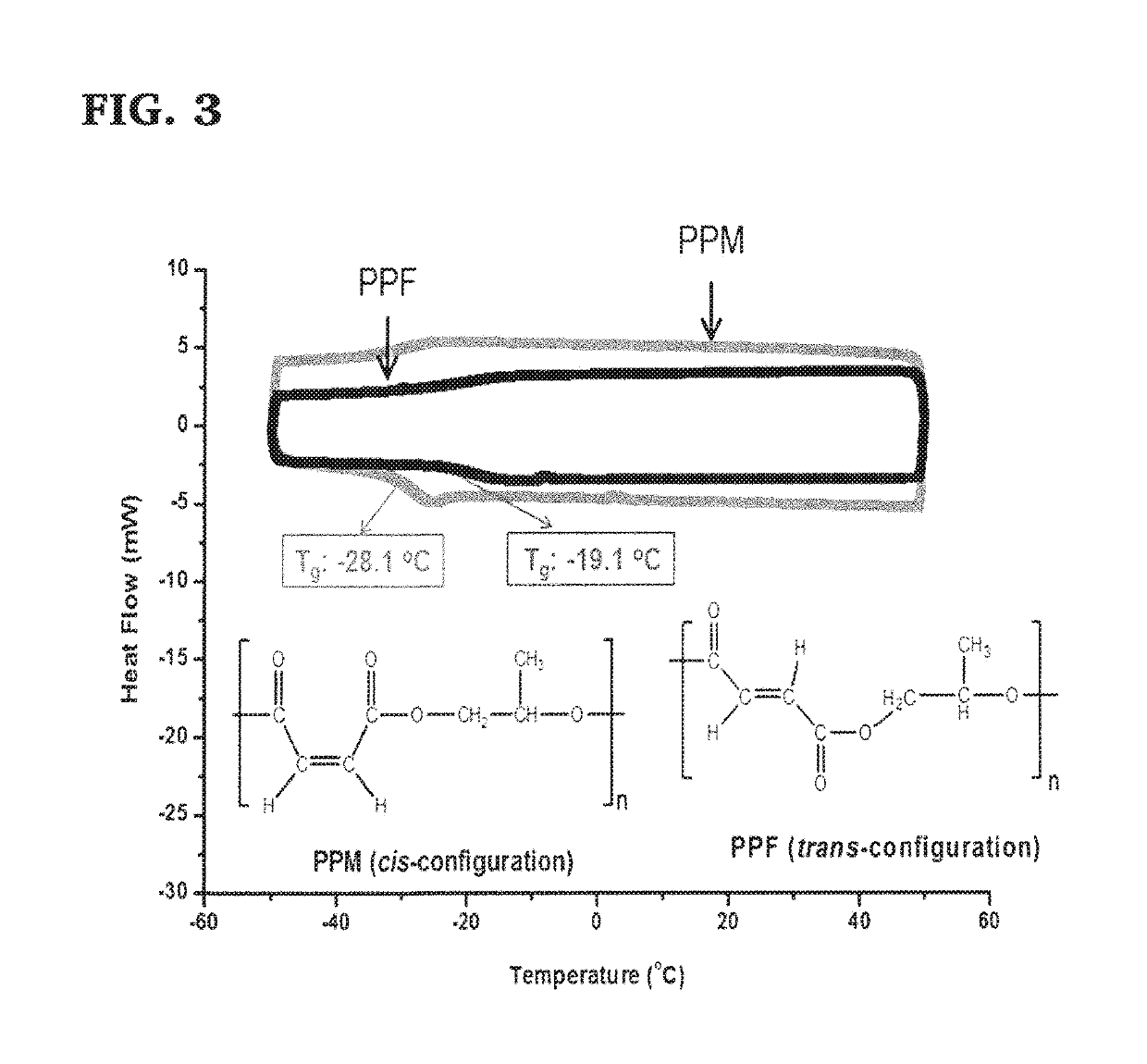

Well-defined degradable poly(propylene fumarate) polymers and scalable methods for the synthesis thereof

ActiveUS10465044B2Constrained and predictable material propertyCheap to makeAdditive manufacturing apparatusProsthesisSynthesis methodsOxygen

Method for making poly(propylene fumarate) (PPF) polymer made by ring-opening polymerization of propylene oxide and maleic anhydride in the presence of magnesium ethoxide initiator, wherein PPF is specifically designed for us in 3D manufacturing of medical devices. PPF polymers have a number average molecular weight (Mn) of from about 450 Daltons to about 3400 Daltons; a molecular mass distribution (m) of from 1.0 to 2.0; and contains less than 1% w / w of poly(maleic anhydride-co-propylene oxide) polymer chains particularly. PPF polymers are non-toxic, degradable, and resorbable and can be used in tissue scaffolds and medical devices that are implanted within a living organism.

Owner:THE UNIVERSITY OF AKRON +1

Elastic surface co-extruded wood-plastic profile and preparation method thereof

ActiveCN110682636AImprove wear resistanceGuaranteed wear resistanceSynthetic resin layered productsRubber layered productsPolyolHigh density

The invention discloses an elastic surface co-extruded wood-plastic profile which comprises a core material layer, an elastic inner layer and an elastic surface layer, wherein the elastic inner layercomprises the following raw materials in parts by weight: 20-30 parts of natural rubber, 15-20 parts of polypropylene oxide polyols, 15-20 parts of high density polyethylene, 20-25 parts of poplar powder, 3-8 parts of a coupling agent, 2-5 parts of a compatibilizer, 3-5 parts of a plasticizer and 5-8 parts of calcium carbonate; the elastic surface layer comprises the following raw materials in parts by weight: 20-30 parts of high density polyethylene, 20-25 parts of poplar powder, 10-15 parts of an elastic material, 3-6 parts of a compatibilizer, 3-5 parts of a coupling agent, 2-3 parts of anantioxidant, 1-2parts of an ultraviolet-resistant agent and 2-4 parts of calcium carbonate. Designing of a double elastic layer of the co-extruded wood-plastic profile ensures that the co-extruded wood-plastic profile has high resilience, wear resistance and oxidation resistance, and the service life is significantly prolonged.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com