High-elasticity silane-terminated polypropylene oxide sealant and preparation method thereof

A polypropylene oxide and silane-capped technology, which is applied in the direction of adhesives, polyether adhesives, polymer adhesive additives, etc., can solve the problems of unsatisfactory sealing, anti-vibration, general sealant elasticity, etc., and achieve the preparation process Simple and environmentally friendly, with high bonding strength and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Corresponding to the above formula system, a preparation method of a highly elastic silane-terminated polypropylene oxide sealant comprises the following steps:

[0045] (1) Mix silane-terminated polypropylene oxide polymer, diluent, calcium carbonate, carbon black, thixotropic agent, light stabilizer, and antioxidant at 80-120°C and 0.085-0.095MPa vacuum, And maintain the above mixing conditions for 2~6 hours;

[0046] (2) After reducing the temperature of the mixture obtained in the previous step to below 50°C, add the dehydrating agent, adhesion promoter, and catalyst, and mix evenly under a gas protection atmosphere;

[0047] (3) Discharge, sealed and packaged according to specifications.

[0048] Preferably, the protective atmosphere is one of nitrogen, helium, neon, argon, krypton, and carbon dioxide, more preferably, nitrogen.

[0049] The present invention will be further described below in conjunction with specific implementation examples:

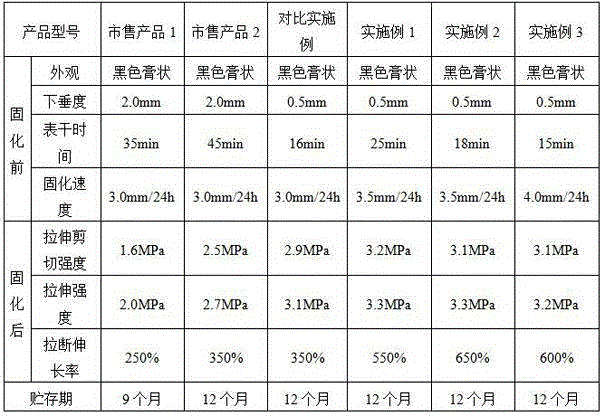

Embodiment 1

[0051] (1) 100 parts by mass of dimethoxysilyl-terminated polypropylene oxide with a viscosity of 13 Pa·s (atmospheric pressure and a temperature of 25°C, the same below), 40 parts by mass of poly(propylene oxide) with a molecular weight of 3000 Polyoxypropylene glycol, 70 parts by mass of light calcium carbonate, 70 parts by mass of heavy calcium carbonate, 10 parts by mass of carbon black, 5 parts by mass of PAMIDD680, 1 part by mass of 2-(2-hydroxyl-3,5-dibutyl-tert-phenylbenzene base)-5-chlorobenzotriazole, 1 mass part 2,6-di-tert-butyl-4-methyl phenol Mix evenly at 120°C and 0.085MPa vacuum, and maintain the above mixing conditions for 2 hours;

[0052] (2) After reducing the temperature of the mixture obtained in the previous step to below 50°C, add 4 parts by mass of vinyltrimethoxysilane, 2 parts by mass of N-(β-aminoethyl)-γ-aminopropyltrimethoxy The reaction product of base silane, 1 mass part of γ-aminopropyltrimethoxysilane, 1 mass part of tetraethyl orthosilicat...

Embodiment 2

[0055] (1) 100 parts by mass of diethoxysilyl-terminated polypropylene oxide with a viscosity of 18 Pa·s, 60 parts by mass of polyoxypropylene glycol with a molecular weight of 3000, 50 parts by mass of light calcium carbonate, 50 parts by mass Parts by mass of heavy calcium carbonate, 40 parts by mass of carbon black, 8 parts by mass of CrayvallacSL, 2 parts by mass of 2-(2-hydroxyl-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole, 1.5 parts by mass Bis(3,5-di-tert-butyl-4-hydroxyphenyl)sulfide was mixed uniformly at 80°C and 0.095MPa vacuum, and the above mixing conditions were maintained for 6 hours;

[0056] (2) After reducing the temperature of the mixture obtained in the previous step to below 50°C, add 1 mass part of vinyltriethoxysilane, 2 mass parts of γ-(2,3-epoxypropoxy)propyltrimethoxy Base silane, 3 parts by mass of γ-aminopropyltrimethoxysilane, and 3 parts by mass of dibutyltin dilaurate are uniformly mixed under an inert gas nitrogen protective atmosphere;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com