Graphene water-based slurry and preparation method thereof

A graphene water-based slurry technology, which is applied in the field of graphene water-based slurry and its preparation, can solve problems such as poor performance, many layers, and many bubbles, achieve efficient peeling, improve dispersibility and conductivity, and increase wetting sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

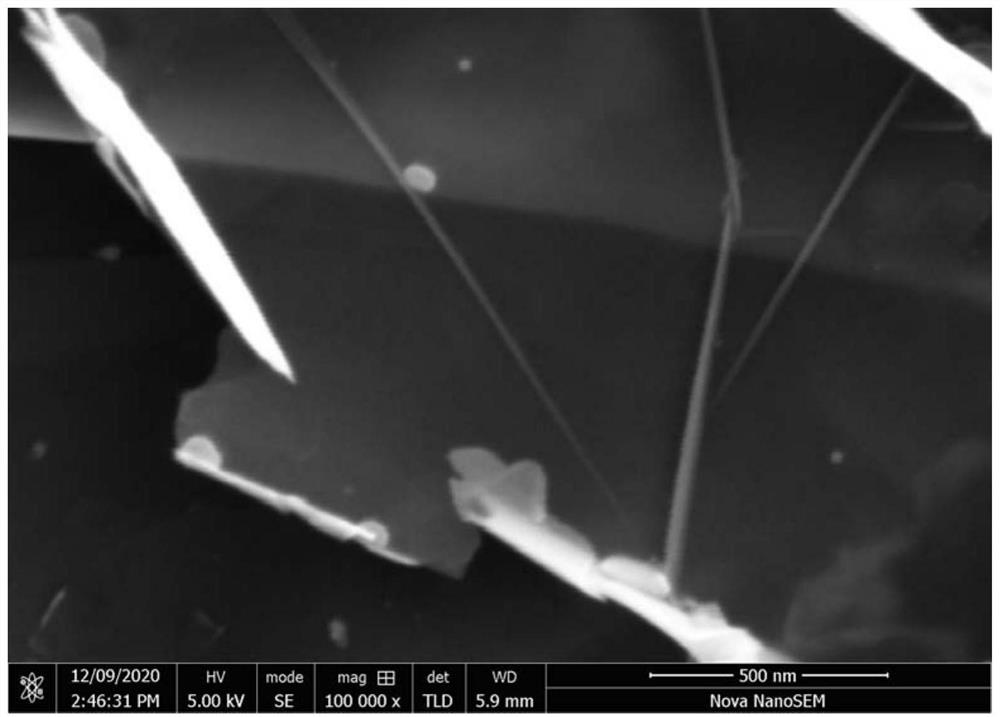

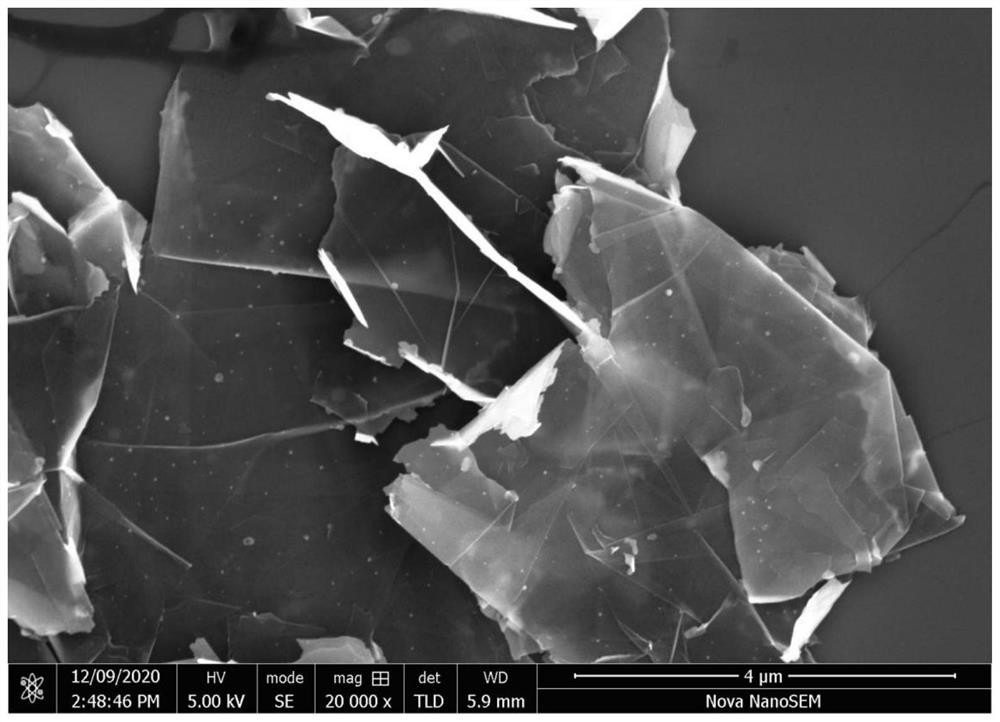

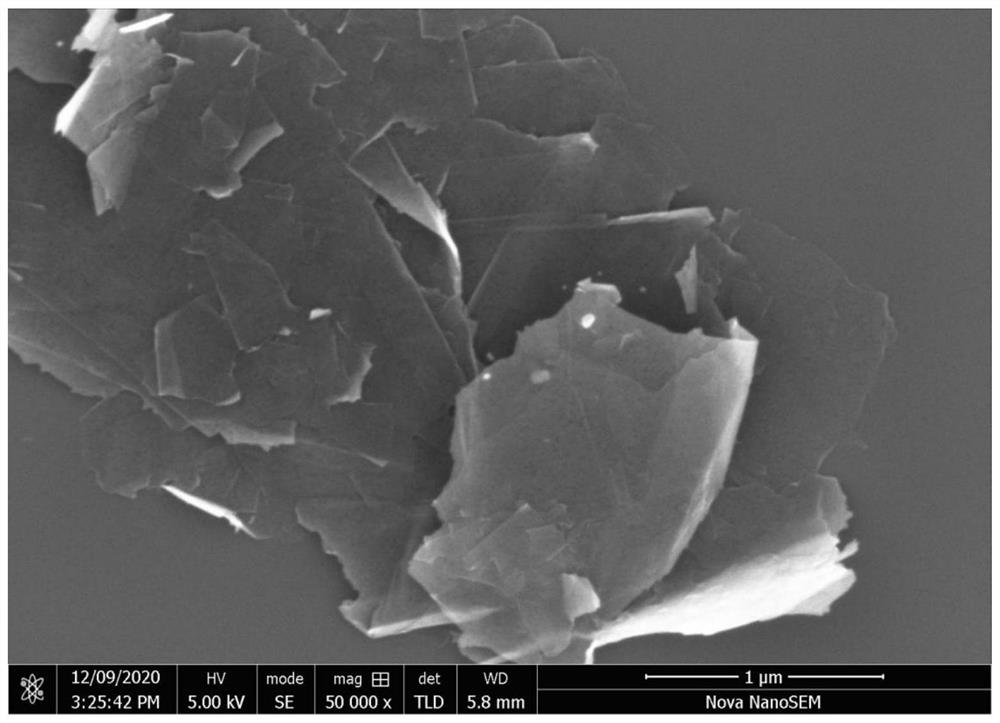

Image

Examples

preparation example Construction

[0023] The graphene aqueous slurry preparation method of the specific embodiment of the present invention, comprises the following steps:

[0024] The expanded graphite aqueous solution with a dispersant is placed in a liquid phase exfoliation device, and the expanded graphite is subjected to liquid phase exfoliation to prepare the graphene aqueous slurry;

[0025] Wherein, the dispersant is a block copolymer of polyethylene oxide and polypropylene oxide, and in the block copolymer, the molar ratio of the ethylene oxide monomer unit to the propylene oxide monomer unit is 1 :9~4:6.

[0026] The graphene water-based slurry preparation method of the specific embodiment of the present invention, in some specific embodiments, the expansion ratio of the expanded graphite is 200 to 600 times, specifically for example, it can be 200 times and its mesh number is 20 to 20 times. Between 400 mesh.

[0027] The graphene aqueous slurry preparation method of the specific embodiment of the...

Embodiment 1

[0054] Mix expanded graphite powder (5wt%, expansion ratio 400 times, mesh number 200 mesh), dispersant L62 (1.25wt%), water (93.75wt%), pre-disperse the above mixed material, so that each group Fully mixed, the expanded graphite is fully wetted in water under the action of wetting agent;

[0055] The above-mentioned mixed material is peeled off through a microchannel device, the pressure is controlled at 500 bar, and the number of peeling passes is 1 to prepare a graphene aqueous slurry.

[0056] Test the pole sheet resistivity test, viscosity, 1-month surface solid content change rate of the graphene aqueous slurry, and observe its bubble situation, the results are listed in Table 1.

Embodiment 2、3、4

[0058] Compared with Example 1, the number of peeling passes was changed from 1 to 2, 3, and 4 respectively, and the others remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com