Ultrahigh-hardness transparent two-component aliphatic polyurethane coating and preparation method thereof

An aliphatic polyurethane, two-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of UV aging resistance, difficulty in meeting the requirements, poor scratch resistance, etc., and achieve excellent The effect of UV aging resistance, good scratch resistance and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

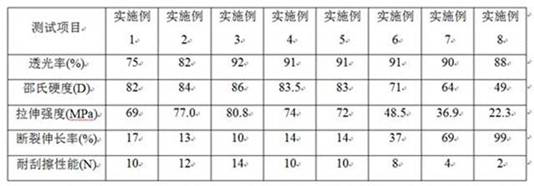

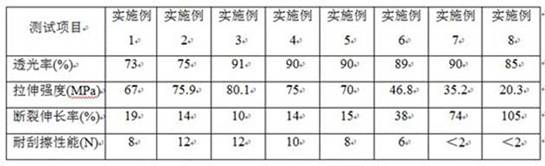

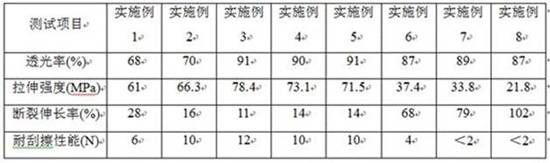

Examples

Embodiment 1

[0021] Preparation of polyol components: In a 5 L open plastic bucket, weigh 1000 g XCP-700 (polyester polyol, hydroxyl value 167 mg KOH / g), 400 g NPG, 400 g BDO, 9 g T-9, 18 g of UV-1130 and 18 g of stabilizer 9000 were stirred at 70 °C for 30 min to obtain the polyol component, ready to use.

[0022] Preparation of isocyanate prepolymer: weigh 250 g MPG and 1000 g IPDI in a 5 L three-neck glass flask, and react at 90°C for 4 h to obtain isocyanate prepolymer, which is ready for use.

Embodiment 2

[0024] Preparation of polyol components: In a 5 L open plastic bucket, weigh 1000 g XCP-700 (polyester polyol, hydroxyl value 167 mgKOH / g), 400 g BDO, 400 g TMP, 9 g T-9, 18 g UV-1130, 18 g stabilizer 9000, and stirred at 70°C for 30 min to obtain the polyol component, which is ready for use.

[0025] Preparation of isocyanate prepolymer: In a 5 L three-neck glass flask, weigh 250 g MPG, 500 g IPDI, and 500 g THDI, and react at 90 °C for 4 h to obtain isocyanate prepolymer, which is ready for use.

Embodiment 3

[0027] Preparation of polyol components: In a 5 L open plastic bucket, weigh 500 g XCP-700 (polyester polyol, hydroxyl value 167 mgKOH / g), 500 g DL-1000 (polyether polyol, hydroxyl value 112 mgKOH / g) g), 400 g CHDM, 400 g TMP, 9 g T-9, 18 g UV-1130, 18 g stabilizer 9000, and stirred at 70 °C for 30 min to obtain the polyol component, which is ready for use.

[0028] Preparation of isocyanate prepolymer: weigh 300 g NPG and 1000 g IPDI in a 5 L three-neck glass flask, and react at 90°C for 4 h to obtain isocyanate prepolymer, which is ready for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com