Preparation method of green and environment-friendly waterborne polyurethane nanofibers

A water-based polyurethane and nanofiber technology, applied in the direction of single-component polyurethane rayon, fiber processing, filament/thread forming, etc., to avoid harm to the human body and the environment, and to achieve good fiber formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of water-based polyurethane spinning solution: Mix 70 parts of polypropylene oxide diol, 25 parts of isophorone diisocyanate and 5 parts of 2,2-dimethylolpropionic acid chain extender into a three-necked flask Then add 0.5 parts of organic bismuth catalyst to the three-necked flask, raise the temperature to 80-90°C, continue to react for 4-6 hours, add 5 parts of acetone for dilution, cool down to 70°C, continue stirring and add 8 parts of triethylamine to react 12 A polyurethane prepolymer was obtained after 10 minutes, and the polyurethane prepolymer was dispersed at a high speed in water with 7 parts of sulfonate chain extenders, the dispersion speed was 1000r / min, and the dispersion continued for 25 minutes to obtain a water-based polyurethane with a solid content of 25%. Spinning liquid, remove acetone under negative pressure;

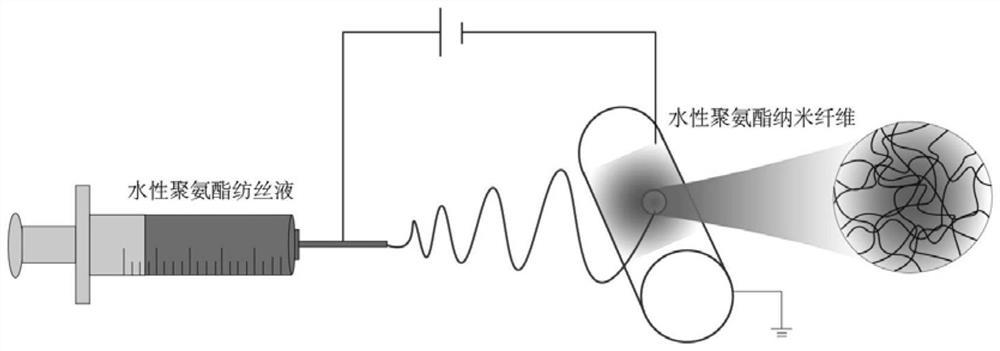

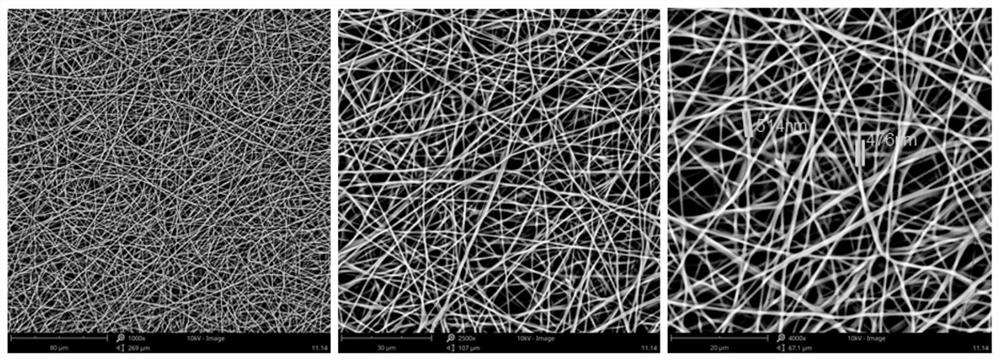

[0040] (2) Preparation of water-based polyurethane nanofibers: put the water-based polyurethane spinning solution prepared...

Embodiment 2

[0043] (1) Preparation of water-based polyurethane spinning solution: Mix 60 parts of polypropylene oxide diol, 28 parts of isophorone diisocyanate and 4 parts of 2,2-dimethylolpropionic acid chain extender into a three-necked flask Then add 0.8 parts of organic bismuth catalyst to the three-necked flask, heat up to 80-90°C, react for 4-6 hours, then add 6 parts of acetone for dilution, cool down to 65°C, continue stirring and add 10 parts of triethylamine to react for 10 minutes The polyurethane prepolymer is obtained afterward, and the polyurethane prepolymer is dispersed in water with 9 parts of sulfonate chain extenders at a high speed, the dispersion speed is 1200r / min, and the dispersion is continued for 30 minutes to obtain a water-based polyurethane textile with a solid content of 30%. Silk liquid, remove acetone under negative pressure;

[0044](2) Preparation of water-based polyurethane nanofibers: put the water-based polyurethane spinning solution prepared in step (...

Embodiment 3

[0046] (1) Preparation of water-based polyurethane spinning solution: Mix 75 parts of polypropylene oxide diol, 22 parts of isophorone diisocyanate and 3 parts of chain extender into a three-necked flask, and then add 1.0 part catalyst, heat up to 80-90°C, cool down for 4-6 hours, add 6 parts of acetone to dilute, continue to stir and add 8 parts of triethylamine to react for 14 minutes to obtain a polyurethane prepolymer. After adding 10 parts of polyurethane prepolymer Carry out high-speed dispersion in water of the chain extender, the dispersion speed is 800r / min, and disperse for 20 minutes to obtain a water-based polyurethane spinning solution with a solid content of 30%, and remove acetone under negative pressure;

[0047] (2) Preparation of water-based polyurethane nanofibers: put the water-based polyurethane spinning solution prepared in step (1) into a 10 mL needle-free medical syringe, install a metal flat needle and connect it to a positive high voltage. The receive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com