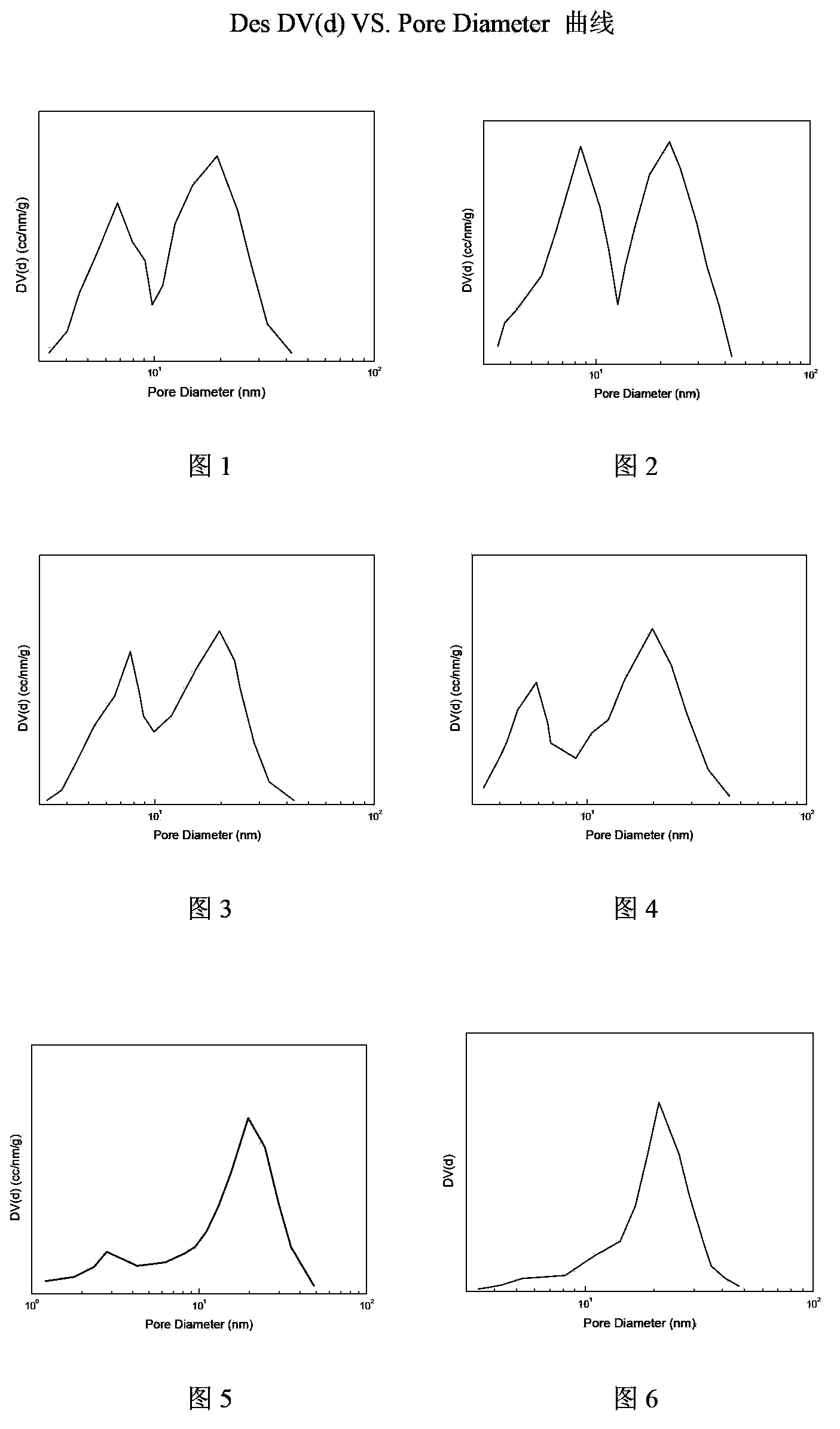

Method for preparing silica gel carrier with dual-mode pore size distribution

A technology of pore size distribution and silica gel, which is applied in the field of preparation of silica gel carriers with dual-mode pore size distribution, which can solve the problems of narrow difference in dual-mode pore size distribution, poor fluidity and disadvantages of supported catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

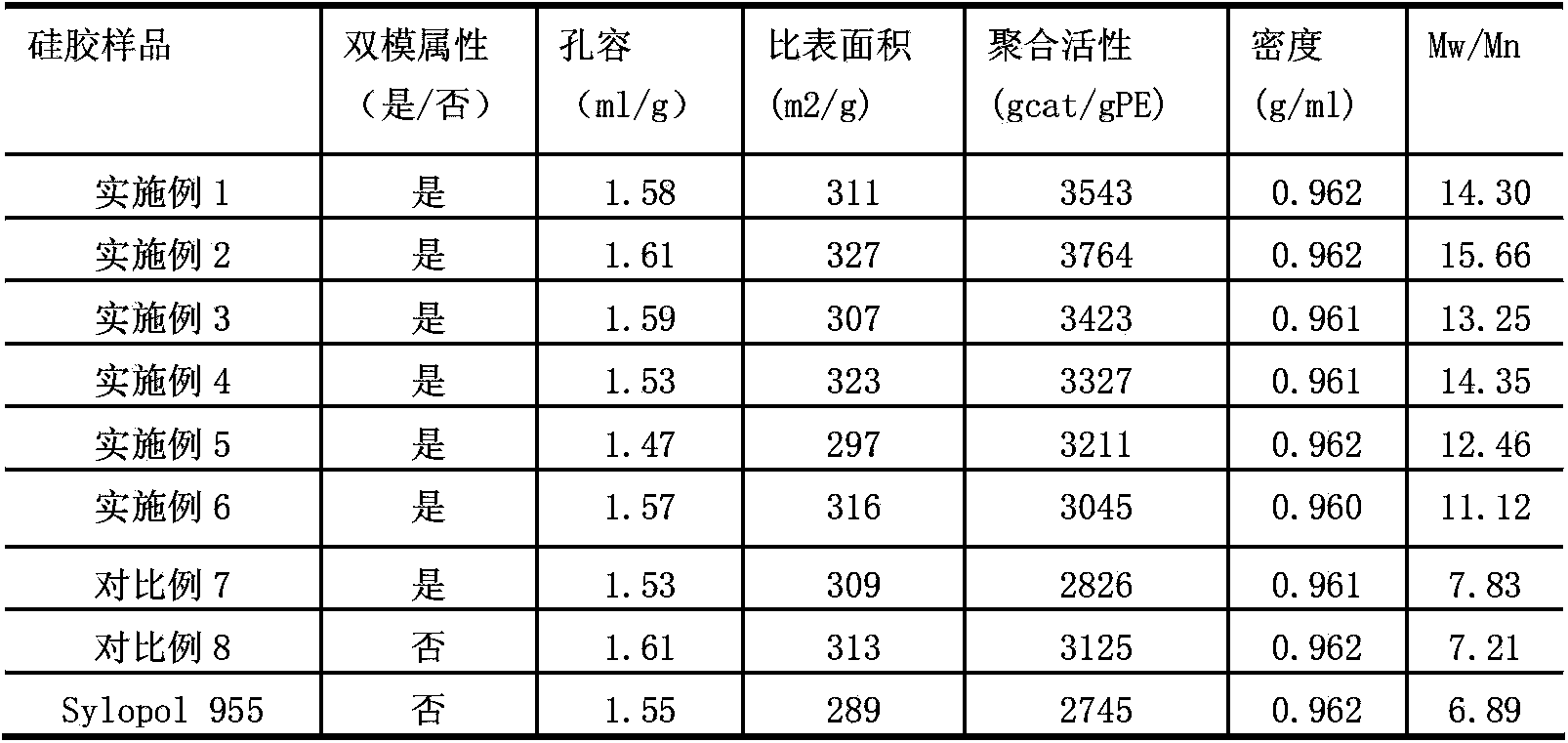

Embodiment 1

[0028] At 50°C, add 5% sulfuric acid solution dropwise to the sodium silicate solution containing 20% silicon dioxide until the pH is 9-9.5 to form a silicon dioxide sol, continue stirring for 1 hour, and the sol hardens into silicon dioxide Gel, then raise the temperature to 90°C and age for 5 hours. After aging, lower the temperature to room temperature, add 5% sulfuric acid solution dropwise until the pH is 0.5-1, let it stand for 1 hour, then add ethanol and polyethylene glycol (Aladdin's reagent) with a commercially available average molecular weight of 4000, and stir Fully dissolve PEG, the ratio of ethanol to water is 1:5, the amount of PEG added is 12% of the total solution, and 20% sodium silicate solution of silicon dioxide is added dropwise at 35°C until the pH rises to 3.5 to obtain the second stage Gel, raise the temperature to 80° C., and age for 6 hours to obtain a dual-mode silica gel slurry. After washing with deionized water for 3 times in a plate and fram...

Embodiment 2

[0030] At 40°C, add 8% sulfuric acid solution dropwise to the sodium silicate solution with 15% silicon dioxide until the pH is 8.5-9 to form a silicon dioxide sol, continue to stir for 0.5 hours, and the sol hardens into silicon dioxide Gel, then raise the temperature to 70°C and age for 7 hours. After aging, lower the temperature to room temperature, add 8% sulfuric acid solution dropwise to pH 0.5-1, let it stand for 3 hours, then add 1-butanol and polyethylene glycol (Aladdin reagent) with an average molecular weight of 8000 in the market , Stir to fully dissolve PEG, the ratio of 1-butanol to water is 1:4, the amount of PEG added is 8% of the total solution, add 20% silicon dioxide sodium silicate solution dropwise at 35°C until the pH rises to 3.5 , to obtain the second-stage gel, raise the temperature to 90° C., and age for 6 hours to obtain a dual-mode silica gel slurry. After washing with deionized water for 4 times in a plate and frame filter press, dry it with a GL...

Embodiment 3

[0032] At 40°C, add 5% sulfuric acid solution dropwise to the sodium silicate solution containing 20% silica until the pH is 8.5-9 to form a silica sol, continue stirring for 0.5 hours, the sol hardens into silica Gel, then raise the temperature to 80°C and age for 7 hours. After aging, lower the temperature to room temperature, add 5% sulfuric acid solution dropwise to pH 0.5-1, let it stand for 3 hours, then add ethanol and commercially available polypropylene glycol (Aladdin reagent) with an average molecular weight of 3000, and stir to make PPG Fully dissolved, the ratio of ethanol to water is 1:10, the amount of PPG added is 10% of the total solution, and 20% sodium silicate solution of silicon dioxide is added dropwise at 50°C until the pH rises to 3, and the second stage condensation is obtained. gel, raise the temperature to 80° C., and age for 6 hours to obtain a dual-mode silica gel slurry. After washing with deionized water for 4 times in a plate and frame filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com