Synthesis device and method for xylylene diisocynate

A technology of xylylene diisocyanate and synthesis equipment, which is applied in chemical instruments and methods, preparation of isocyanic acid derivatives, preparation of organic compounds, etc., can solve the problem of inconspicuous by-product effects, poor product quality, Difficult to be widely used and other problems, to achieve the effect of increasing contact probability and residence time, high conversion rate of raw materials and product yield, and convenient industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

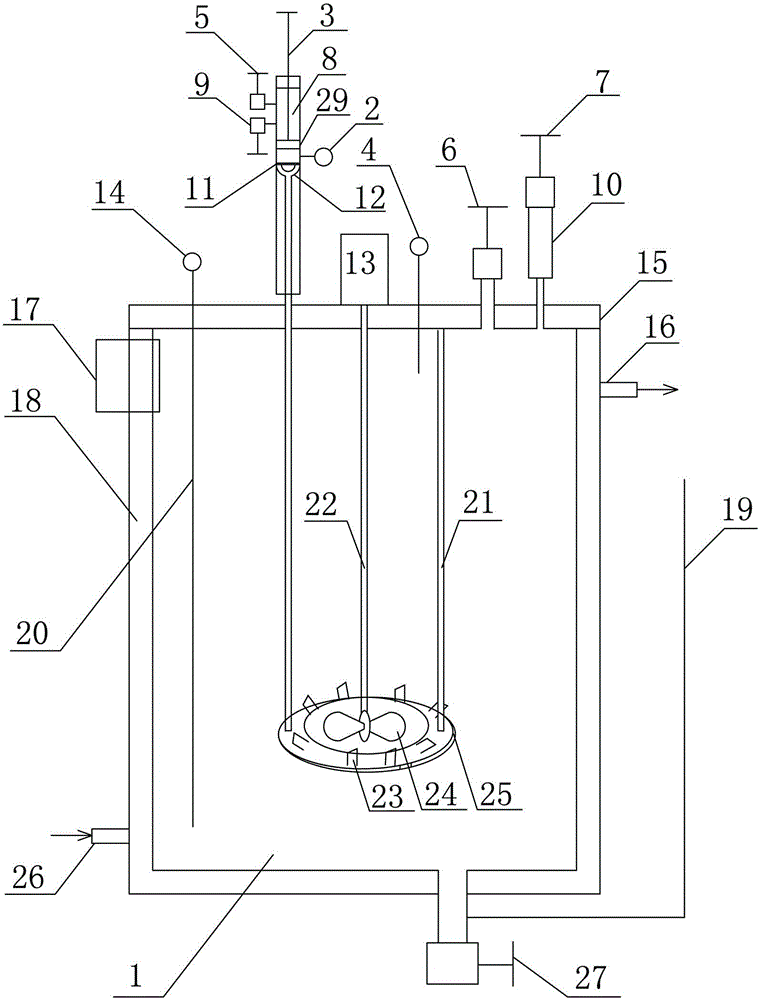

[0041] The embodiment of the present invention also provides a synthetic method of xylylene diisocyanate, comprising the following steps:

[0042] (1) Provide the synthesis device provided in the above examples, inject the reactant organic solution with a mass fraction of 3% to 8% into the inside of the reactor, and stir; wherein the reactant organic solution is m-phthalylene Amine hydrochloride organic solution, xylylenediamine carbonate organic solution or m-phenylenedicarbamoyl chloride organic solution. Wherein, the step (1) specifically includes: opening the feed inlet control valve 6, using a material pump to pump m-xylylenediamine hydrochloride or xylylenediamine carbonate or m-xylylenediamine hydrochloride or m-xylylenediamine carbonate with a mass fraction of 3-8% The organic solution of phenylenedicarbamoyl chloride is poured into the reaction kettle 1, and the agitator 13 is opened. The organic solution preferably includes a low-boiling aromatic organic solvent tha...

Embodiment 1

[0048] Embodiment 1 of the present invention provides a method for synthesizing xylylene diisocyanate. The method uses the above-mentioned synthesis device to synthesize xylylene diisocyanate by using a luminescent reaction method, and specifically includes the following steps:

[0049] Step 1. Open the feed inlet control valve 6, inject the chlorobenzene solution of m-xylylenediamine carbonate with a mass fraction of 5% into the reactor 1 with a material pump, and start stirring 13;

[0050] Step 2. Open the valve installed on the inlet 26 of the frozen brine heat transfer medium at -10 to 0°C and the valve installed on the outlet 16 of the frozen brine heat transfer medium in sequence, and cool the reaction kettle 1 through the heat conduction layer 18 , the temperature is controlled at 0-5°C;

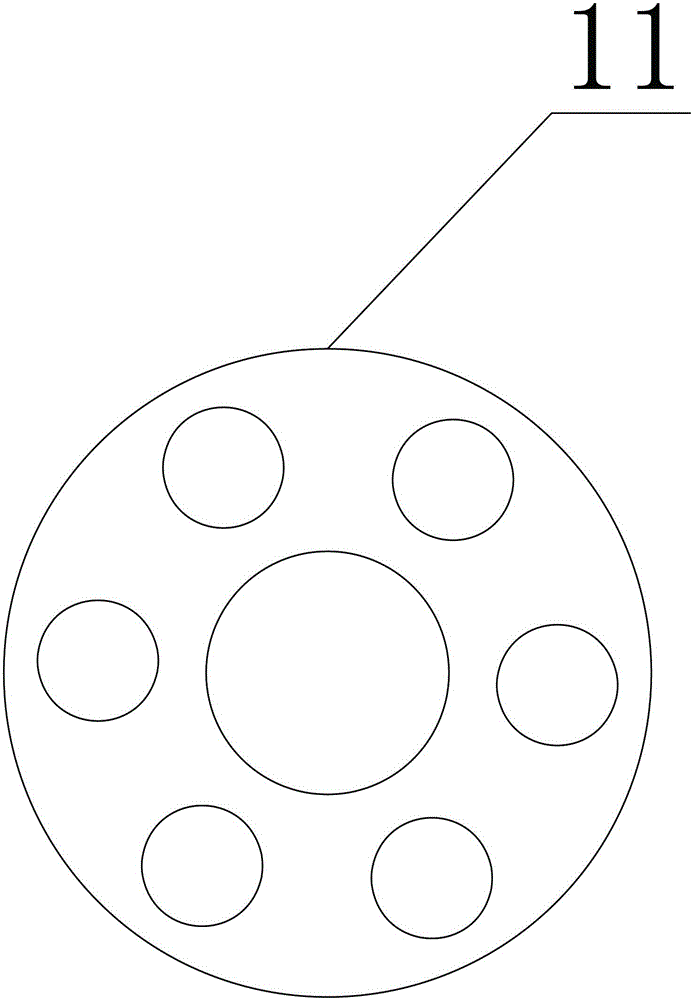

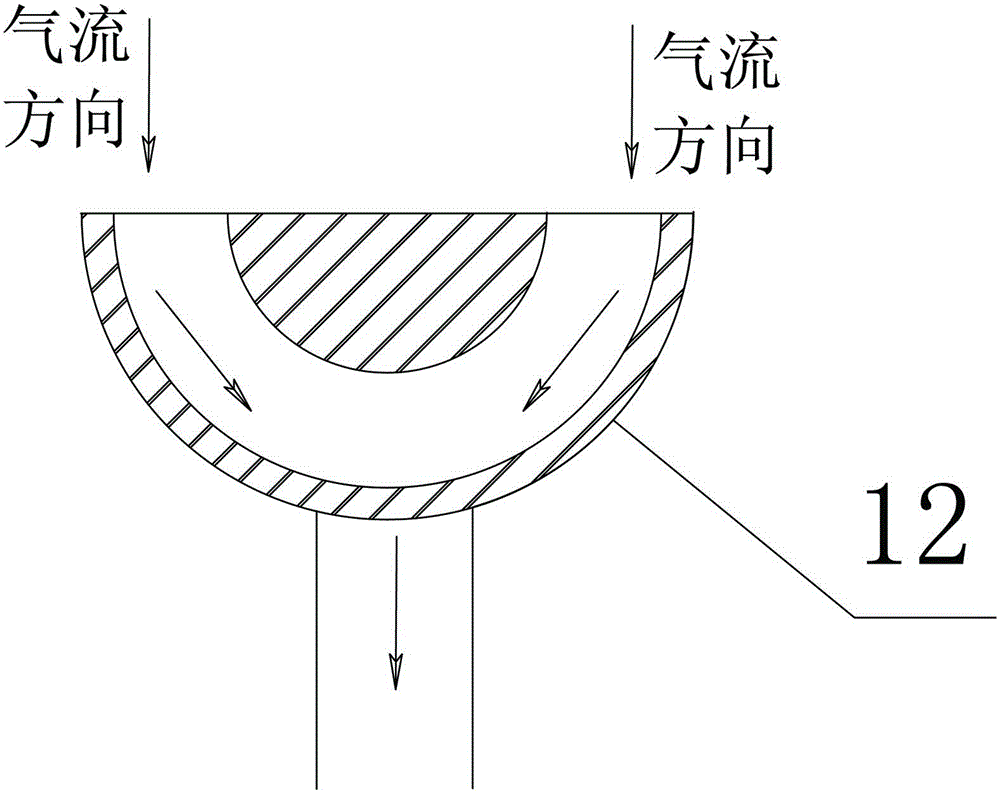

[0051] Step 3, adjusting the nitrogen inert gas inlet control valve 5, the phosgene regulating valve 9 and the piston rod 3, so that the gas pressure in the gas distributor 25 is sta...

Embodiment 2

[0054] The method for synthesizing xylylene diisocyanate provided in Example 2 of the present invention is basically the same as the synthetic method provided in Example 1, except that the material used in step 1 is m-phthalylene dimethanol with a mass fraction of 7%. The benzene solution of amine hydrochloride; the freezing medium that step 2 adopts is ammonium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com