Primer-topcoat combined anti-corrosion paint suitable for various base materials and preparation method thereof

An anti-corrosion paint and bottom surface technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of lack of adhesion, and achieve the effects of excellent adhesion, simple operation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The specific preparation method of the bottom-surface-integrated anticorrosion paint suitable for various substrates comprises the following steps:

[0045] (1) Add solvent into the container containing low-hydroxyl acrylic resin, stir at a speed of 800-1000r / min, so that the low-hydroxyl acrylic resin is evenly dispersed in the solvent;

[0046] (2) During the stirring process, add additives, organic bentonite and hydrophobic fumed silica, and stir for 10 to 15 minutes;

[0047] (3) Add pigments and fillers, increase the stirring speed to 1200-1500r / min, and place it in an environment lower than 50 degrees Celsius, and stir for 15-20 minutes;

[0048] (4) Use a sand mill to grind the stirred mixture obtained in step (3), and finally add a leveling agent and stir for 15 to 25 minutes at a speed of 800 to 1000 r / min;

[0049] (5) Add solvent, adjust viscosity to 90±5Ku / 30°C, filter out impurities, and obtain component A;

[0050](6) Mix the hexamethylene diisocyanate t...

Embodiment 1

[0055] A bottom-surface integrated anti-corrosion paint suitable for various substrates, which is composed of component A and component B in a ratio of 7:1 by weight, wherein:

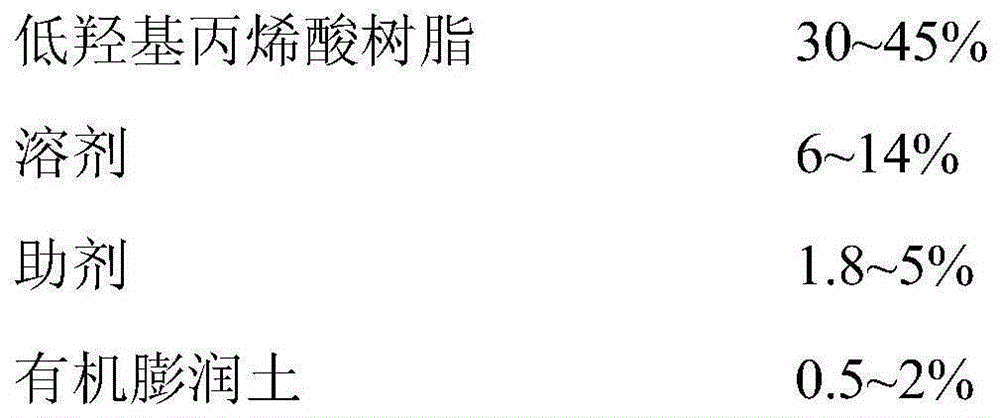

[0056] Part A contains the following ingredients, expressed in weight percentage

[0057]

[0058]

[0059] Part B contains the following ingredients, expressed in weight percentage

[0060] Hexamethylene diisocyanate trimer 49.20%

[0061] Solvent 50.80%.

Embodiment 2

[0063] A bottom-surface integrated anti-corrosion paint suitable for various substrates, which is composed of component A and component B in a ratio of 10:1 by weight, wherein:

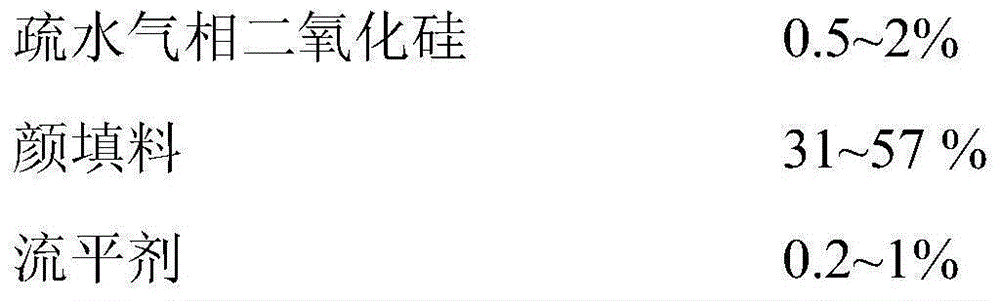

[0064] Part A contains the following ingredients, expressed in weight percentage

[0065]

[0066] Part B contains the following ingredients, expressed in weight percentage

[0067] Hexamethylene diisocyanate trimer 51.77%

[0068] Solvent 48.23%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com