B component isocyanate prepolymer and polyurethane double components for preparing microcellular polyurethane elastomer and application

A polyurethane elastomer and isocyanate prepolymerization technology is applied in the field of polyurethane materials to achieve good light resistance and thermal stability, high mechanical properties, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

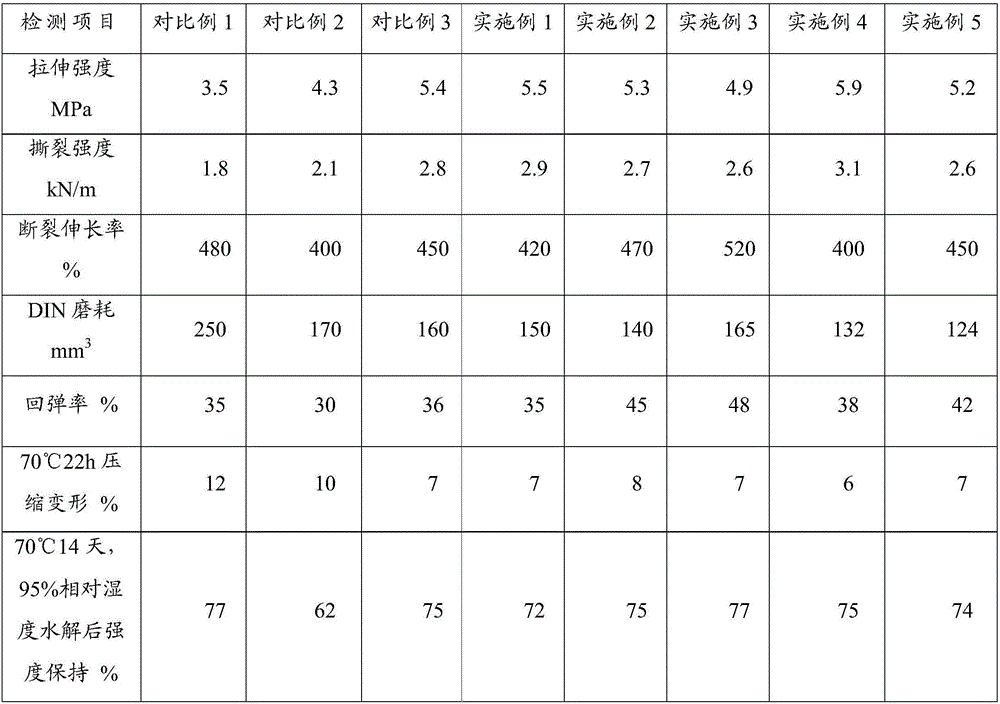

Examples

Embodiment 1

[0024] 1. Preparation of poly(ethylene glycol dimer acid) 1,4-butanediol 1,3-butanediol trimethylpentanediol ester polyol

[0025] A conventional batch method is used to produce polyethylene dimer acid glycol 1,4-butanediol 1,3-butanediol trimethylpentanediol polyol with a molecular weight of about 3000. The reactions in the preparation process can be divided into There are two stages of esterification reaction and transesterification reaction.

[0026] In the reactor, add dimer acid 3600g, ethylene glycol 300g, 1,4-butanediol 100g, 1,3-butanediol 50g and trimethylpentanediol 50g successively, described ethylene glycol, 1, The mass ratio of 4-butanediol, 1,3-butanediol and trimethylpentanediol is 1:0.33:0.17:0.17. Turn on the stirring and start to heat up. At the same time, nitrogen gas is introduced into the upper part of the reaction kettle to raise the temperature to 185~ Keep the temperature at 190°C for 2 hours to stabilize the dehydration rate (through the rectification...

Embodiment 2

[0034] 1. Preparation of component A polyol mixture

[0035] The raw materials needed to prepare the A-component polyol mixture include: 2000 g of polyethylene glycol dimer acid 1,4-butanediol 1,3-butanediol trimethylpentanediol ester polyol with a molecular weight of about 1500 1250g of polyethylene adipate glycol diethylene glycol trimethylpentanediol trimethylol propane ester polyol with a molecular weight of about 3200, polyethylene adipate glycol with a molecular weight of about 1000 Diethylene glycol 1,3-butanediol polyol 580g, plasticizer 400g, chain extender 450g (the mass ratio of ethylene glycol, diethylene glycol, triethanolamine is 1:0.2:0.3), catalyst 70g, Foaming agent 200g (mass ratio of deionized water and HCFC-141B is 1:3), foam stabilizer 50g; wherein, the polyethylene dimer glycol 1,4-butanediol 1,3-butanedi The mass percent of alcohol trimethylpentanediol ester polyol is 40%, and the mass percent of described polyethylene adipate glycol diethylene glycol t...

Embodiment 3

[0041] 1. Preparation of component A polyol mixture

[0042] The raw materials needed to prepare the A-component polyol mixture include: 750 g of polyethylene glycol dimer acid 1,4-butanediol 1,3-butanediol trimethylpentanediol ester polyol with a molecular weight of about 600 , polyethylene adipate glycol diethylene glycol trimethylpentanediol trimethylol propane ester polyol with a molecular weight of about 1200 3000g, polyethylene adipate glycol with a molecular weight of about 3200 Diethylene glycol 1,3-butanediol polyol 500g, plasticizer 140g, chain extender 400g (the mass ratio of ethylene glycol, diethylene glycol and triethanolamine is 1:0.23:0.1), catalyst 125g, hair Foaming agent 75g (mass ratio of deionized water and HCFC-141B is 1:4), foam stabilizer 10g; wherein, the polyethylene dimer glycol 1,4-butanediol 1,3-butanediol The mass percent of trimethylpentanediol ester polyol is 15%, and the mass percent of described polyethylene adipate glycol diethylene glycol t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com