Self-repairing polyurethane resin raw material, self-repairing polyurethane resin, self-repairing coating material, self-repairing elastomeric material, self-repairing polyurethane resin raw material production method and self-repairing polyurethane resin production method

A polyurethane resin, self-healing technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as indentation, pits, etc., which cannot be prevented from damage and become brittle, and achieve self-healing and chemical resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

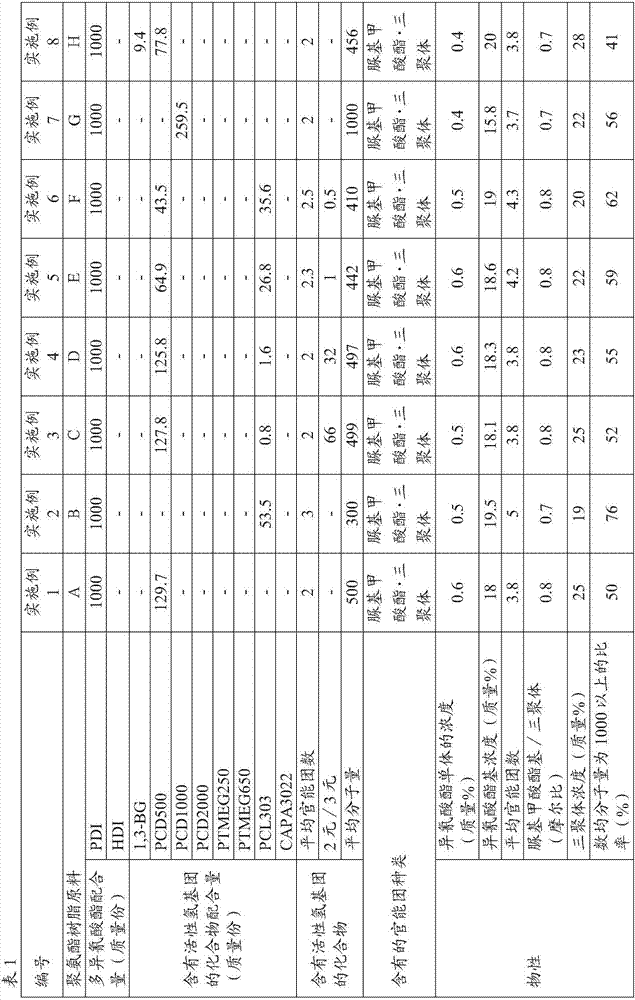

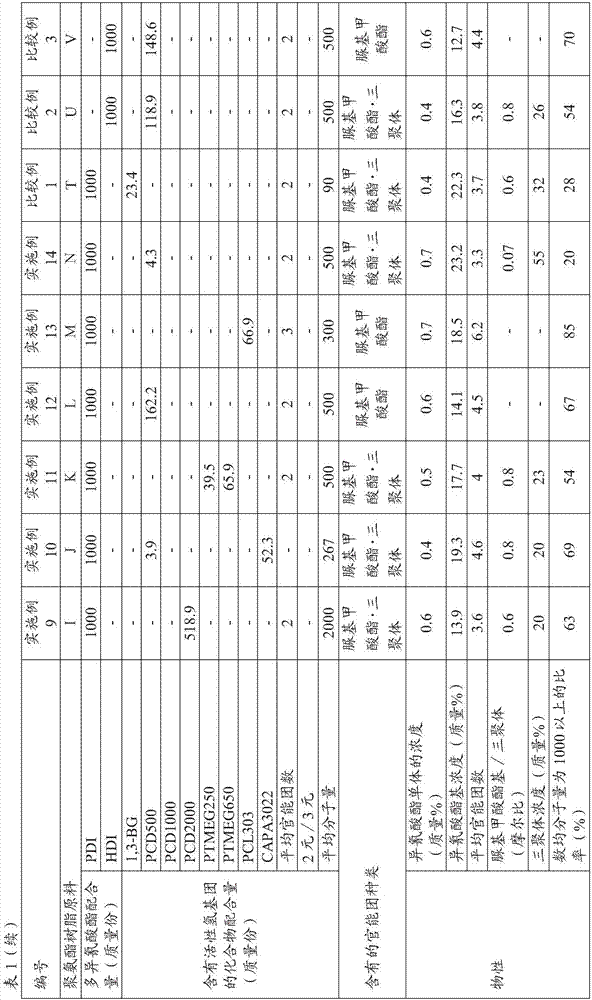

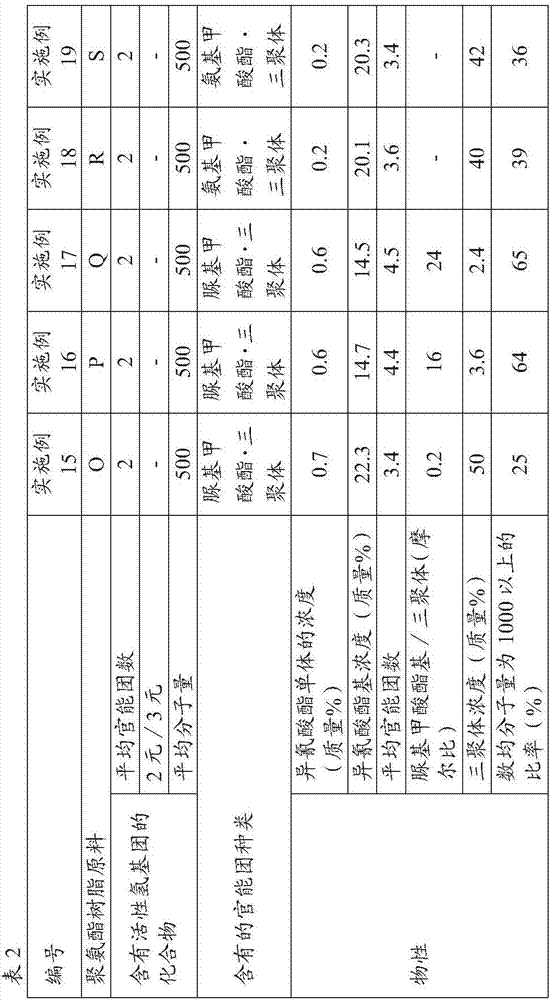

[0316] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated in detail, this invention is not limited to them. In addition, in the following description, unless otherwise specified, "part" and "%" are based on mass. In addition, the numerical value of the Example shown below can be replaced with the numerical value (namely, upper limit value or lower limit value) described in embodiment.

[0317] In addition, the measurement methods used in each Example and each comparative example are as follows.

[0318]

[0319] Using pentamethylene diisocyanate obtained in Production Example 1 described later or commercially available hexamethylene diisocyanate as a standard substance, the standard prepared from the area value of the chromatogram obtained under the following HPLC analysis conditions was used. curve, and calculate the concentration of unreacted isocyanate monomer (pentamethylene diisocyanate, hexamethylene diisocyanate) i...

manufacture example 1

[0368] Production example 1 (production of pentamethylene diisocyanate)

[0369] 99.9 mass % of pentamethylene diisocyanate (it may abbreviate as PDI hereafter) was obtained by the same operation as Example 1 in the specification of international publication pamphlet WO2012 / 121291.

[0370] More specifically, in a jacketed pressurized reactor equipped with an electromagnetic induction stirrer, an automatic pressure regulating valve, a thermometer, a nitrogen gas introduction line, a phosgene introduction line, a condenser, and a raw material feed pump, the 2000 parts by mass of o-dichlorobenzene. Next, 2300 parts by mass of phosgene was added from the phosgene introduction line, and stirring was started. Cool water was passed through the jacket of the reactor to maintain the internal temperature at about 10°C. Using a feed pump, a solution obtained by dissolving 400 parts by mass of pentamethylenediamine (a) in 2600 parts by mass of o-dichlorobenzene was charged into it over...

Embodiment 1

[0376] Embodiment 1 (manufacture of polyurethane resin raw material (A))

[0377] In the four-necked bottle that has stirrer, thermometer, reflux pipe and nitrogen inlet pipe, pack 1000 parts by mass of PDI, 129.7 parts by mass of PCD500 (polycarbonate diol, trade name ETERNACOLL UH-50, produced by Ube Industries, The number of functional groups is 2, and the number-average molecular weight is 500), 0.6 parts by mass of 2,6-bis(tert-butyl)-4-methylphenol (hereinafter referred to as BHT sometimes.), 0.6 parts by mass of phosphorous acid tris(thirteen Alkyl) ester was reacted at 80°C for 2 hours, and then cooled so that the internal temperature was 60°C.

[0378] Next, 0.15 parts by mass of N-(2-hydroxypropyl)-N,N,N-trimethylammonium-2-ethylhexanoate was added as a trimerization catalyst. The refractive index and isocyanate group concentration were measured, and the reaction was continued until a predetermined reaction rate (20% (hereinafter also the same)) was reached. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com