Waterborne polyurethane latex emulsion for nylon fabric and preparation method thereof

A water-based polyurethane and nylon fabric technology, applied in dyeing, textile and papermaking, etc., can solve the problems of fastness, elasticity, cold resistance not meeting the requirements, poor film-forming elasticity of water-based acrylic resin, and difficulty in meeting market demand, etc. Good process implementation, good compatibility, the effect of reducing production and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

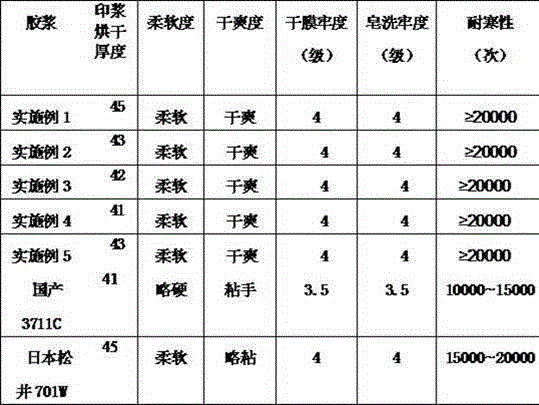

Examples

Embodiment 1

[0044] 26.6 parts of hydrogenated diphenylmethane diisocyanate, 8.5 parts of hexamethylene diisocyanate (HDI), 55 parts of polytetramethylene glycol (molecular weight 2000), 40 parts of polycarbonate diol (molecular weight 1000), polyethylene 5 parts of diol (molecular weight 800), 25 parts of acetone, 7 parts of sodium diaminosulfonate (molecular weight 220), 6 parts of isophorone diamine, 7.1 parts of ethylenediamine, 130 parts of deionized water;

[0045] Preparation:

[0046] (1) Prepolymerization reaction: 26.6 parts of hydrogenated diphenylmethane diisocyanate, 8.5 parts of hexamethylene diisocyanate, 55 parts of polytetramethylene glycol (molecular weight 2000), polycarbonate diol (molecular weight 1000 ) is 40 parts, polyethylene glycol (molecular weight: 800) is 5 parts, put into the reaction kettle, heat up to 70-80°C and stir for 1-2 hours;

[0047] (2) Chain extension reaction: Add 25 parts of acetone to the above prepolymer, 7 parts of chain extender sodium dia...

Embodiment 2

[0051] Raw material weight ratio: 30.1 parts of hydrogenated diphenylmethane diisocyanate, 9 parts of hexamethylene diisocyanate (HDI), 70 parts of polytetramethylene glycol (molecular weight 3000), polycarbonate diol (molecular weight 2000) 60 parts, polyethylene glycol (molecular weight 1000) 8 parts, acetone 35 parts, sodium dihydroxysulfonate (molecular weight 550) 10 parts, isophorone diamine 6 parts, triethylene diamine 5.3 parts, deionized water 163.4 parts Part: preparation method is the same as embodiment 1, obtains product, solid content 50.3%.

[0052] This embodiment product is soft to the touch due to polytetramethylene glycol, polycarbonate diol, polyethylene glycol, sodium dihydroxysulfonate molecular weight in the ratio of raw materials; select isophorone diamine and triethylene Diamines jointly extend the chain, have good synergistic effect and good wear resistance.

Embodiment 3

[0054] Raw material weight ratio: 40.5 parts of hydrogenated diphenylmethane diisocyanate, 25.9 parts of hexamethylene diisocyanate (HDI), 50 parts of polytetramethylene glycol (molecular weight 1000), polycarbonate diol (molecular weight 1000) 50 parts, 11 parts of polyethylene glycol (molecular weight 800), 25 parts of acetone, 6 parts of sodium diaminosulfonate (molecular weight 220), 6 parts of sodium dihydroxysulfonate (molecular weight 550), 8 parts of triethylenediamine, 5.1 parts of ethylenediamine, 177.5 parts of deionized water: the preparation method is the same as in Example 1 to obtain a product with a solid content of 50.1%.

[0055] The product of this example is due to the synergistic reaction of diamine sulfonate and dihydroxy sulfonate as raw materials, with soft hand feeling, excellent product performance and good fastness; the proportion of hydrogenated diphenylmethane diisocyanate and hexamethylene diisocyanate is relatively large , The product feels sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com