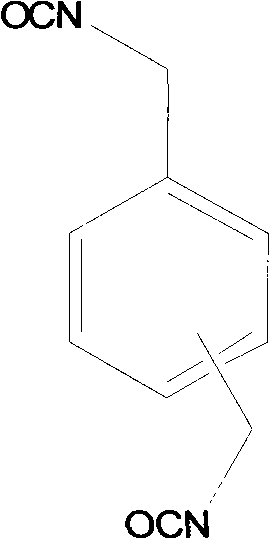

Method for preparing xylylene diisocyanate based on salification-phosgenation reaction

A technology for xylylenediamine hydrochloride and salt-forming reaction, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of isocyanic acid derivatives, etc. The problem of incomplete salt formation of base diamine and low space-time conversion rate of photochemical reaction can achieve the effect of suppressing by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this method, the salt-forming reaction adopts a continuous mode, and the phosgenation reaction adopts a batch mode. A reactor with a jet reactor and stirring was used as a salt-forming reactor with a volume of 1000 milliliters, and 414 g of o-dichlorobenzene was charged in advance as a reaction solvent. The volume of the phosgenation reactor is 5 liters. 681g (5 moles) of m-xylylenediamine and 2724g of o-dichlorobenzene (total amine concentration of feed is 20wt%) were put into the raw material tank to form m-xylylenediamine solution (or called reaction solution). The temperature of the reaction solution was maintained at 30°C by means of external cooling. The hydrogen chloride gas is passed into the gas phase nozzle of the jet reactor through a high-pressure pump, and the feeding speed of hydrogen chloride is 7.8L / min, and the m-xylylenediamine solution is passed into with a feed pump at a speed of 56.4g / min. The liquid phase nozzle of the jet reactor, m-xylylened...

Embodiment 2

[0047] In this embodiment, the same reactor as in Embodiment 1 was used, and 414 g of o-dichlorobenzene was pre-loaded in the salt-forming reactor as a reaction solvent. The volume of the phosgenation reactor is 5 liters. Drop into 480.7g (3.53 moles) m-xylylenediamine and 2724g o-dichlorobenzene (feeding total amine concentration is 15wt%) in raw material tank to form m-xylylenediamine solution (or called reaction solution) . The temperature of the reaction solution was kept at 30°C by means of external cooling. The hydrogen chloride gas is passed into the gas phase nozzle of the jet reactor through a high-pressure pump, and the feeding speed of hydrogen chloride is 5.8L / min, and the m-xylylenediamine solution is passed into with a feed pump at a speed of 56.4g / min. The liquid phase nozzle of the jet reactor, m-xylylenediamine solution and hydrogen chloride are mixed and reacted in the jet reactor and enter into the salt-forming reactor. After the concentration of the hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com