Method for preparing high-purity m-xylylene diisocyanate

A high-purity technology for iso-xylylene diisocyanate, which is applied in the field of devices for preparing high-purity iso-xylylene diisocyanate, can solve problems such as a large amount of tar and self-polymerization, avoid self-polymerization and improve the precision The effect of distillation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

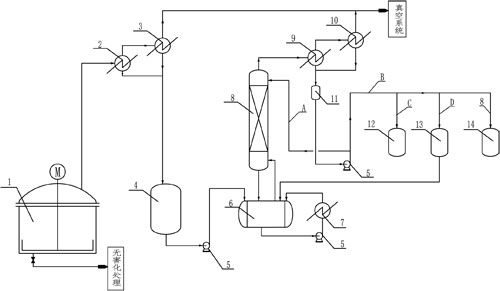

[0021] Example 1, such as figure 1 Shown, a kind of method for preparing high-purity m-xylylene diisocyanate is characterized in that: realize by following device:

[0022] The gas phase outlet at the top of the flash evaporator 1 is connected to the first condenser 2 and the second condenser 3 in sequence, the return pipes of the first condenser 2 and the second condenser 3 are connected to the buffer tank 4, and the discharge pipe at the bottom of the buffer tank 4 passes through the suction pump 5 is connected to the circulation storage tank 6, and the light phase outlet of the circulation storage tank 6 is connected to the batch rectification tower 8, and the gas phase outlet at the top of the batch rectification tower 8 is connected to the third condenser 9 and the fourth condenser 10 in turn, and the third condenser 9 and the fourth condenser 10 are connected successively. The condensing pipe of the four condensers 10 is connected to the reflux tank 11, and the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com