Biodiesel continuous ester interchange technology

A technology of biodiesel and transesterification, which is applied in the fields of biofuel, petroleum industry, and fat production. It can solve the problems of low conversion rate, high energy consumption, and long reaction time, and achieves reduced consumption, continuous separation, and easy tower loading The effect of distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

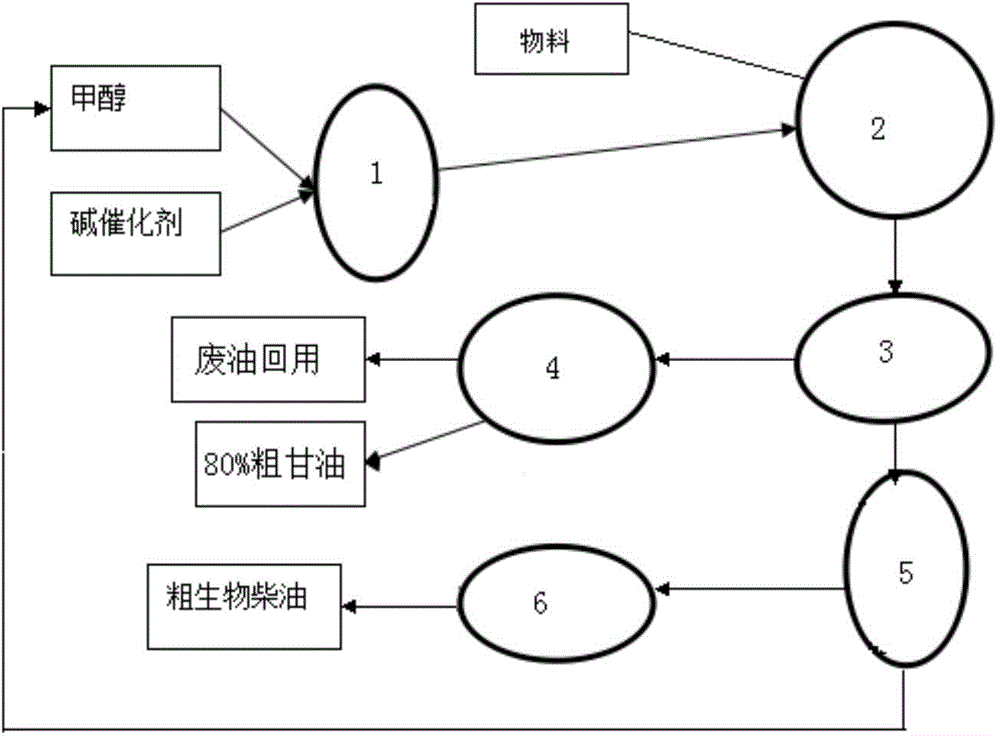

[0026] See figure 1 , the biodiesel continuous transesterification process of the present embodiment comprises the following steps:

[0027] Step 1, methanol and alkali catalyst are mixed in the mixer 1; the mixing temperature is 50°C-60°C; in the step 2, the temperature of the transesterification reaction is 50°C-80°C, and the reaction time is 0.8-1.5 hours ;

[0028] Step 2: Continuously pump the mixed solution of step 1 and the waste oil with low acid value or esterification into the continuous transesterification reactor 2 through the metering pump; the temperature of the transesterification reaction is 50℃~80℃, and the reaction time is 0.8~ 1.5 hours; the continuous transesterification reactor 2 includes a cylinder body, a bracket, a guide tube, a guide tube bracket and a stirring propulsion device; the cylinder body is fixed on the support; the guide tube is fixed on the inner cavity of the cylinder body through the guide tube bracket In the middle, the lower space and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com