Multilayer-evaporation-based bio-diesel continuous rectification system and process

A biodiesel and rectification system technology, applied in the field of biodiesel separation and purification, can solve the problems of reduced evaporation, increased thermal resistance of fouling, large energy consumption, etc., to eliminate high temperature decomposition and polymerization, increase heating vaporization, improve The effect of rectification yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

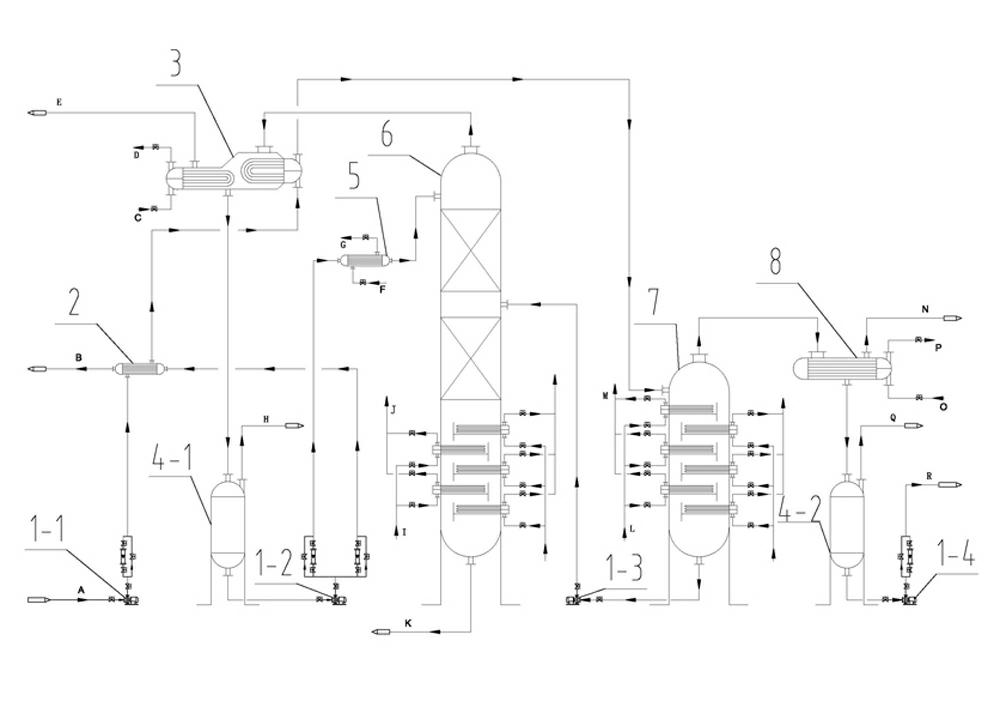

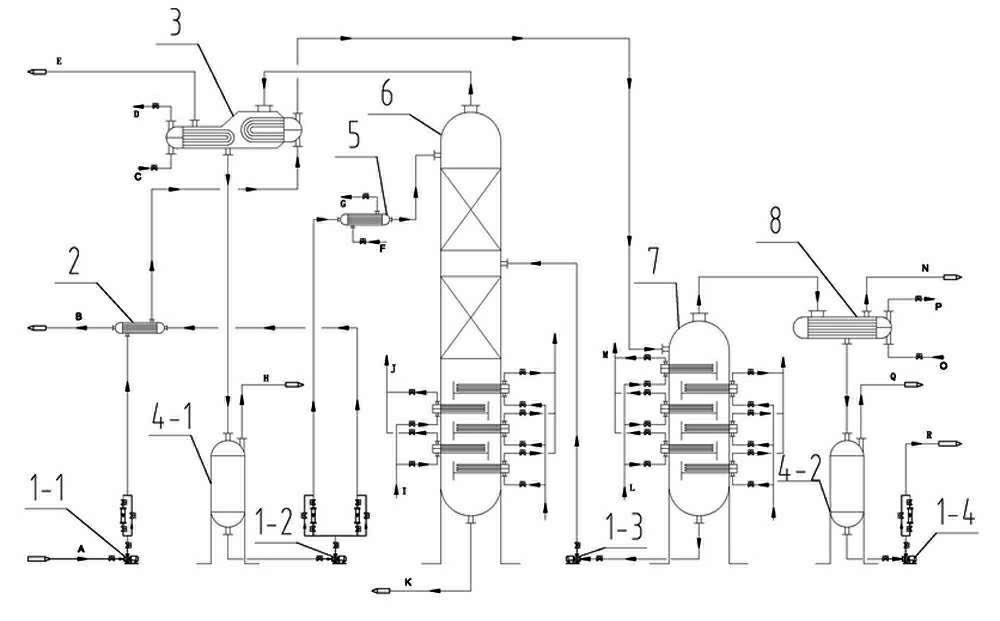

[0022] Example: such as figure 1 As shown, this biodiesel continuous rectification system based on multi-layer evaporation includes a feed pump 1-1, A is a crude biological raw material feed port, and the feed pump 1-1 is connected with a product-raw material heat exchanger 2, Product-raw material heat exchanger 2 is connected to multi-layer evaporator 7 through combined condenser 3, L on multi-layer evaporator 7 is the oil inlet of heat transfer oil, M is oil outlet of heat transfer oil, and the upper part of multi-layer evaporator 7 is connected to There is a condenser 8, 0 on the condenser 8 is the cooling water inlet, P is the cooling water outlet, N is the vacuum pump interface, the condenser 8 is connected with the product tundish 4-2, and the Q on the product tundish 4-2 is Vacuum pump interface, product tundish 4-2 is connected with discharge pump 1-4, R is the light component product outlet, the bottom of multilayer evaporator 7 is connected with rectification tower 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com