Method for preparing 1,2-propylene glycol and normal propyl alcohol by using biologic glycerol

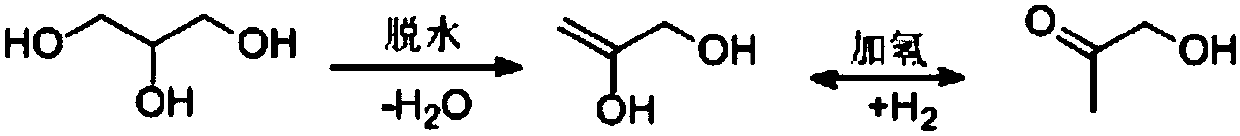

A technology for n-propanol and propylene glycol is applied in the field of biological glycerol catalytic hydrogenolysis to prepare 1,2-propanediol and n-propanol, which can solve the problems of increased time cost, wasted space cost, large equipment investment, etc. The effect of high utilization rate, equipment cost saving and long catalytic life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Reaction conditions:

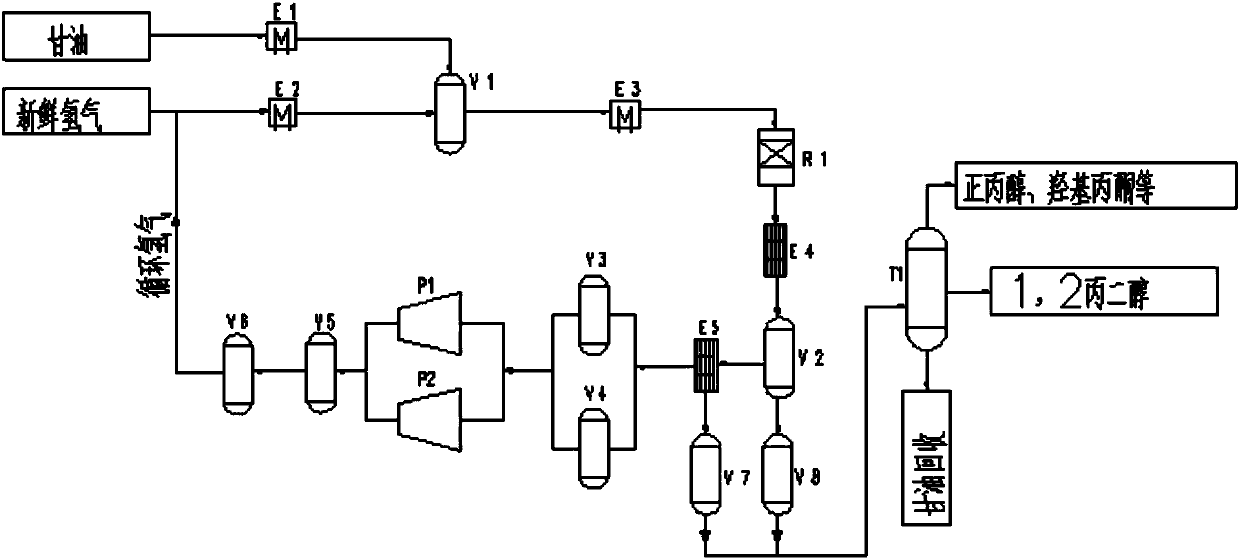

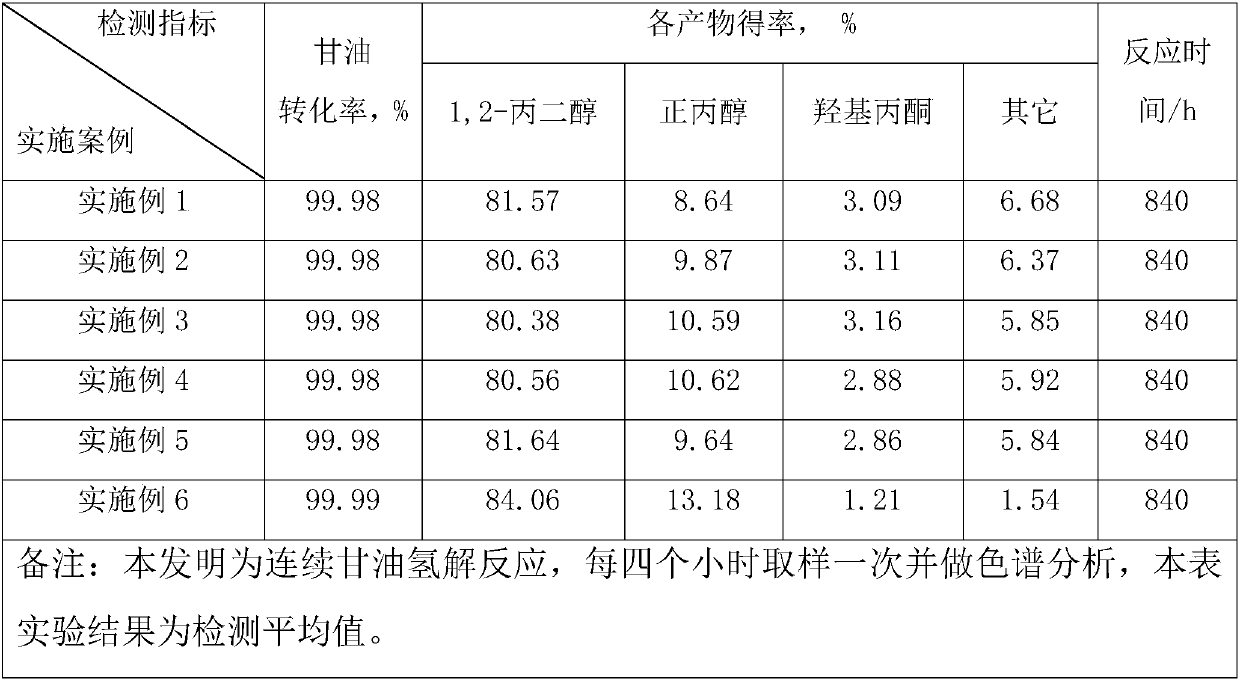

[0033]A fixed-bed continuous reaction device filled with a copper-based catalyst is used to continuously feed glycerin and hydrogen. The glycerin preheater is 70°C, the hydrogen preheater is 220°C, and the hydrogen gas enters the reactor together after the glycerin is vaporized in the 220°C vaporization tank. The bed temperature is 220°C, the reaction pressure is 1.0MPa, the mass space velocity is 0.5 / h, and the molar ratio of hydrogen to oil is 30:1. Reaction excess hydrogen enters the tail gas buffer tank, control the pressure of the left and right pre-pressurized buffer tanks V4 and V3 to 0.55-0.60MPa, the pressure of the high-pressure buffer tank V5 and the pressure of the stabilized buffer tank V6 to 1.4-1.45MPa, and the pressure of the stabilized buffer tank V6 to decompress at the outlet The valve pressure is 1.2MPa, and the left and right booster pumps P2 and P1 are automatically controlled alternately at an interval of 240s. The reaction...

Embodiment 2

[0035] Reaction conditions:

[0036] The basic process of the process is the same as in Example 1. The preheating temperature of hydrogen and glycerin, the temperature of glycerin vaporization tank and the temperature of reaction bed remain unchanged, and the difference in process parameters lies in mass space velocity of 0.6 / h, hydrogen-oil ratio of 25:1, reaction system pressure of 0.8MPa, left and right pre-pressurized buffer tanks The pressure of V3 and V4 is 0.50-0.55MPa, the pressure of high-pressure buffer tank V5 and pressure-stabilizing buffer tank V6 is 1.20-1.25MPa, the pressure of pressure-reducing valve at the outlet of voltage-stabilizing buffer tank V6 is 1.0MPa, and the left and right booster pumps P2 and P1 are automatically controlled at an interval of 240s Used interchangeably. The hydrogenation reaction lasted for 840 hours, and the equipment in the reaction process operated stably, and the hydrogen circulation was good. Take comprehensive samples of coll...

Embodiment 3

[0038] The basic process of the process is the same as in Example 1. The preheating temperature of hydrogen and glycerin, the temperature of glycerin vaporization tank and the temperature of reaction bed remain unchanged. The difference in process parameters is that the mass space velocity is 0.8 / h, the ratio of hydrogen to oil is 20:1, the pressure of the reaction system is 1.0MPa, and the left and right pre-pressurized buffer tanks The pressure of V3 and V4 is 0.50-0.55MPa, the pressure of high-pressure buffer tank V5 and pressure-stabilizing buffer tank V6 is 1.20-1.25MPa, the pressure of pressure-reducing valve at the outlet of V6 of stabilizing buffer tank is 1.2MPa, and the interval between left and right booster pumps P2 and P1 is automatically controlled by 240s Used interchangeably. The hydrogenation reaction lasted for 840 hours, and the equipment in the reaction process operated stably, and the hydrogen circulation was good. Take comprehensive samples of collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com