Combined rectifying column and application thereof

A rectification column and combined technology, applied in the field of combined multi-purpose rectification devices, can solve the problems of inapplicable small-scale solvent separation and recovery, complex composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

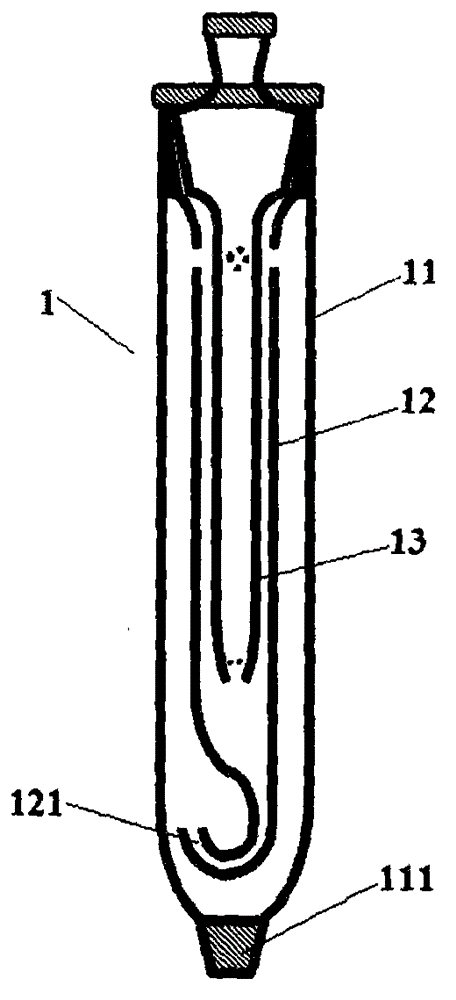

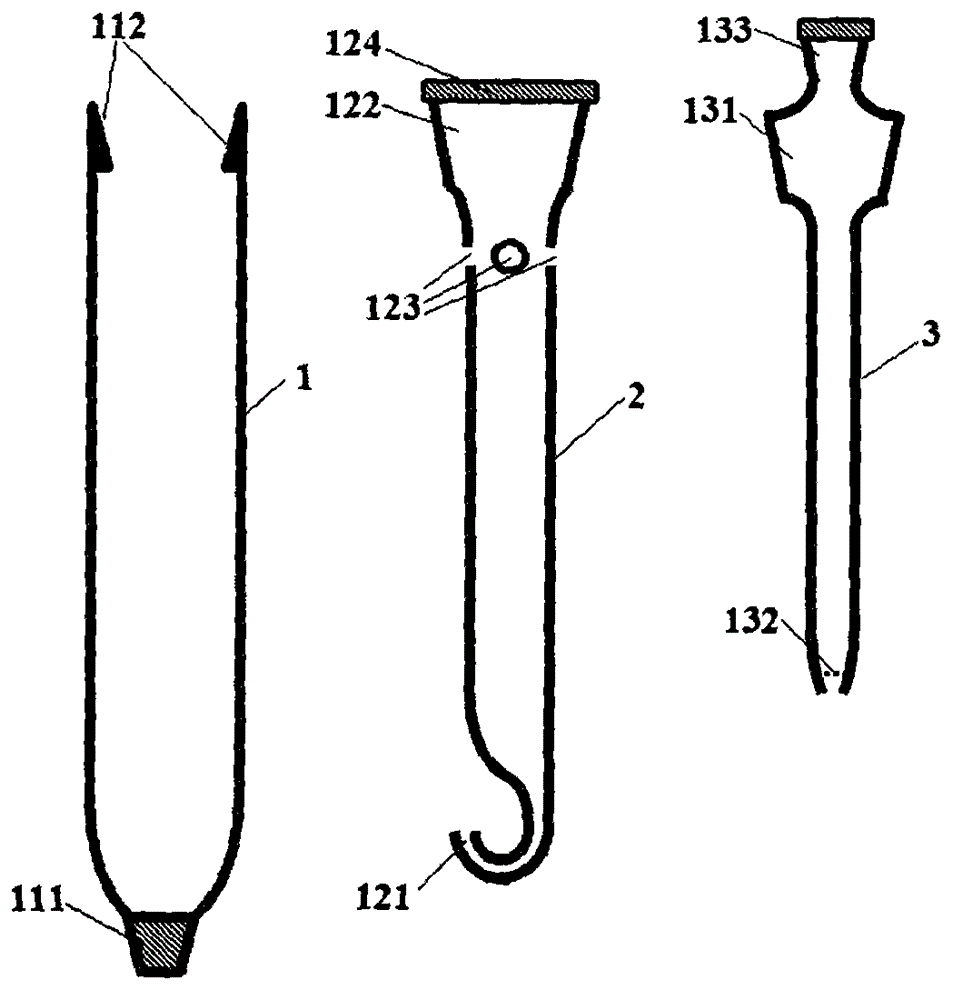

[0139] In this embodiment, the normal-pressure rectification of n-hexane is taken as an example, and a laboratory scale glass device (such as Figure 6 ),by figure 2 The three-piece assembly structure shown, and the method of the third aspect of the present invention are used to specifically illustrate the operation of the present invention. The operation method of this embodiment includes the following steps:

[0140] 1) Put an appropriate amount of glass column filler 5 into the inner casing 13 of the combined rectification column, put the inner casing 13 filled with the filler into the middle casing 12 through the opening at the top of the middle casing 12, and tighten it slightly , so that the two interfaces are sealed through the glass grinding mouth; then they are set in the outer cylinder 11 through the opening at the top of the outer cylinder 11, and slightly tightened, so that the two interfaces are sealed through the glass grinding mouth;

[0141] 2) Inject 2000mL...

Embodiment 2

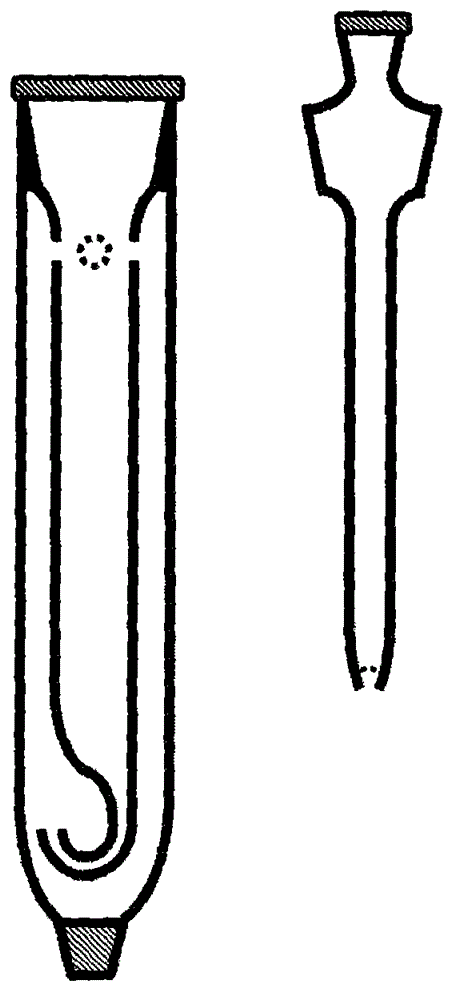

[0147] In the present embodiment, the vacuum distillation of rose essential oil is taken as an example, and a laboratory scale glass device (such as Figure 7 ),by image 3 The shown two-piece assembly structure and the method of the third aspect of the present invention are used to illustrate the operation of the present invention. The operation method of this embodiment includes the following steps:

[0148] 1) Put an appropriate amount of stainless steel ring packing 5 into the inner casing 13 of the combined rectification column, and set the inner casing 13 with the packing on the outer cylinder 11 / intermediate casing 12 through the opening at the top of the middle casing 12. Tighten slightly in the sleeve, so that the interface between the two is sealed through the glass grinding port;

[0149] 2) Inject 2000mL of rose crude oil into a 3L three-necked rectification bottle 2 through mouth a of rectification bottle 2, add an appropriate amount of zeolite, then seal mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com