Continuous rectification separation method and device for (methyl) hydroxyethyl acrylate crude product

A technology of hydroxyethyl acrylate and crude product, applied in separation method, distillation separation, carboxylate preparation and other directions, can solve the problems of low product rectification yield, great separation difficulty, increased by-products, etc., and achieves improved rectification Yield, the effect of reducing side reactions and reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

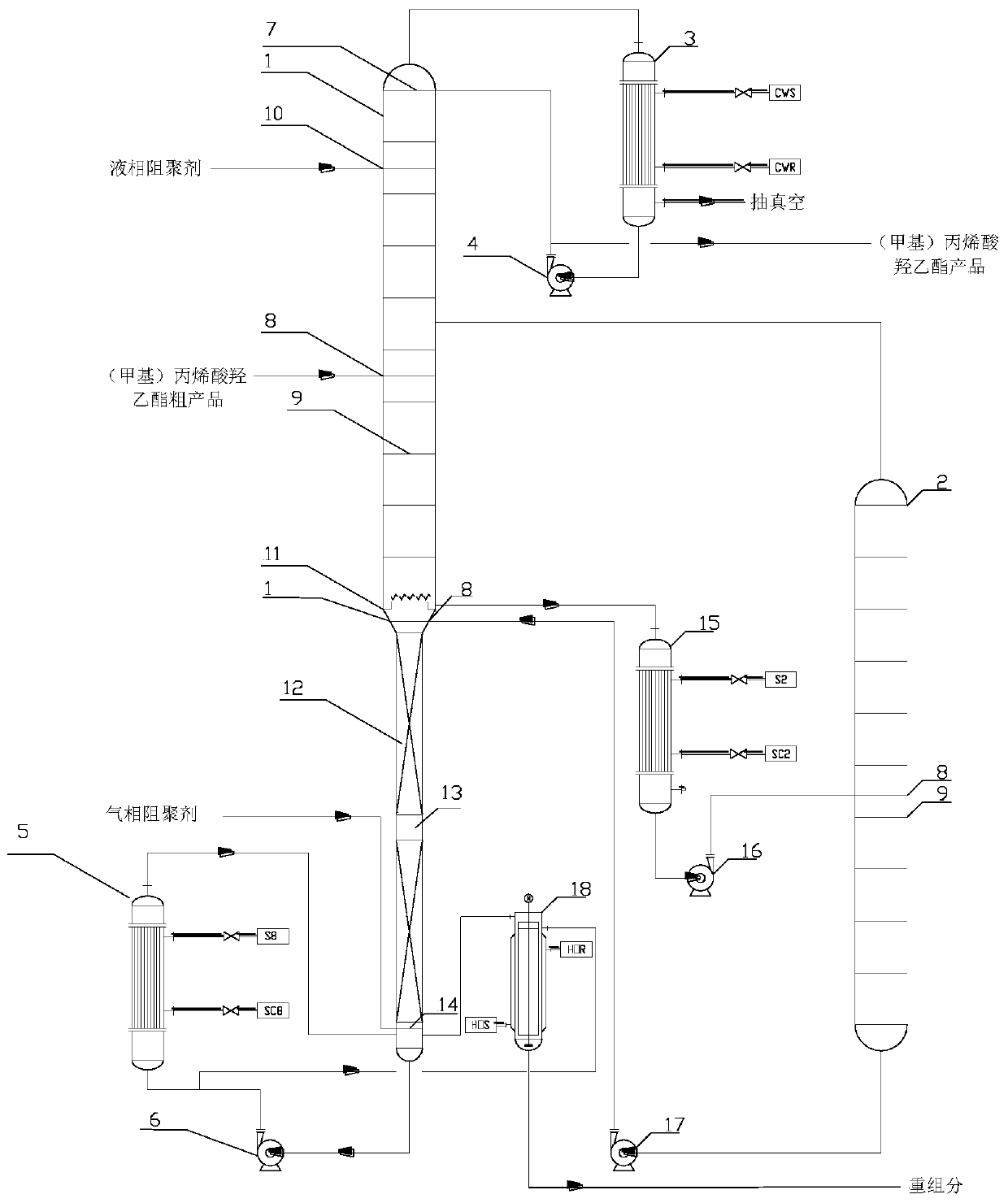

[0052] See attached figure 1 , the continuous rectification device of the crude product of hydroxyethyl methacrylate, comprising a rectification tower main tower 1 and a rectification tower auxiliary tower 2 connected with the main tower by a gas phase pipeline, the rectification tower main tower 1 is divided into an upper section and a lower section, The interior of the upper section is respectively provided with a reflux distributor 7, a multi-layer separation tray 9, a liquid phase polymerization inhibition distributor 10, a feed distributor 8 and a liquid collector 11 from top to bottom. A reflux distributor 7 is arranged at the top of the main tower of the rectification tower, a feed distributor 8 is arranged at the middle of the upper section of the tower, a multi-layer separation tray 9 is arranged at the upper section of the tower, and a liquid phase polymerization inhibitor distributor 10 is arranged at the top of the tower. A liquid collector 11 is arranged at the bo...

Embodiment 2

[0065] Embodiment 2: The liquid collector 11 of this embodiment is composed of a folded plate with an inclination angle of 40° to the horizontal direction and a bottom plate with a 20 mm mesh at the bottom, and the porosity of the bottom plate is 35%. The backflow distributor 7 and the feed distributor 8 are both composed of a T-shaped feed pipe and a branch pipe perpendicular to it, and the branch pipe communicates with the main pipe, and nozzles are distributed at the lower end. The distance between adjacent branch pipes is 150mm, and the distance between nozzles is 300mm. The nozzle is in the shape of a 90° fan. The nozzle at the lower end of the annular pipeline of the liquid phase inhibition distributor faces the tower wall at an inclination angle of 65° from the horizontal direction. Sealed on both sides, open on both sides, the gas phase enters in a circular flow, and the distance between the front feed port and the front baffle is 100mm. Others are the same as embodime...

Embodiment 3

[0071] Embodiment 3: The liquid collector 11 of this embodiment is composed of a folded plate with an inclination angle of 45° to the horizontal direction and a bottom plate with a 20mm mesh at the bottom, and the porosity of the bottom plate is 40%. Both the backflow distributor 7 and the feed distributor 8 are composed of a T-shaped feed pipe and a branch pipe perpendicular to it, and the branch pipe communicates with the main pipe, and nozzles are distributed at the lower end. The nozzle is in the shape of a 90° fan. The nozzle at the lower end of the annular pipeline of the liquid phase inhibition distributor faces the tower wall at a 90° inclination angle to the horizontal direction. Sealed, with openings on both sides, the gas phase enters in a circular flow, and the distance between the front feed inlet and the front baffle is 300mm. Others are the same as embodiment 1. The operating parameters of the present invention are: the crude product of hydroxyethyl methacrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com