Method for extracting cinnamomum longepaniculatum leaf essential oil

An extraction method, the technology of camphor leaves, which is applied in the field of extraction of camphor leaf essential oil, can solve the problems of low purity, low extraction rate, high impurity content, etc., and achieve the effect of obvious smell, improved extraction rate, and good quality of essential oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a method for extracting camphor leaf essential oil, which is carried out in the following steps:

[0032] (1) Drying: put the camphor leaves at room temperature and dry them in the shade out of light until the water content is 3%.

[0033] (2) Pulverization: pulverize the dried camphor tree leaves with a pulverizer, and pass through a 20-mesh sieve to obtain camphor camphor leaf powder.

[0034] (3) Enzymolysis: Add appropriate amount of water and cellulase to the camphor leaf powder obtained in step (2), the mass ratio of the added water to the camphor leaf powder is 8:1, and the consumption of the cellulase is 0.5 %, after stirring evenly, place it in a water bath at 45°C for 1 h, and keep stirring during this period.

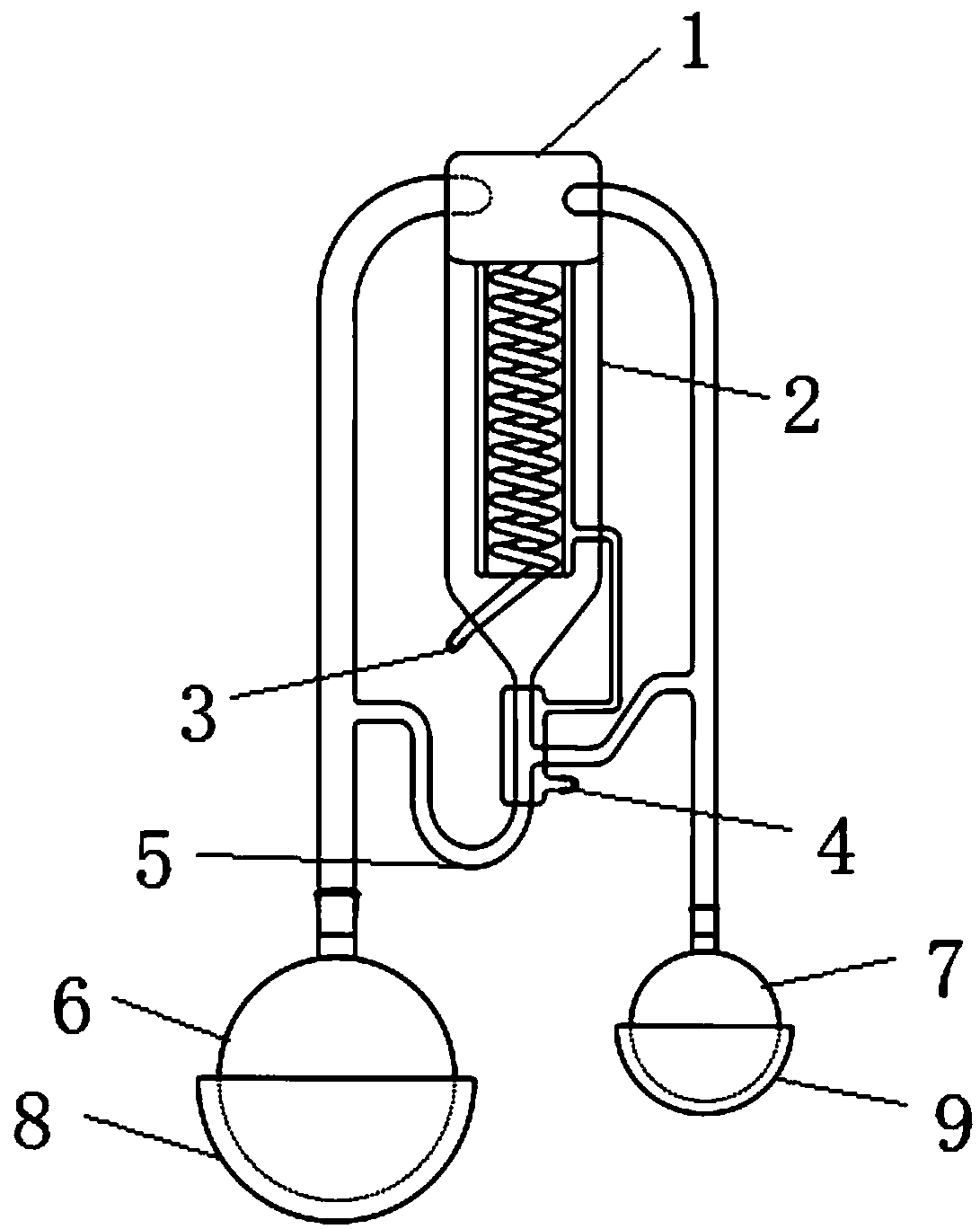

[0035] (4) Simultaneous distillation and extraction: the connection is as good as figure 1 The simultaneous distillation and extraction device shown in the figure performs simultaneous distillation and extraction on the mixture...

Embodiment 2

[0040] The invention provides a method for extracting camphor leaf essential oil, which is carried out in the following steps:

[0041] (1) Drying: place the leaves of the camphor tree at room temperature and dry in the shade out of light until the water content is 4%.

[0042] (2) Pulverization: pulverize the leaves of camphor oleifera dried in the shade with a pulverizer, and pass through a 40-mesh sieve to obtain camphor leaf powder.

[0043] (3) Enzymolysis: Add appropriate amount of water and cellulase to the camphor leaf powder obtained in step (2), the mass ratio of the added water to the camphor leaf powder is 9:1, and the consumption of the cellulase is 0.6 %, after stirring evenly, place it in a water bath at 45°C for 1 h, and keep stirring during this period.

[0044] (4) Simultaneous distillation and extraction: the connection is as good as figure 1 The simultaneous distillation and extraction device shown, the specific steps are the same as in Example 1. The mixtu...

Embodiment 3

[0049] The invention provides a method for extracting camphor leaf essential oil, which is carried out in the following steps:

[0050] (1) Drying: place the leaves of camphor oleifera at room temperature and dry in the shade out of light until the water content is 5%.

[0051] (2) Pulverization: pulverize the dried camphor tree leaves with a pulverizer, and pass through a 60-mesh sieve to obtain camphor camphor leaf powder.

[0052] (3) Enzymolysis: Add appropriate amount of water and cellulase to the camphor leaf powder obtained in step (2), the mass ratio of the added water to the camphor leaf powder is 10:1, and the consumption of the cellulase is 0.6 %, after stirring evenly, place it in a water bath at 45°C for 1 h, and keep stirring during this period.

[0053] (4) Simultaneous distillation and extraction: the connection is as good as figure 1 The simultaneous distillation and extraction device shown, the specific steps are the same as in Example 1, the mixture obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com