Natural luster finishing machine roller for electromagnetic and resistance heating by using power current

A technology of power frequency current and ironing machine, which is applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc. It can solve the problems that affect the use efficiency of equipment, the number of electric heating rods is large, and stop production maintenance, etc., so as to facilitate heat conduction and reduce heat loss , The effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

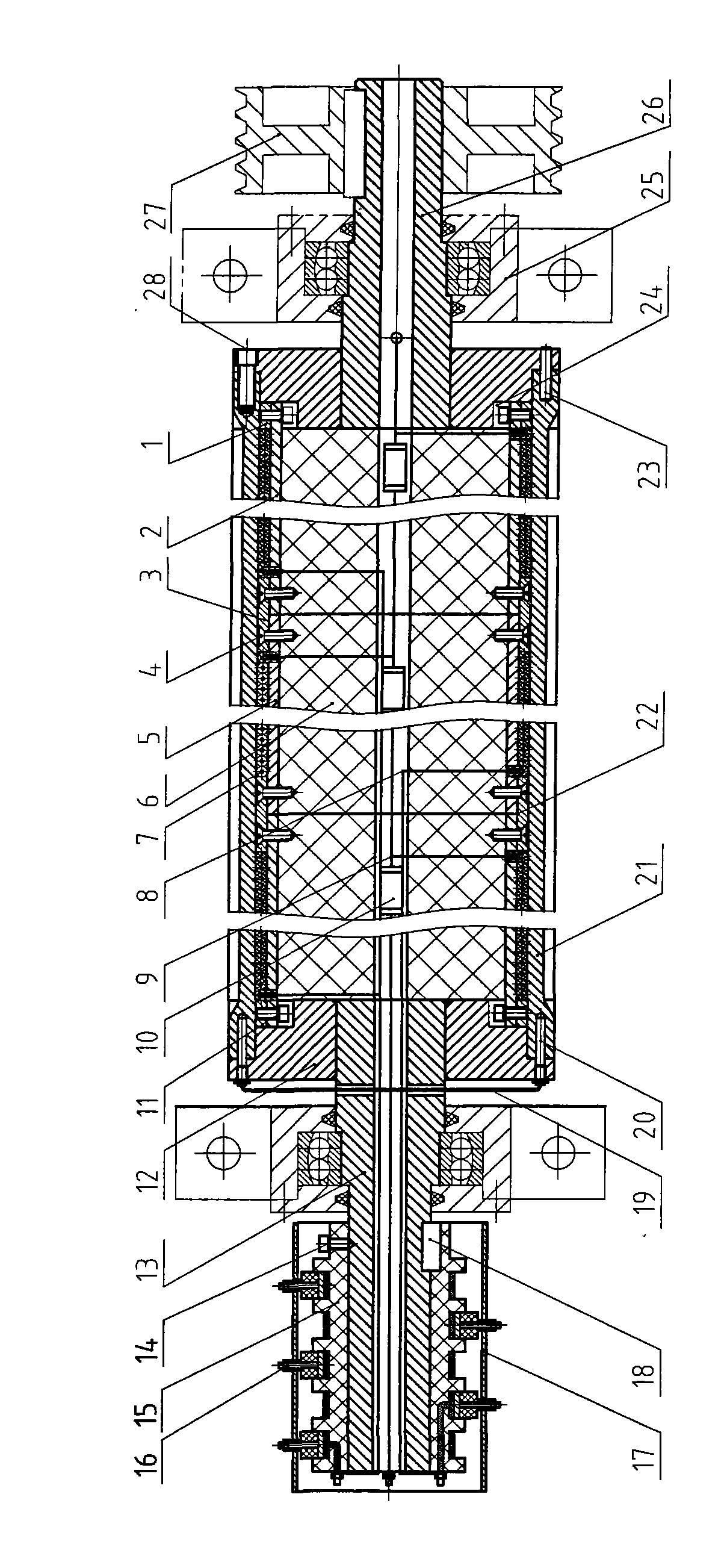

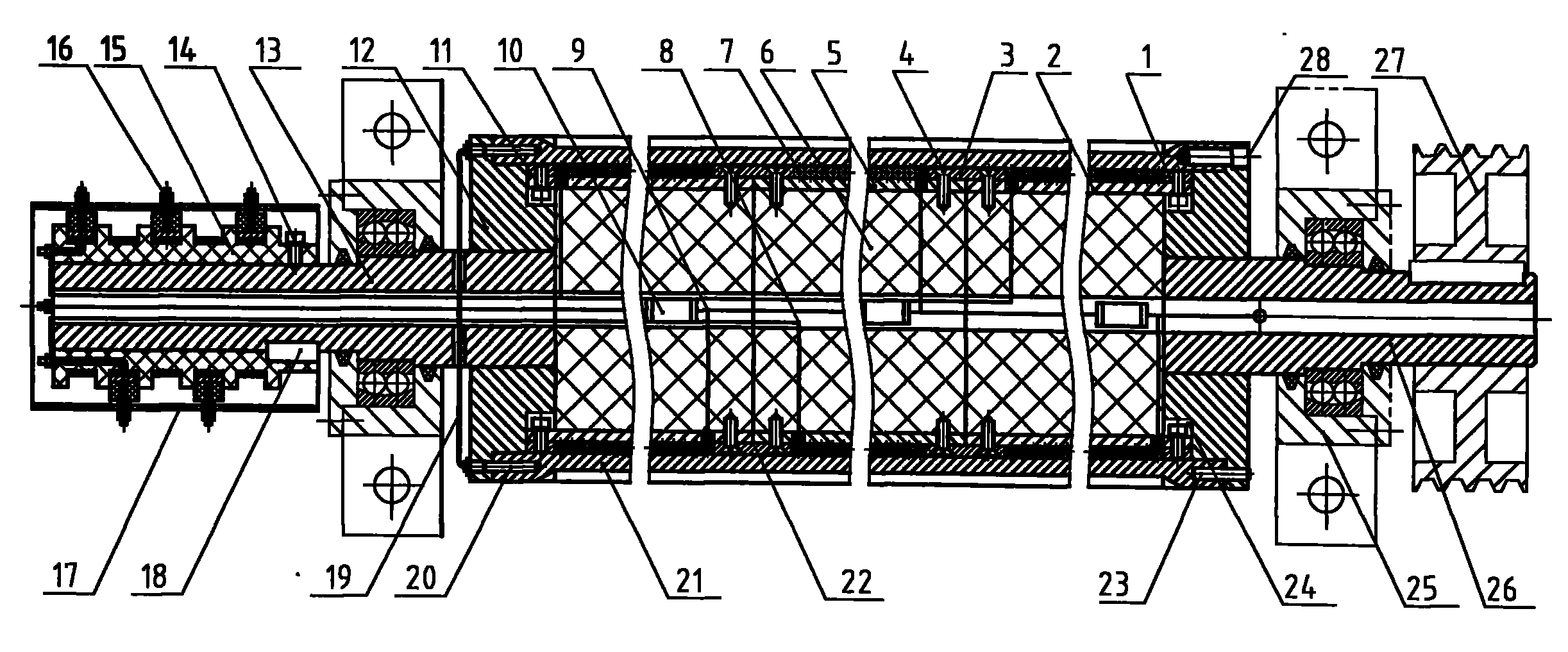

[0013] The invention comprises a roller body (21), a heating device, and a rotating power connection device. The heating device is arranged inside the roller body (21), and the rotating power connection device is arranged on the journal (13) on the left side of the roller body (21). The rotating electrical device includes a wiring rotor (15), a carbon brush (16) and a bracket (17).

[0014] Both sides of the roller body (21) are provided with end caps (12) and axle journals (13, 26), and the axle journals (13, 26) are welded together with end caps (12) respectively, and then with positioning pins (23) and Screw (28), is fixed on the two ends of roller body (21). Bearing seat (25) is installed in the middle part of axle journal (13,26), and belt pulley (27) is installed in the outside of right axle journal (26), is used for driving the rotation of ironing roller.

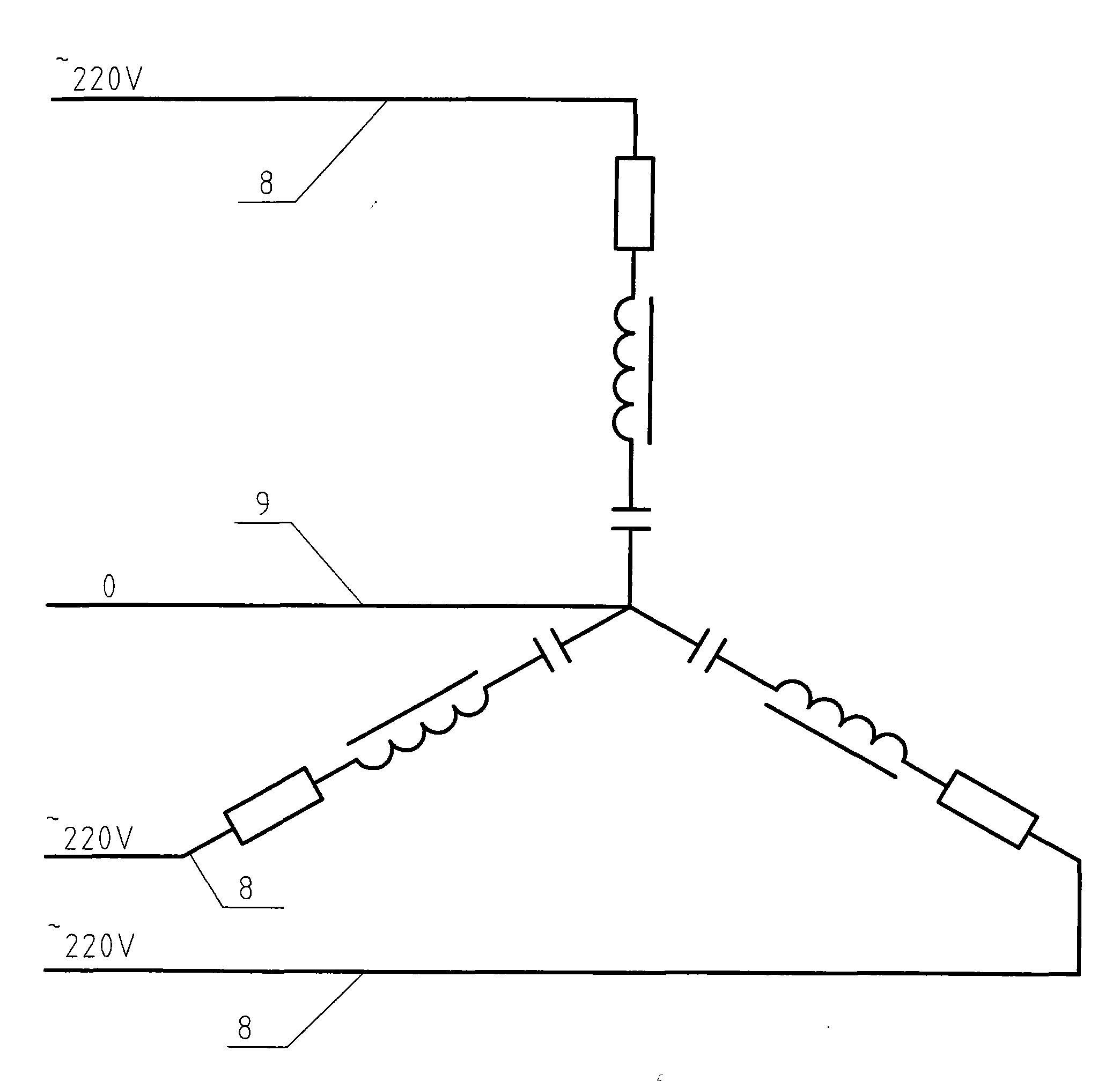

[0015] The heating device comprises a coil (7), a core barrel (22), a heat insulating tube (6) and a capacitor (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com