Manufacturing and Installation of Insulated Pipes or Elements Thereof

a technology of insulating pipes and components, which is applied in the field of manufacturing and installation of insulating pipes or elements thereof, can solve the problems of reducing insulation efficiency, reducing insulation efficiency, and reducing insulation efficiency, so as to facilitate assembly of insulating systems, reduce bulkheads and/or spacers, and simplify manufacturing and/or installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

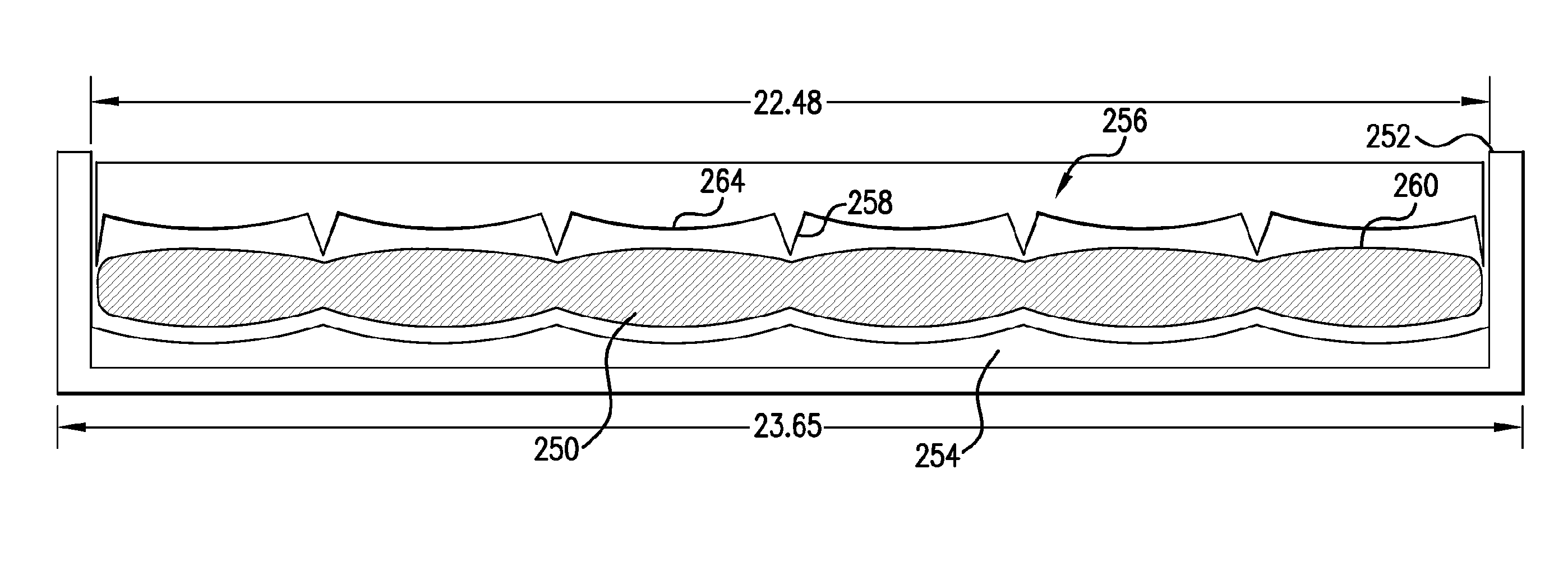

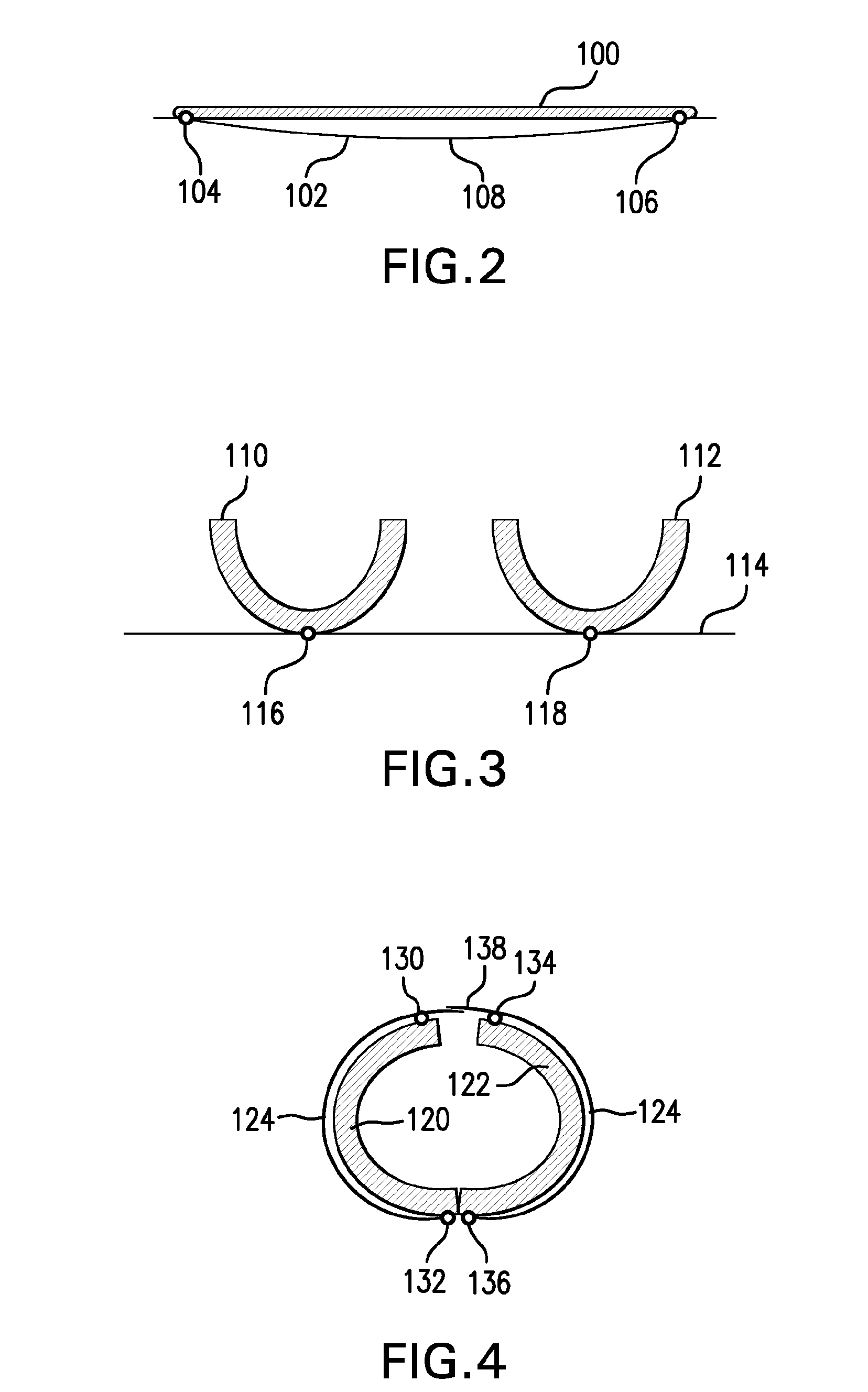

[0238]In a first embodiment a container is altered by modifying the pressure within the container, preferably from a lower initial pressure to a higher final pressure. Equalization of the gas pressure in the container with the gas pressure in the annular space, allows compressible material within the container to expand to a greater volume.

[0239]In a specific example, a container that includes a porous, resilient, volumetrically compressible material, enclosed in a flexible gas-impermeable material, is placed inside a pressure chamber and the pressure in the chamber is reduced below atmospheric pressure. The container is sealed to be gas impermeable while the container is maintained at the reduced pressure in the chamber. The reduced pressure in the container can be any pressure that is less than atmospheric pressure. Typically, the reduced pressure is about 1 kPa or more (e.g., about 10 kPa or more, or about 20 kPa or more). Preferably, the reduced pressure is about 100 kPa or less...

second embodiment

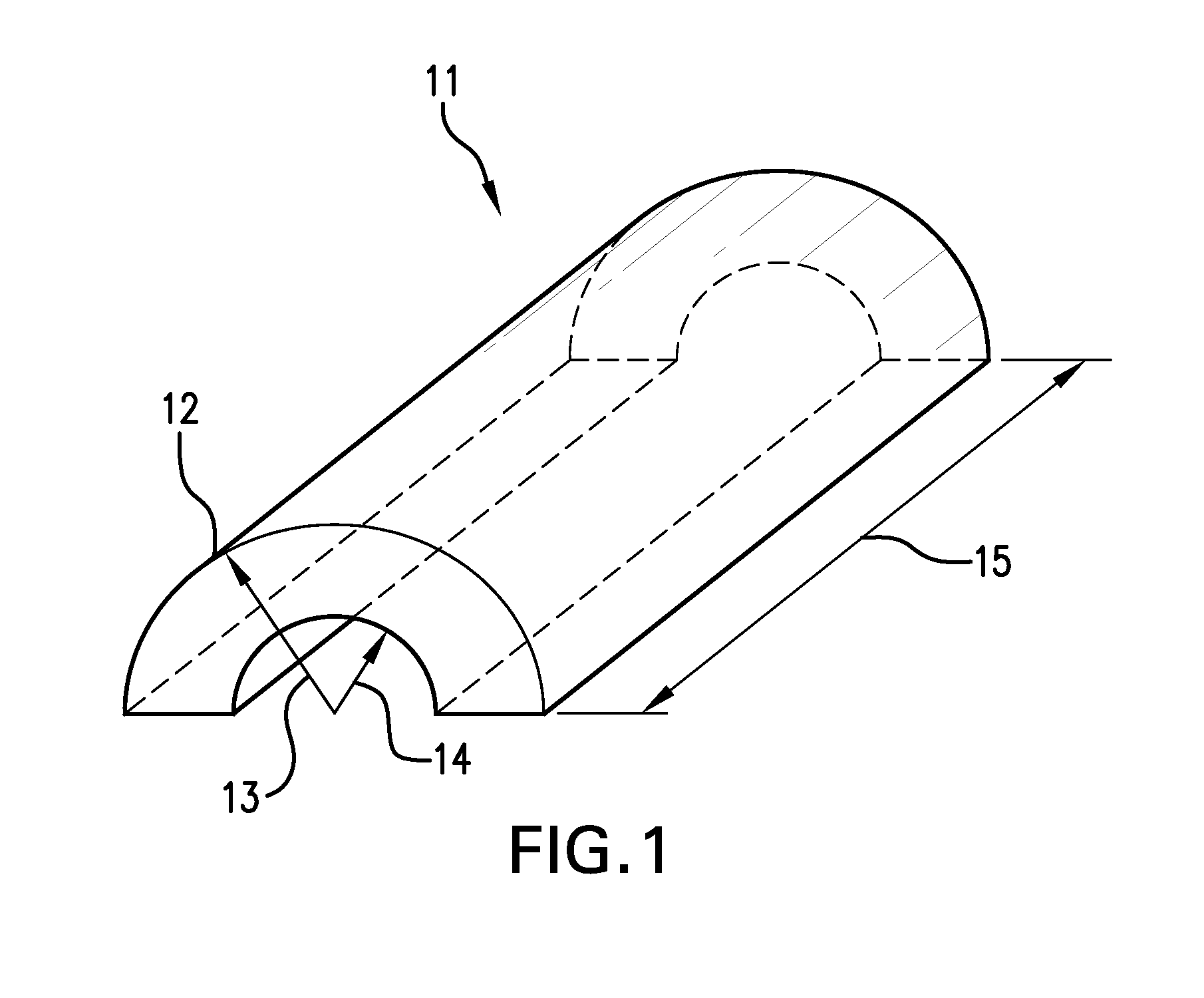

[0245]In the invention, a container is altered to permit an increase in the volume of the compressible material and thereby form an insulated pipe-in-pipe assembly. Preferably, the compressible material is restrained is restrained at the first volume within the at least one container. That is, the container itself restrains the compressible material without or, alternatively, in addition to the action of a pressure differential between the pressure within the container and the pressure outside the container. In this regard, alteration refers to any operation that allows the compressible material to expand.

[0246]Subsequently, the container may be altered to reduce the level of restraint on the compressible material to increase the volume of the compressible material to a second volume that is greater than the first volume, thereby forming an insulated pipe-in-pipe assembly. Examples of suitable alterations include destroying the integrity of the container, transforming an inelastic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com