Manufacturing method for flexible soft copper bar assembly for electric connection

A soft copper bar and electrical connection technology, applied in connection, electrical components, cable/conductor manufacturing, etc., can solve problems such as safety, poor reliability, accidents, short circuits, etc., achieve good anti-corrosion effect, practical and convenient, and reasonable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

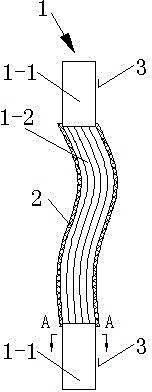

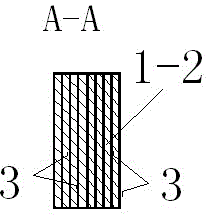

[0029] Such as figure 1 , 2 , 3, and 4, a method for preparing a flexible soft copper bar assembly for electrical connection, the flexible soft copper bar assembly includes a plurality of strip-shaped copper sheets 1, and a plurality of strip-shaped copper sheets 1 are laminated on form a copper bar together, and its two ends are resistance welded to form a hard connection section 1-1. The hard connection section 1-1 has a mounting hole 1-1-1, which is located between the left and right hard connection sections 1-1. The soft-state connection section 1-2 has an insulating sleeve 2, and the outer surface of the hard-state connection section 1-1 has a metal coating 3; and it: the preparation steps are:

[0030] a, blanking; the blanking is that the copper strip is cut into strip copper sheets meeting the product design requirements by a cutting machine, and cleaned;

[0031] b, hot-melt welding; said hot-melt welding is after a plurality of strip-shaped copper sheets are lamina...

Embodiment 2

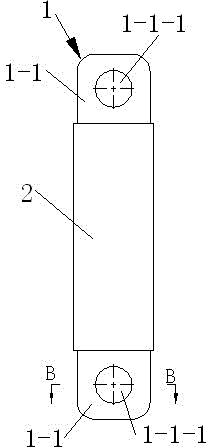

[0037] Such as Figure 5 As shown, a method for preparing a flexible soft copper bar assembly for electrical connection, the flexible soft copper bar assembly includes a plurality of strip-shaped copper sheets 1, and a plurality of strip-shaped copper sheets 1 are stacked together to form a copper bar , and its two ends are resistance welded to form a hard connection section 1-1, the hard connection section 1-1 has installation holes 1-1-1, and the soft connection section between the left and right hard connection sections 1-1 1-2 has an insulating sleeve 2, the outer surface of the hard connection section 1-1 has a metal coating 3, and the upper and lower surfaces of each strip copper sheet 1 located at the hard connection section 1-1 also has a metal coating 3; It is characterized in that: the described preparation steps are:

[0038] a, blanking; the blanking is that the copper strip is cut into strip copper sheets meeting the product design requirements by a cutting machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com