Vacuum compound heat insulating pipe

A technology of vacuum heat insulation and heat insulation pipe, applied in the direction of protecting pipelines, drilling pipes, casings through heat insulation, etc., can solve the problems of short heat insulation life, long-term maintenance, difficult vacuum degree, etc. The effect of easy processing, convenient replacement and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

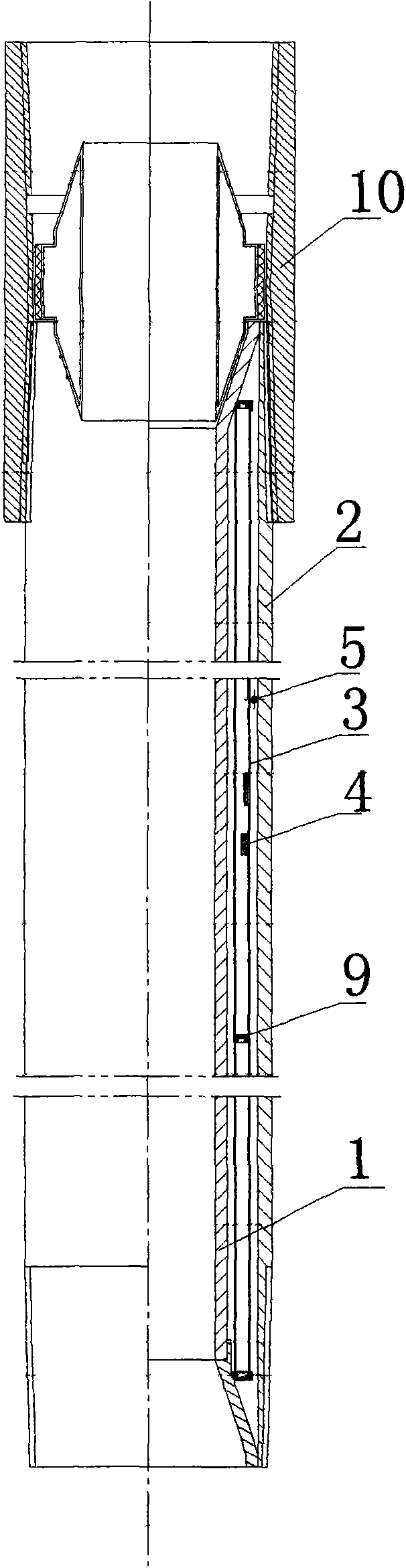

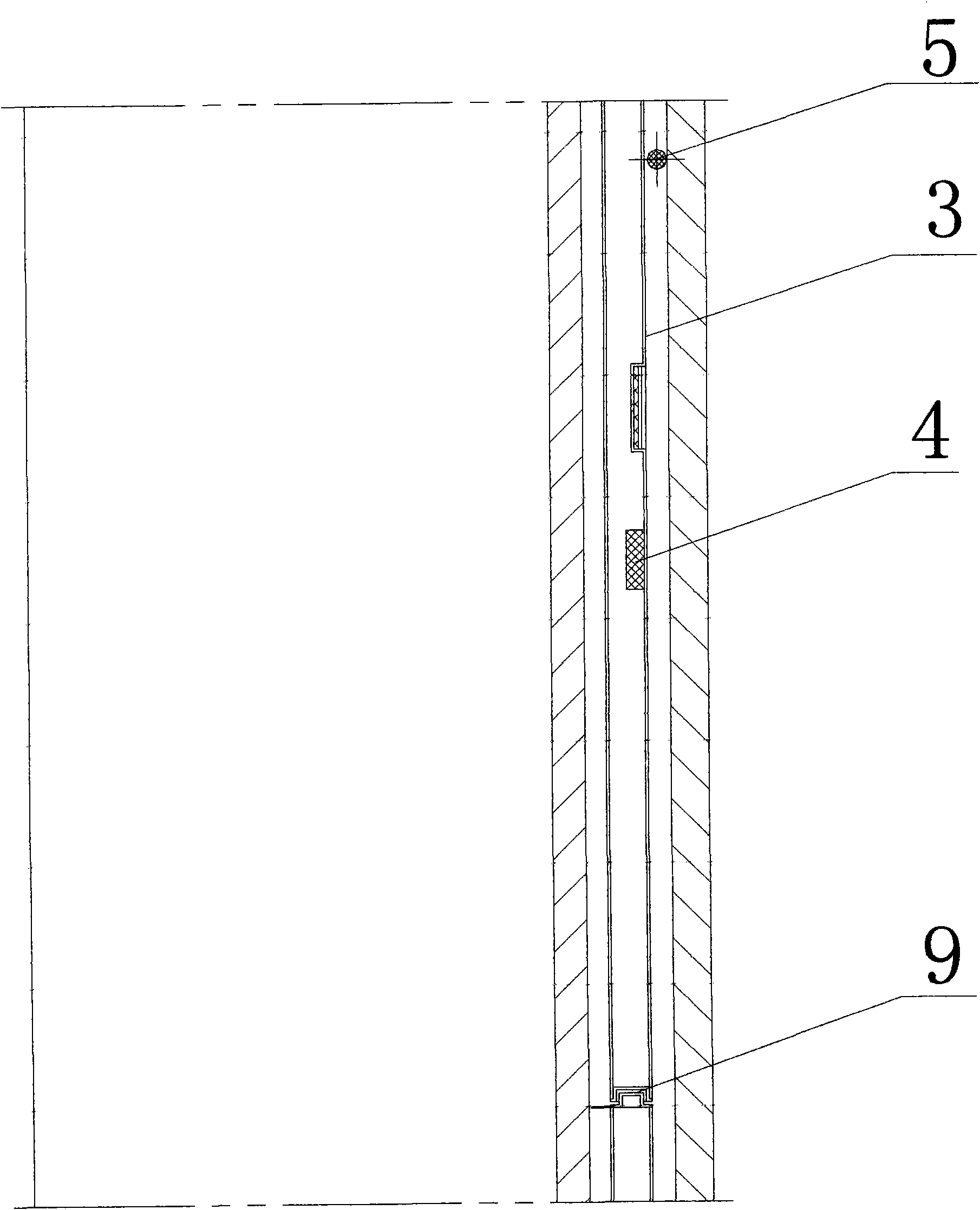

[0023] Embodiment 1: This embodiment includes an inner tube 1 and an outer tube 2, and a separate layer of stainless steel vacuum heat insulation tube 3 is arranged between the inner and outer tubes. The stainless steel vacuum heat insulation tube 3 is a stainless steel tube with a thickness greater than or equal to 0.3mm The double-layer stainless steel vacuum tube welded by the plate, the vacuum degree is higher than 1×10 -1 Pa. The stainless steel vacuum heat insulation pipe 3 is composed of a first stainless steel vacuum heat insulation pipe 31 and a second stainless steel vacuum heat insulation pipe 32 which are spliced together in the axial direction. The first stainless steel vacuum heat insulation pipe 31 is insulated from the second stainless steel vacuum heat insulation pipe. A groove 4 with a concave-convex structure is provided between the butt ends of the pipes 32 , and the first stainless steel vacuum heat-insulated pipe 31 and the second stainless steel vacuum...

Embodiment 2

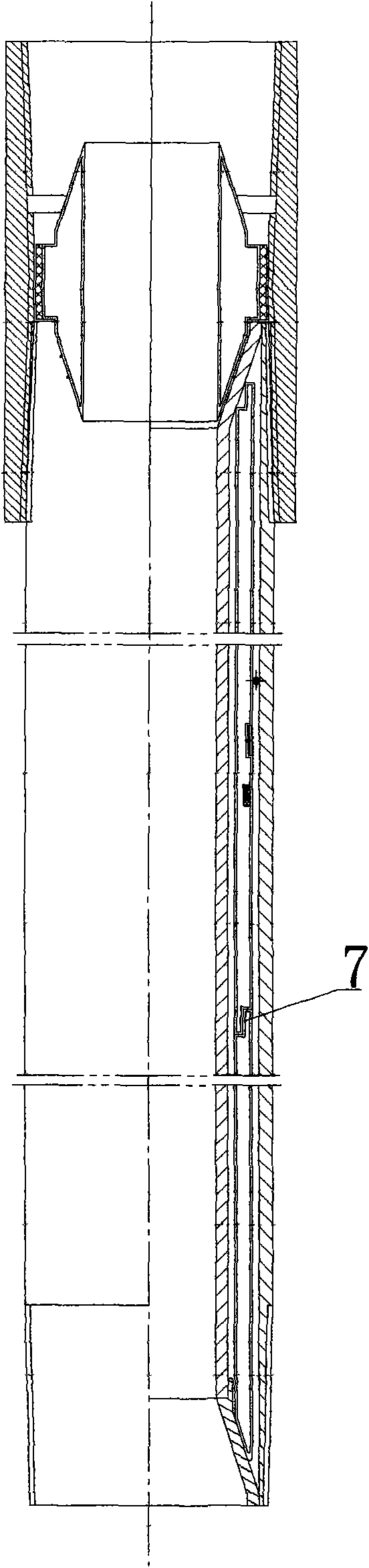

[0024] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that the butt end faces of the first stainless steel vacuum heat insulation pipe 31 and the second stainless steel vacuum heat insulation pipe 32 are steps 7 .

Embodiment 3

[0025] Embodiment 3: This embodiment is basically the same as Embodiment 1, except that the butt end faces of the first stainless steel vacuum heat insulation pipe 31 and the second stainless steel vacuum heat insulation pipe 32 are plane 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com