Bag for crushing objects

a bag and object technology, applied in the field of containers, can solve the problems of user losing a portion of the pill, losing or contaminating a portion of the dose, and many people having difficulty swallowing a pill or tablet regardless, so as to reduce the amount of crushed medicine and reduce the amount of lost or contaminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This application refers in detail below to the exemplary embodiments of the bag according to the invention, which are illustrated in the accompanying drawings. Wherever possible, the application uses the same reference numbers throughout the drawings to refer to the same or similar items.

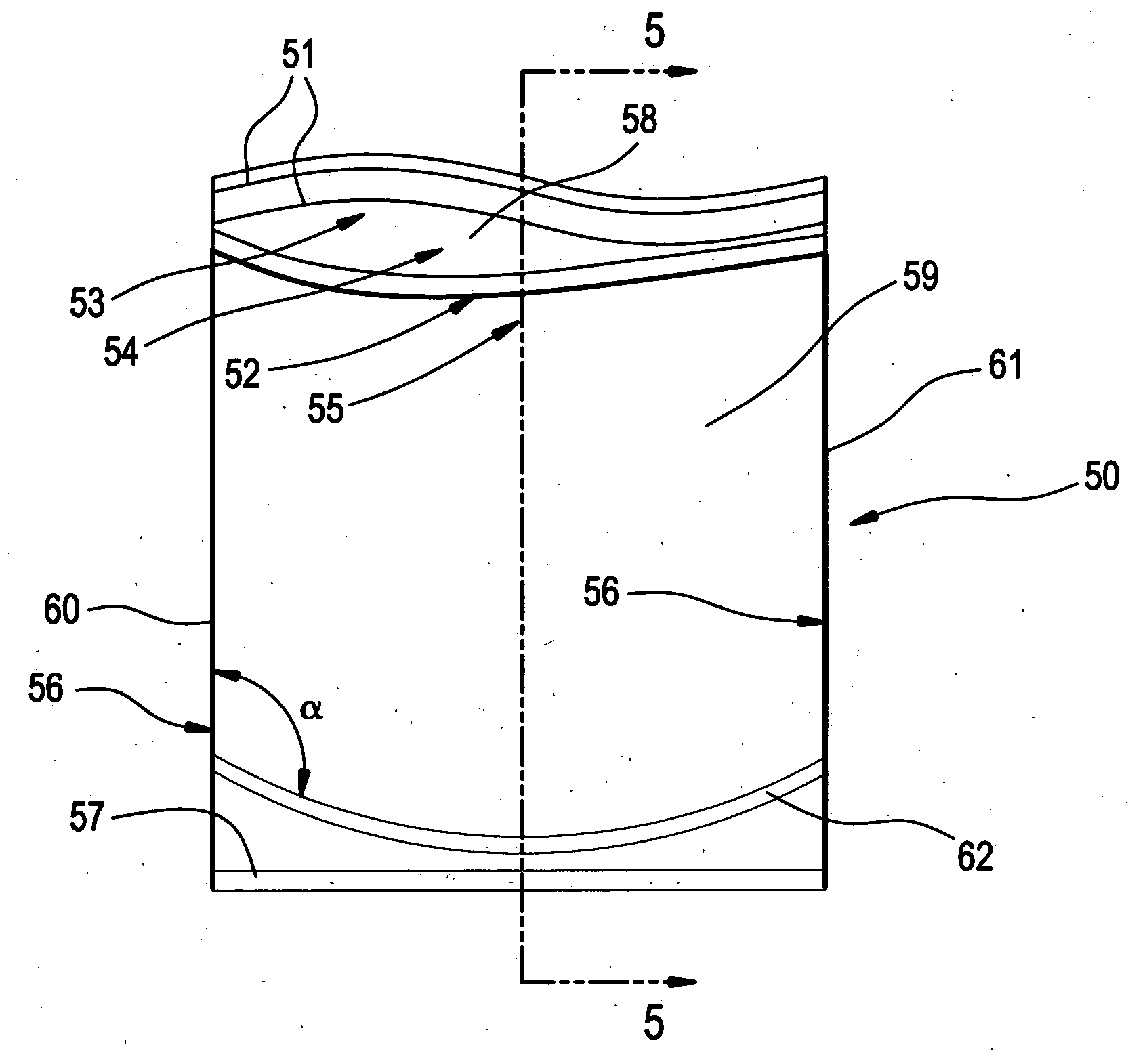

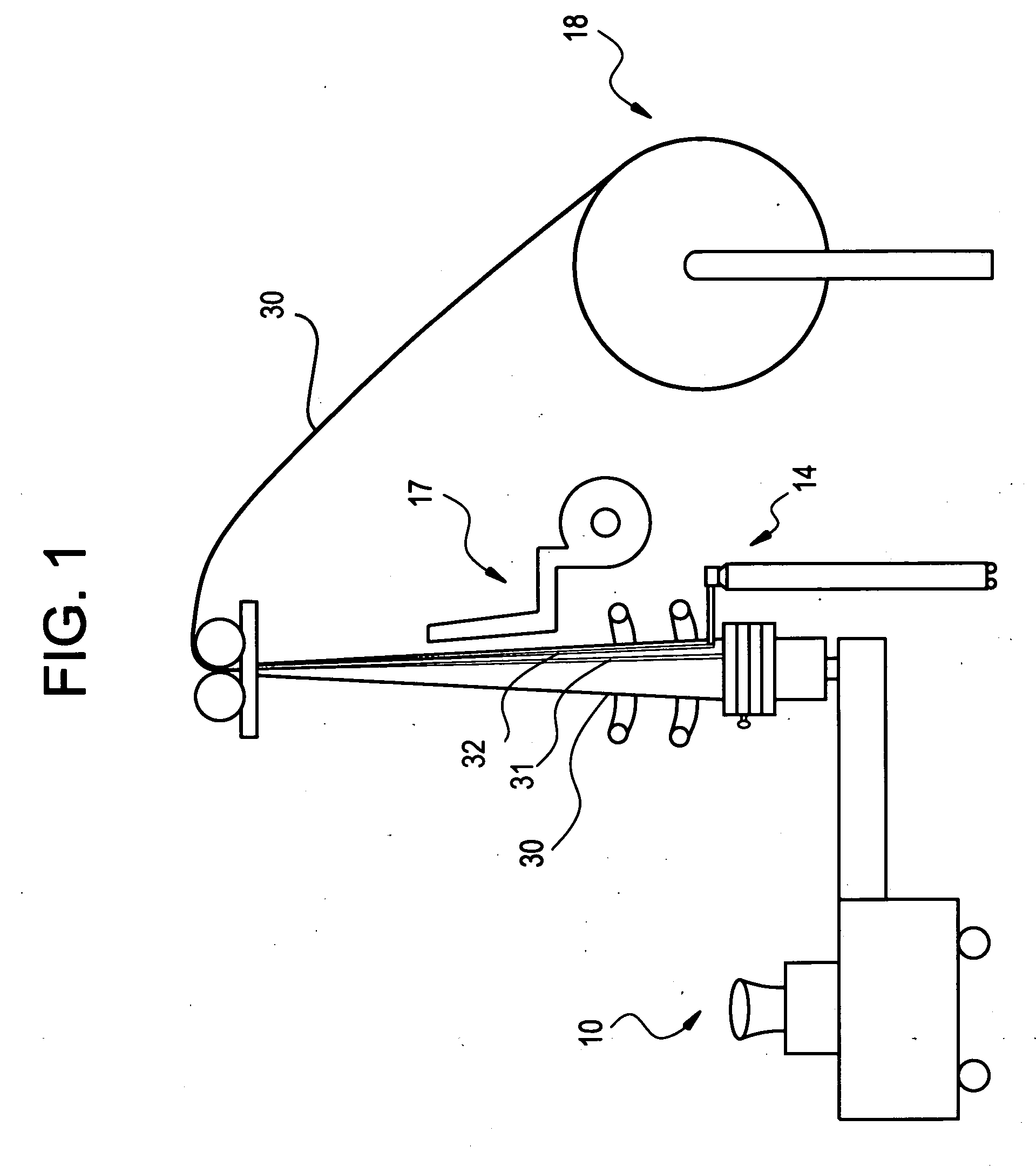

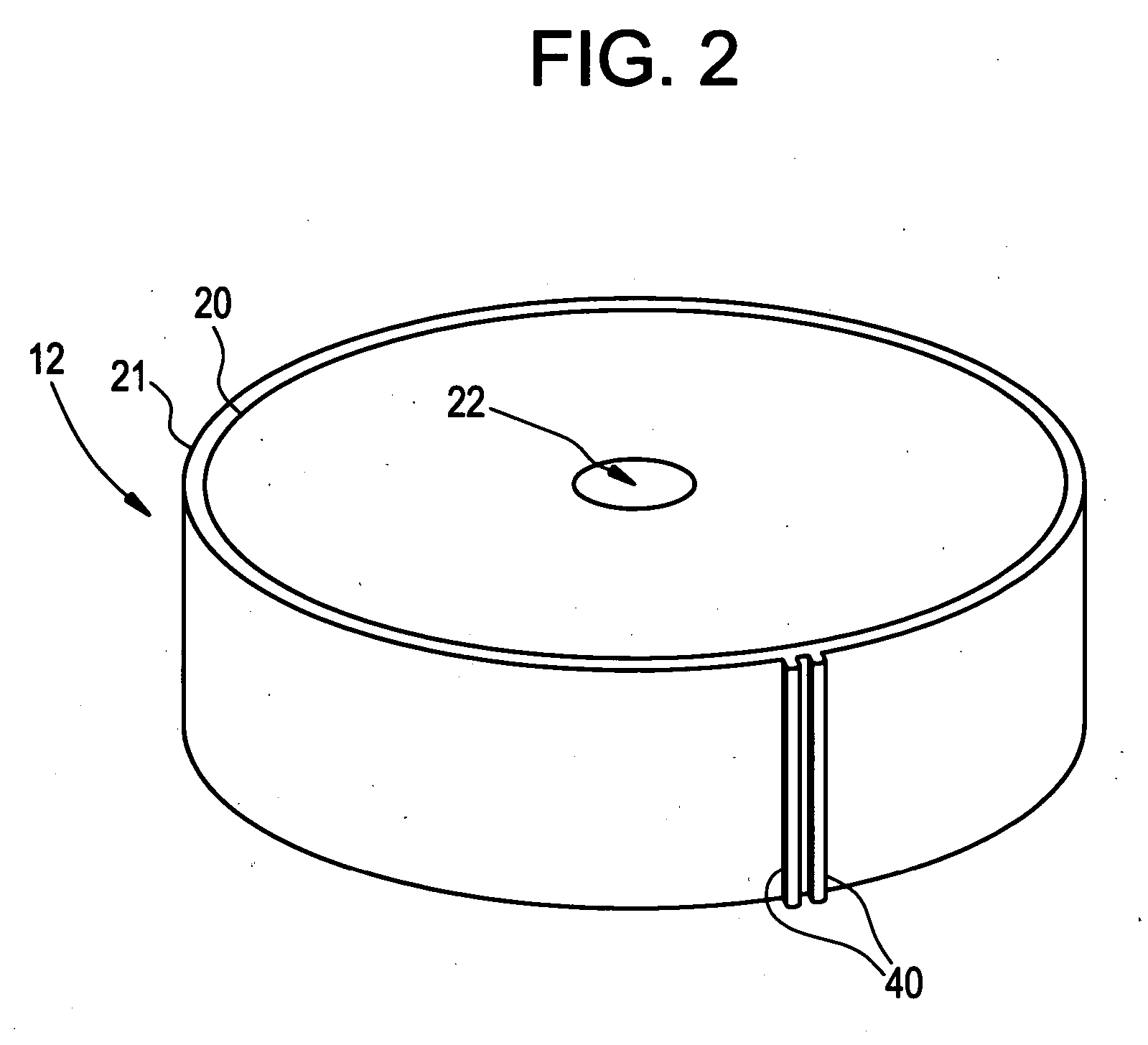

[0015]FIG. 1 schematically illustrates a system suitable for manufacturing bags according to the invention. Raw material such as FDA-approved, food-grade, LDPE resin is fed into the intake 10 of an extrusion machine 11, which melts the raw material and extrudes it through a die assembly 12 to create a tubular film 30. After exiting the die assembly 12, the tubular film 30 is cooled, for example, by the blower 17 and rolled onto a spool 18. Die assembly 12 shown in FIG. 2 is configured to include one or more notches 40 so that the tubular film 30, shown in FIG. 3, includes one or more longitudinal ridges 31 (e.g., two ridges are illustrated in FIG. 1), which eventually constitute gripper 51 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com