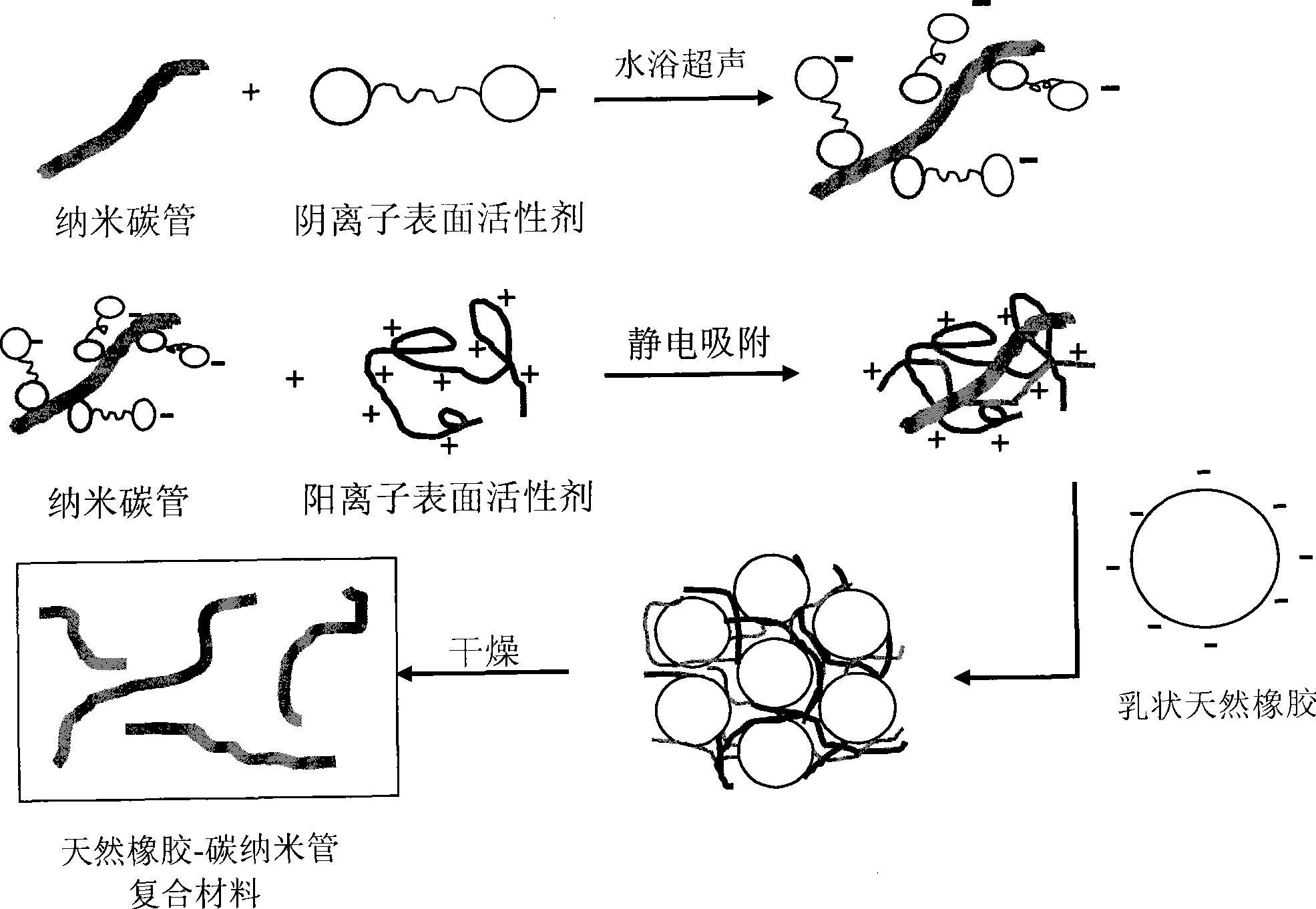

Method for preparing natural rubber-carbon nano tube composite material by using static electricity self-assembly

An electrostatic self-assembly and carbon nanotube technology, which is applied in the field of preparation of natural rubber composite materials, can solve the problems of energy consumption, environmental pollution, harm to the health of operators, etc., and achieves easy large-scale production, simple preparation process, and compatibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Put 1 part of multi-walled carbon nanotubes prepared by gas-phase cracking method, with a diameter of 10-30nm, a length of 5-15μm, and a purity of ≥95.0%, in a flask filled with concentrated sulfuric acid and concentrated nitric acid solutions and boil to reflux After cooling for 1.5 hours, dilute with a large amount of deionized water, filter and wash the microporous membrane until neutral, and obtain surface-functionalized carbon nanotubes.

[0028] (2) The surface functionalized carbon nanotubes obtained in (1) and 0.5 parts of sodium lauryl sulfate are added to deionized water for 0.5 hours, and the pH is adjusted to 10, and then 0.1 parts of pH 10 are added thereto. Polydiallyldimethylammonium chloride was stirred with magnetic force for 5 hours and then washed with deionized water several times to remove excess surfactant to obtain an aqueous dispersion of carbon nanotubes.

[0029] (3) The carbon nanotube water dispersion obtained in (2) is added to 20 parts ...

Embodiment 2

[0032] (1) Put 0.5 parts of multi-walled carbon nanotubes prepared by gas-phase cracking, with a diameter of 10-30 nm, a length of 5-15 μm, and a purity of ≥95.0% in a flask filled with concentrated sulfuric acid and concentrated nitric acid solutions and boiled to reflux After cooling for 2 hours, dilute with a large amount of deionized water, filter and wash the microporous membrane until neutral, and obtain surface-functionalized carbon nanotubes.

[0033] (2) Add the surface-functionalized carbon nanotubes obtained in (1) and 0.25 parts of sodium lauryl sulfate into deionized water for 0.5 hours to sonicate, adjust the pH value to 10, and then add 0.05 parts of pH value to it. 10 polydiallyldimethylammonium chloride, magnetically stirred for 6 hours, and washed with deionized water several times to remove excess surfactant to obtain an aqueous dispersion of carbon nanotubes.

[0034] (3) the carbon nanotube aqueous dispersion obtained in (2) is added to 40 parts of pH valu...

Embodiment 3

[0037] (1) Put 0.8 parts of multi-walled carbon nanotubes prepared by gas-phase cracking method, with a diameter of 10-30nm, a length of 5-15μm, and a purity of ≥95.0%, in a flask filled with concentrated sulfuric acid and concentrated nitric acid solutions and boiled to reflux Cool for 1 hour, dilute with a large amount of deionized water, wash the microporous membrane with vacuum filtration until neutral, and obtain surface functionalized carbon nanotubes.

[0038] (2) Add the surface-functionalized carbon nanotubes obtained in (1) and 0.4 parts of sodium lauryl sulfate into deionized water for 0.5 hours to sonicate, adjust the pH to 10, and then dropwise add 0.08 parts of it to which the pH value is 10 The polydiallyldimethylammonium chloride was stirred magnetically for 7 hours, and then washed with deionized water several times to remove excess surfactant to obtain an aqueous dispersion of carbon nanotubes.

[0039](3) The carbon nanotube water dispersion obtained in (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com