Process for preparing attapulgite and natural rubber nano composite material

A nano-composite material and attapulgite technology are applied in the field of preparation of mineral and polymer-based nano-composite materials to achieve the effects of reducing costs and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Preparation of attapulgite and natural rubber nanocomposite

[0035] (1) sample

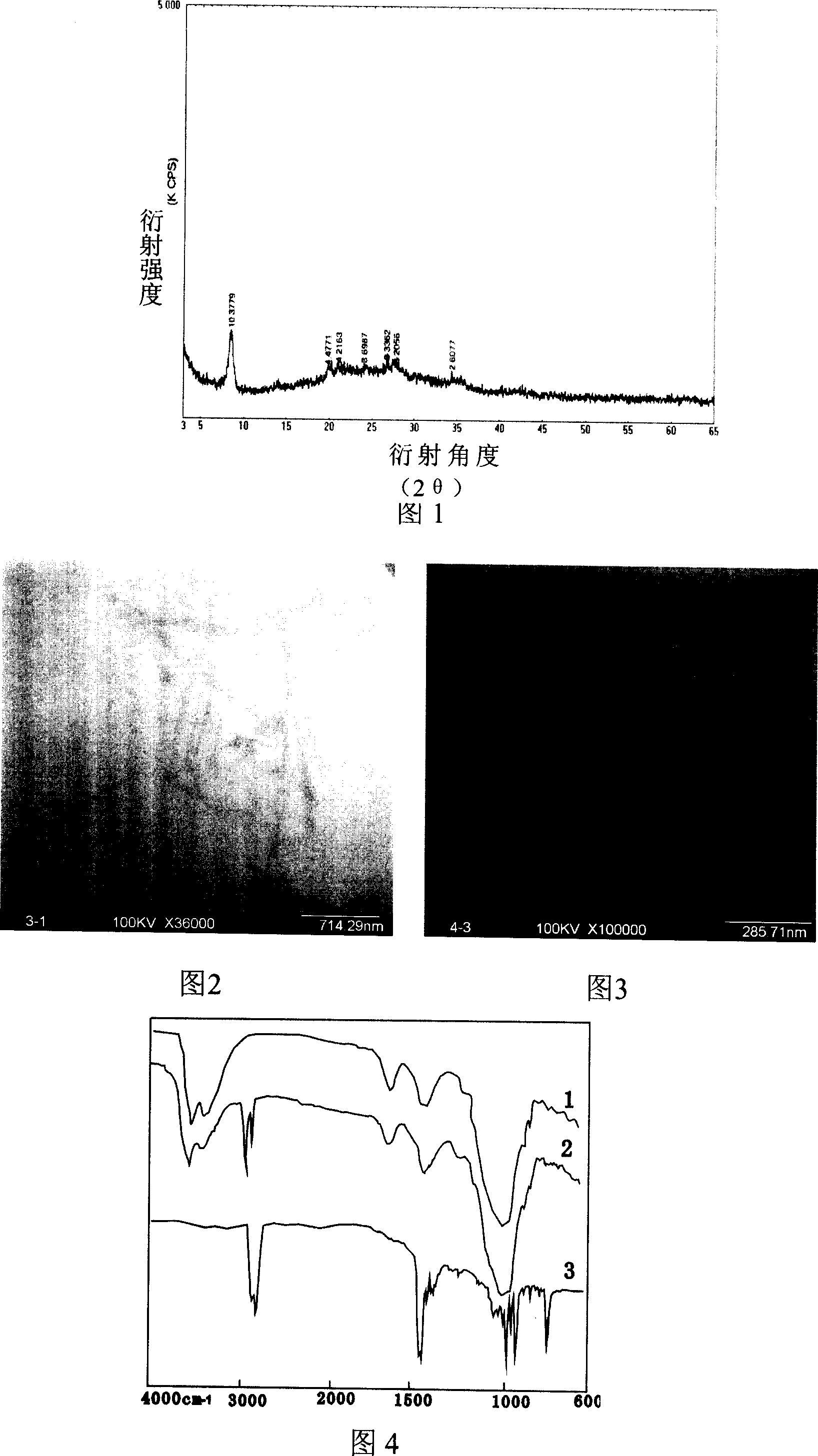

[0036] The attapulgite raw ore is produced in Xuyi, Jiangsu, and the attapulgite purified sample is self-made from the attapulgite raw ore. Figure 1 is the XRD pattern of the attapulgite purified sample. The strongest diffraction peak at d1.03779 nanometers in Figure 1 is the strongest characteristic diffraction peak of attapulgite, and the other diffraction peaks are very weak, indicating that the main phase in the purified sample is attapulgite.

[0037] (2) Reagents

[0038] Sodium polyacrylate, analytically pure, Tianjin Damao Chemical Instrument Supply Station;

[0039] Sodium hexametaphosphate, chemically pure, China Pharmaceutical Group Shanghai Chemical Reagent Company;

[0040] Natural rubber latex, produced in Hainan, solid content 63.05%, PH=9;

[0041] Sulfur, analytically pure, China Rongguang Petroleum Products Co., Ltd.;

[0042] Accelerators M, DM, stear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com