Bioactive glass nano-composite particle with antibacterial effect and disguised efficient hemostatic membrane-like structure and preparation method of bioactive glass nano-composite particle

A bioactive glass, antibacterial technology, applied in the field of biomedical materials, can solve the problems of no wound hemostasis effect, limited applicable wound types, single hemostasis mechanism, etc. The effect of cascade reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] Preparation of macroporous bioactive glass: 1% surfactant cetyl ammonium bromide and 3.5% tetraethyl orthosilicate are dissolved in the mixed ammonia solution of ethanol and ether (water: ethanol: ether: ammonia water=150 :20:40:4), the pH value is 10-12, the temperature is controlled at 20-30°C, and stirred at 800-1000 rpm for 4 hours, the solution is gelled and then gelled to form a gel, the gel is 8000- Centrifuge at 12,000 rpm for 5 minutes to collect samples, dry in vacuum at 30-60°C for 12-24 hours to remove moisture from the prepared wet gel, grind thoroughly, and calcinate at 550°C for 5 hours to remove surfactants and form a macroporous structure.

[0079] Preparation of aminated macroporous bioactive glass: disperse 50% macroporous bioactive glass particles in isopropanol, add 3-aminopropyltriethoxysilane dropwise, the speed is 1 ml / min, 200-500 rpm Stir, cool and reflux for 24-36 hours, centrifuge at 8,000-12,000 rpm for 5 minutes to collect, wash with deioni...

Embodiment 1

[0106] This example relates to the synthesis of macroporous bioactive glass

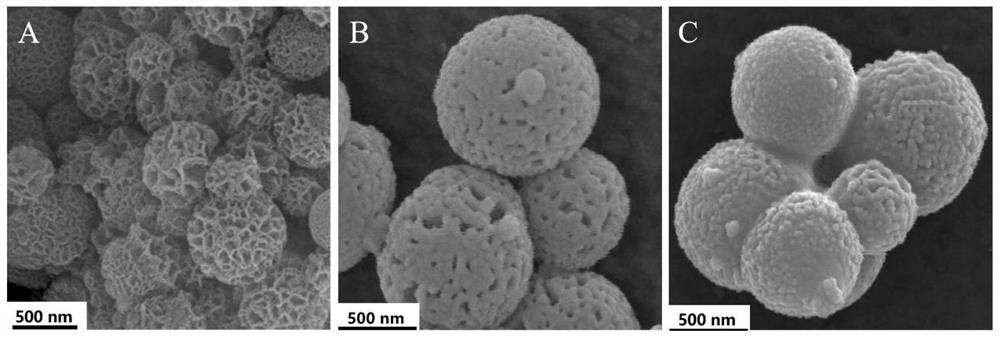

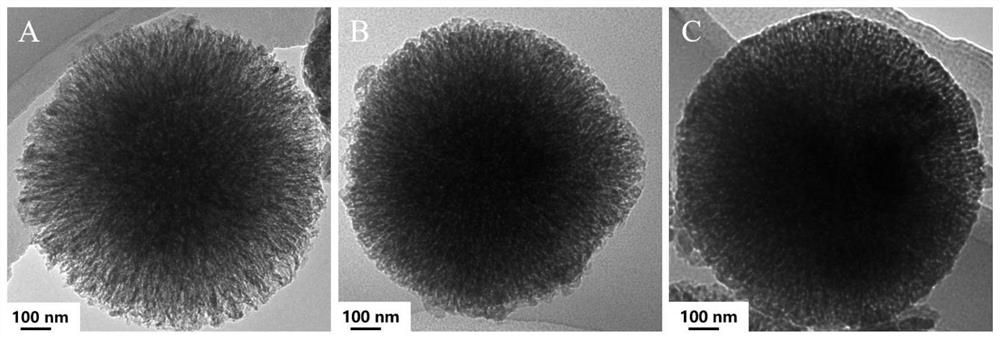

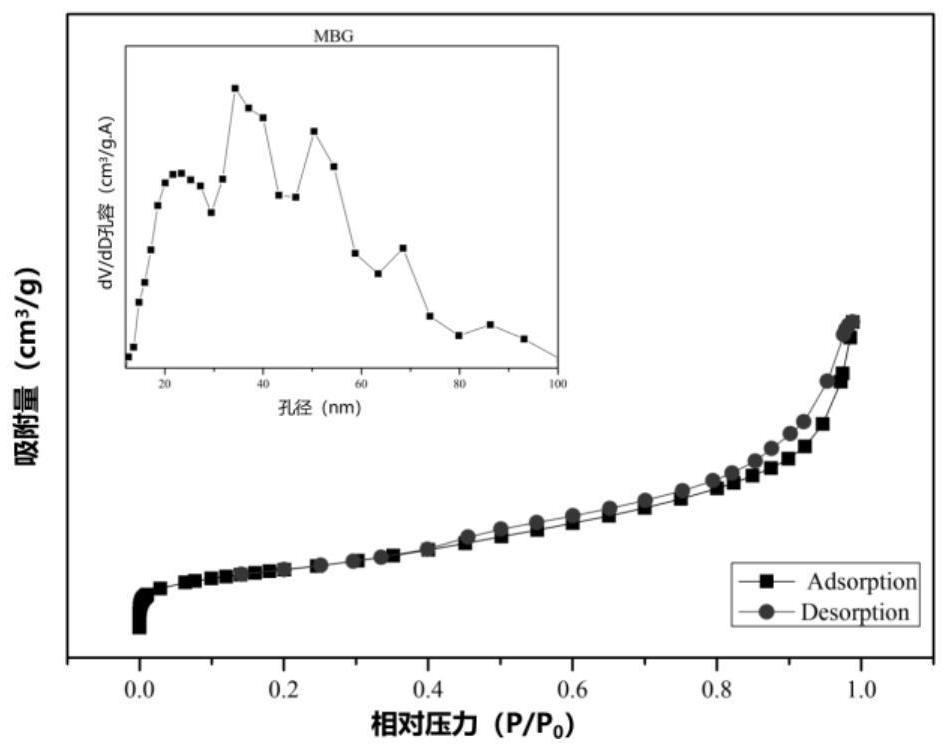

[0107] Add 210mL of 9.5% ethanol and 19% diethyl ether mixed aqueous solution, add 2g of surfactant CTAB, add 4mL of ammonia water dropwise, adjust the pH value to 10-12, add 7.5mL of ethyl orthosilicate TEOS into the syringe pump, weigh 1.4g of Ca(NO 3 ) 2 4H 2 Add O to the above solution, stir at 20-30°C, 1000 rpm for 4 hours, centrifuge at 10,000 rpm for 5 minutes to collect the precipitate, wash with absolute ethanol and deionized water three times, and dry in vacuum for 24-36 hours Afterwards, it is fully ground and fired at 550°C for 5 hours to obtain a macroporous bioactive glass. The diameter size distribution is 400-700nm, the pore size distribution is 50-70nm, and the specific surface area is 242.84m 2 g -1 .

[0108] Scanning electron microscopy ((SEM, JSM-7500F, JEOL, Japan) and transmission electron microscopy (TEM, Talos F200X, FEI, USA) were used to observe the morphology and mac...

Embodiment 2

[0110] This example relates to the synthesis of macroporous bioactive glass

[0111] Add 210mL of 9.5% ethanol and 19% ethylene glycol ethyl ether mixed aqueous solution, add 2g of surfactant CTAB, add 4mL of ammonia water drop by drop, adjust the pH value to 10-12, add 7.5mL of ethyl orthosilicate TEOS to the syringe pump , weighed 1.4g of Ca(NO 3 ) 2 4H 2 Add O to the above solution, stir at 20-30°C, 1000 rpm for 4 hours, centrifuge at 10,000 rpm for 5 minutes to collect the precipitate, wash with absolute ethanol and deionized water three times, and dry in vacuum for 24-36 hours Afterwards, it is fully ground and fired at 550°C for 5 hours to obtain a macroporous bioactive glass. Its diameter size distribution is 300-400nm, pore size distribution is 20-40nm, specific surface area is 698.36m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com