Bio-based polyhydric alcohol prepared by using rape seed oil

A bio-based polyol, rapeseed oil technology, applied in the preparation of carboxylate, the preparation of organic compounds, organic chemistry and other directions, can solve the problems of inconvenient purchase, limited production capacity, affecting product production, etc., to achieve convenient purchase, environmental protection The effect of low pollution and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

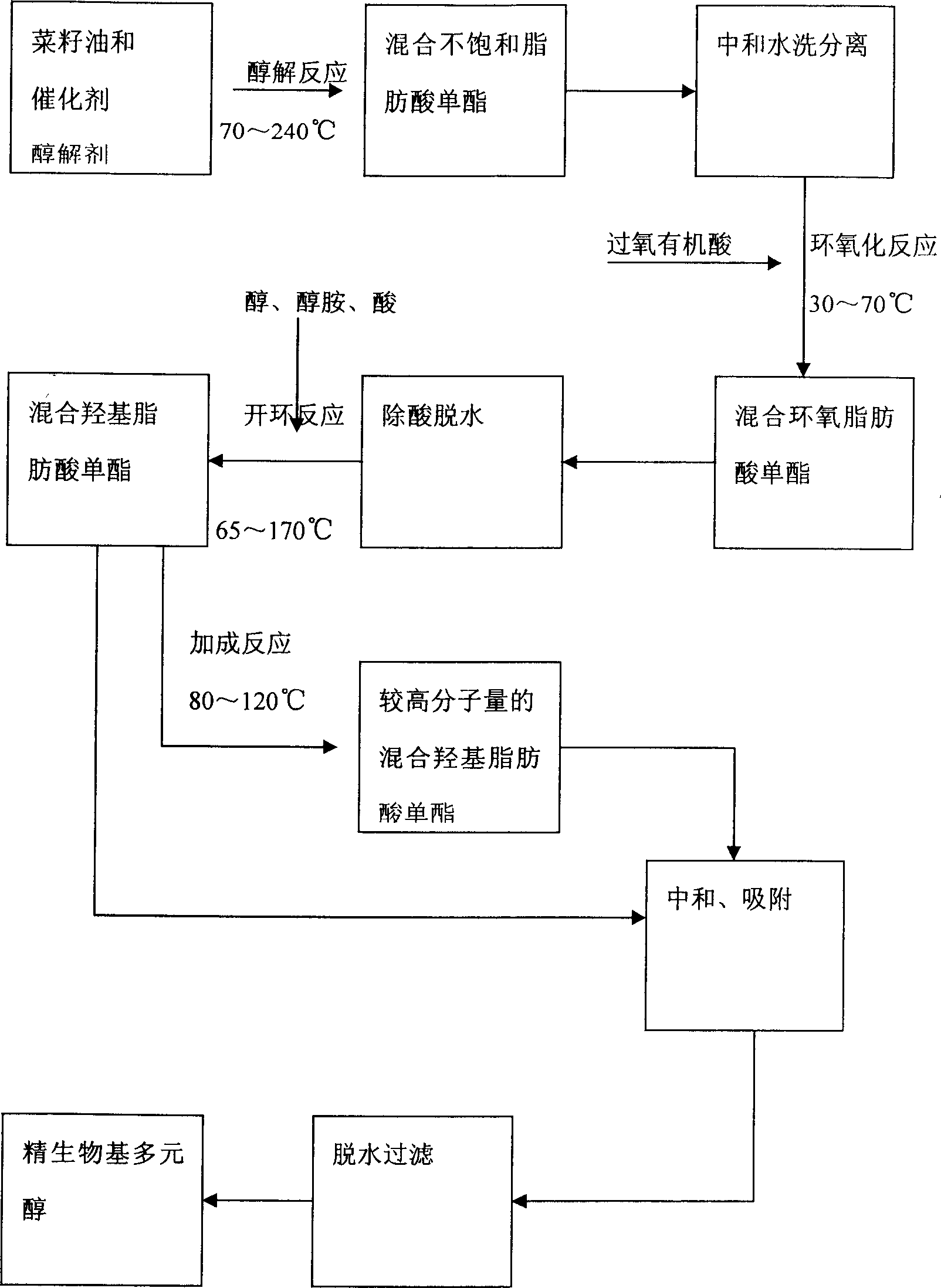

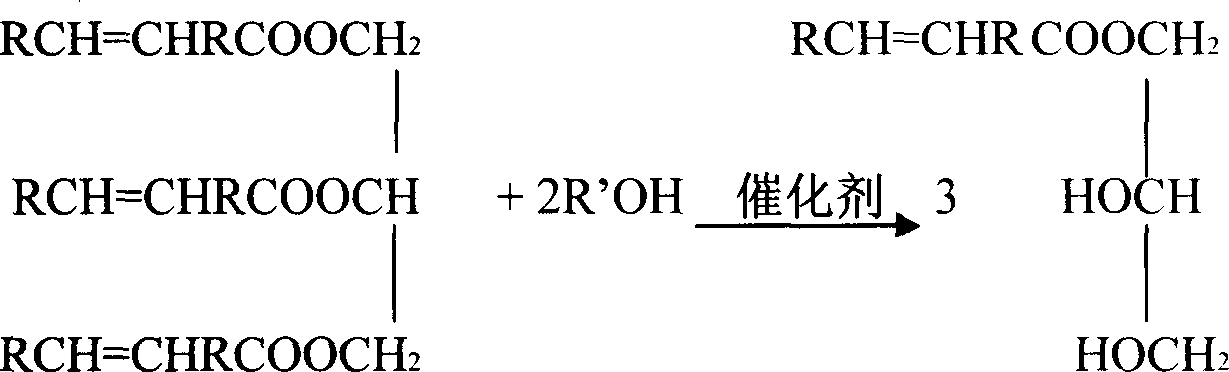

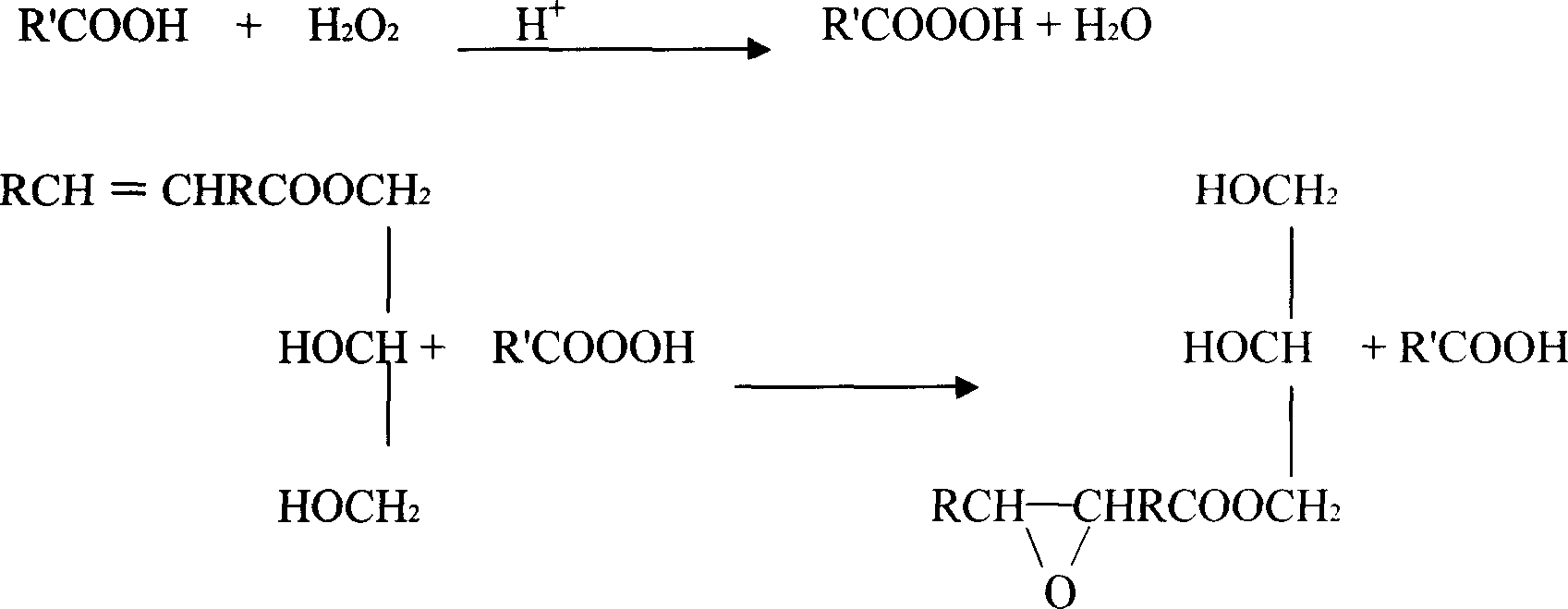

Method used

Image

Examples

Embodiment 1

[0064] Add 1000g of refined rapeseed oil, 211g of glycerol, and 1.1g of potassium hydroxide into a 2L glass kettle, stir, heat up to 120-240°C, and carry out alcoholysis reaction for 5 hours. Leave it on for 3-6 hours. Cool down to 75°C, add 3.6g of 50% phosphoric acid, keep for 30 minutes, add 250g of water, stir for 15 minutes, separate after standing, add 250g of water, stir for 15 minutes, separate after standing, and obtain mixed unsaturated fatty acid monoester 1015g.

Embodiment 2

[0066] Get mixed unsaturated fatty acid monoester 1185g and 250 grams of formic acid (80%), 60 grams of acid clay in the above-mentioned embodiment 1 and add in the glass kettle of 2L, stir, add dropwise the 37% hydrogen peroxide of 376 grams, at 30 ~ React at 70°C for 6-10 hours, separate the upper layer after standing still; control the temperature of the upper layer mixed epoxy fatty acid monoester at 70-80°C, wash with 5% sodium carbonate twice, then wash with saturated brine and soft water Each 2 times, finally remove water with the method of underpressure distillation, obtain mixed epoxy fatty acid monoester, detect its epoxy value 4.50%.

Embodiment 3

[0068] Mix the product in Example 2 with 1245 g of epoxy fatty acid monoester, add 420 g of diethylene glycol, and 4.2 g of potassium hydroxide, add it to a 2L glass kettle, stir and heat up, and control the reaction temperature at 65 to 170° C., and the reaction time is 5 ~9 hours. Afterwards, it is refined, and the specific method is as follows: add 13.7g of 50% phosphoric acid for neutralization for 15 minutes, add 2g of magnesium silicate for adsorption, and then dehydrate for 60 minutes at a vacuum degree of 100-750KPa and a temperature of 80-120°C, and filter Finally, the product 1400g refined bio-based polyol was obtained, and the hydroxyl value was 475mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com