Epoxy resin composition, metal-based copper-clad plate and manufacturing method thereof

A technology of epoxy resin and composition, applied in epoxy resin glue, metal layered products, chemical instruments and methods, etc., can solve the problems of uneven performance, low reliability, poor stability, etc., and achieve high production efficiency , low cost, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

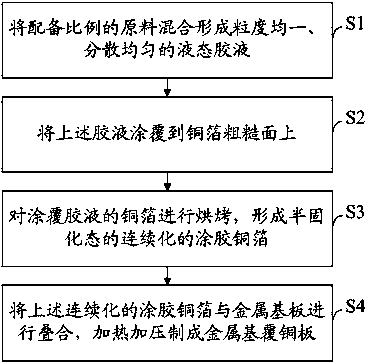

[0059] Weigh 100 parts by mass of epoxy resin (bisphenol A type epoxy resin), 10 parts by mass of thermoplastic resin / rubber (polyphenylene oxide), 20 parts by mass of curing agent (aliphatic polyamine), 2 Parts by mass of curing accelerator (2-methylimidazole), 2 parts by mass of additives (aluminate coupling agent), 30 parts by mass of thermally conductive filler (magnesium oxide), 5 parts by mass of organic solvent (acetone) in In a clean container, stir and disperse at high speed at room temperature for 5 hours to form a liquid glue with uniform particle size and uniform dispersion. Use imported ultra-precision coating equipment to coat the above glue on the rough surface of the copper foil with a coating thickness of 100 μm, and bake it at a temperature of 70-185°C for 10 minutes to form a semi-cured glue-coated copper foil. Then take a piece of the prepared glue-coated copper foil, laminate its glued surface with the metal substrate, heat and press to make a metal-based ...

Embodiment 2

[0061] Weigh 100 parts by mass of epoxy resin (bisphenol F epoxy resin), 25 parts by mass of thermoplastic resin / rubber (polyamide resin), 20 parts by mass of curing agent (alicyclic polyamine), 2 parts by mass Curing accelerator (2-ethyl-4-phenylimidazole), 5 parts by mass of additive (polyurethane), 170 parts by mass of thermally conductive filler (alumina), 15 parts by mass of organic solvent (methanol) in a clean container In the process, stir and disperse at high speed at room temperature for 8 hours to form a liquid glue with uniform particle size and uniform dispersion. Use imported ultra-precision coating equipment to coat the above glue on the rough surface of the copper foil with a coating thickness of 75 μm, and bake it at a temperature of 80-190°C for 2 minutes to form a semi-cured glue-coated copper foil. Then take a piece of the prepared glue-coated copper foil, laminate its glued surface with the metal substrate, heat and press to make a metal-based copper-clad ...

Embodiment 3

[0063] Weigh 100 parts by mass of epoxy resin (biphenyl type epoxy resin), 45 parts by mass of thermoplastic resin / rubber (nitrile rubber), 20 parts by mass of curing agent (diacetone acrylamide), 2 parts by mass of curing agent Accelerator (imidazole), 8 parts by mass of additive (soluble castor oil), 500 parts by mass of thermally conductive filler (aluminum oxide), 30 parts by mass of organic solvent (toluene) in a clean container, high-speed stirring and dispersion at room temperature for 6 After hours, a liquid glue with uniform particle size and uniform dispersion is formed. Use imported ultra-precision coating equipment to coat the above glue on the rough surface of the copper foil with a coating thickness of 150 μm, bake at 75-160°C for 20 minutes to form a semi-cured glue-coated copper foil, and then Take a piece of the prepared glue-coated copper foil, laminate its glued surface with the metal substrate, heat and press to make a metal-based copper-clad laminate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com