Refined fertilizer produced from sludge and producing method thereof

A technology of organic fertilizer and sludge, which is applied in the field of refined organic fertilizer and its preparation, can solve the problems affecting the rapid reproduction of compost microorganisms, slow humification speed, ammonia volatilization loss, etc., to achieve good health, less nutrient loss, The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

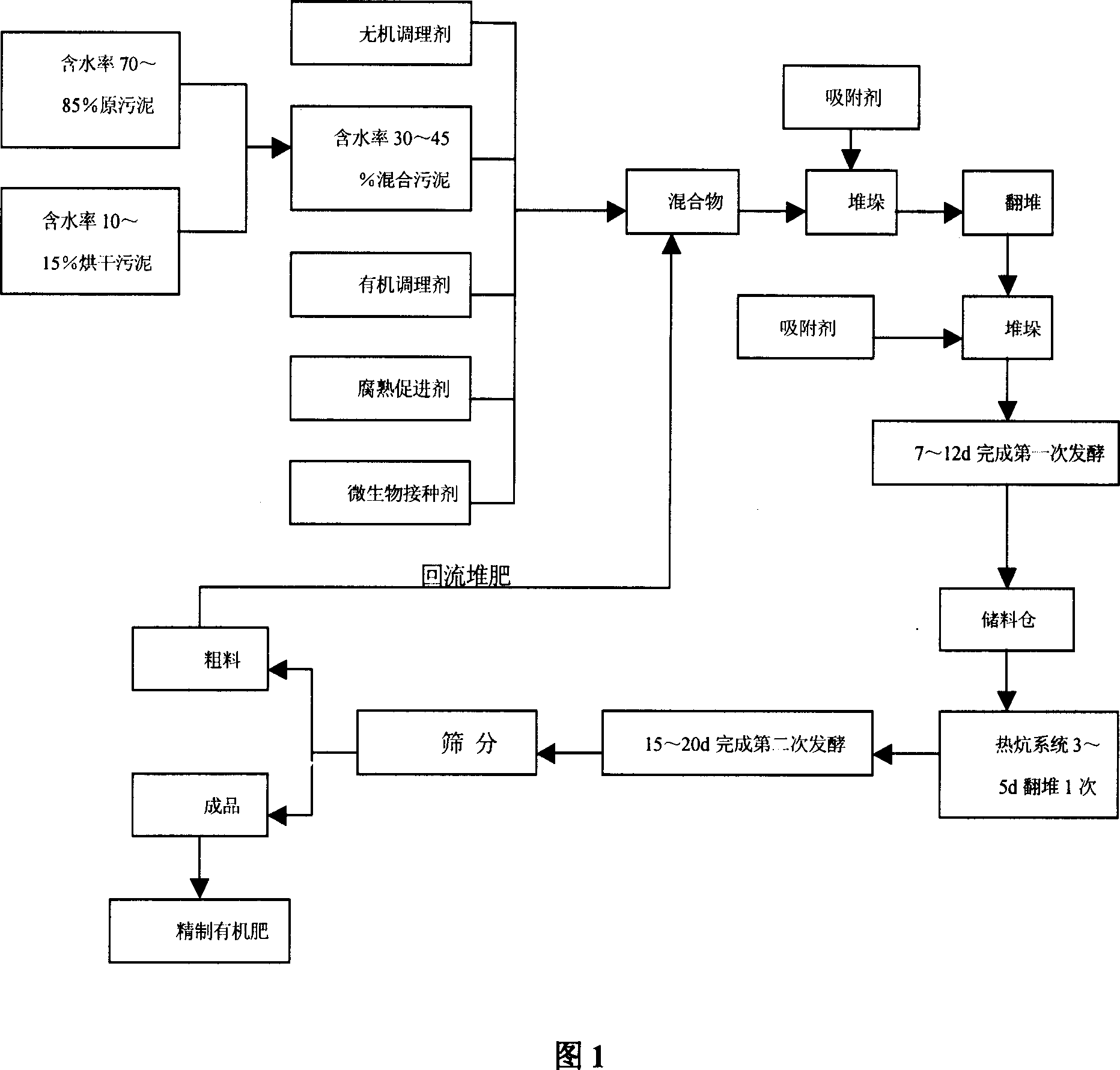

Method used

Image

Examples

Embodiment 1

[0041] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0042] (1) Mix the raw sludge with a moisture content of 78% and the dried sludge with a moisture content of 14% in a volume ratio of 1:2.5, so that they are uniformly mixed to form a mixed sludge with a moisture content of 32%.

[0043] (2) Select 5000kg (60%, mass percentage, the same below) of the above-mentioned mixed sludge and 1750kg (21%) organic conditioner (60% mushroom dregs, 25% crop straw, 15% cow dung), 667kg (8% ) inorganic conditioner (fly ash 75%, phosphate rock powder 25%), 800kg (9.6%) decomposing accelerator (yeast waste liquid 40%, distiller's grains 50%, sugar waste liquid 8%, sugar 2%) and 33kg (0.4%) Mix the microbial inoculant, enzyme and quick rot agent evenly. The water content is 40%, the C / N is 29:1, the organic matter content is 52%, and the pH value is about 7.

[0044](3) The above-mentioned compost materials are piled up, the pile...

Embodiment 2

[0048] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0049] (1) Mix the raw sludge with a moisture content of 80% and the dried sludge with a moisture content of 10% in a volume ratio of 1:1, so that they are uniformly mixed to form a mixed sludge with a moisture content of 45%.

[0050] (2) select 10000kg (69%) above-mentioned mixed sludge and 2899kg (20%) organic conditioner (litter 70%, soy sauce residue 15%, humic acid 15%), 725kg (5%) inorganic conditioner ( Fly ash 50%, phosphate rock powder 50%), 609kg (4.2%) decomposing accelerator (yeast waste liquid 60%, distiller's grains 20%, sugar refining waste liquid 8%, granulated sugar 1%, monosodium glutamate waste liquid 11%) and 87kg (0.6%) microbial inoculant VT-1000 bacterial agent was mixed evenly. The water content is 43%, the C / N is 26:1, the organic matter content is 45%, and the pH value is about 7.

[0051] (3) The above-mentioned compost materials are ...

Embodiment 3

[0055] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0056] (1) Mix the raw sludge with a moisture content of 80% and the dried sludge with a moisture content of 15% in a volume ratio of 1:3, so that they are uniformly mixed to form a mixed sludge with a moisture content of 31%.

[0057] (2) select 10000kg (60%) above-mentioned mixed sludge and 3333kg (20%) organic conditioner (litter 70%, soy sauce residue 15%, humic acid 15%), 2250kg (13.5%) inorganic conditioner ( Fly ash 50%, phosphate rock powder 50%), 833kg (5%) decomposing accelerator (yeast waste liquid 60%, distiller's grains 21%, sugar refining waste liquid 8%, granulated sugar 1%, monosodium glutamate waste liquid 10%) and 83kg (0.5%) of microbial inoculants (50% of enzyme bacteria quick-rot agent, 50% of VT-1000 bacterial agent) were mixed evenly. The water content is 43%, the C / N is 25:1, the organic matter content is 46%, and the pH value is about 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com