Cement based capillary crystalline high-performance waterproofing powder and application thereof

A permeable crystallization, cement-based technology, applied in the field of cement-based permeable crystalline waterproof materials, can solve the problems of low manufacturing cost and production efficiency, poor waterproof effect, difficult factory production, etc., to improve workability, reduce shrinkage, Reduce the effect of flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

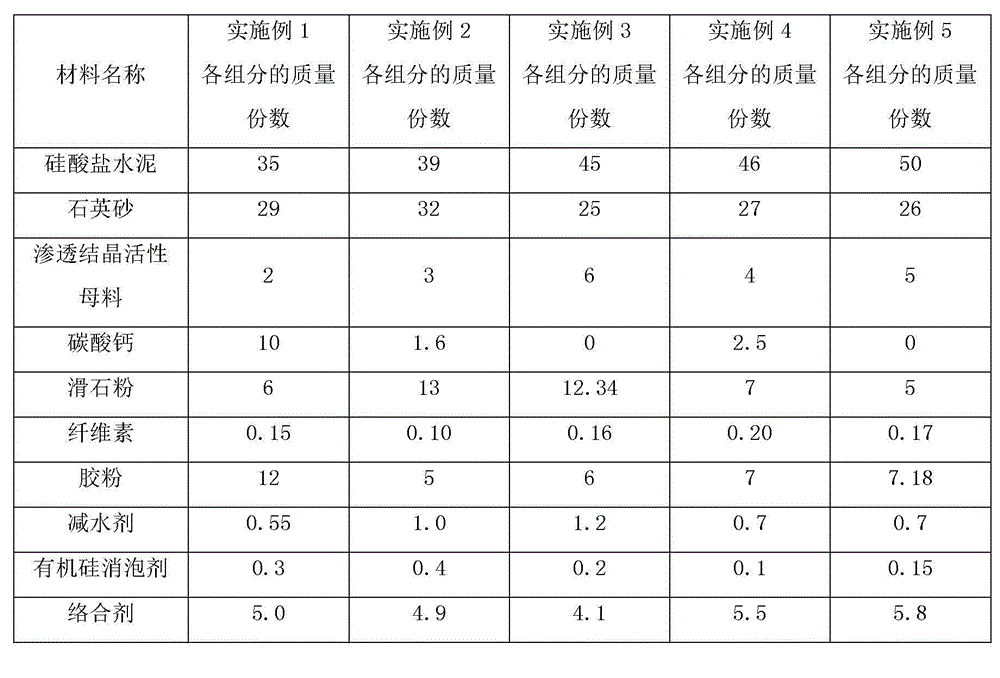

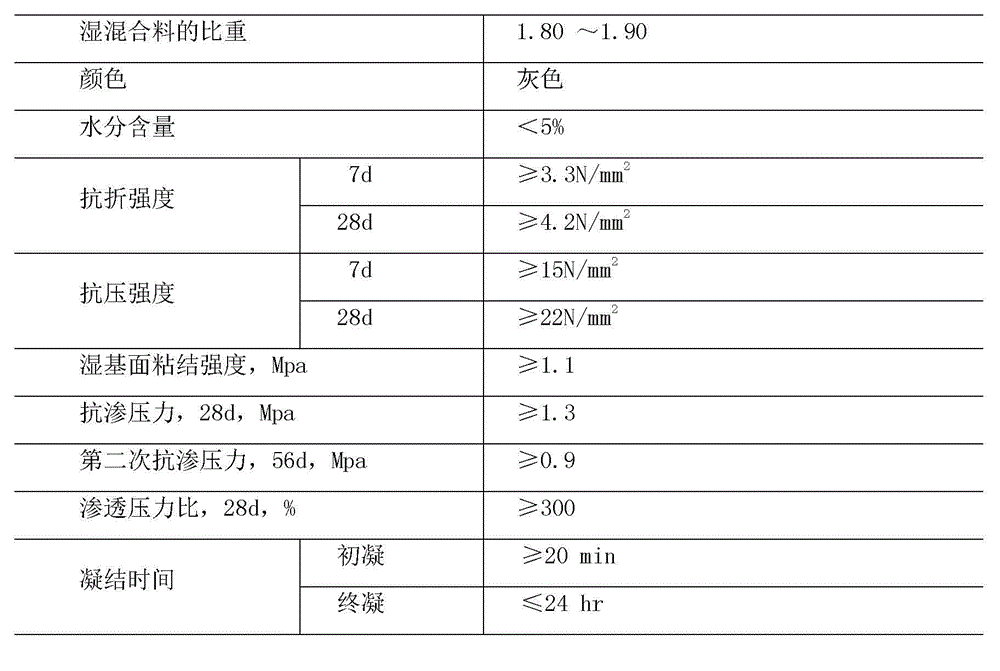

[0029] In specific implementation, the raw material composition of cement-based permeable crystalline high-performance waterproof material is listed in Table 1 according to parts by mass:

[0030] Table 1 Component ratio of cement-based permeable crystalline high-performance waterproof materials

[0031]

[0032] The active masterbatch contains calcium carbonate and calcium chloride, the mass ratio of calcium carbonate and calcium chloride is 1:1, and the total amount of calcium carbonate and calcium chloride is not less than 97% of the osmotic crystallization active masterbatch by mass percentage. %; Cellulose is non-ionic cellulose hydroxypropyl methyl ether; Rubber powder is rubber powder obtained by copolymerization of vinyl tertiary carbonate and vinyl ester at a ratio of 1:2.27 in parts by mass; Water reducer is Powdered naphthalene-based water reducer, commonly used naphthalenesulfonate formaldehyde condensate; Portland cement particle size 0.025-0.04mm; quartz sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com