Technology for producing wall material by using waste

A wall and waste technology, applied in the field of new-type non-burning building materials, can solve the problems of destroying the original structure and ecological balance of the land, not being able to arbitrarily process and revise, and wasting limited energy, so as to save valuable land resources and physical strength. Enhance and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

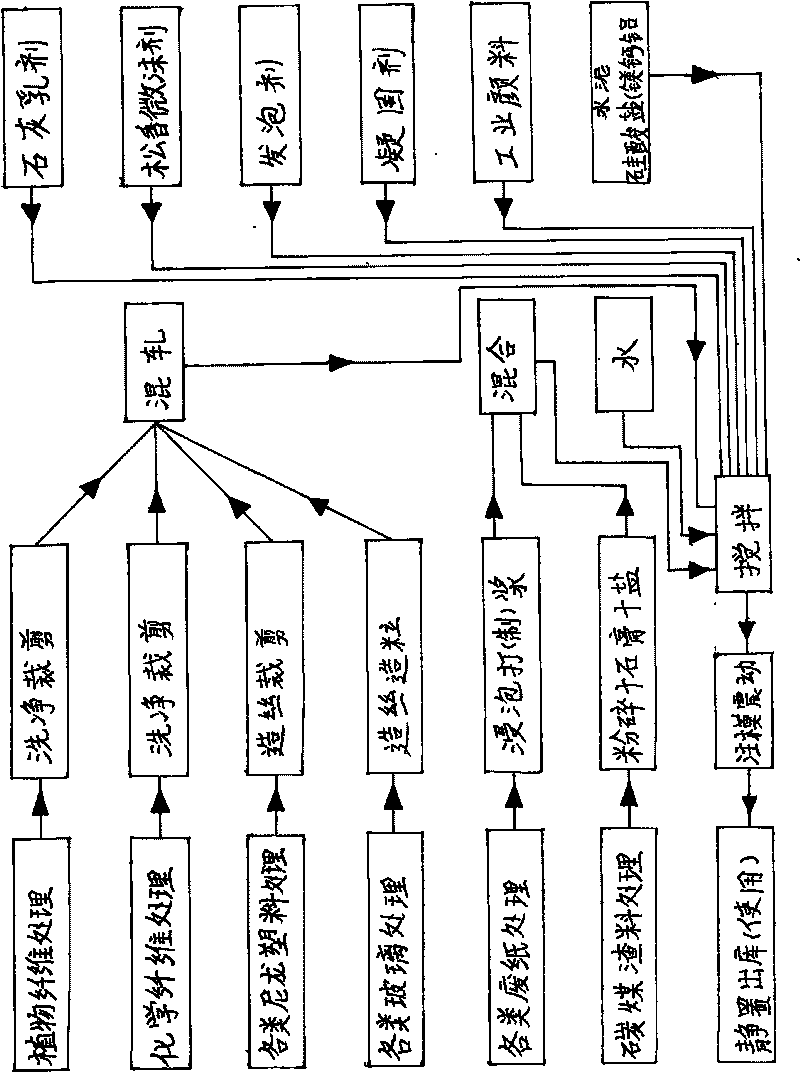

[0009] See Process Flow Diagram 1, which illustrates the basic procedure categories for its materials. Fig. 2 is the waste velvet figure except carbon cinder material. The processed velvet is then cut to the required length specifications. The specific production of velvet is as follows:

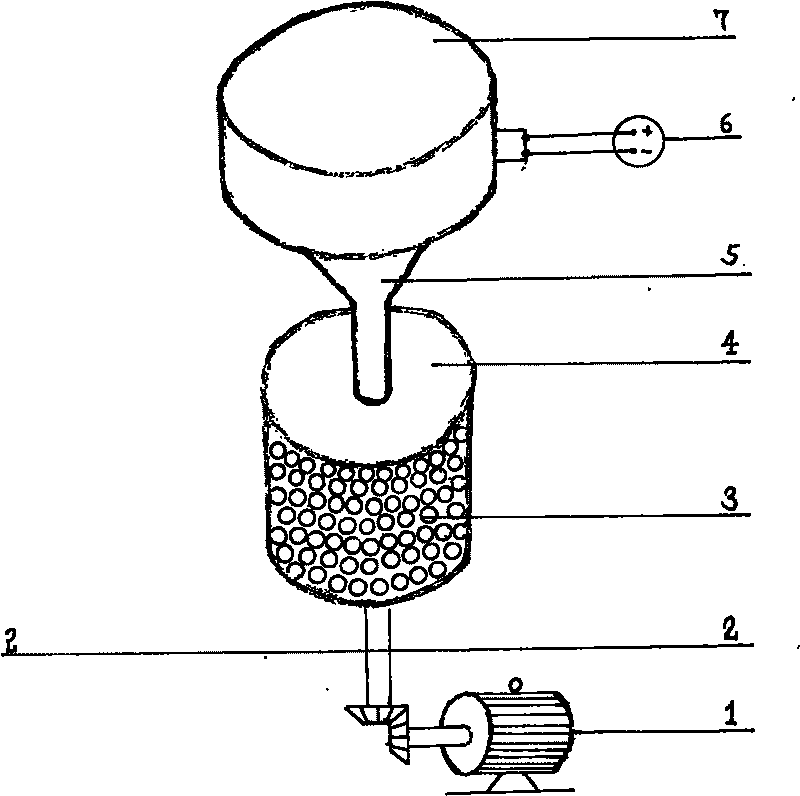

[0010] Firstly, the waste is processed through primary processing such as breaking into powder or block. Then put it into the hot melting furnace 7, fully melt into a viscous liquid state, and then pass through the discharge pipe 5 to the high-speed centrifugal rotating container 4, and the melted material is poured out through the spinning hole 3, and becomes velvet, that is, marshmallow silk shape, and then processed and cut to the required length specifications can be used. Each kind of waste should be processed and melted separately, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com