Patents

Literature

38 results about "Contact phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

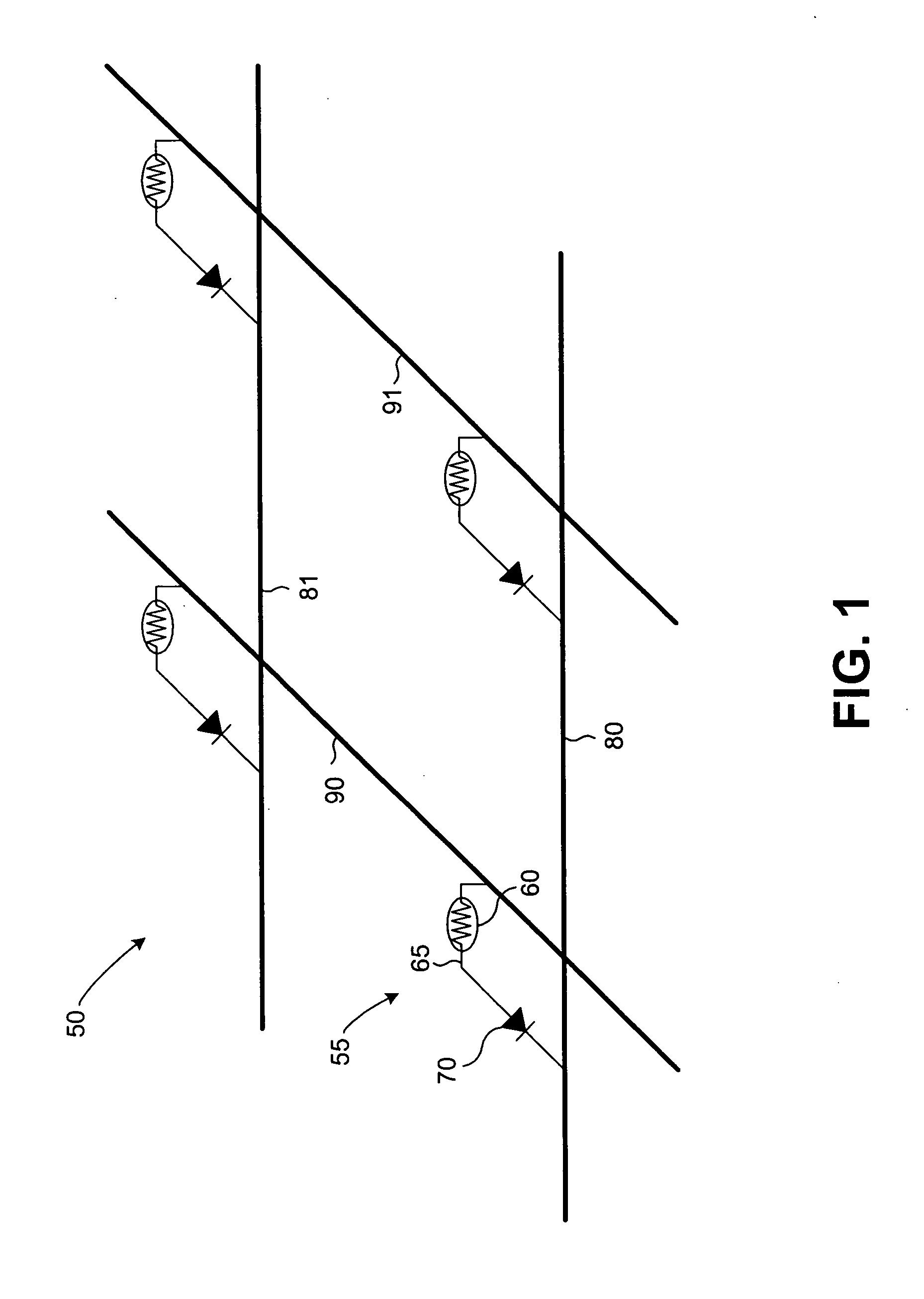

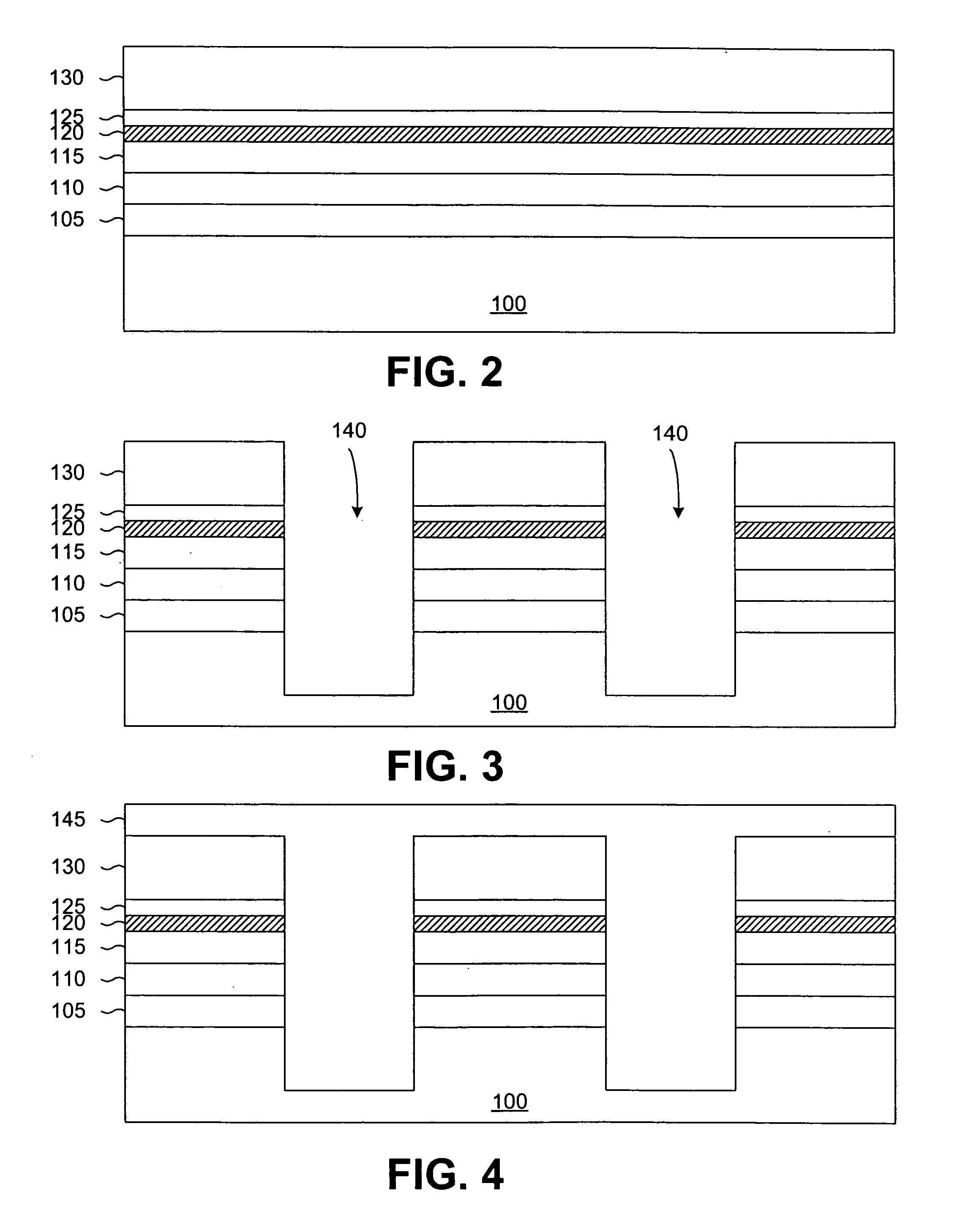

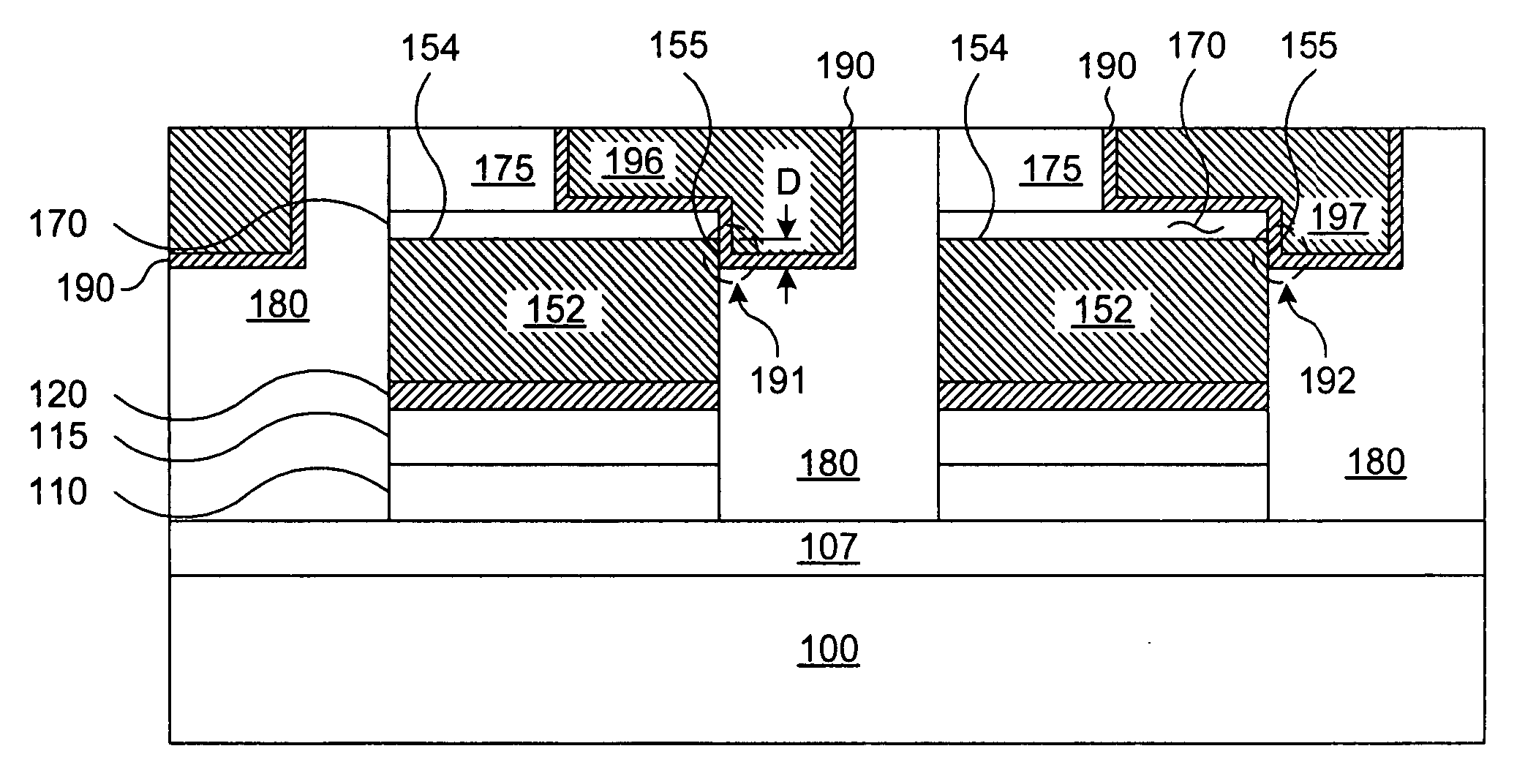

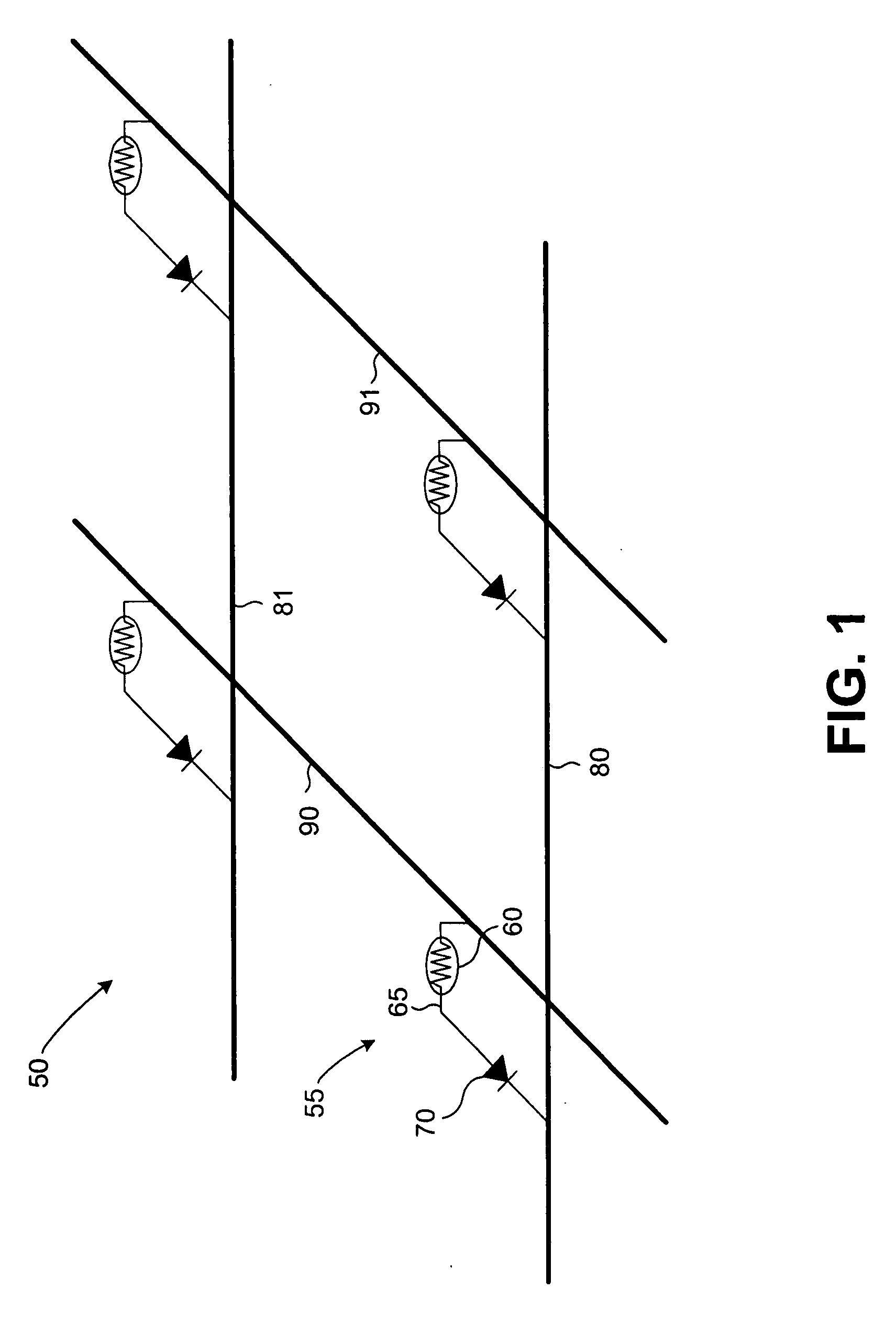

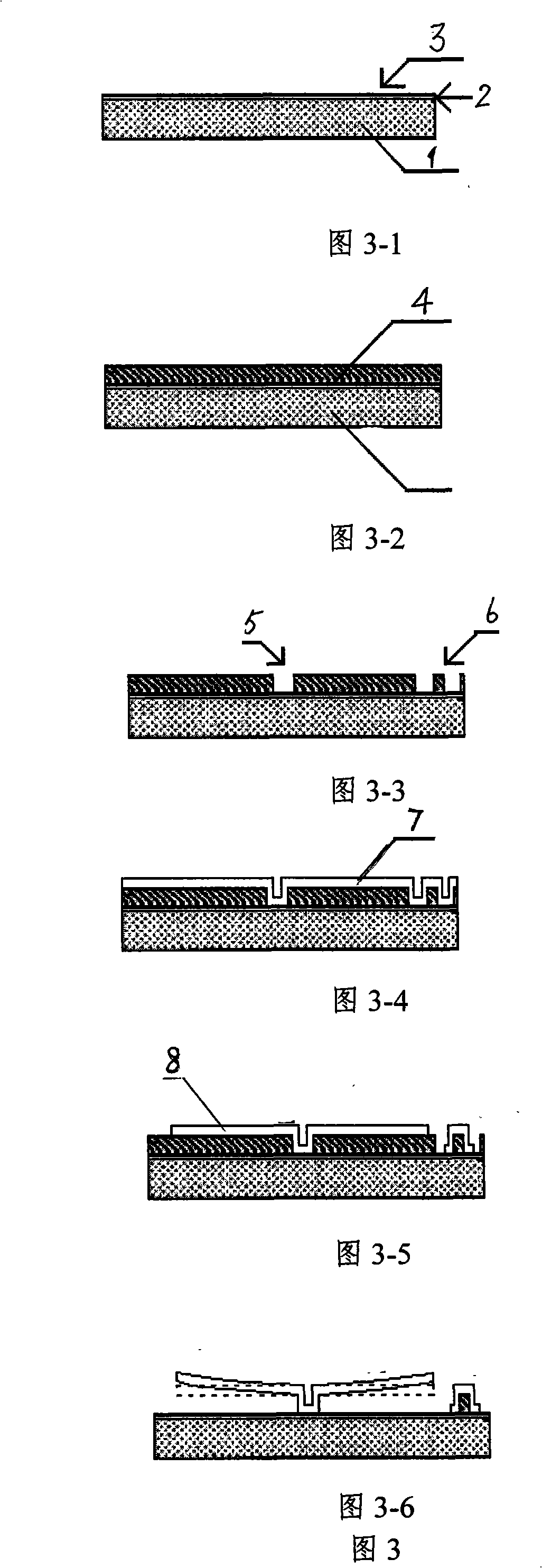

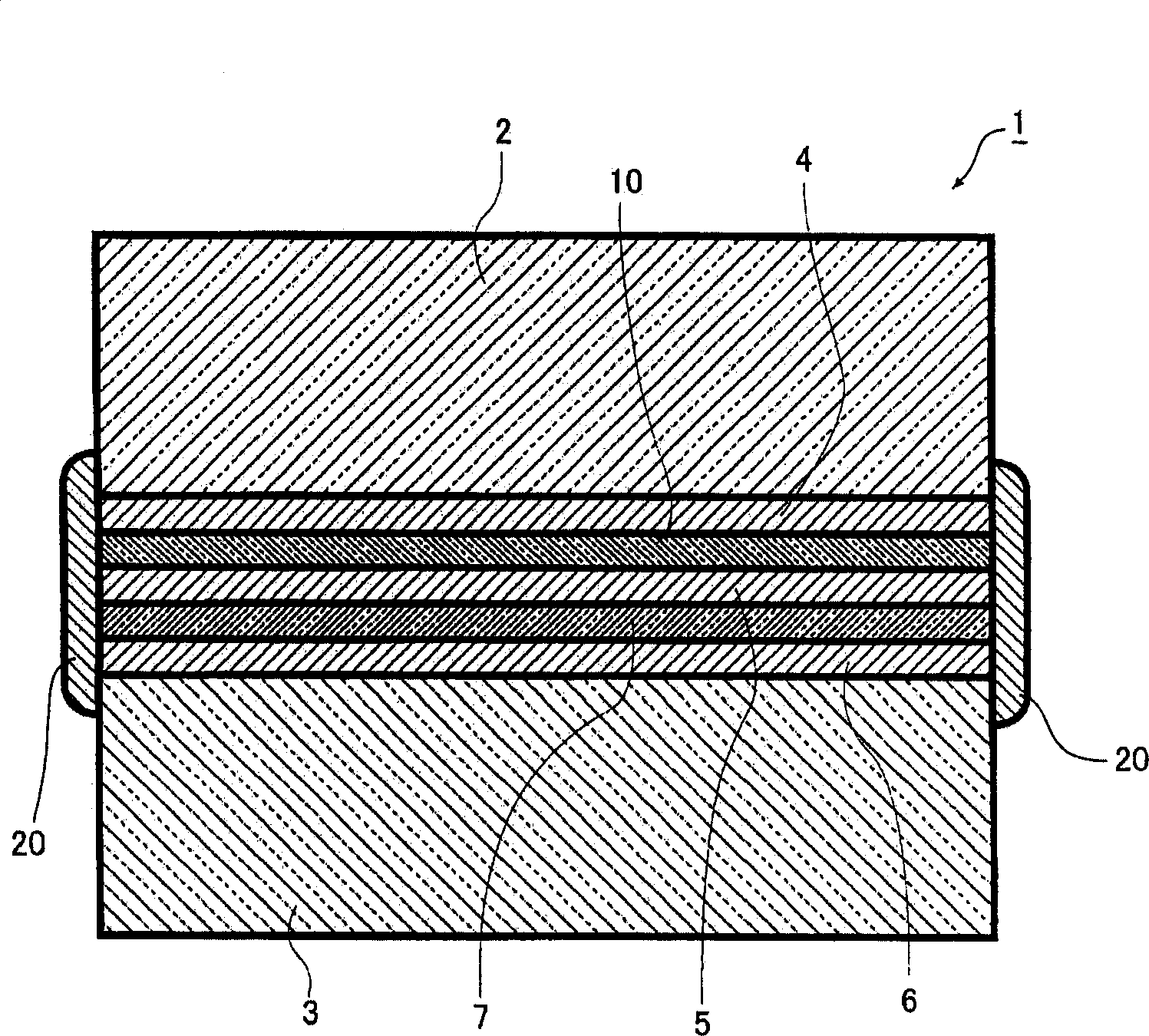

Common word line edge contact phase-change memory

InactiveUS7364935B2Solid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryCommon word

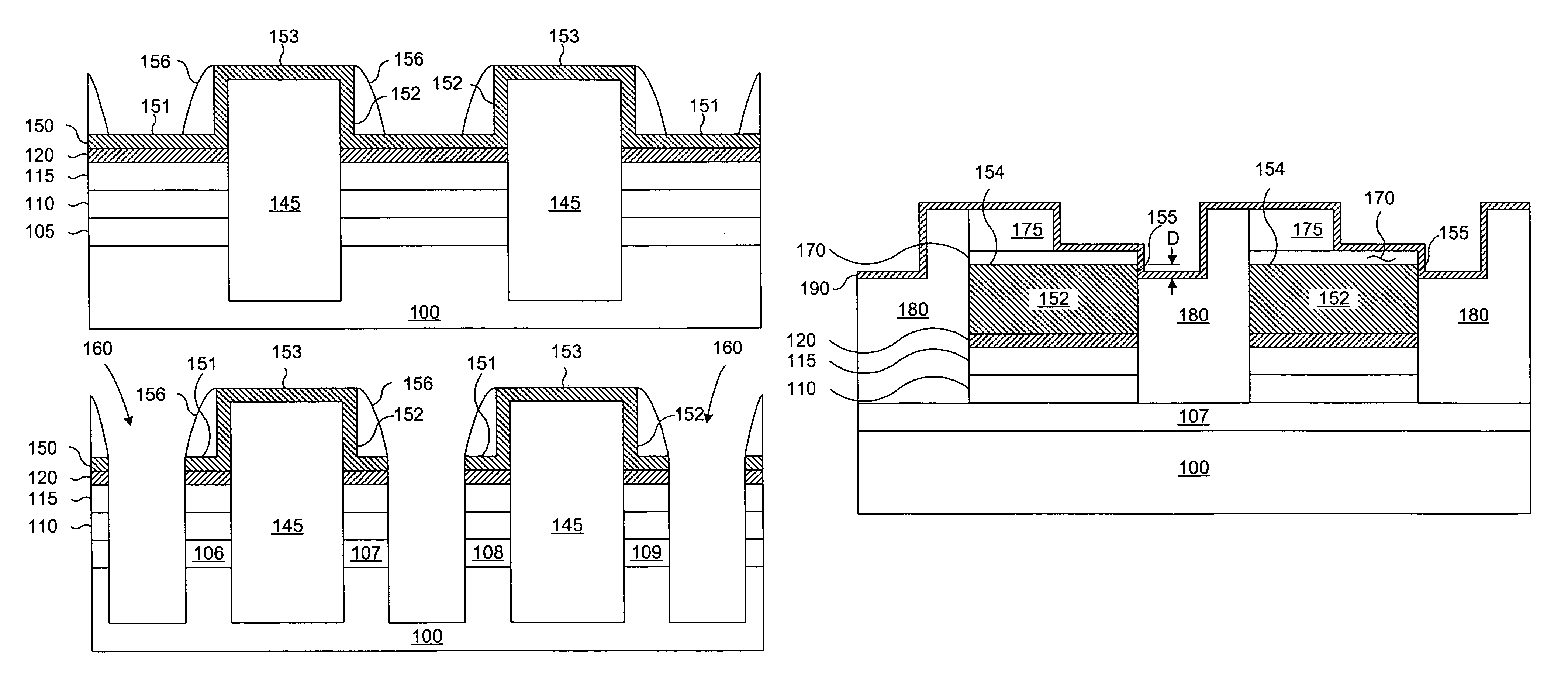

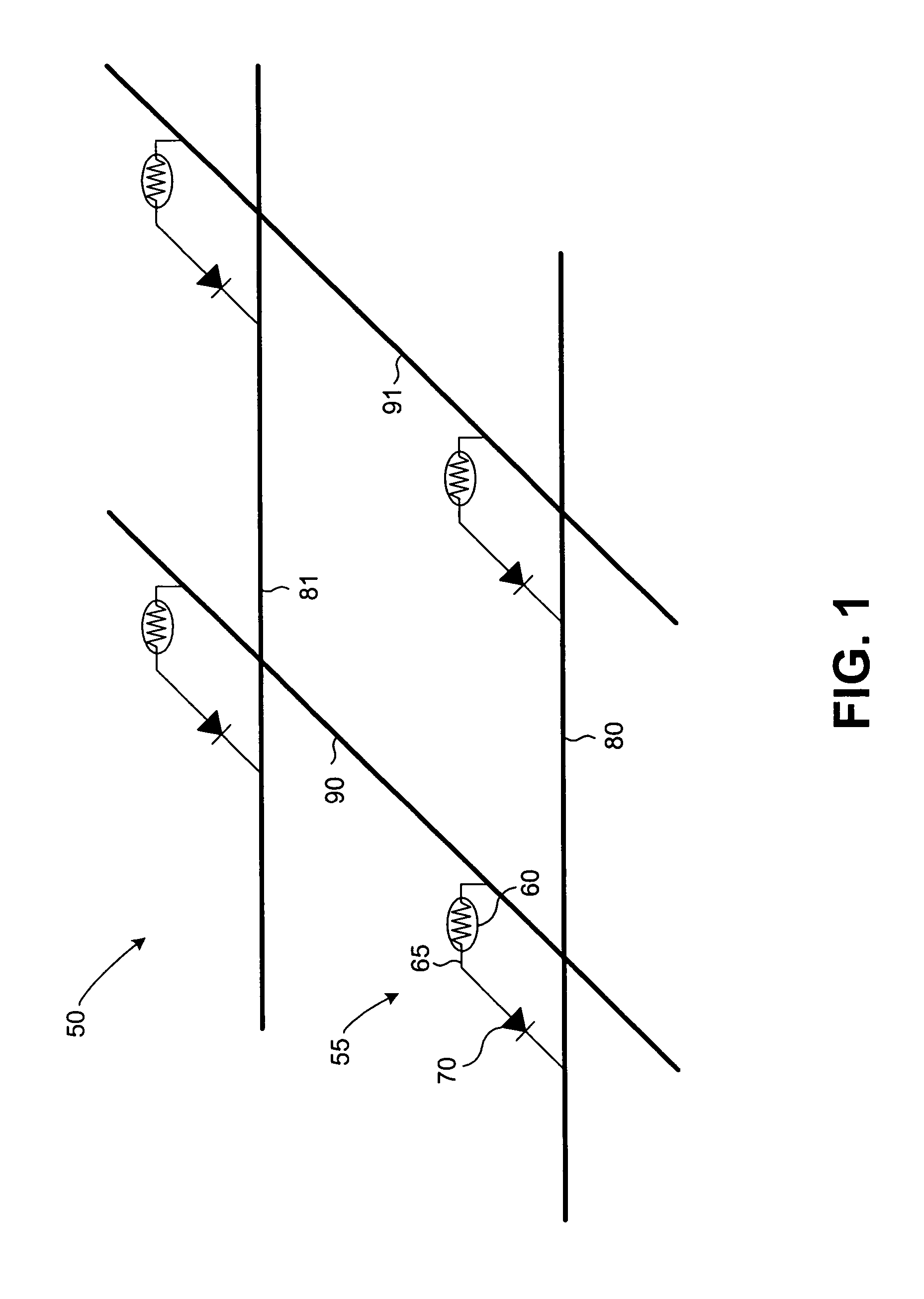

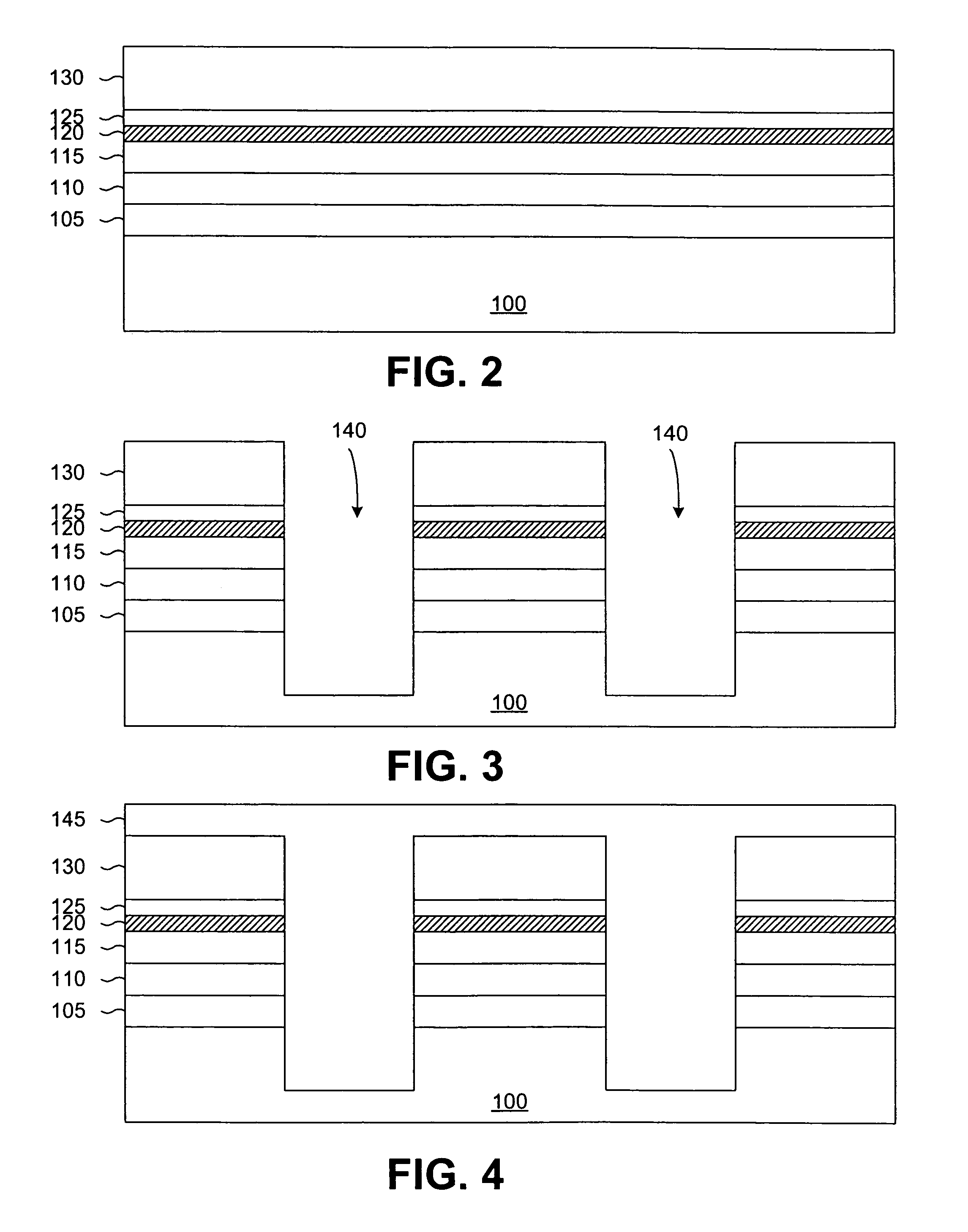

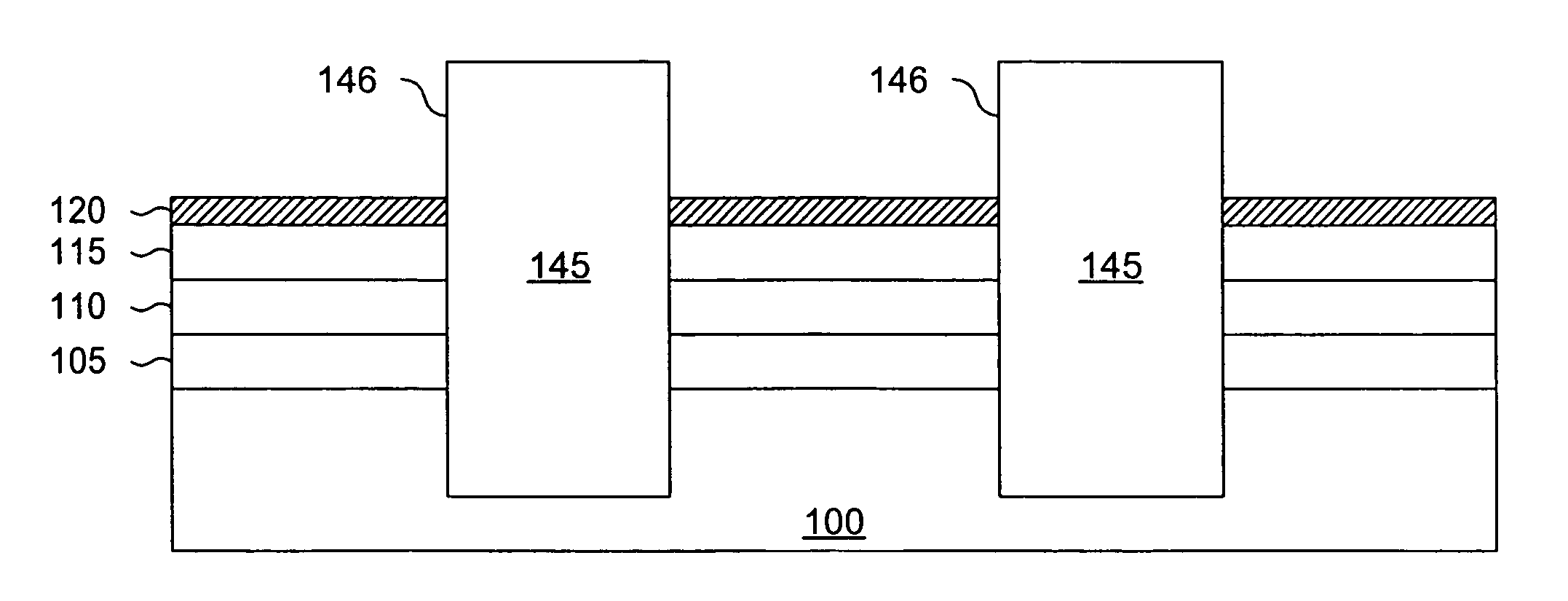

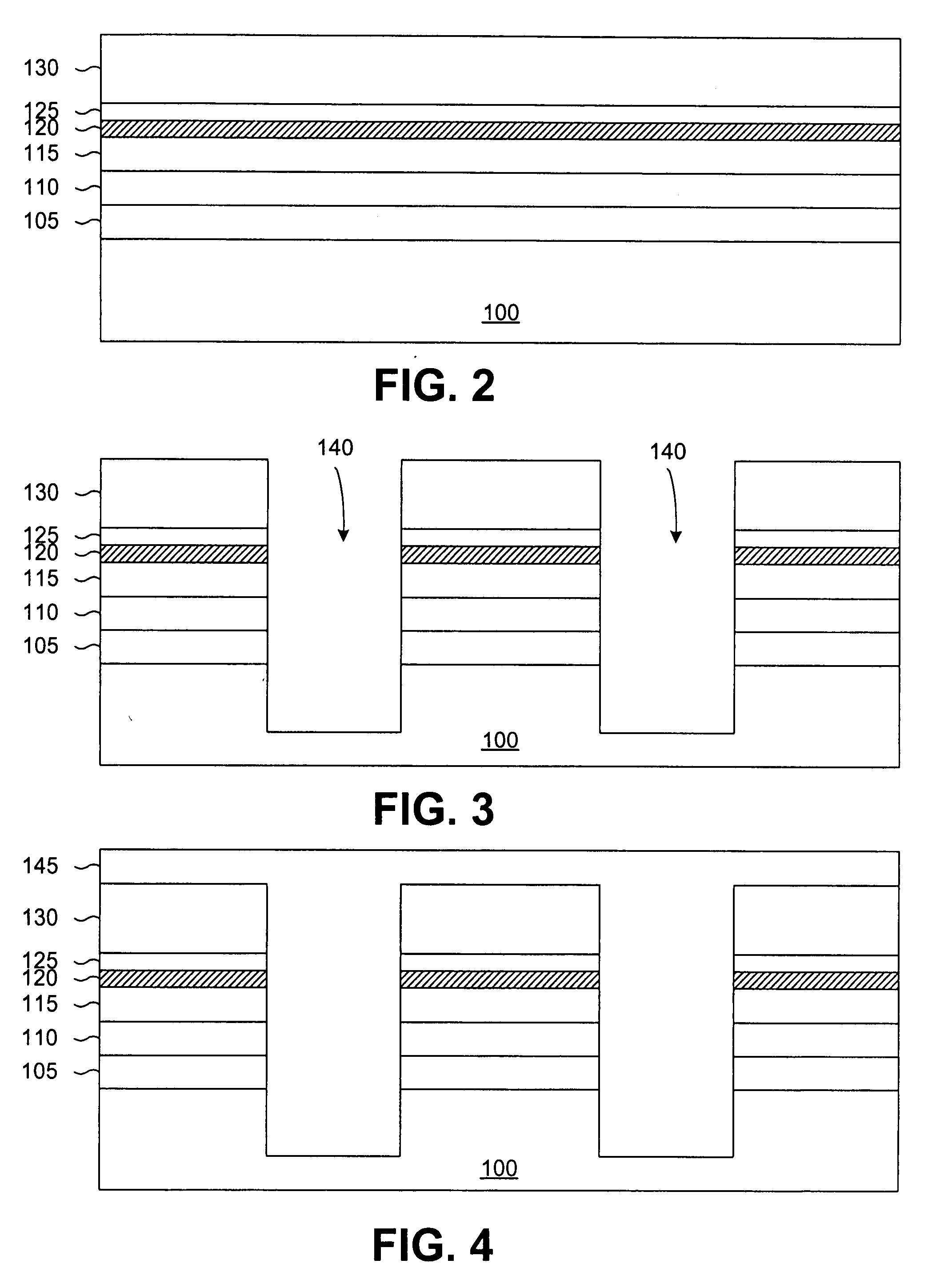

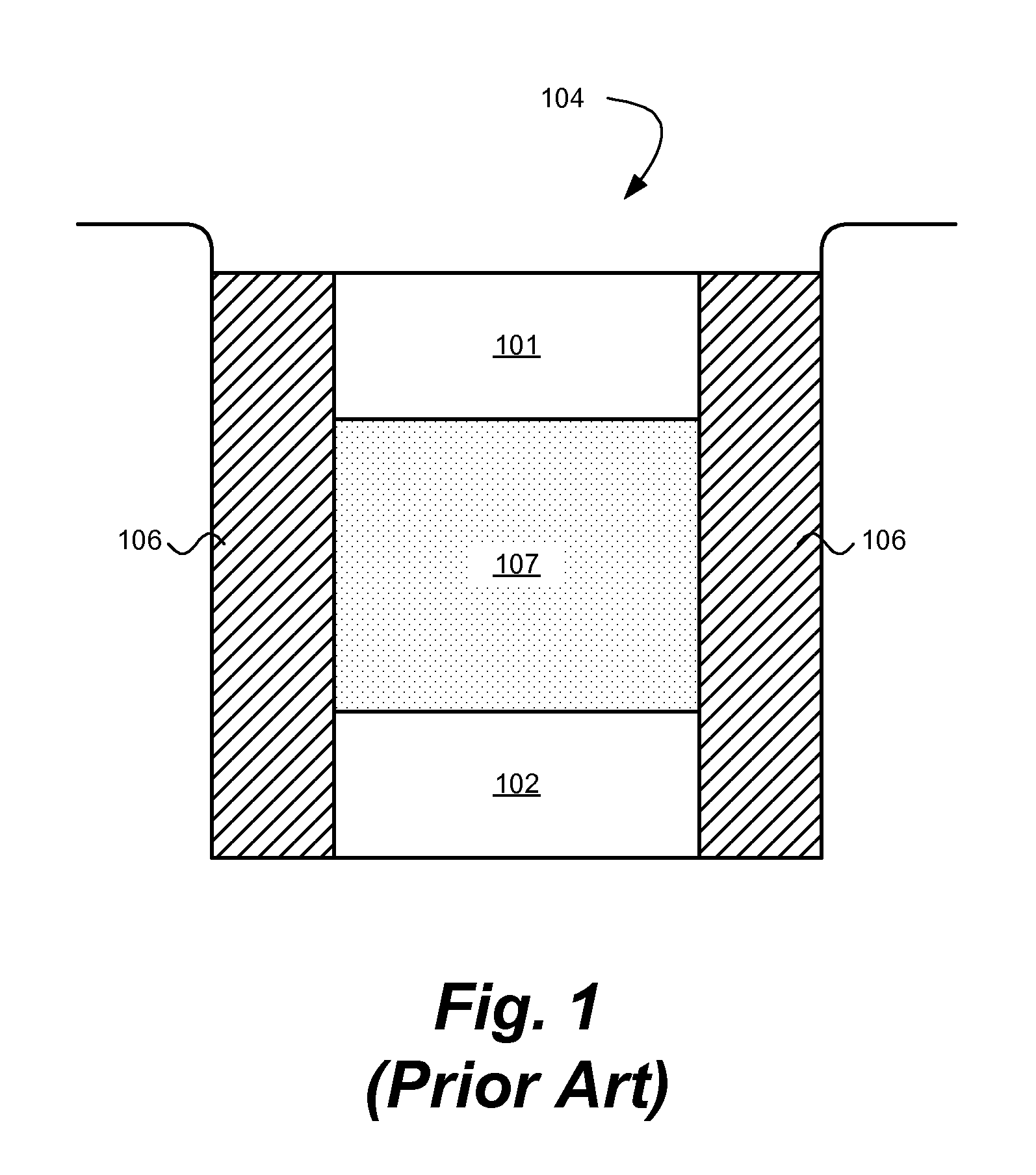

A method of fabricating a phase-change memory cell is described. The cross-sectional area of a contact with a phase-change memory element within the cell is controlled by a first dimension of a bottom electrode and a second dimension controlled by an etch process. The contact area is a product of the first dimension and the second dimension. The method allows the formation of very small phase-change memory cells.

Owner:MACRONIX INT CO LTD

Common word line edge contact phase-change memory

InactiveUS20060094154A1Need be addressSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryEngineering

A method of fabricating a phase-change memory cell is described. The cross-sectional area of a contact with a phase-change memory element within the cell is controlled by a first dimension of a bottom electrode and a second dimension controlled by an etch process. The contact area is a product of the first dimension and the second dimension. The method allows the formation of very small phase-change memory cells.

Owner:MACRONIX INT CO LTD

Common word line edge contact phase-change memory

Owner:MACRONIX INT CO LTD

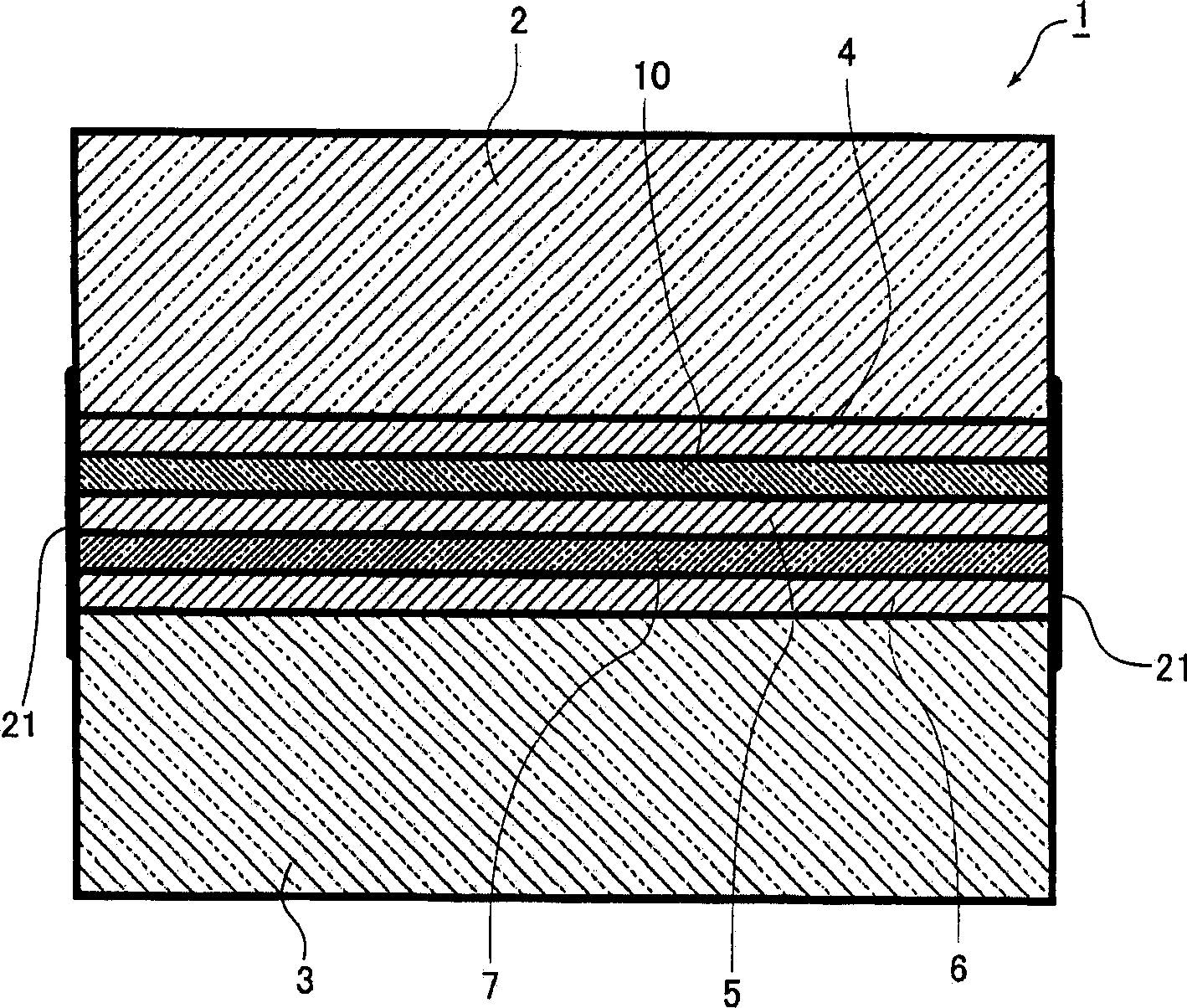

Self-aligned in-contact phase change memory device

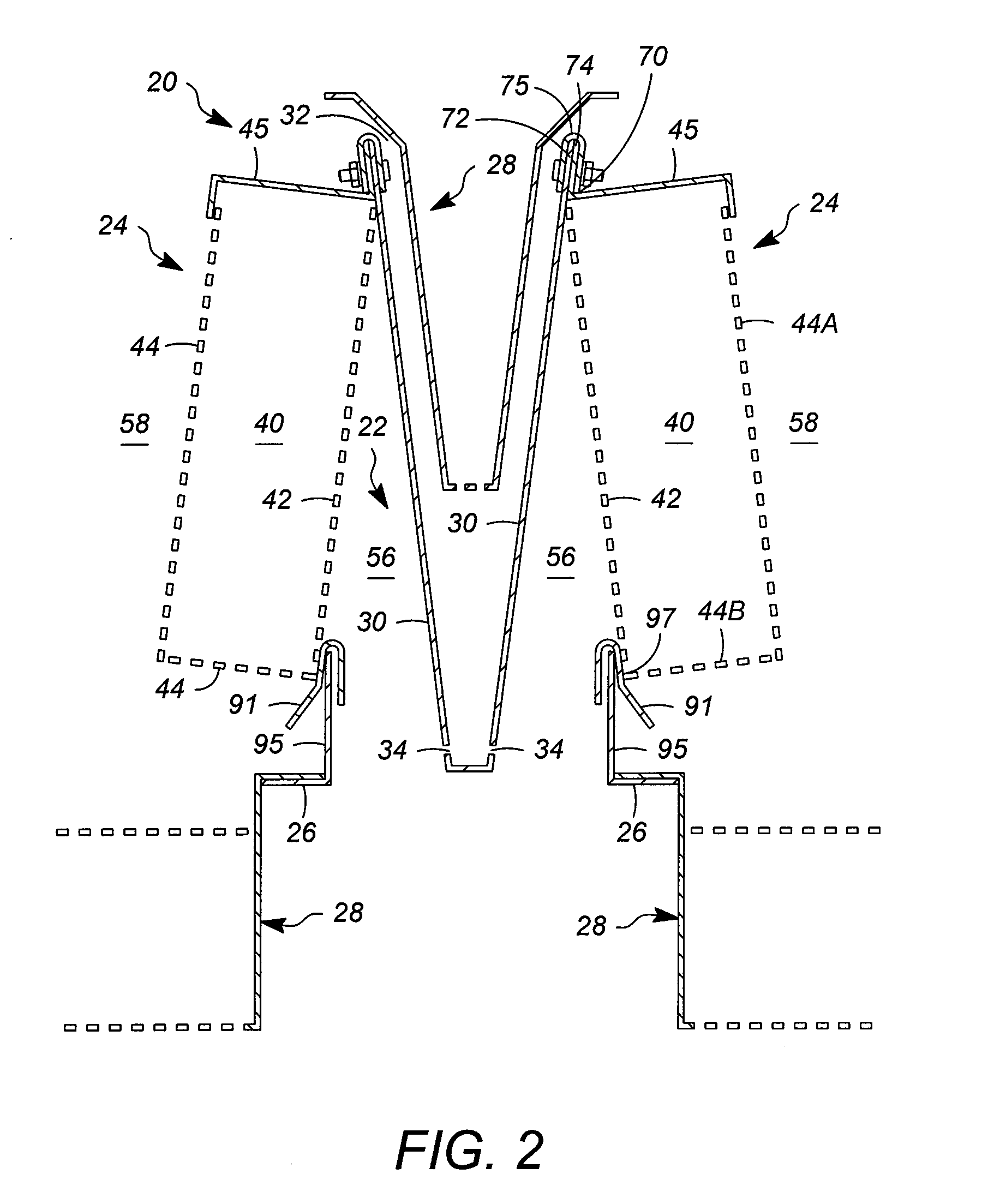

InactiveUS20090298223A1Solid-state devicesSemiconductor/solid-state device manufacturingBit lineContact phase

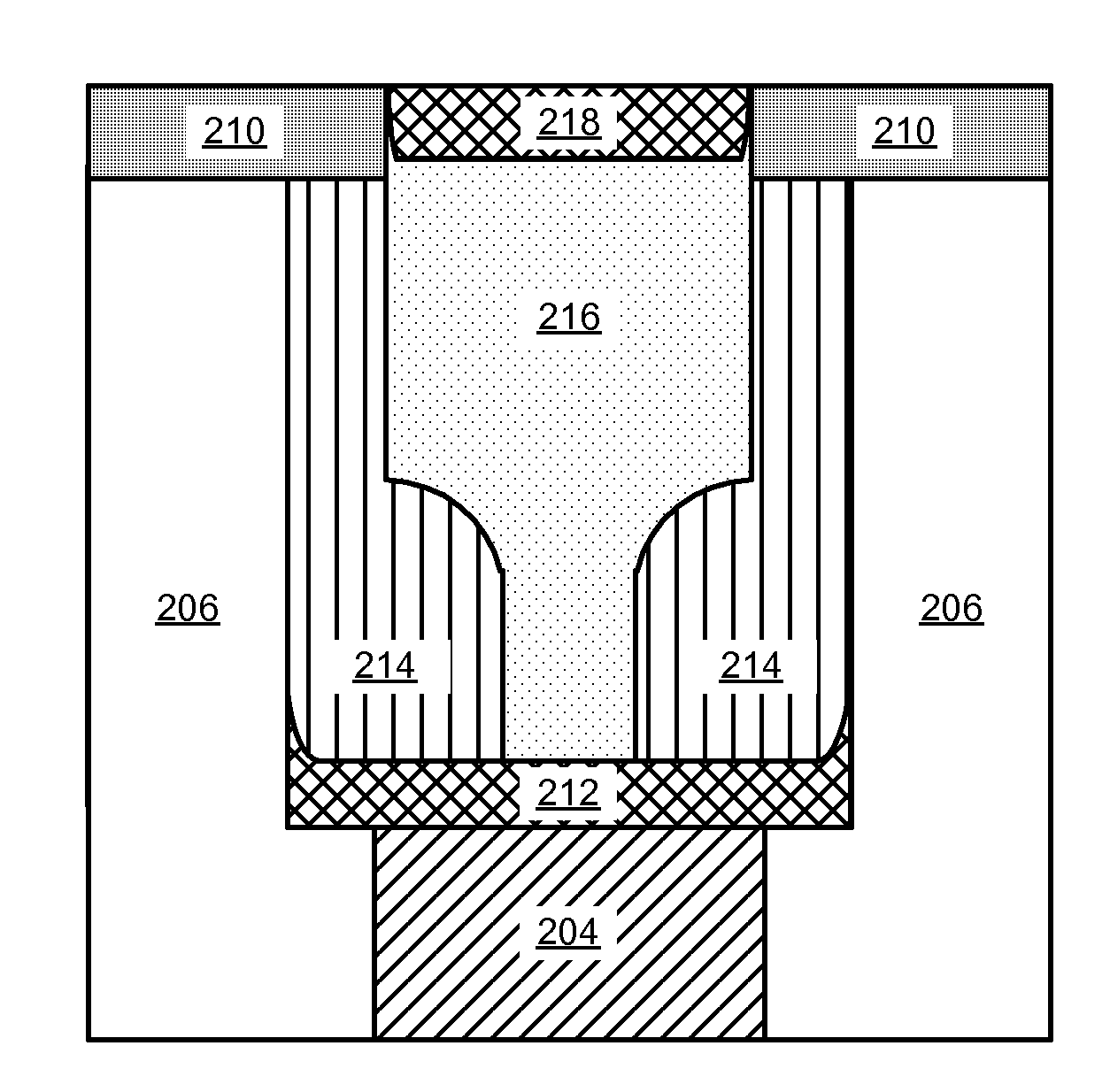

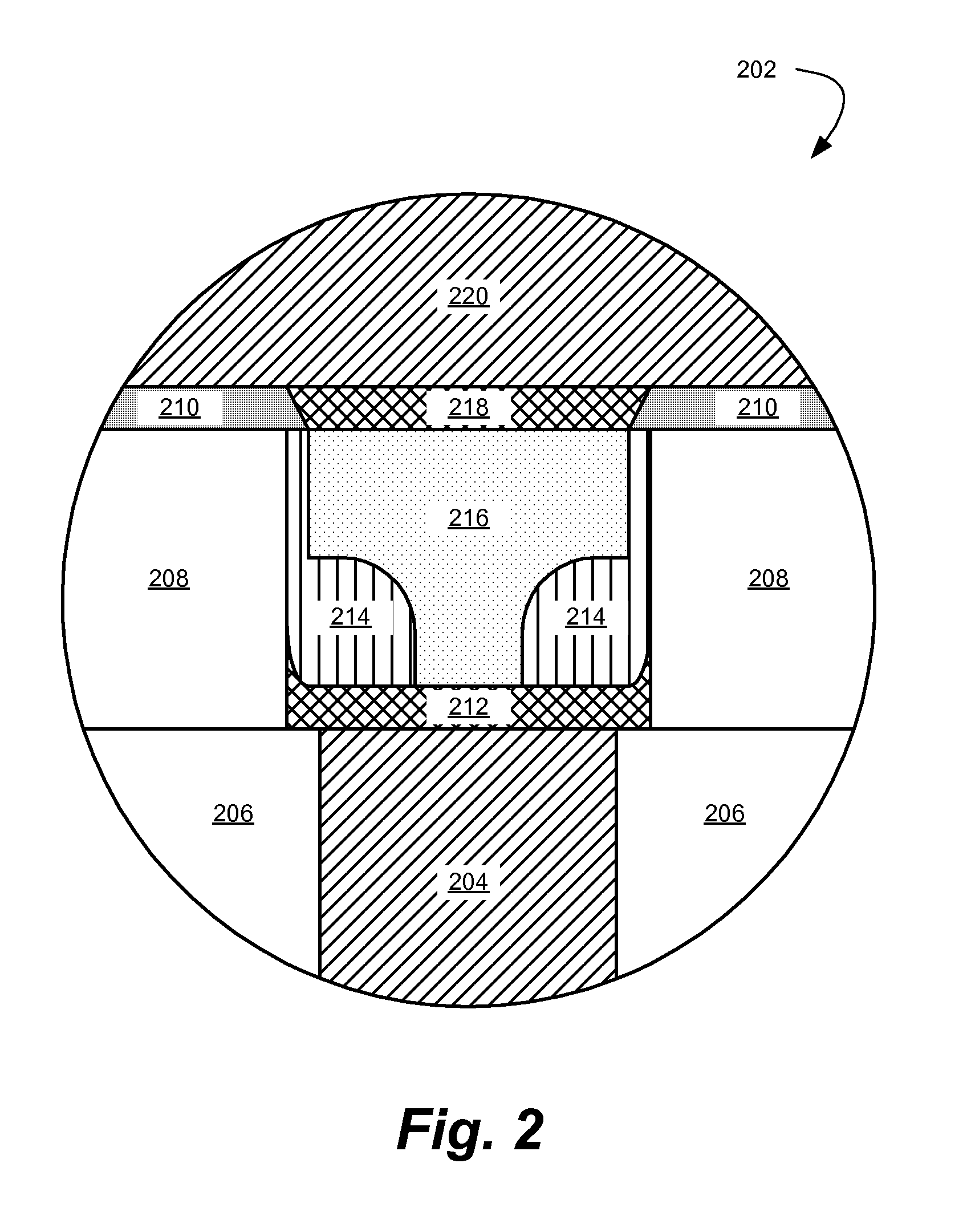

A memory cell and a method of making the same, that includes insulating material deposited on a substrate, a bottom electrode formed within the insulating material, a plurality of insulating layers deposited above the bottom electrode and at least one of which acts as an intermediate insulating layer. Then defining a via in the insulating layers above the intermediate insulating layer, creating a channel for etch with a step spacer, defining a pore in the intermediate insulating layer, removing all insulating layers above the intermediate insulating layer, filling the entirety of the pore with phase change material, and forming an upper electrode above the phase change material. Additionally, the formation of bit line connections with the upper electrode.

Owner:GLOBALFOUNDRIES US INC

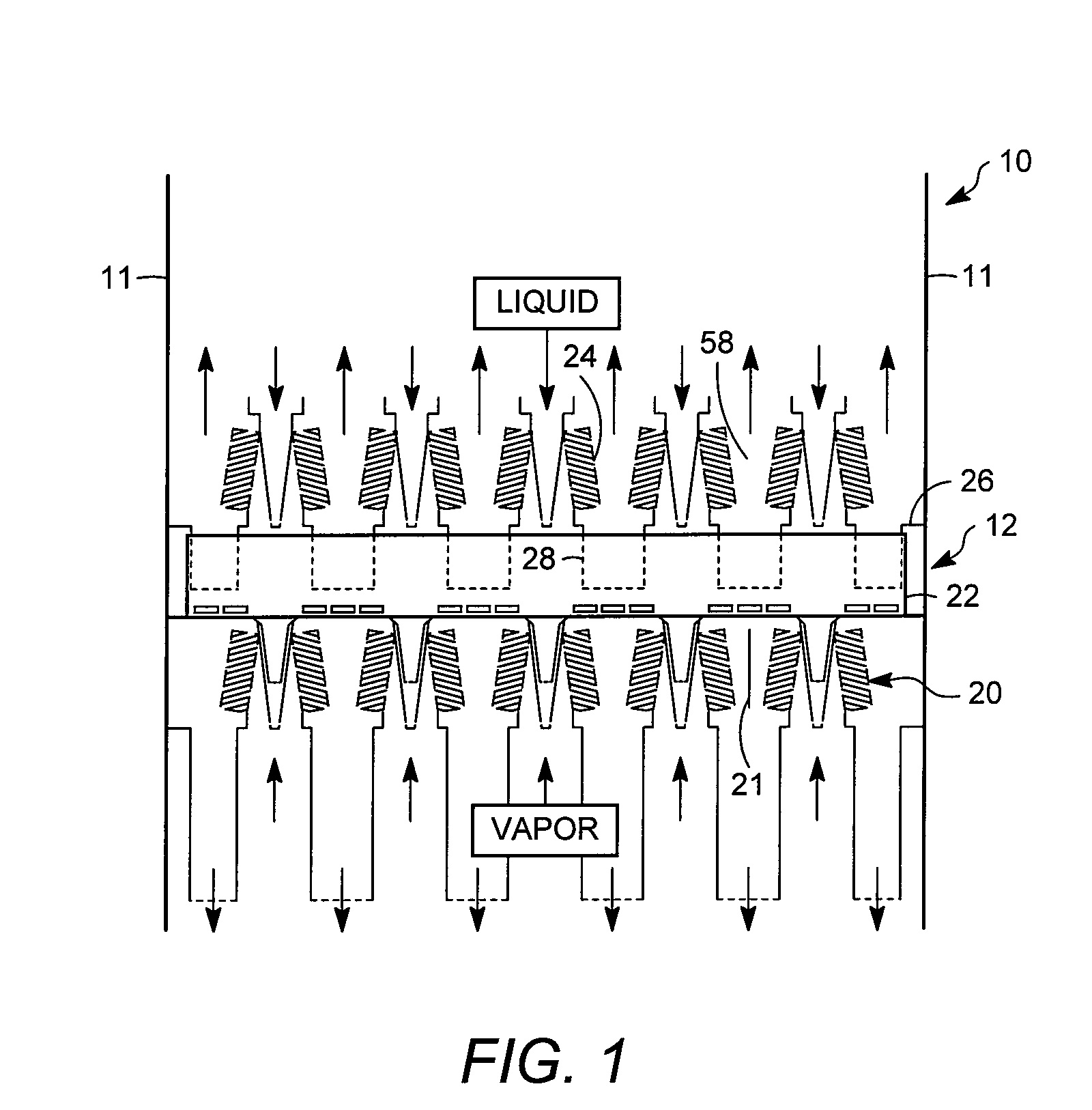

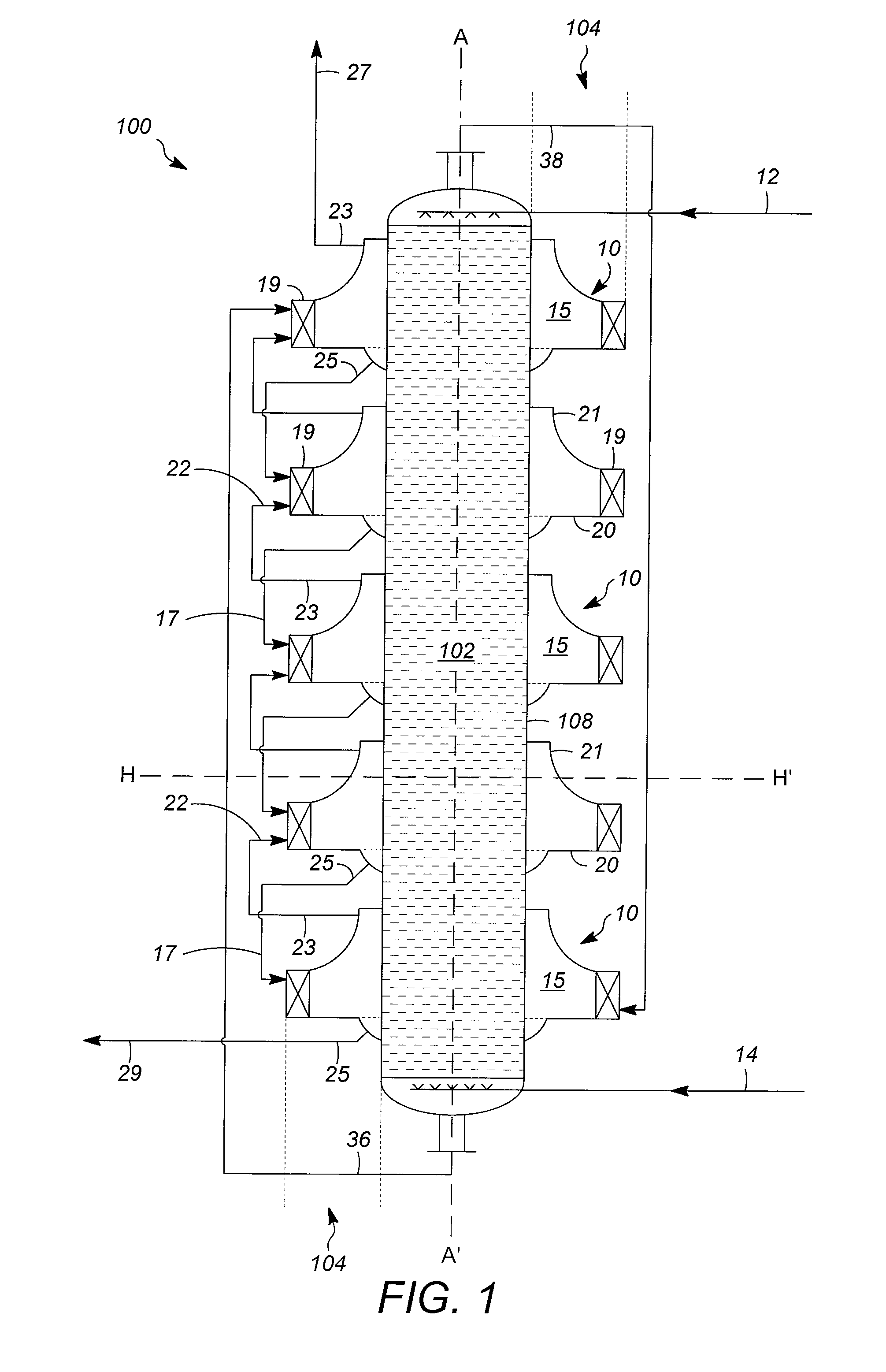

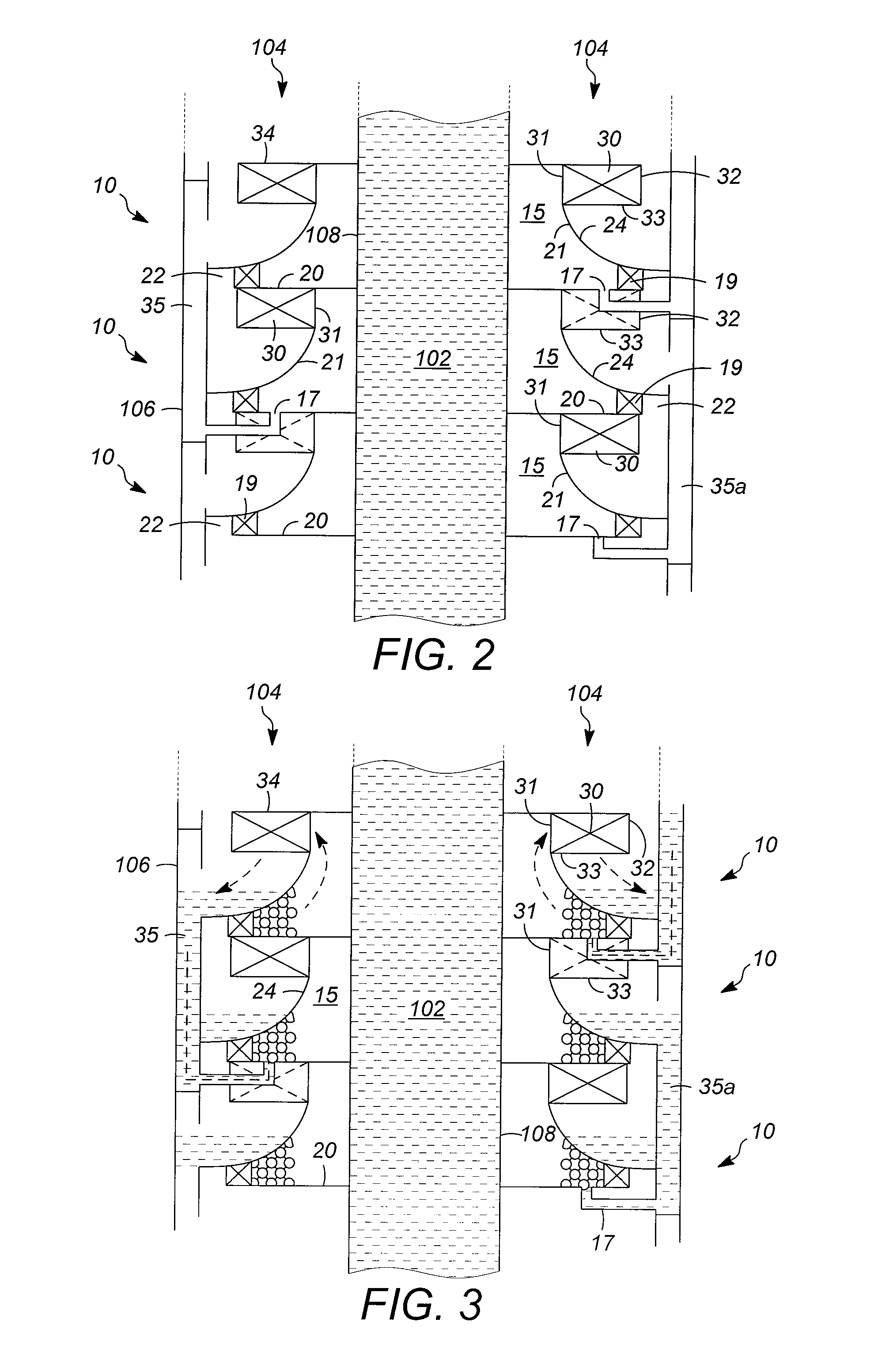

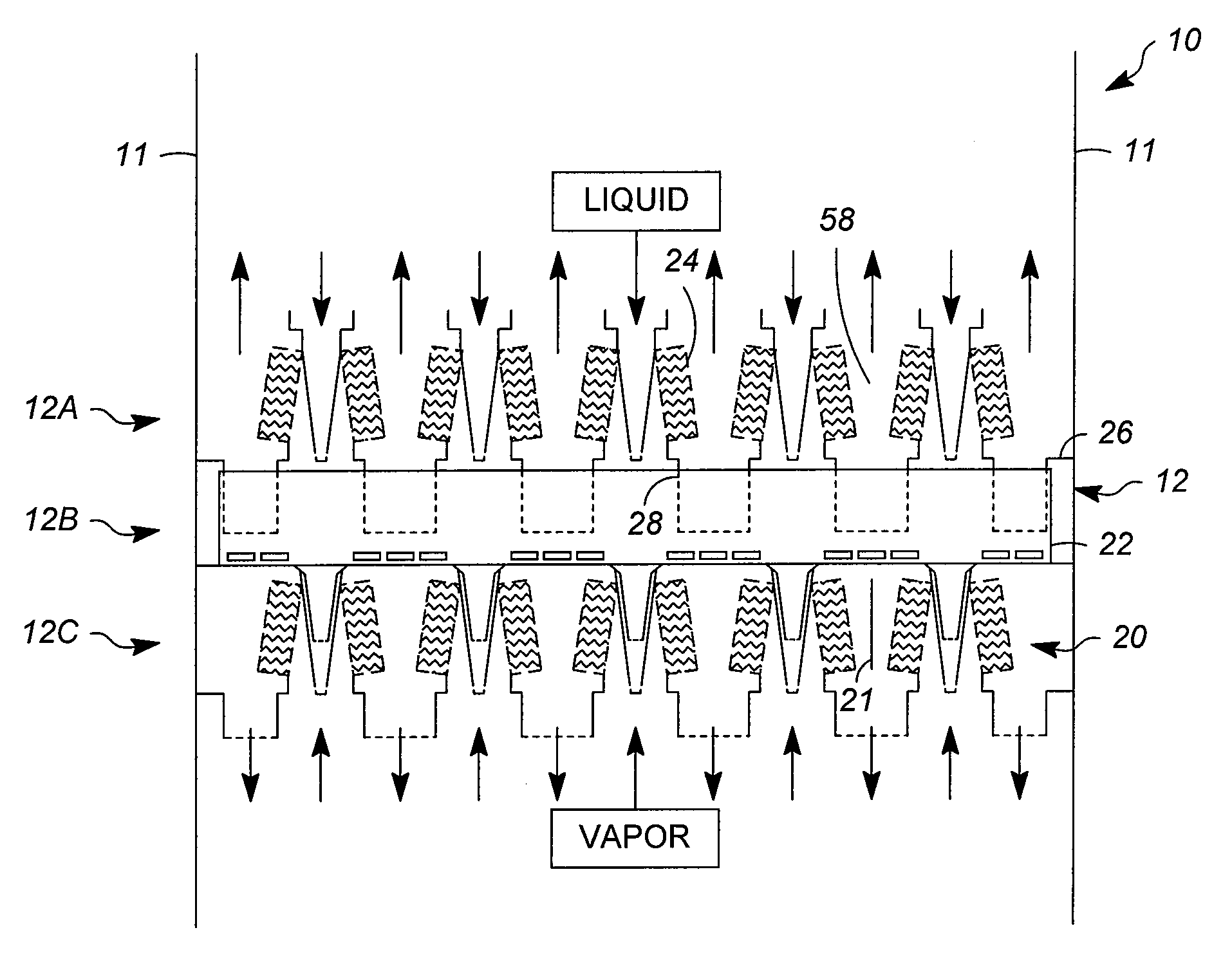

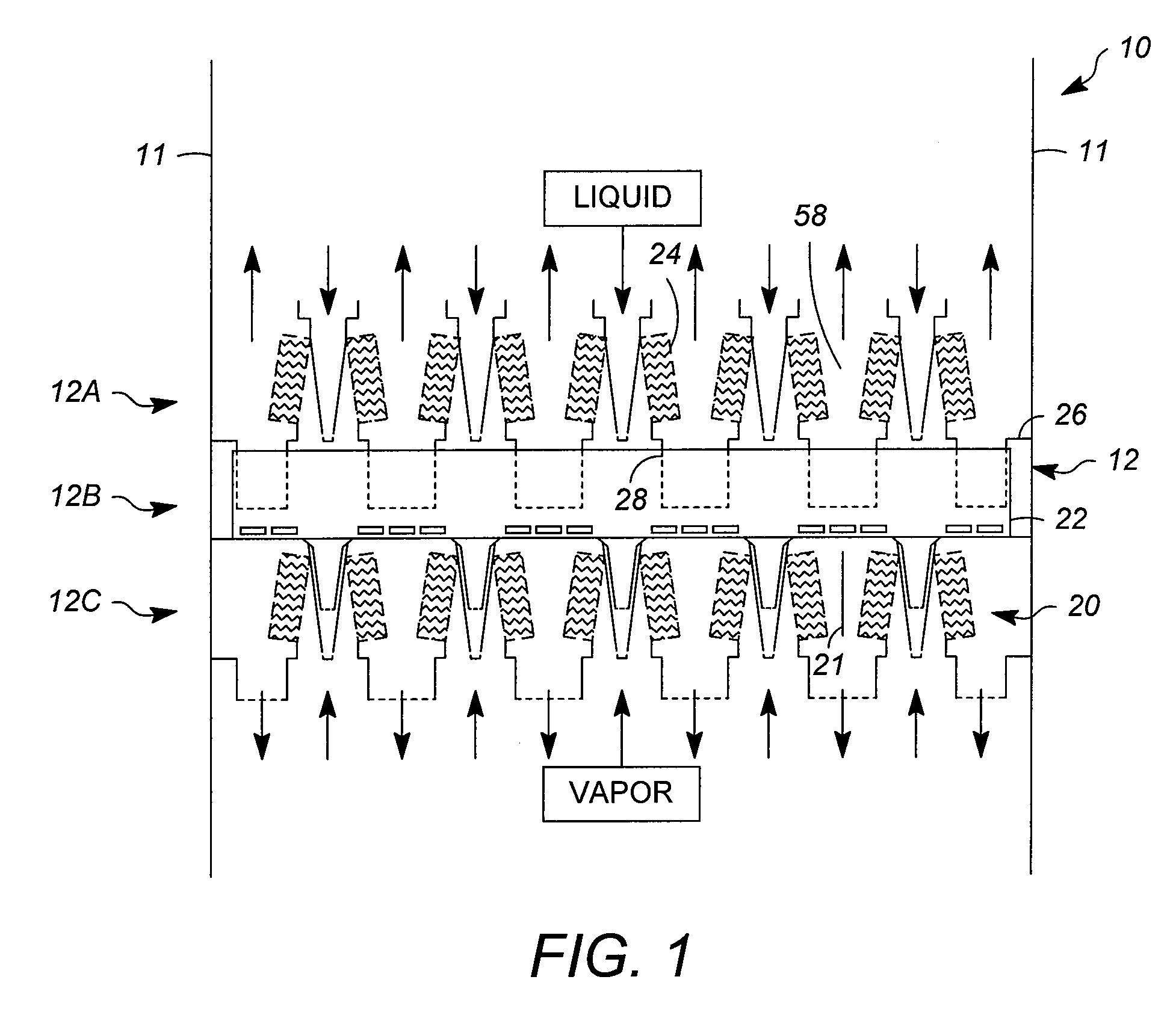

Vapor-liquid contacting in co-current contacting apparatuses

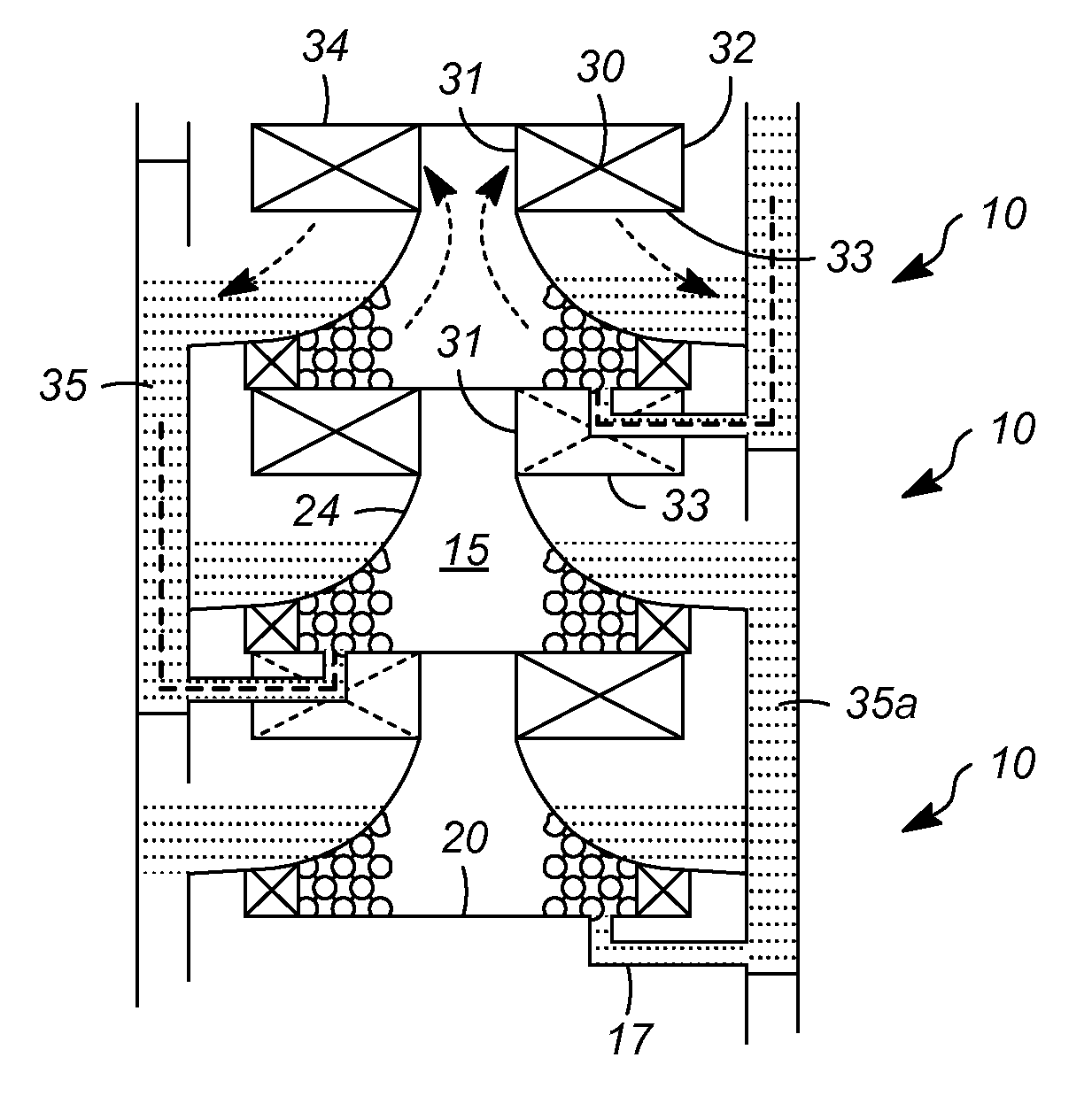

InactiveUS20100162891A1Reducing liquid handling capabilityLarge capacityCarburetting airLiquid degasificationVapor liquidEngineering

Improved contacting modules and apparatuses containing the modules, for carrying out vapor-liquid contacting, are described. In representative contacting modules, liquid (and possibly vapor) are discharged into co-current flow channels in a non-uniform manner (e.g., from only one side of the channels). Particular contacting modules comprise at least one liquid downcomer and a demister, wherein the liquid downcomer and an inlet surface of the demister define a co-current flow channel and wherein liquid is discharged from an outlet of the downcomer. The use of one or more added liquid distribution devices to more uniformly distribute the discharged liquid improves vapor-liquid contacting efficiency in the co-current flow channel and consequently vapor-liquid mass transfer and approach to equilibrium for the contacting stage.

Owner:UOP LLC

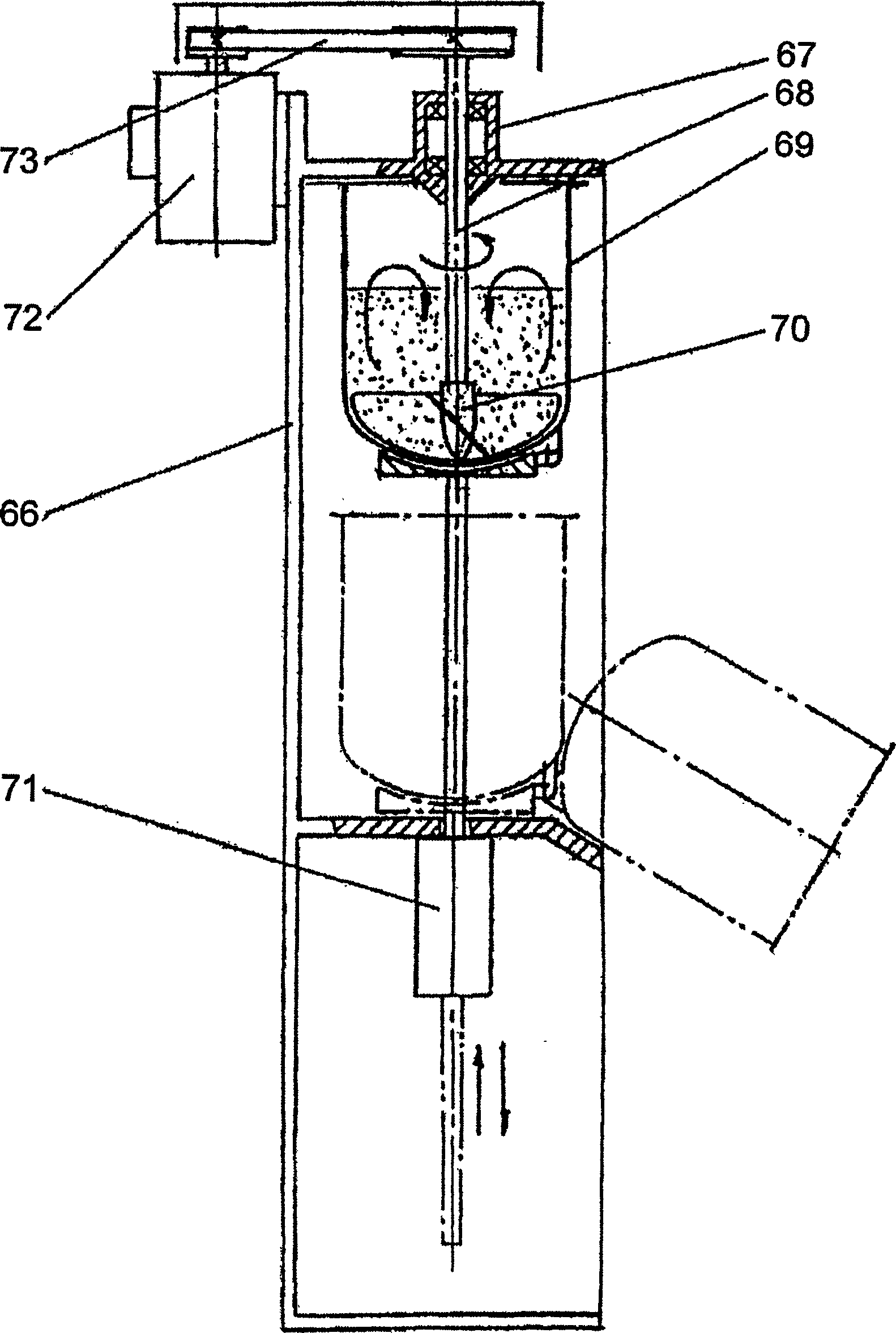

Method for producing granulated sorbents and installation for carrying out the method

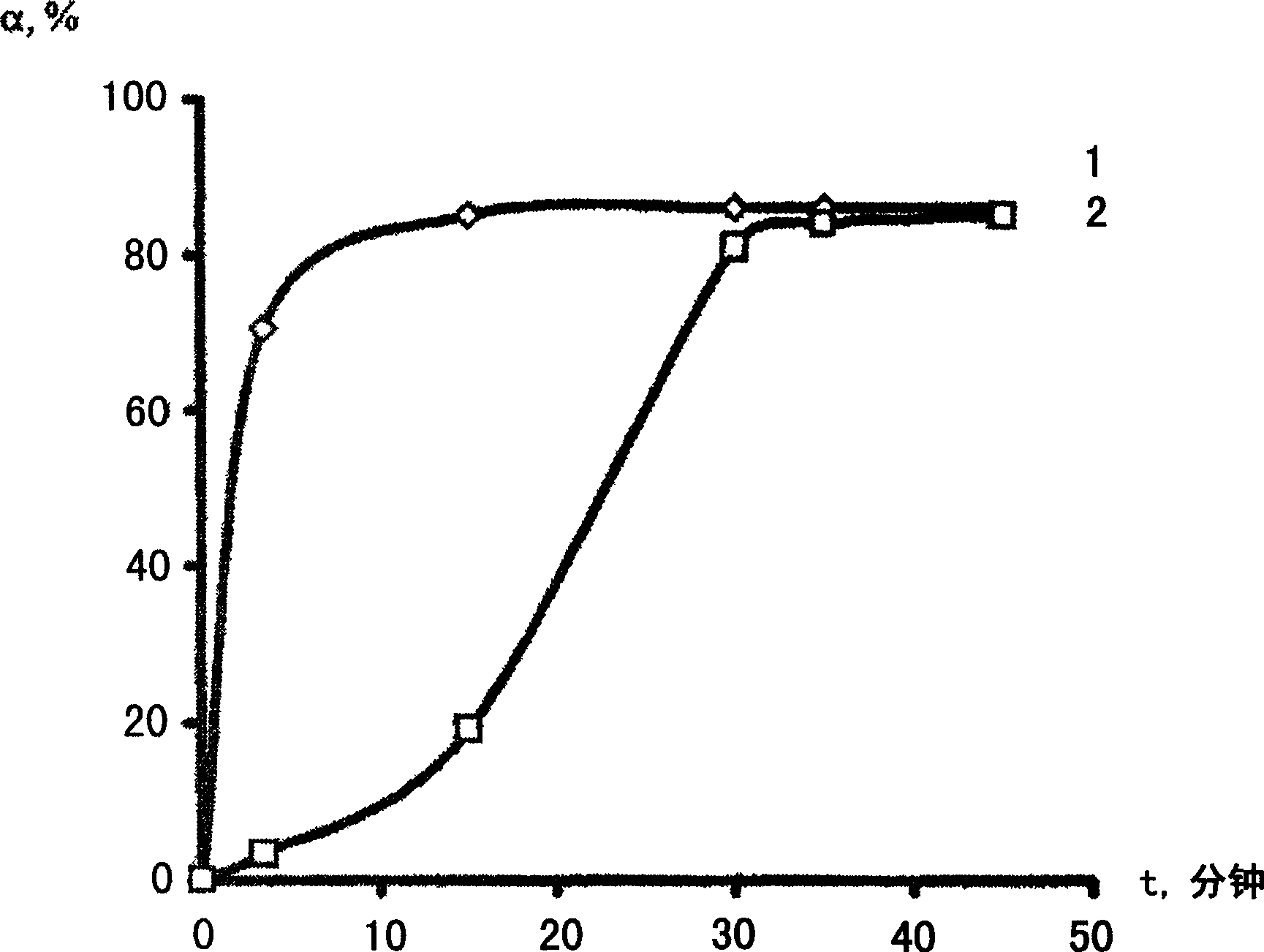

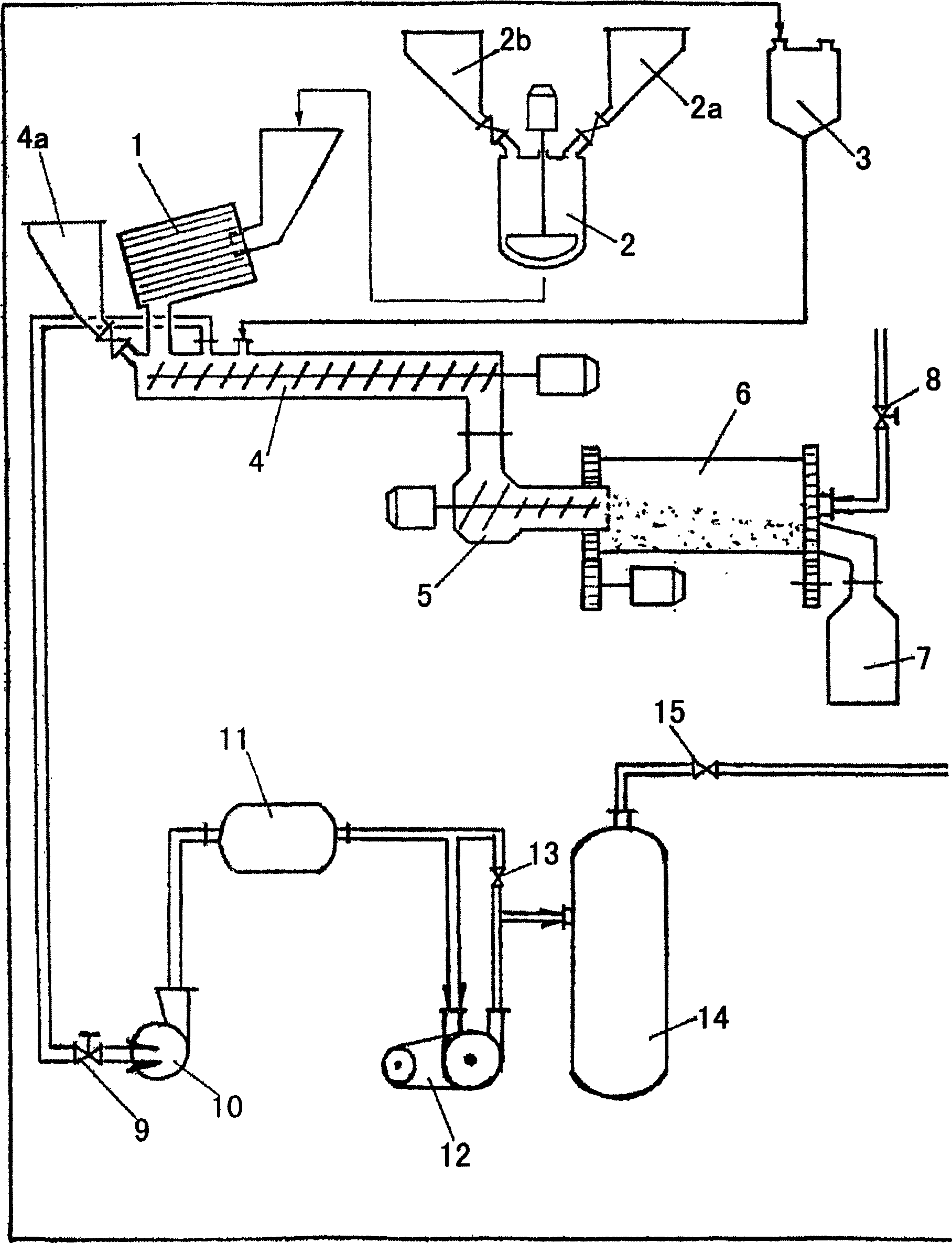

The invention relates to a method for producing granulated sorbents, and to an installation for carrying out the method. The aim of the invention is to obtain the chloride form of the double hydroxide of aluminium and lithium as LiCL2AI / OH)3 nH2O (DHAL-CL) in a waste-free solid phase of aluminium hydroxide and lithium salts in a mixer, with subsequent continuous activation of crystalline DHAL-CI in a centrifugal mill activator in order to obtain a defectuous material structure. The product obtained is mixed with chlorinated polyvinyl chloride as a binding agent and with liquid methylene chloride. The granulation is carried out by extruding the paste produced and refining the same in the granulator. The methylene chloride produced is collected by an organic liquid absorbent having a high boiling point. The methylene chloride steam is guided out of the material flow in the carrier gas flow in the manner of an ideal displacement in the counter-current of the contact phases. The methylene chloride recuperation is carried out in two steps according to the thermal method, during the heating of the absorbent used. The inventive method is characterised by essentially reduced environmental impact in relation to prior art, due to the closed material circuits used. The granulated sorbent is especially suitable for the selective extraction of lithium from chloride salt lye of any mineralization, with an extraction degree of 95 %.

Owner:青海盐湖蓝科锂业股份有限公司

Method for preparing grinding silk

InactiveCN101994167AExcellent productivityReduce wearOther chemical processesArtifical filament manufactureInvestment materialContact phase

The invention relates to a method for preparing a super-tough super-strong specific grinding silk. In the invention, the performance of a polyamide resin slice is adjusted through adjusting auxiliary materials, such as antioxidant, a flexibilizer and / or a reinforcing agent and the like, artificial diamond grinding particles subjected to coupling agent treatment is added to produce the grinding silk with excellent performance. A contact phase of the artificial diamond grinding particles subjected to the coupling agent treatment and the polyamide resin slice is solid-liquid blending by means of segment charging, so as to reduce the abrasion of a building-block type single screw rod extruder by using the artificial diamond grinding particles, and feed volumes are respectively regulated to obtain a plurality of grinding silks having the proportion content of grinding materials, so that the product meets the requirement on various trenchant use environment. The product developed by the process has the advantage of better grinding performance, and can be normally used in the environment of high temperature and acid base.

Owner:慈溪市洁达纳米复合材料有限公司

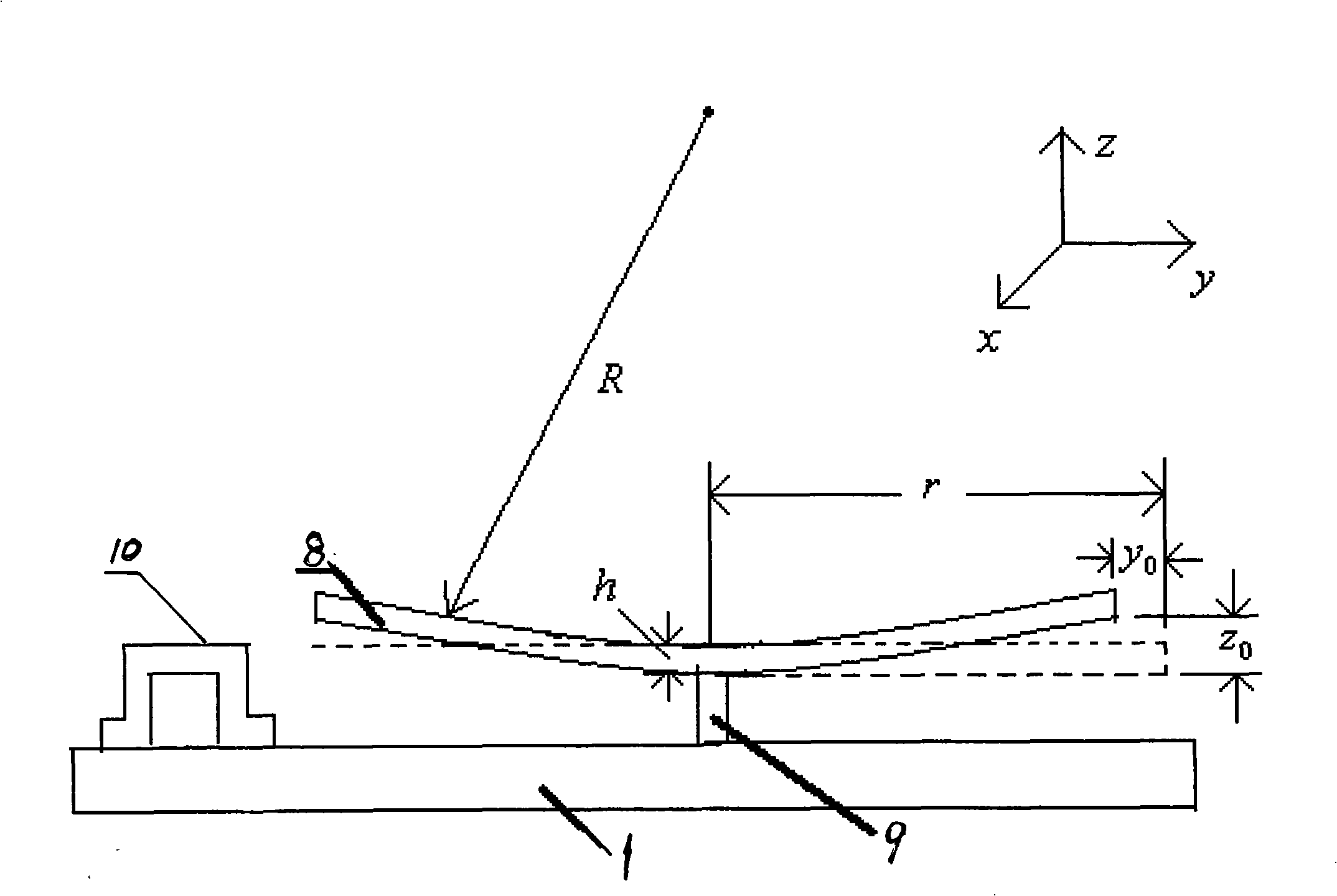

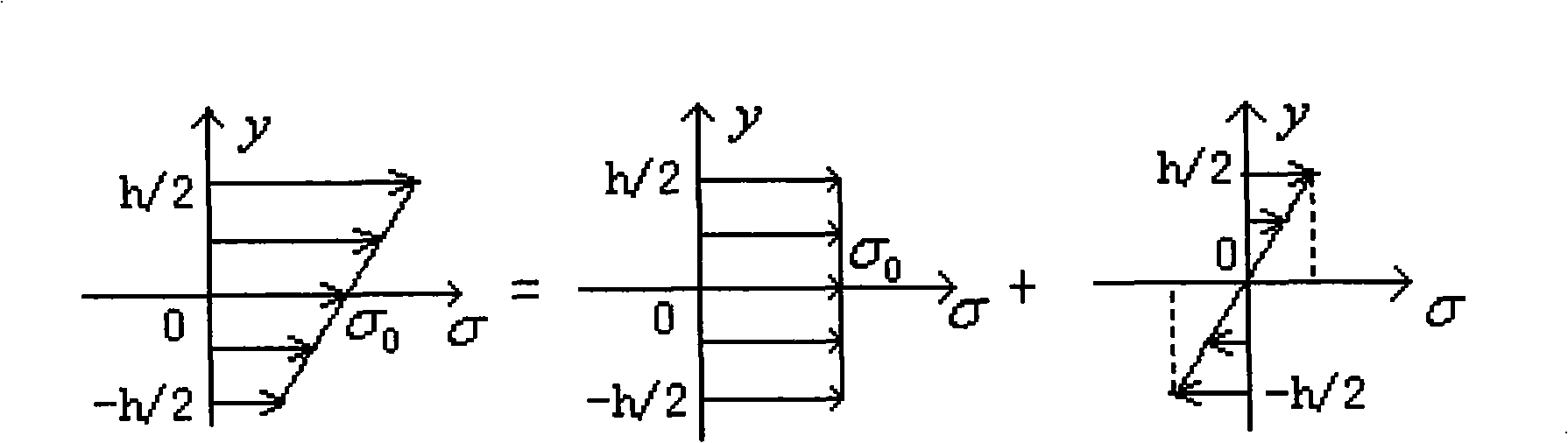

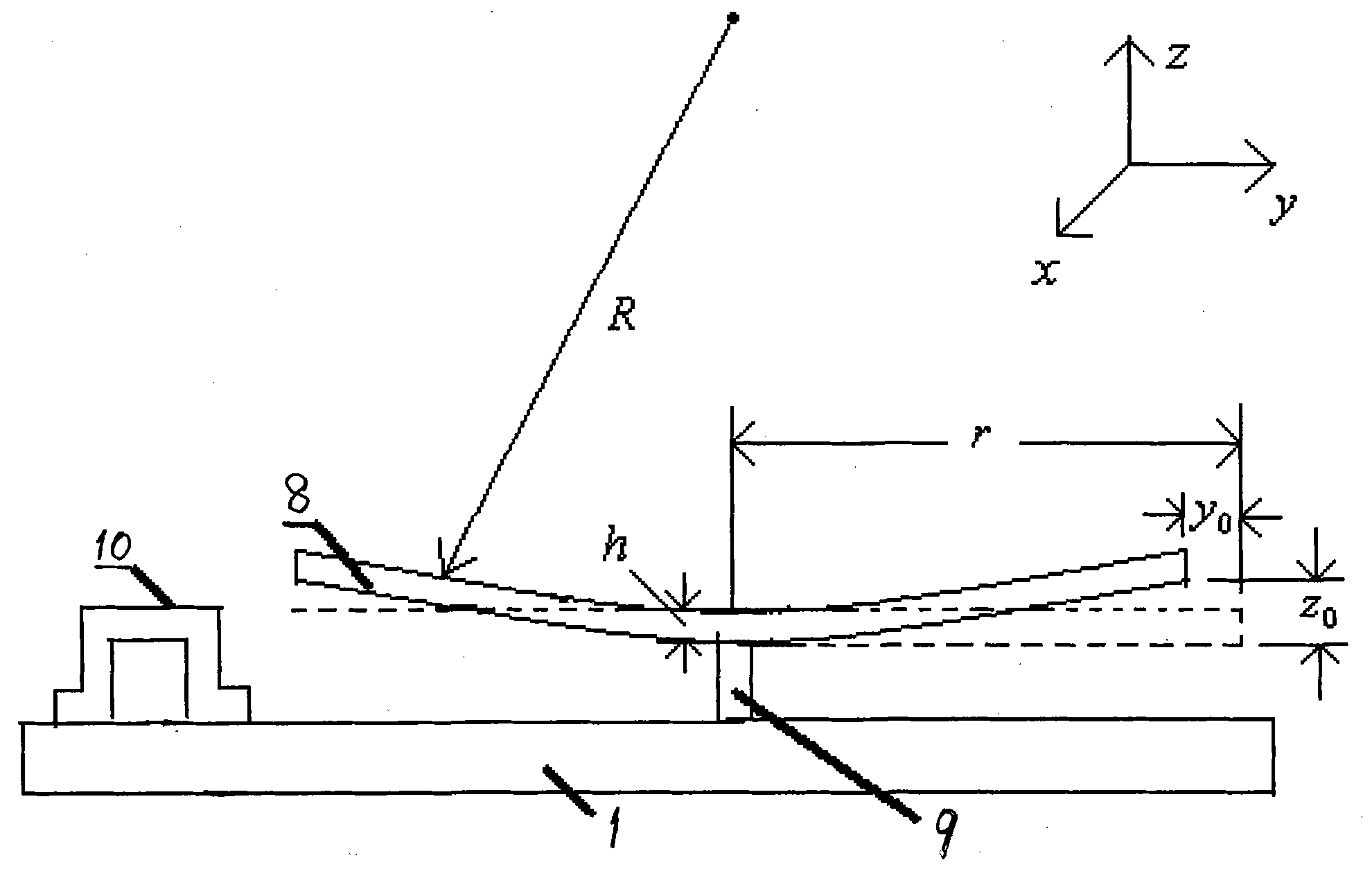

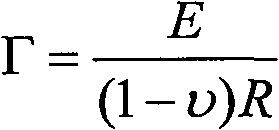

Method for on-line measurement of MEMS membrane stress gradient

InactiveCN101403693AHigh precisionReduce the area occupied by the chipPhase-affecting property measurementsUsing mechanical meansMembrane stressYoung's modulus

The invention discloses a method used for online measuring the stress gradient of MEMS film, comprising the steps as follows: a round film with center fixed is prepared on a structure layer film; after the round film is released, the round film generates deformation under the stress gradient inside the round film; the displacement of the edge of the round film in the vertical direction is measured by a non-contact phase-shifting typed Mirau interferometer, thus calculating the curvature radius of the round film; and the stress gradient of the film can be calculated by the young modulus and Poisson ratio of the film and the curvature radius of the round film. The measurement method is characterized in that a centrosymmetric round film with the center fixed is used as a testing structure and a choring area is fixedly clamped closely to an ideal state, thus improving the precision of the model; the non-contact optical interference method is used for measurement, thus not affecting testing structure and having good repeatability; the method is suitable for measuring the stress gradient of conductive material and non-conductive material simultaneously; and furthermore, the measurement method has the advantages of simple and convenient operation, high measurement precision, small chip occupying area and the like.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

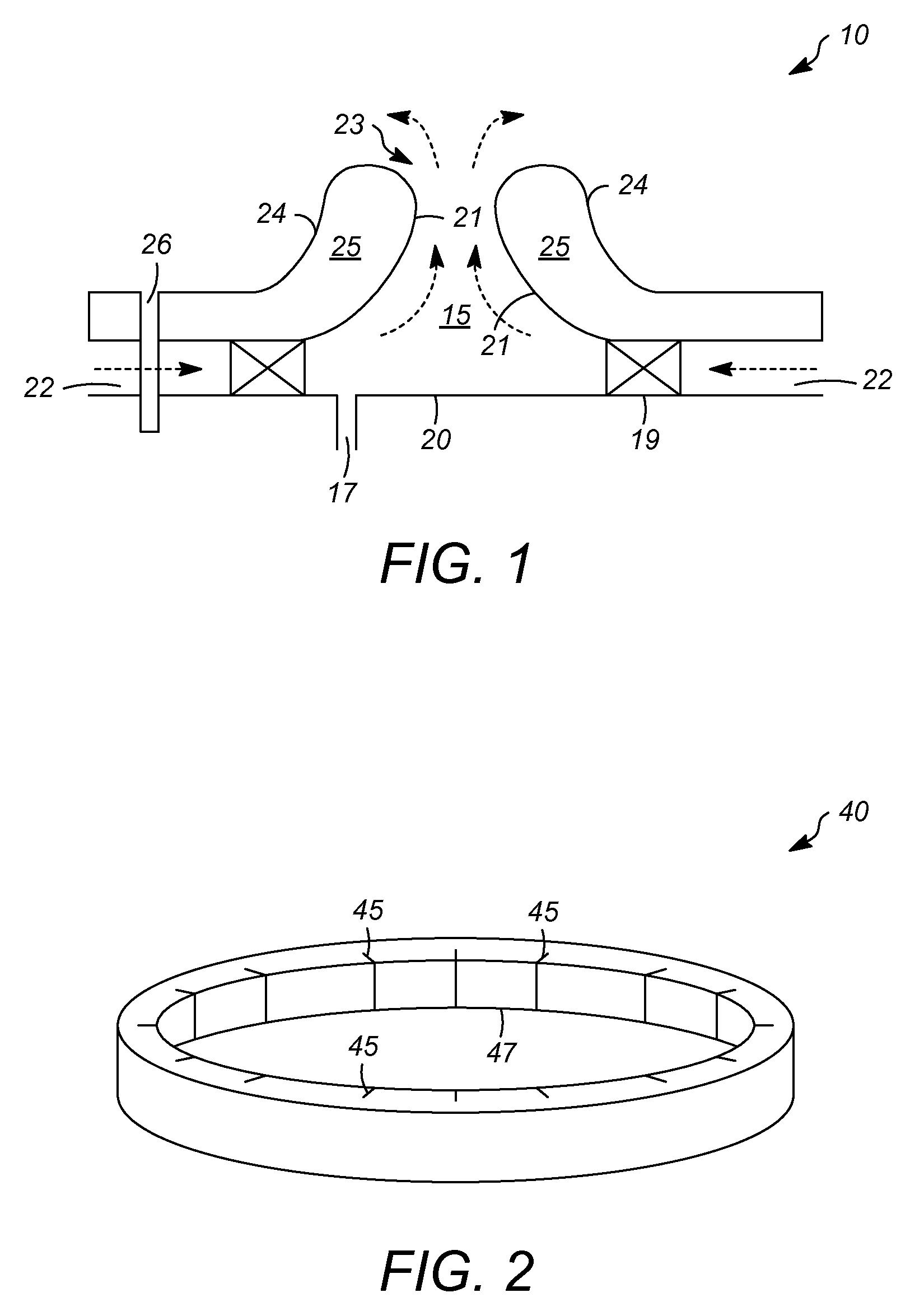

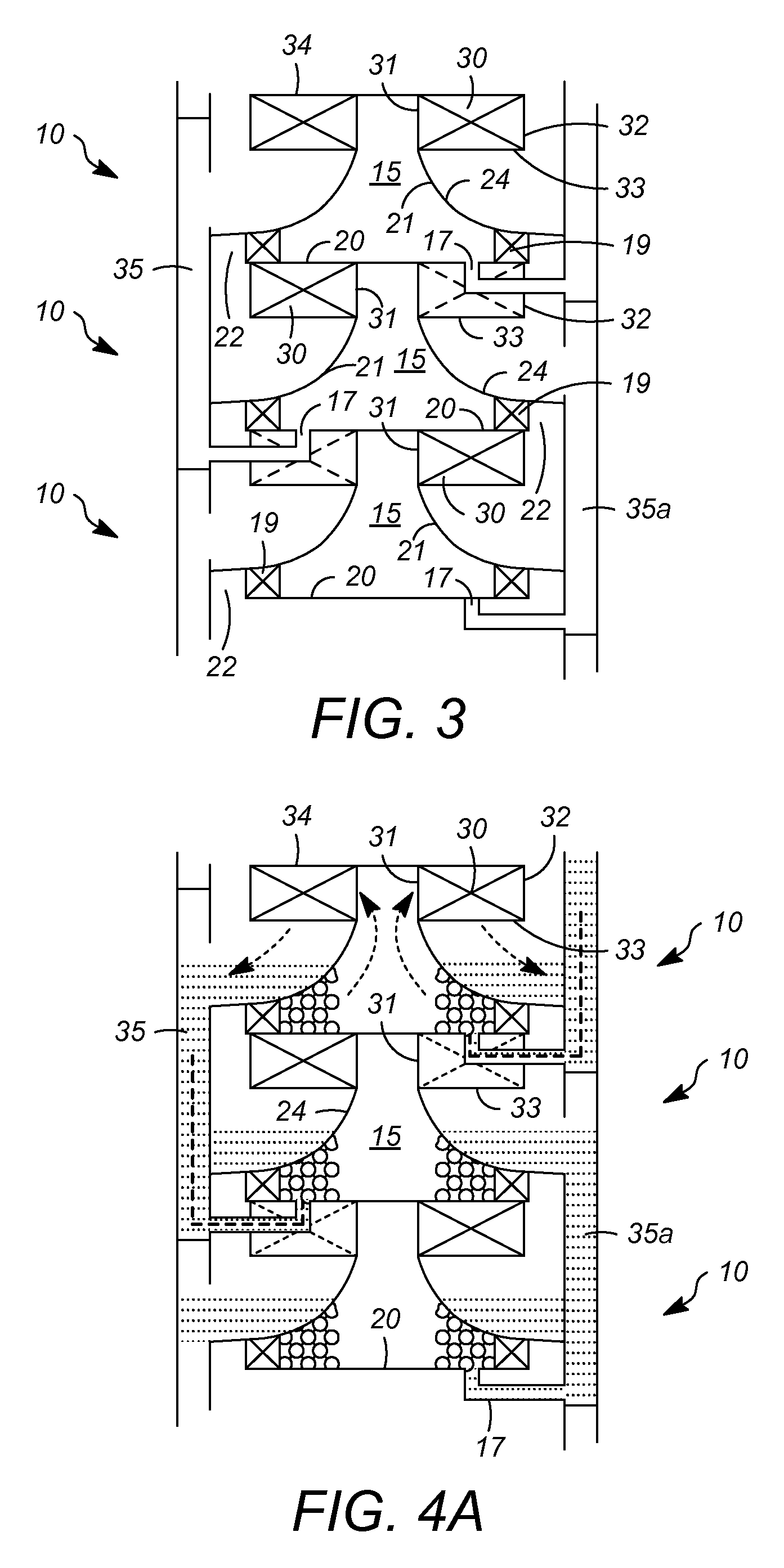

Vapor-Liquid Contacting Apparatuses Having a Secondary Absorption Zone with Vortex Contacting Stages

InactiveUS20110239862A1Increased turbulenceEnhanced mass transferLiquid degasificationFlow mixersVapor liquidProduct gas

Vapor-liquid contacting apparatuses comprising both a primary absorption zone and a secondary absorption zone comprising a plurality of vortex contacting stages are described. The apparatuses provide improved heat and mass transfer between vapor and liquid phases in processes such as absorption, to selectively solubilize contaminants (e.g., acid gases) from an impure vapor (e.g., sour natural gas). Vortex contacting stage(s) in a zone of vapor-liquid contacting, such as a secondary or finishing absorption zone, are used following bulk absorption in a primary or main absorption zone.

Owner:UOP LLC

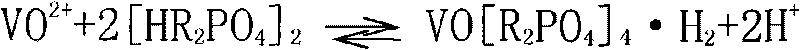

Acid-method regenerative organic phase process in vanadium extraction cycle

InactiveCN101696468AReduce consumptionReduce lossProcess efficiency improvementRegenerative processThree-phase

The invention provides an acid-method regenerative organic phase process in vanadium extraction cycle, which is characterized in that the regeneration of solvent-extraction poor organic phase in extraction cycle adopts sulfuric acid solution with the concentration between 250 and 300 g / l as regenerant; the flow ratio of the poor organic phase to the regenerant is 10-15:1; the volume ratio (contact phase ratio) of the poor organic phase to regeneration aqueous phase in a mixed system is 1.2-1.5:1; and regeneration temperature is controlled between 40 and 50 DEG C. The process has the advantages of producing no three-phase material during regeneration, leaving out three-phase separation tank necessary in alkali-method regeneration, reducing the accompanying loss of organic phase caused by the generation of iron, aluminum and other hydroxide precipitates in the alkali-method regeneration, reducing the cost of products per ton and saving 12,000 yuan for the cost of products per ton and one million yuan for investment in regeneration equipment.

Owner:SHAANXI JINGMAO INVESTMENT

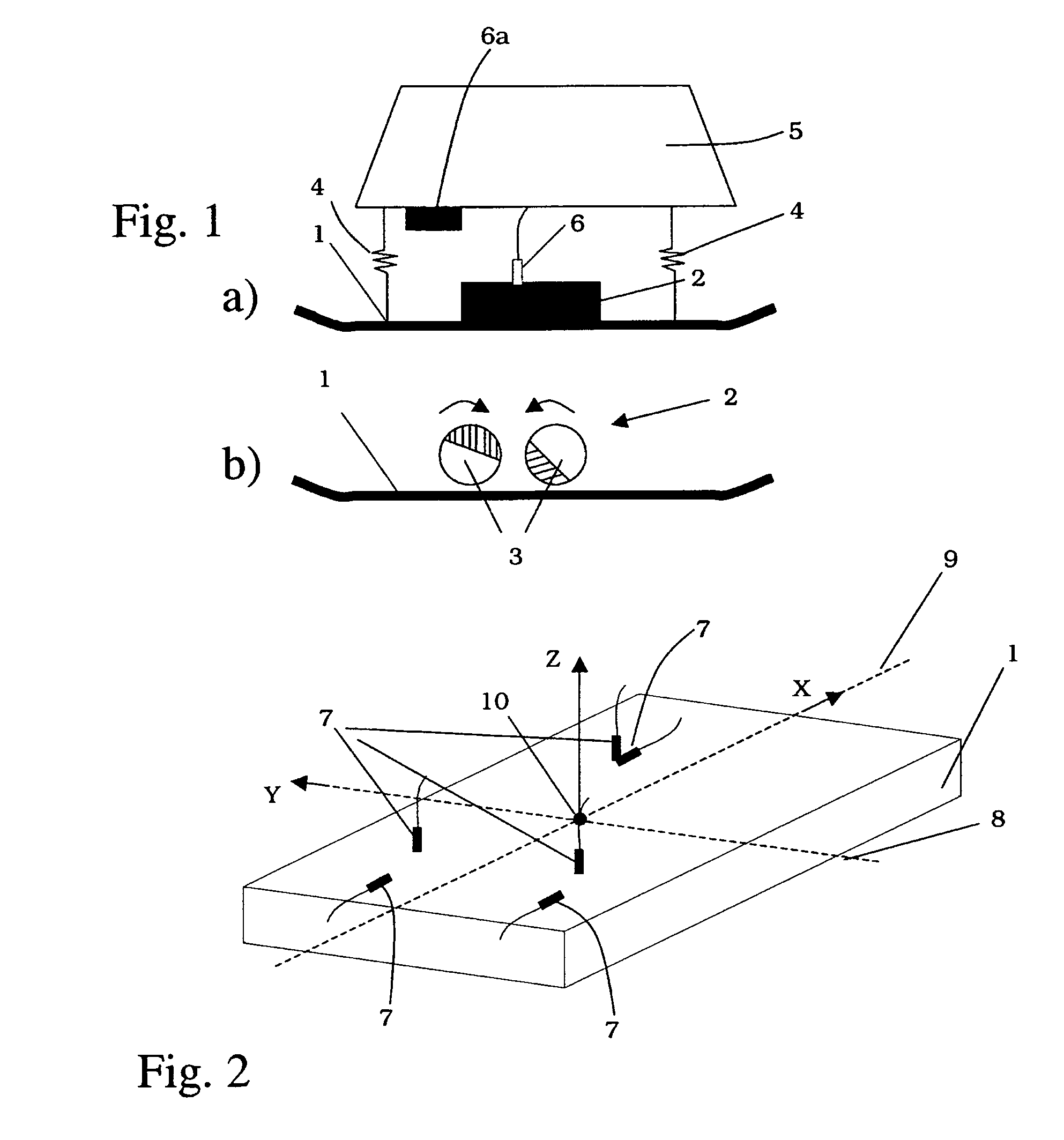

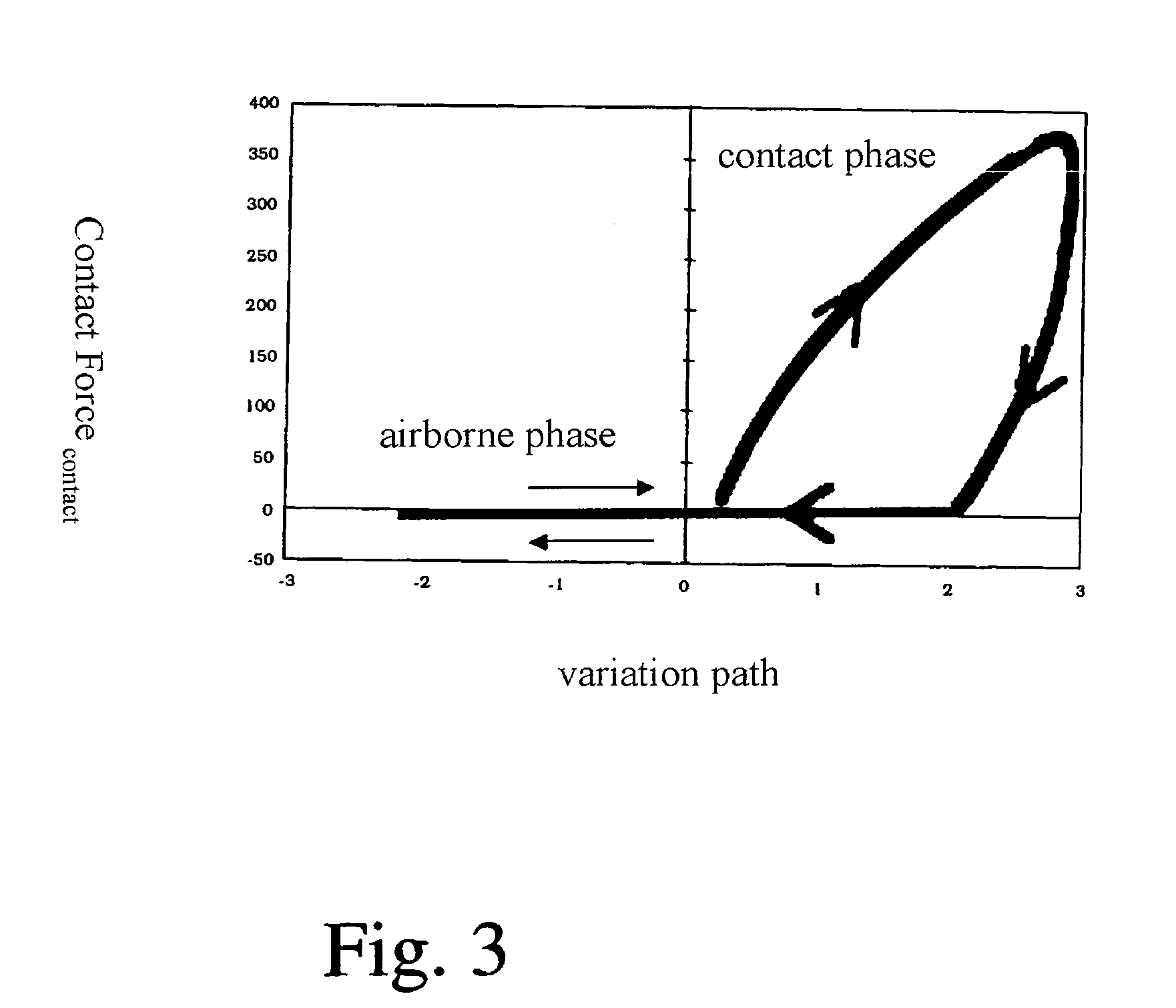

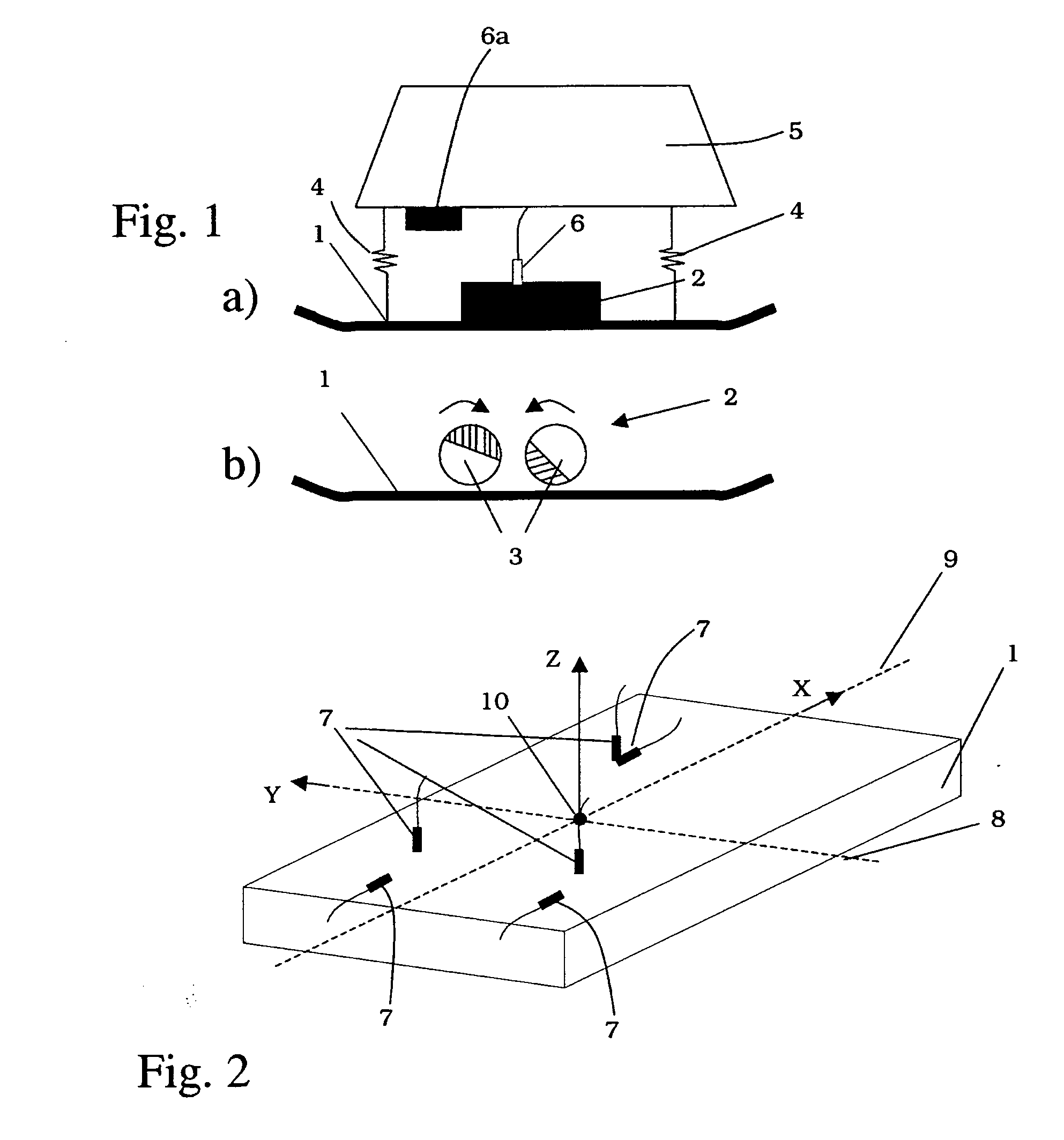

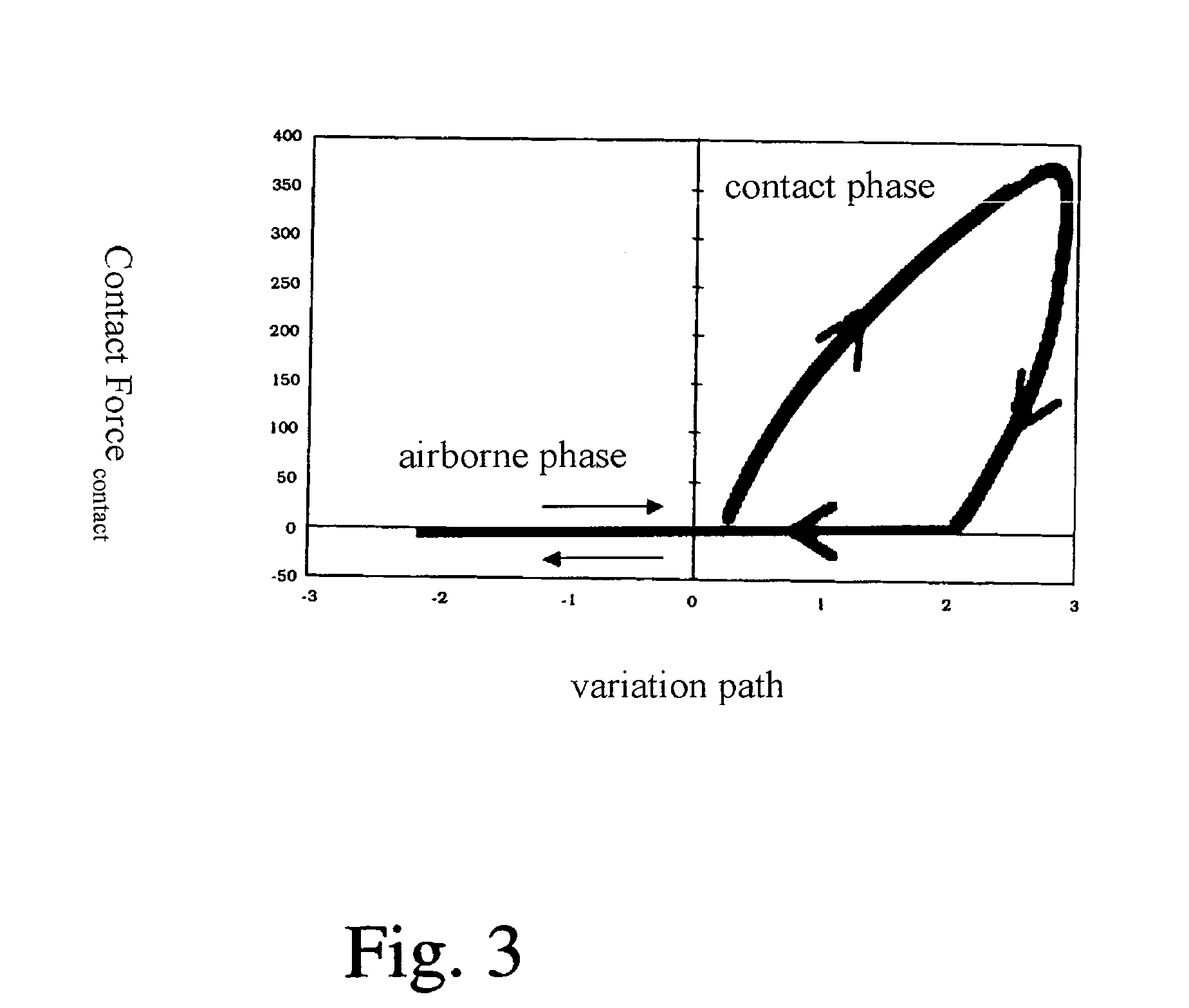

Method and device for measuring soil parameters by means of compaction machines

A soil compaction device has a vibrated contact element that makes contact with the soil during a contact phase and that is exposed to a contact force exerted by the soil and travels over a contact distance. A dynamic stiffness of the soil is formed from the gradient of the contact force and from the contact distance. Furthermore, a contact surface parameter to take account of the actual contact surface of the contact element with the soil is determined. The dynamic deformation modulus is then the product of the contact surface parameter and the dynamic stiffness. The method allows the determination of the dynamic deformation modulus, and hence of the soil stiffness, during the compaction operation.

Owner:WACKER NEUSON SE

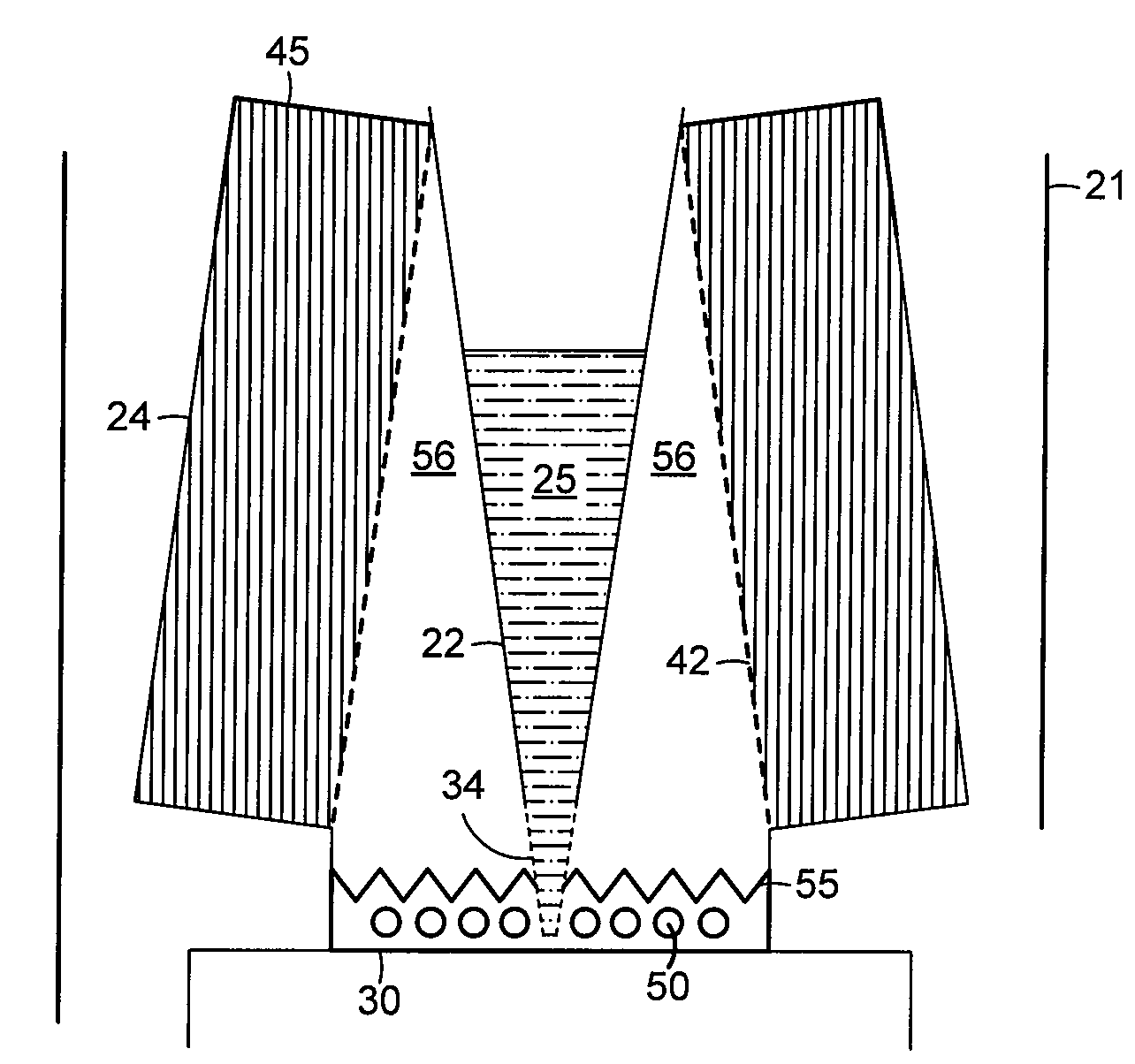

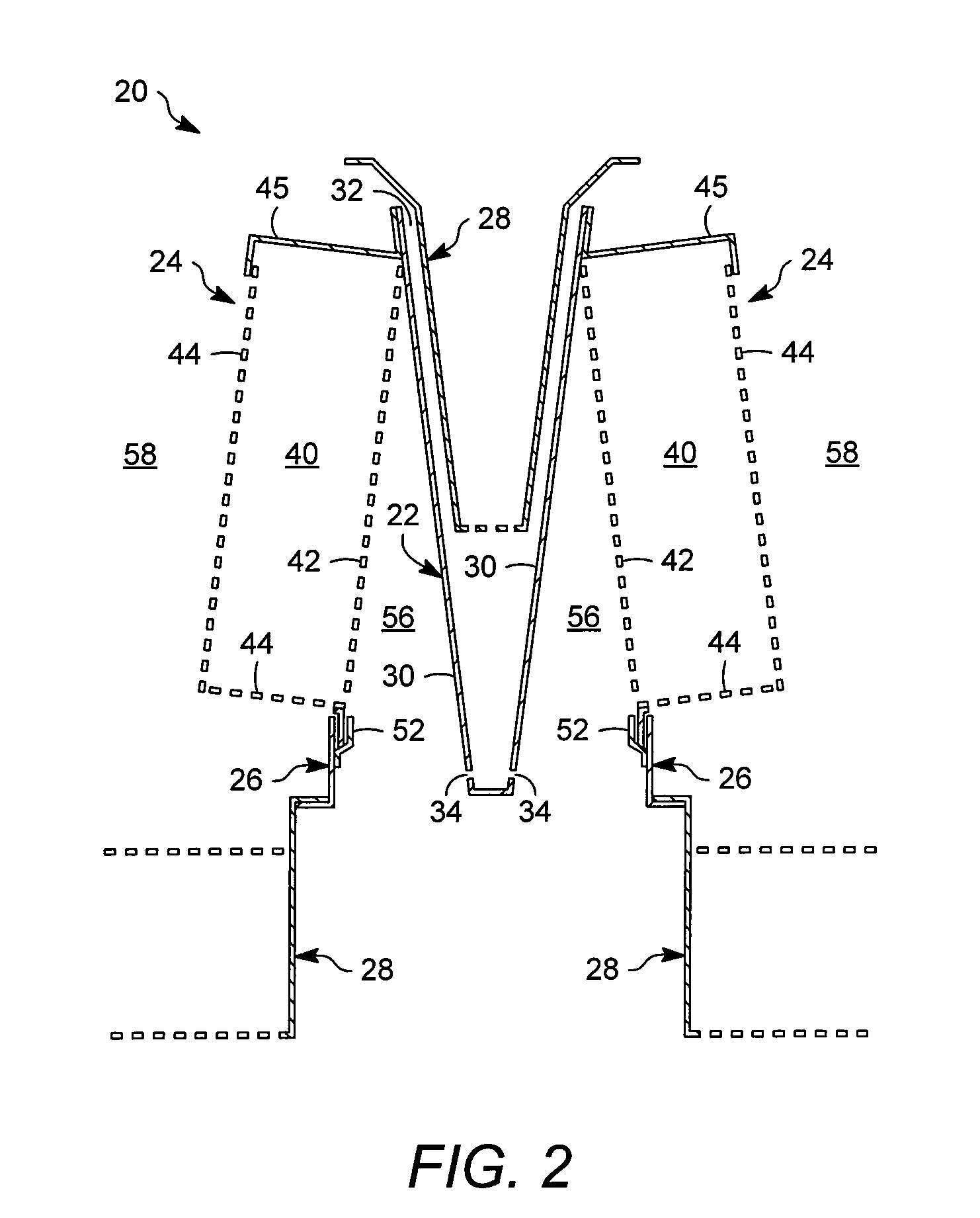

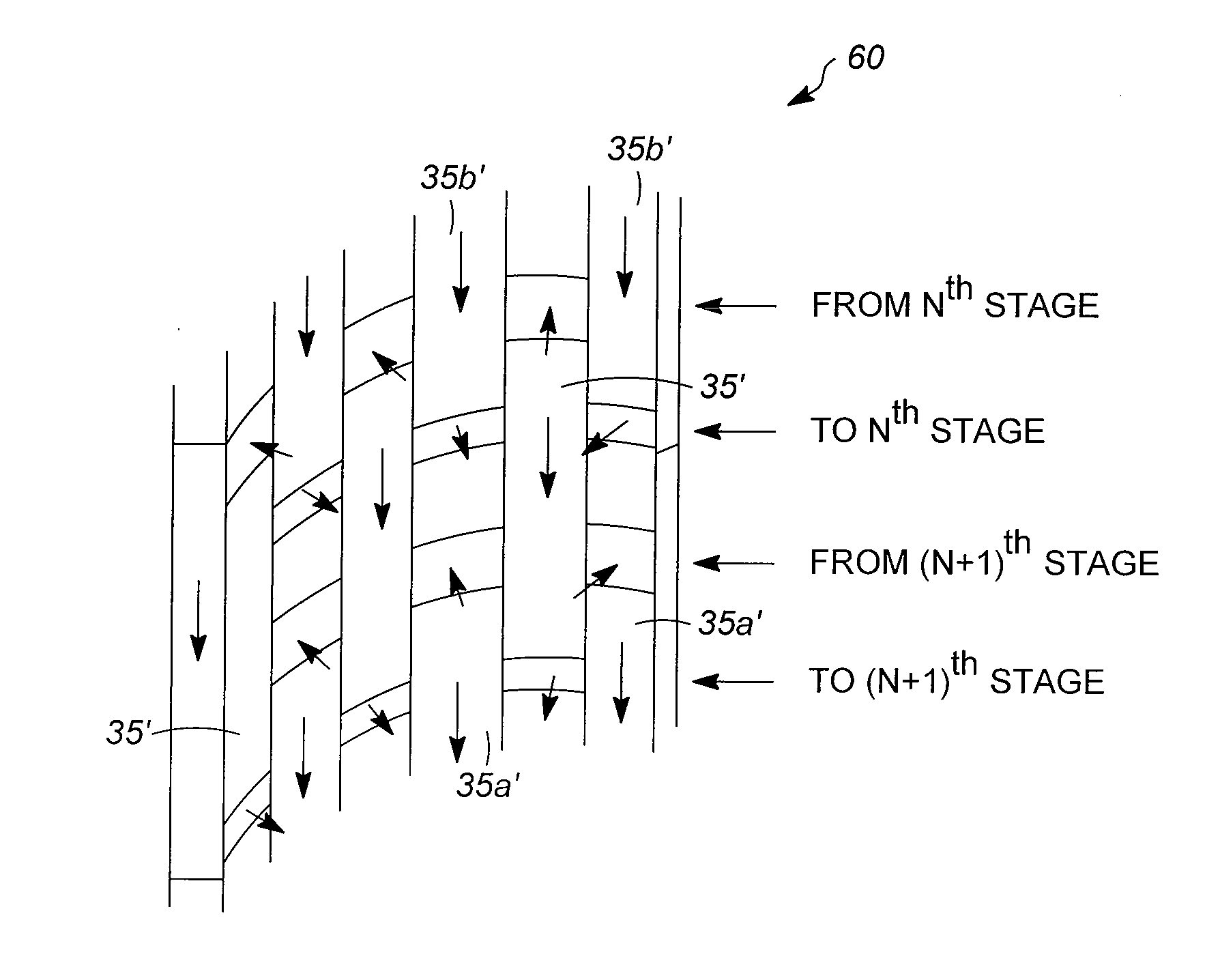

Contacting stages for co-current contacting apparatuses

ActiveUS20100242730A1Reducing liquid handling capabilityLarge capacityCatalytic crackingLiquid degasificationVapor liquidEngineering

Improved contacting stages for carrying out vapor-liquid contacting are described. Particular aspects are directed to co-current vapor-liquid contacting devices with non-parallel contacting stages that provide an efficient usage of column space for fluid flow and contacting, in order to achieve high capacity, high efficiency, and low pressure drop. The fabrication of such contacting stages is improved using one or more structural enhancements, preferably a combination of enhancements, to achieve easy installation and significantly improved rigidity between the various parts and thereby avoid movement / separation of these parts. This reduces the possibility of fluid leakage across, and consequently vapor and / or liquid bypassing of, the contacting stage.

Owner:UOP LLC

Vapor-liquid contacting apparatuses with vortex contacting stages

InactiveUS20100258427A1Narrow downReduction in stage efficiencyCombination devicesTransportation and packagingVapor liquidReactive distillation

Vapor-liquid contacting apparatuses, for example reactors and distillation columns (as well as reactive distillation apparatuses), comprising a vessel with one or more vortex contacting stages, are described. The one or more stages provide high interfacial area for the effective contacting of the different phases, in addition to the effective disengagement of these phases after contacting.

Owner:UOP LLC

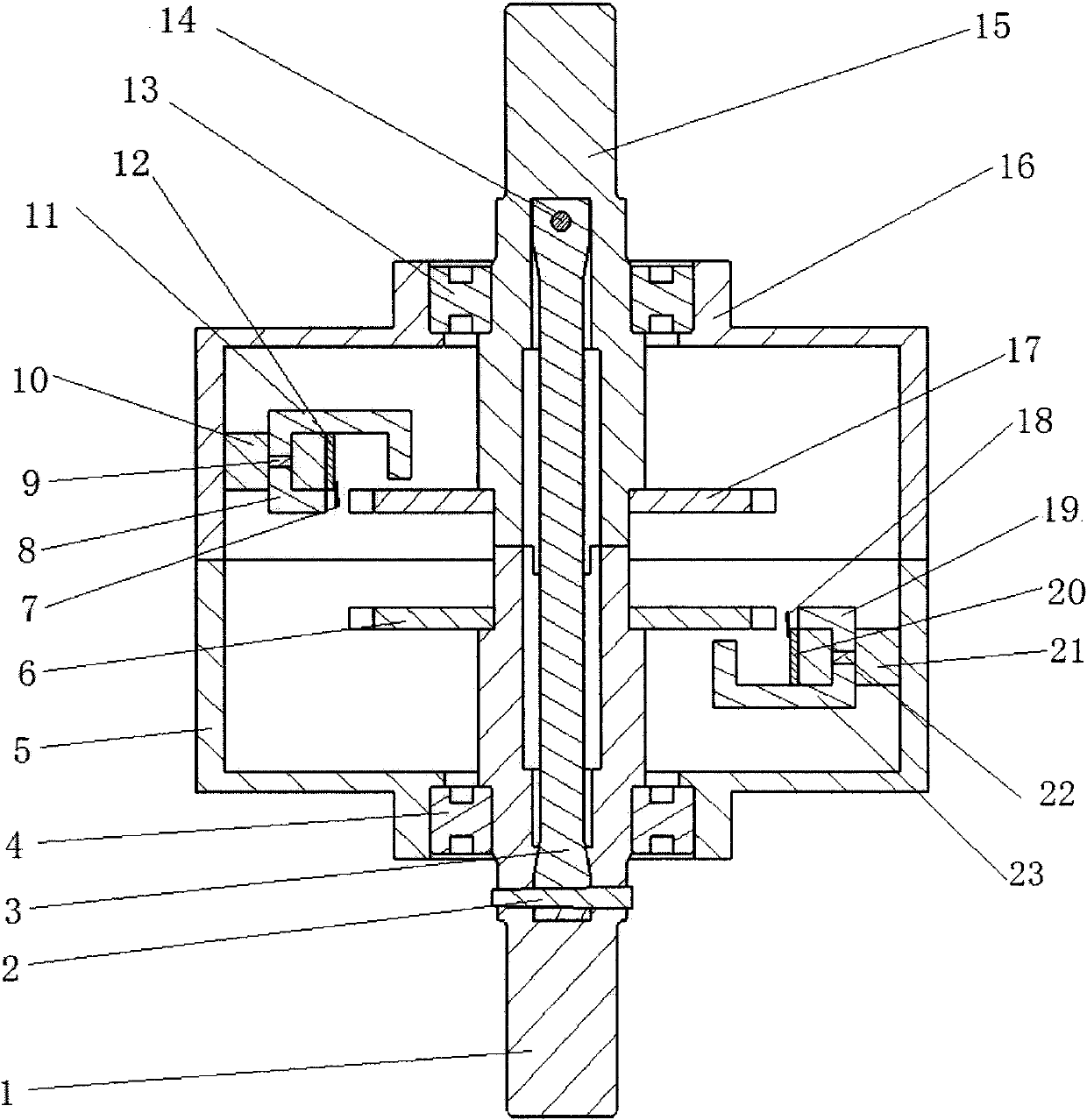

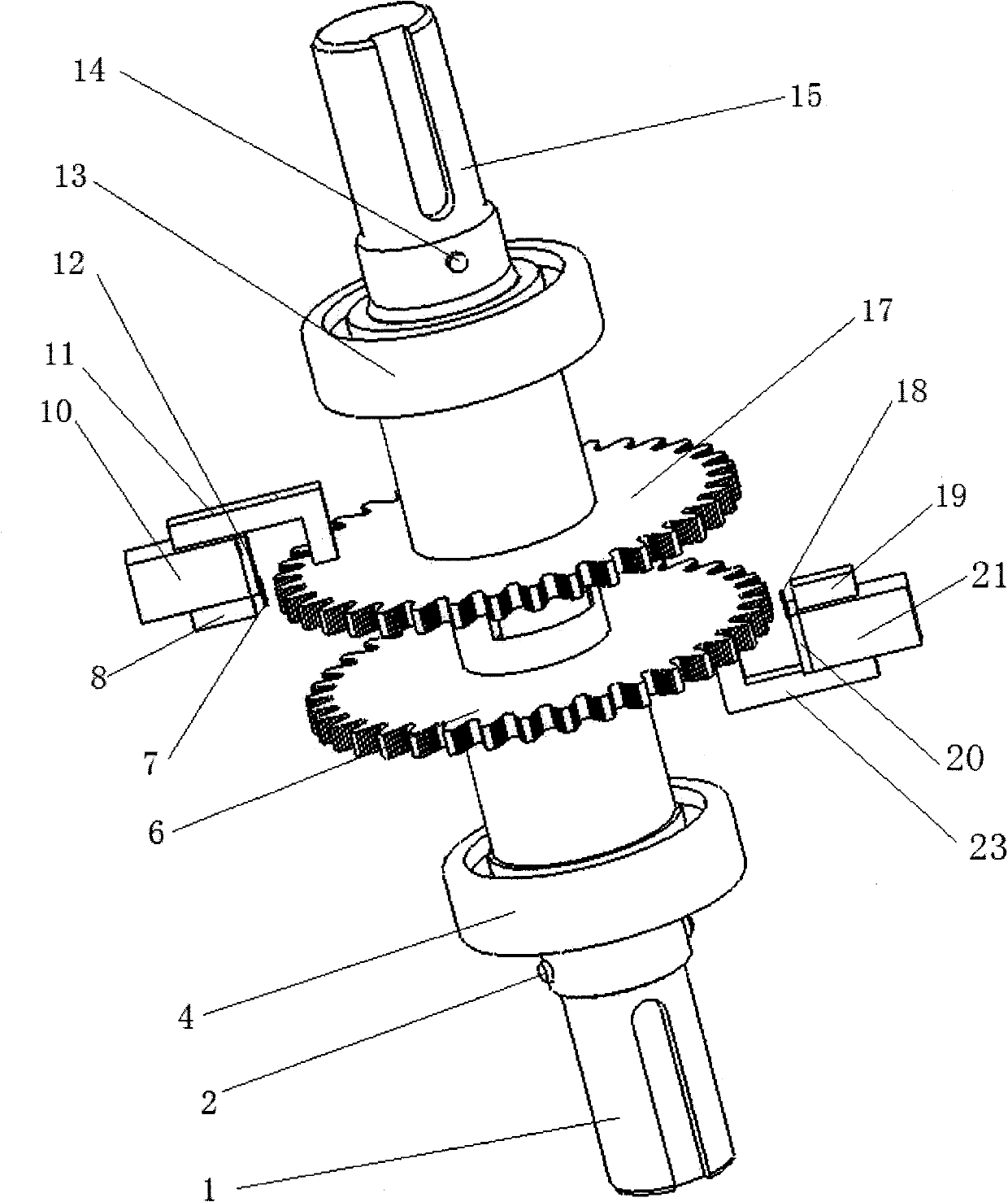

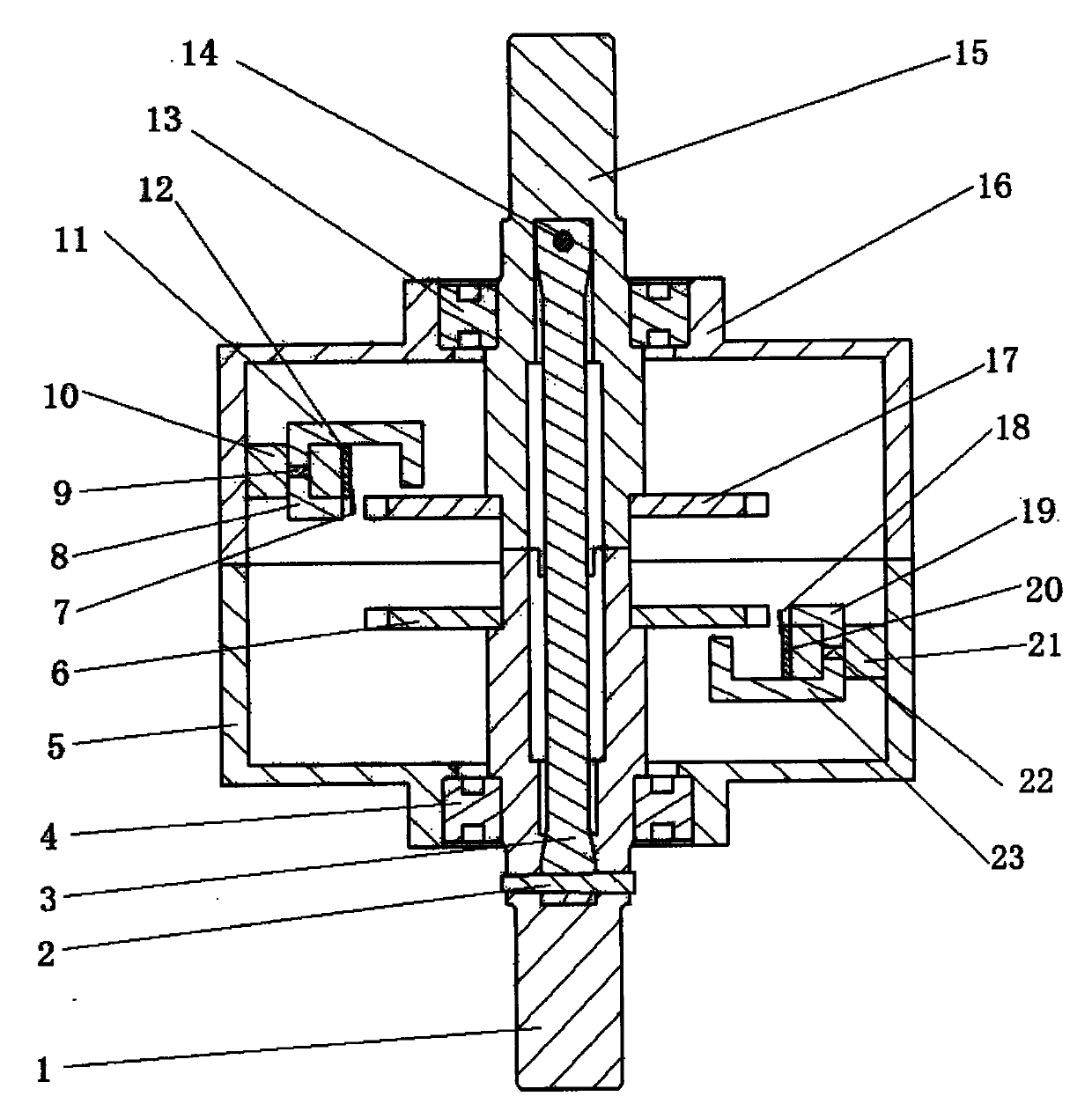

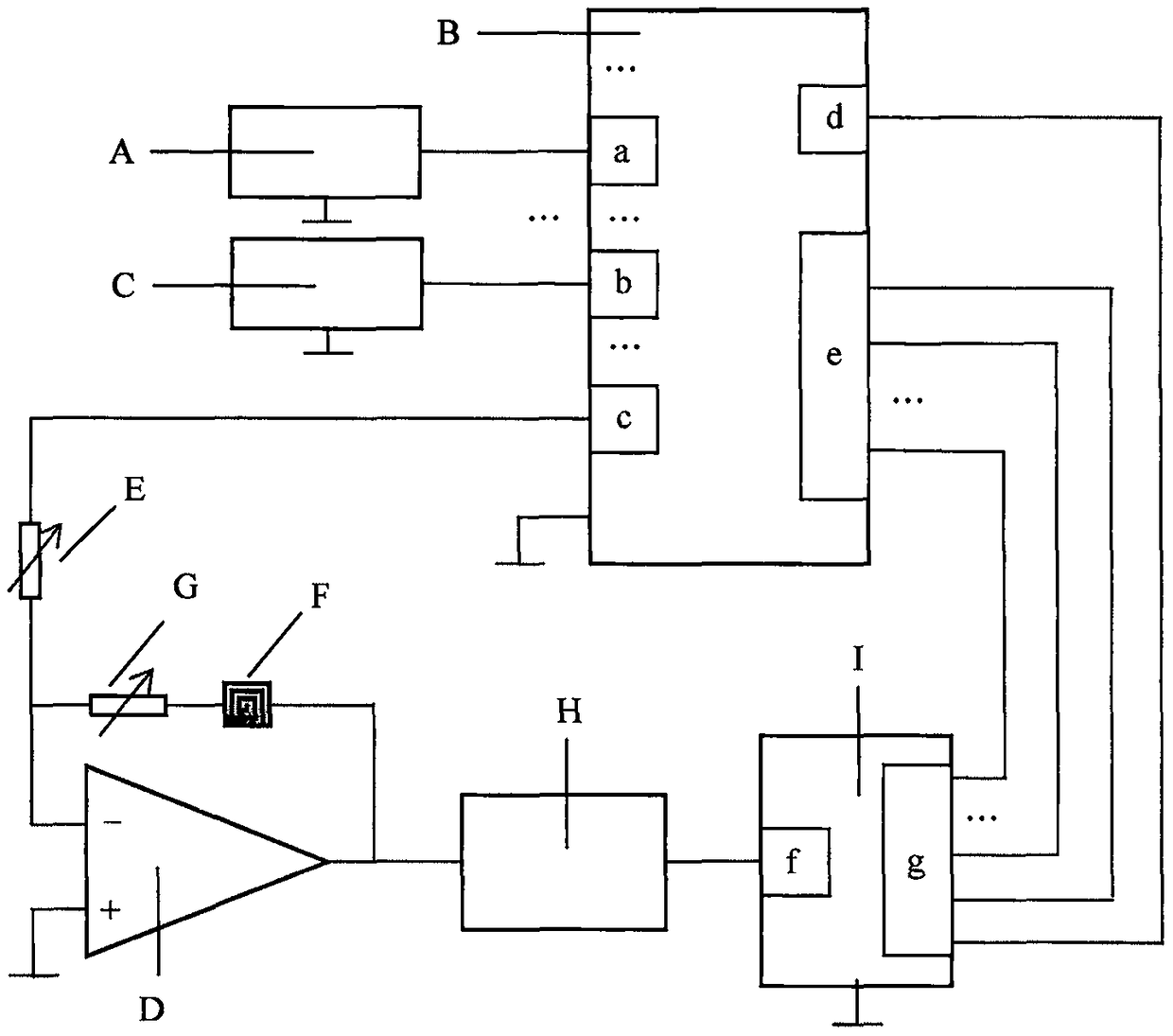

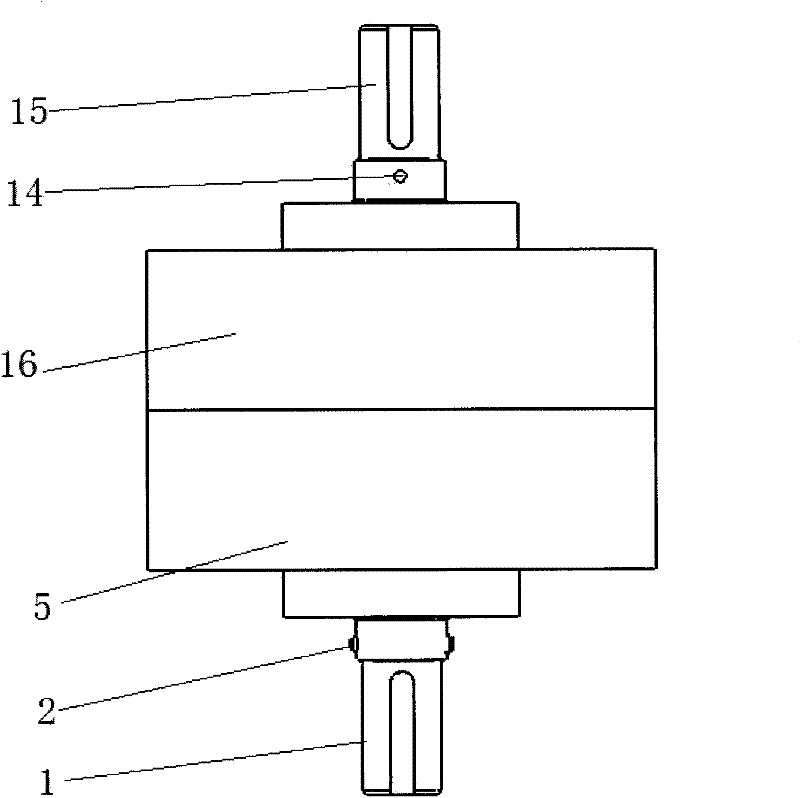

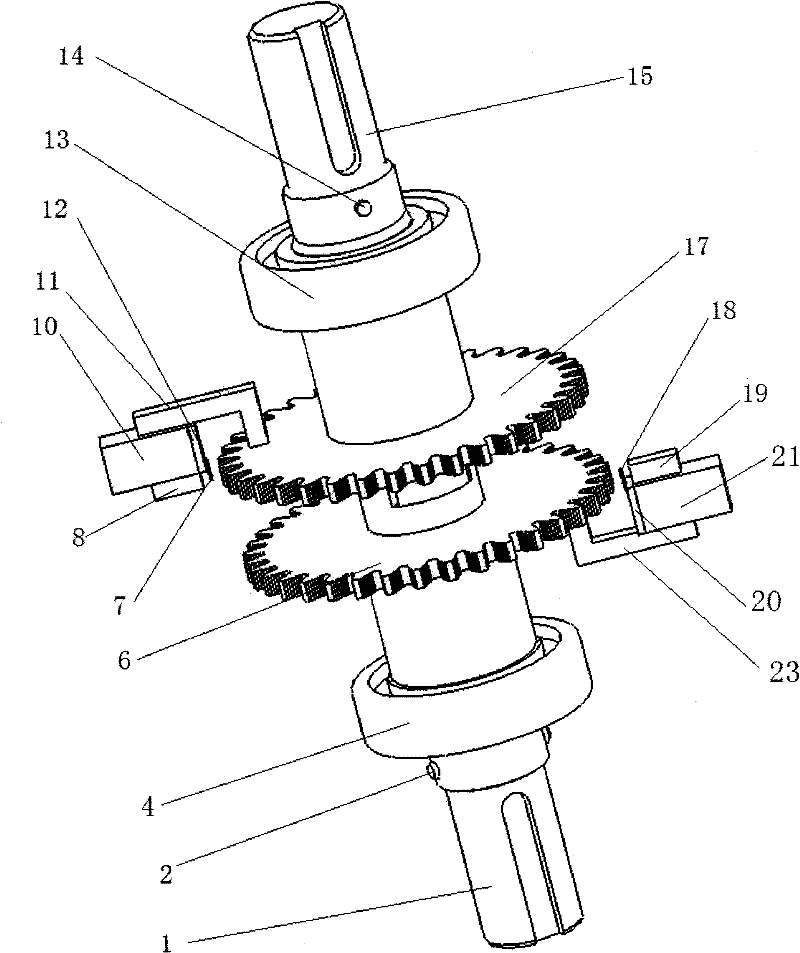

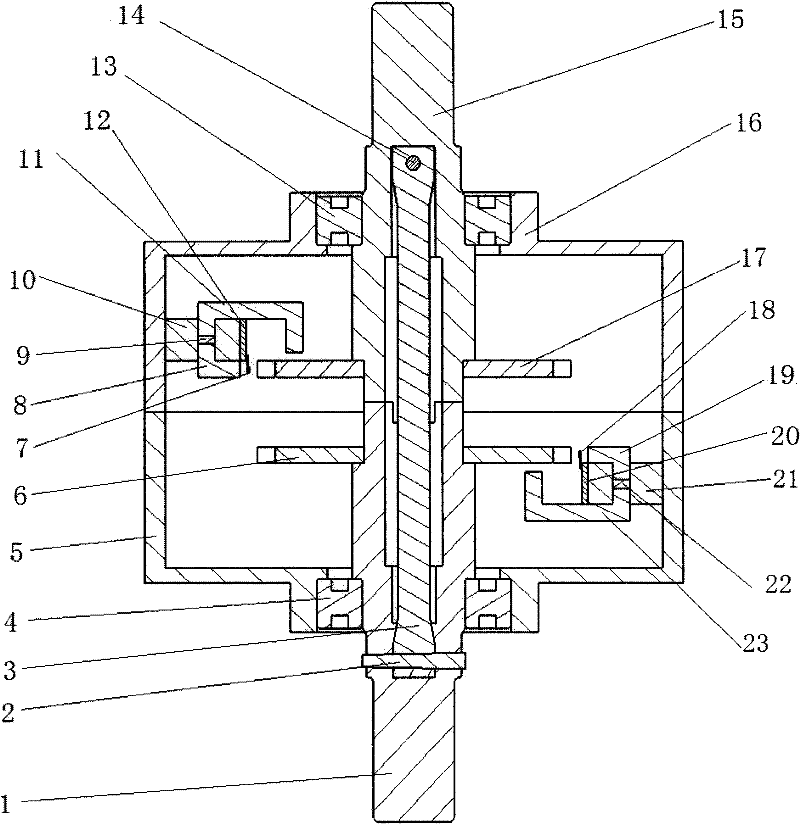

Non-contact phase-difference type torque sensor

InactiveCN101907501ASimple structureReduce volumeWork measurementTorque measurementInterference fitGear wheel

The invention relates to a non-contact phase-difference type torque sensor which comprises an input sleeve, an output sleeve, a Hall sensor, a first involute gear and a second involute gear, wherein the input sleeve is connected with the output sleeve through a torsion bar, a hub bore of the first involute gear is in interference fit with the output sleeve, a hub bore of the second involute gear is in interference fit with the input sleeve, third sections of shaft segments of the input sleeve and the output sleeve are respectively matched with an inner ring of a corresponding bearing, an outer ring of the bearing is respectively matched with two groups of sensor shells which are arranged at two sides of the torsion bar, a magnetic circuit support is respectively fixed on the inner surface of each sensor shell, a magnetic circuit assembly and a circuit board are fixed on each magnetic circuit support, the Hall sensor is welded on the circuit board, and a detection surface of the Hall sensor is arranged in an air gap where the end surface of magnetic-conducting soft iron a just faces to a top addendum circle of the involute gear. The invention has the advantages of simple structure, accurate test, good stability, comparatively lower cost, and the like.

Owner:TONGJI UNIV

Method and Device for Measuring Soil Parameters by Means of Compaction Machines

A soil compaction device has a vibrated contact element that makes contact with the soil during a contact phase and that is exposed to a contact force exerted by the soil and travels over a contact distance. A dynamic stiffness of the soil is formed from the gradient of the contact force and from the contact distance. Furthermore, a contact surface parameter to take account of the actual contact surface of the contact element with the soil is determined. The dynamic deformation modulus is then the product of the contact surface parameter and the dynamic stiffness. The method allows the determination of the dynamic deformation modulus, and hence of the soil stiffness, during the compaction operation.

Owner:WACKER NEUSON SE

Preparation method of metal-coated carbon nano-tube reinforced metal matrix composite

ActiveCN108441662AImprove contact phase boundary compatibilityImprove wettabilityElectrolytic inorganic material coatingTransportation and packagingCarbon nanotubeMetal matrix composite

The invention discloses a preparation method of a metal-coated carbon nano-tube reinforced metal matrix composite. The preparation method comprises the following steps that firstly, a powdered carbonnano-tube is reduced in situ to be coated with metal to obtain metal-coated carbon nano-tube composite powder, and the metal-coated nano-tube composite powder and metal powder are subjected to ball milling and powder mixing to obtain metal-coated carbon nano-tube / metal mixed powder; powder metallurgy warm compaction process is adopted, the metal-coated carbon nano-tube / metal mixed powder is subjected to warm compaction, molding and sintering, and a composite material is subjected to machine shaping to obtain the metal-coated carbon nano-tube reinforced metal matrix composite by processes suchas extrusion, forging and pressing and rolling. The preparation method of the metal-coated carbon nano-tube reinforced metal matrix composite uses the metal-coated carbon nano-tube as a reinforcing body, the contact phase boundary compatibility between the carbon nano-tube and the metal is improved, and the preparation method is simple; and the metal-coated carbon nano-tube reinforced metal matrixcomposite with good mechanical property and thermal physical property can be obtained, and wide application prospects are achieved.

Owner:KUNMING UNIV OF SCI & TECH

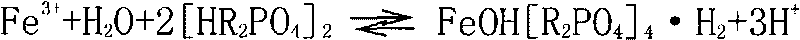

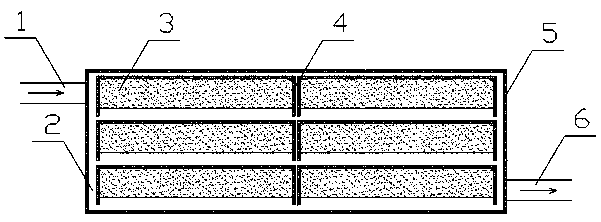

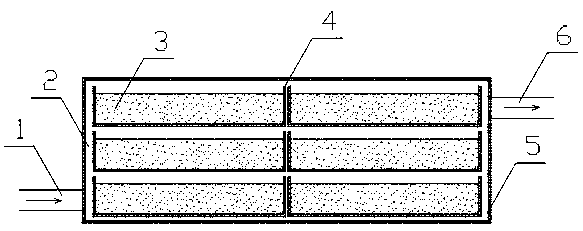

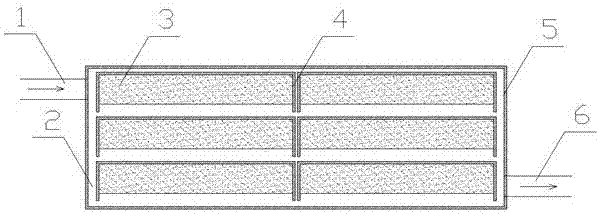

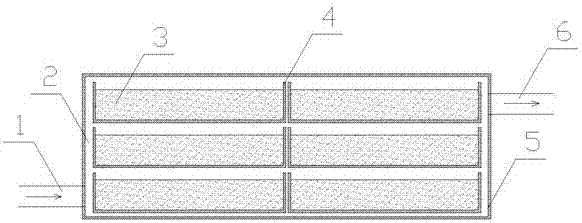

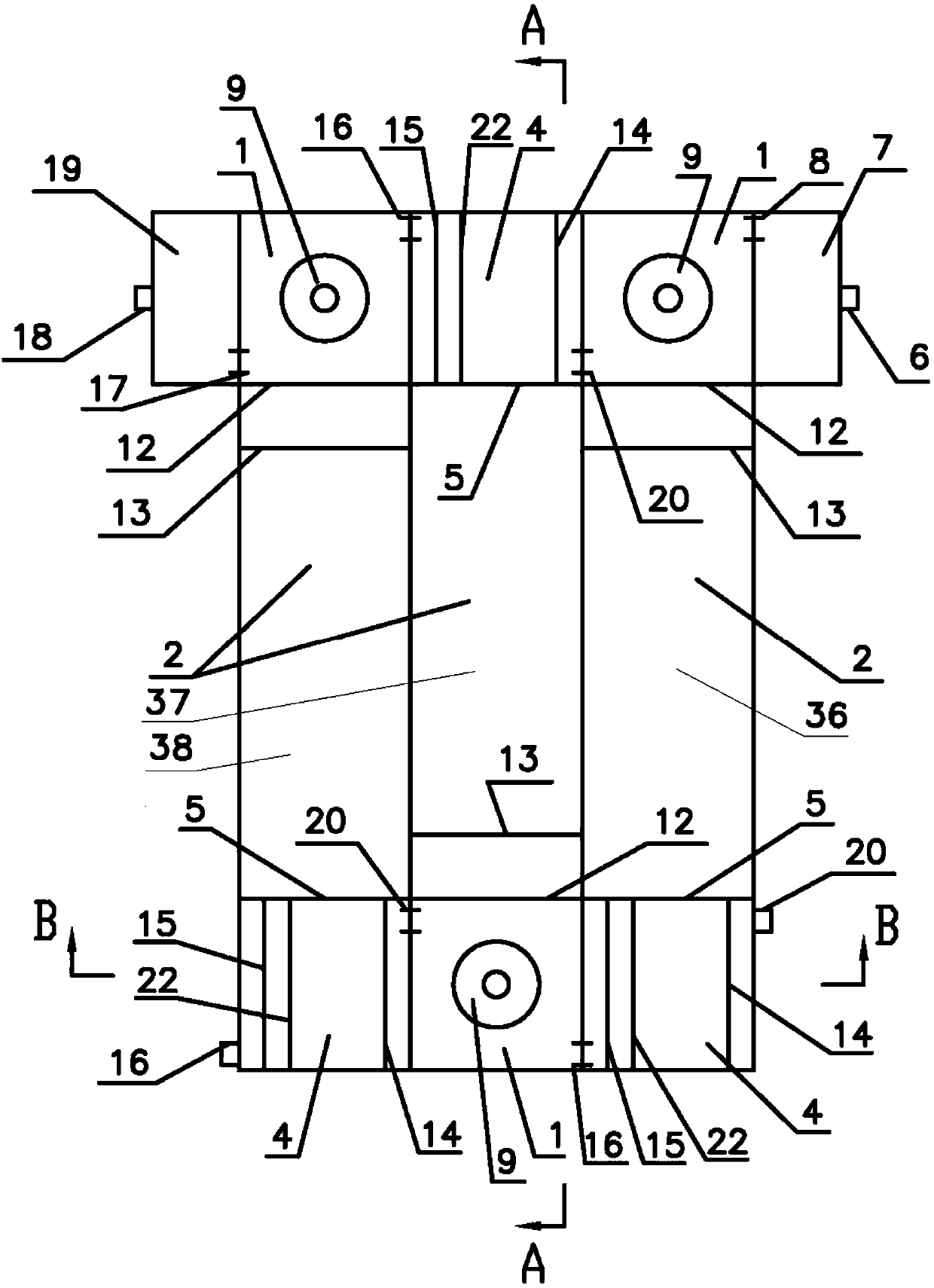

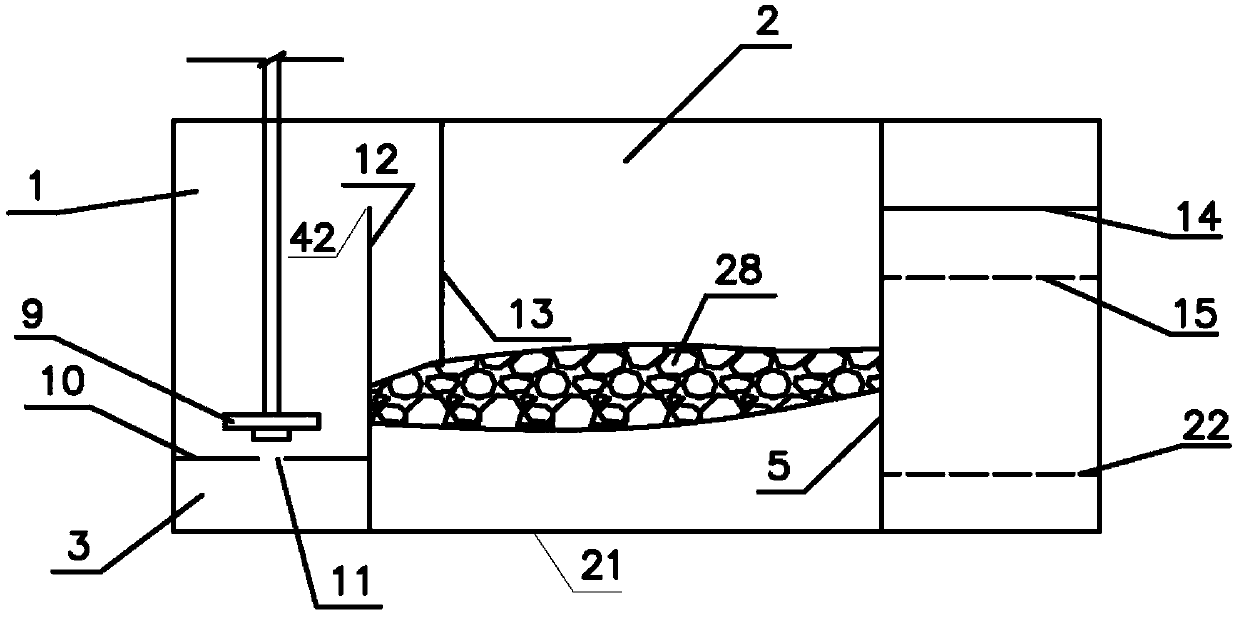

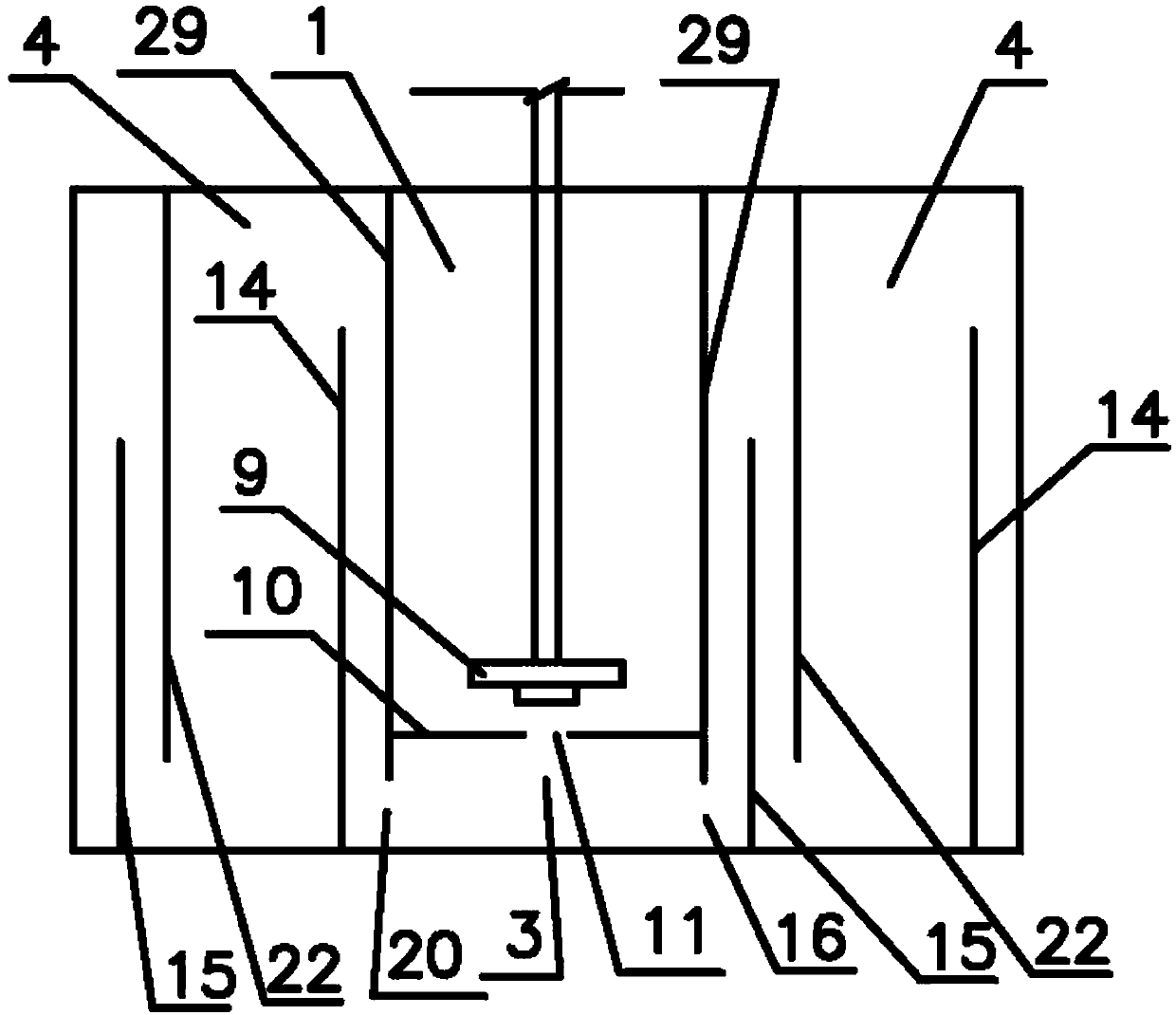

Direct contact phase-changing heat storage device

InactiveCN105371677AImprove performanceClose contactHeat storage plantsFixed frameVolumetric Mass Density

The invention relates to a direct contact phase-changing heat storage device. The direct contact phase-changing heat storage device comprises a heat transfer fluid inlet (1), heat transfer fluid runners (2), phase-changing heat storage materials (3), phase-changing heat storage material fixing frames (4), a heat storage device container shell (5) and a heat transfer fluid outlet (7), wherein the multiple phase-changing heat storage material fixing frames (4) are mounted in the heat storage device container shell (5); gaps between the adjacent phase-changing heat storage material fixing frames (4) as well as between the phase-changing heat storage material fixing frames (4) and the heat storage device container shell (5) are the heat transfer fluid runners (2); the phase-changing heat storage materials (3) are placed in the phase-changing heat storage material fixing frames (4); the heat transfer fluid inlet (1) is formed in one end of the heat storage device container shell (5), and the heat transfer fluid outlet (7) is formed in the other end of the heat storage device container shell (5); and the heat transfer fluid inlet (1) and the heat transfer fluid outlet (7) are used for allowing heat transfer fluid to flow in and flow out respectively. The direct contact phase-changing heat storage device is large in heat storage density, simple in structure, good in heat exchange effect, wide in application range, reliable in performance and low in manufacturing cost.

Owner:邹杰

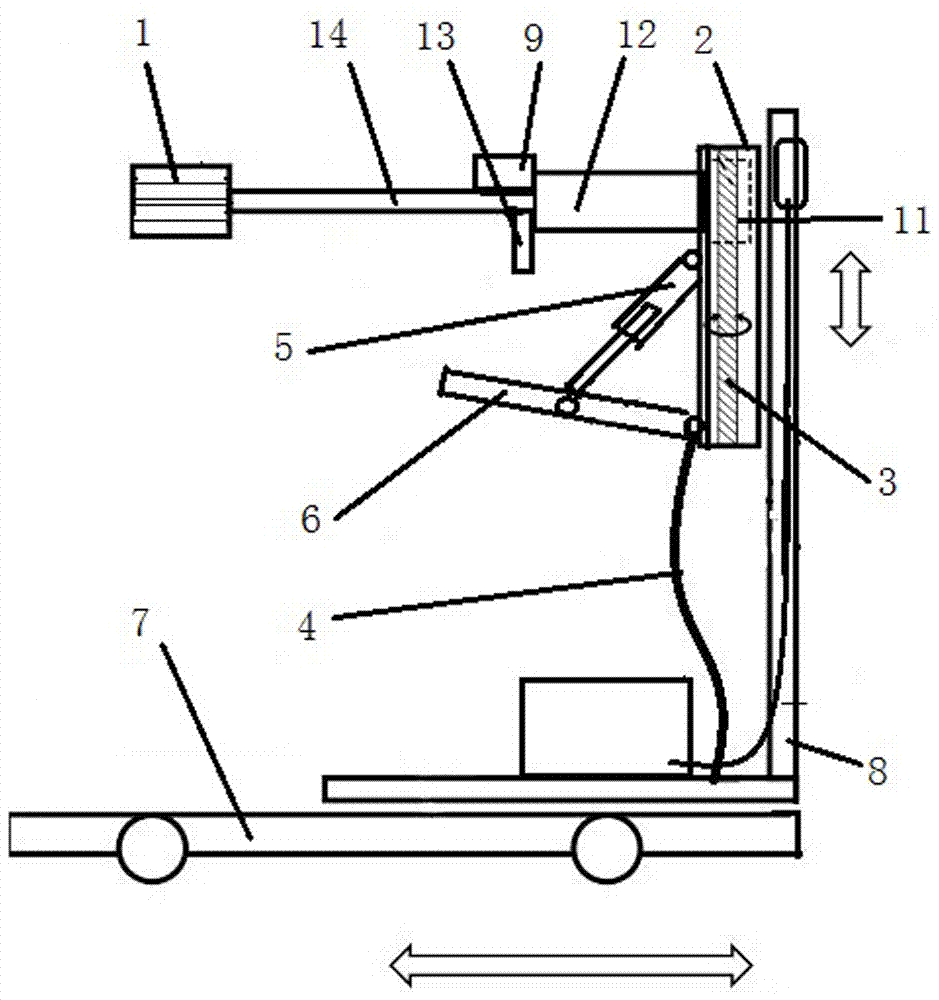

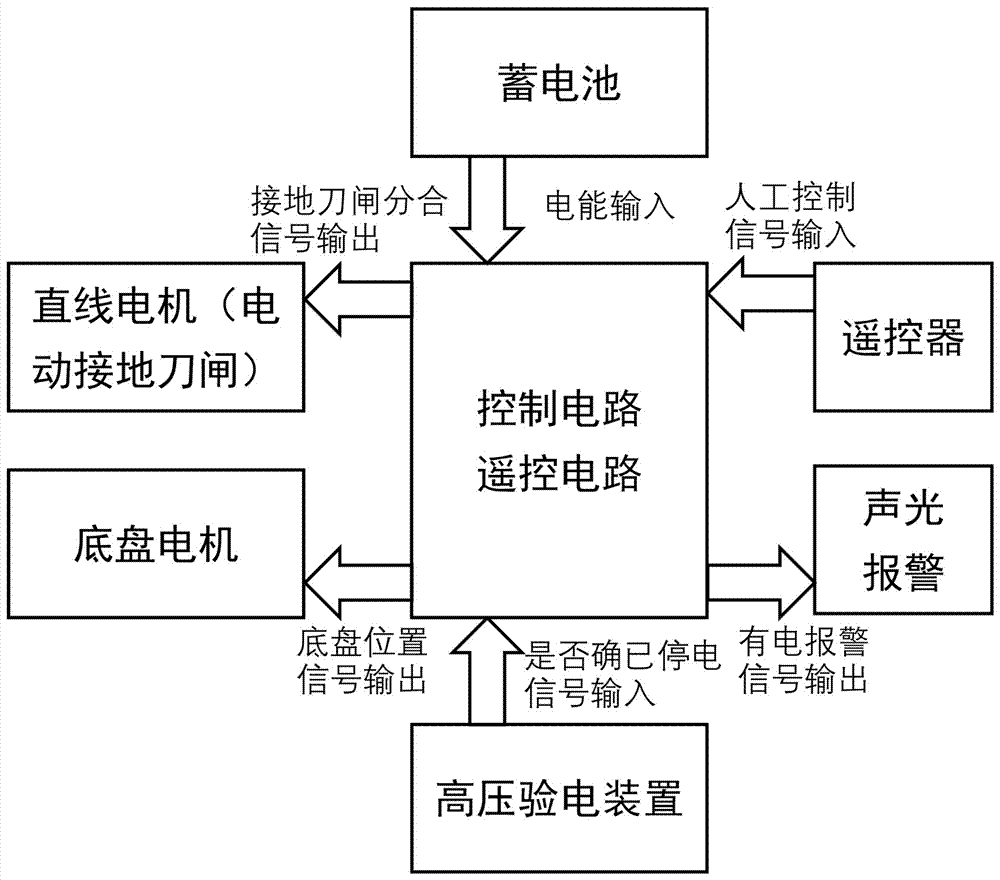

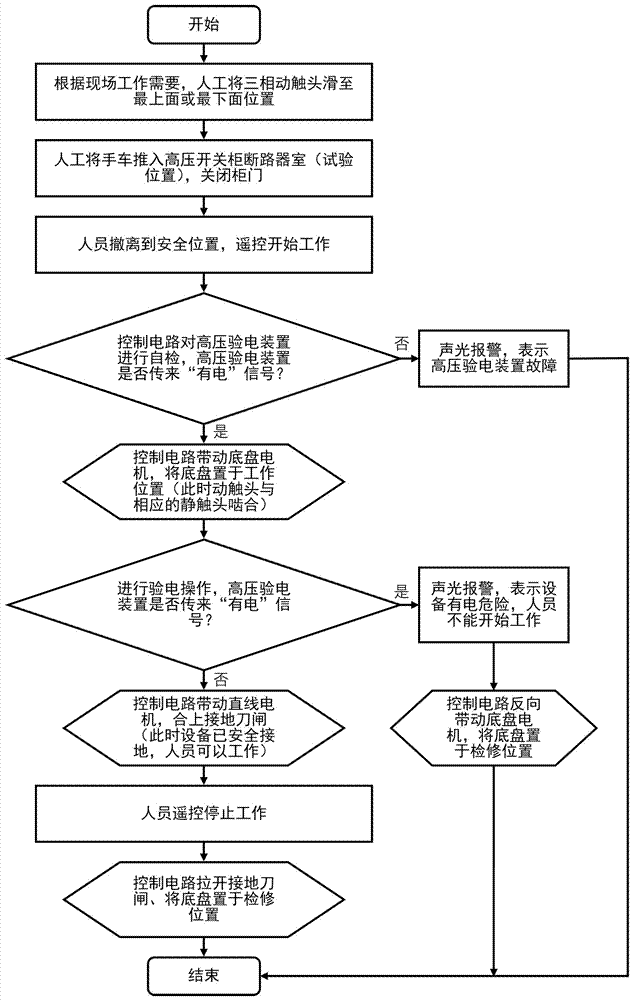

Electrical inspection grounding handcart and working method

PendingCN107153134AImprove securityImprove work efficiencyCurrent/voltage measurementGround contactVehicle frame

The invention relates to an electrical inspection grounding handcart and a working method, and belongs to check-out equipment of electric appliances. The technical scheme adopted by the invention is described as follows: the electrical inspection grounding handcart comprises a self-help movable chassis and is also provided with a three-phase moving contact capable of moving up and down, wherein the three-phase moving contact is arranged on the front end of a moving contact base; the rear part of the moving contact base is arranged on a lifting device; the lifting device is arranged on a vertical vehicle frame; a grounding static contact conductively connected with each phase of the three-phase moving contact is arranged below the moving contact base; a pendulant grounding knife-switch is arranged below the grounding static contact; an extension end of a linear motor is connected at the front end of the grounding knife-switch; the vehicle frame is articulated with the rear end of the linear motor; the extension end of the linear motor moves to drive the grounding knife-switch to upswing and be connected and electrified with each phase of the grounding static contact; the grounding knife-switch is connected with a grounding line.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

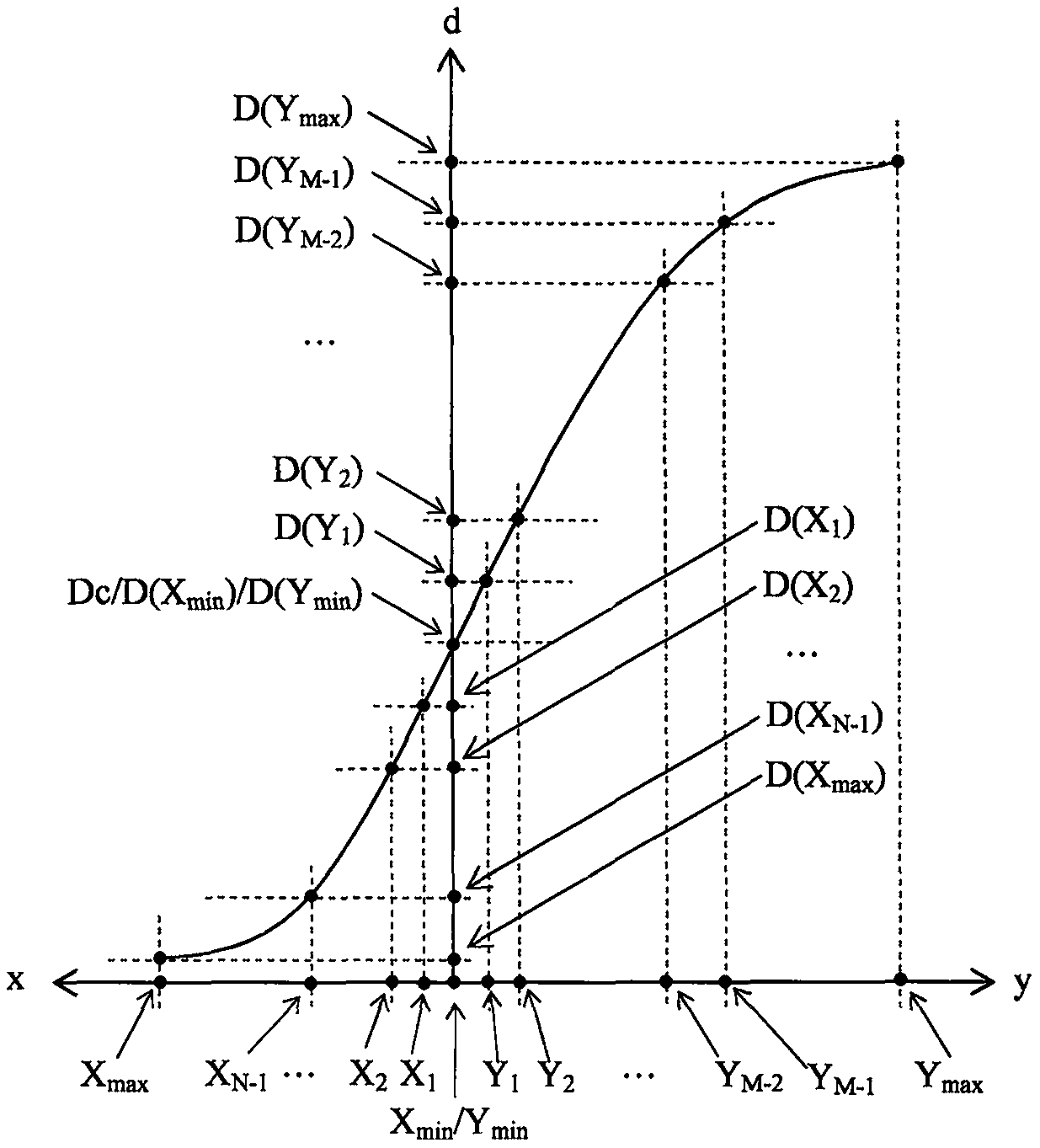

Method for measuring pressure and non-contact displacement by using flexible pressure sensitive coil

InactiveCN109341908AGood repeatabilityStable responseForce measurementUsing electrical meansInter layerIndustrial equipment

The invention relates to a method for measuring pressure and non-contact displacement by using a flexible pressure sensitive coil, which belongs to the technical filed of measuring. The method comprises the following steps: before calibrating, applying a heavy pressure and multiple loading and unloading cycles to the flexible pressure sensitive coil to improve the stability of a conductive networkinside the coil; in calibration phase, obtaining a critical impedance of the flexible pressure sensitive coil and its corresponding critical digital quantity, and obtaining calibration data of non-contact and contact phases; in a measurement phase, comparing a digital quantity corresponding to the impedance of the flexible pressure sensitive coil with a critical digital quantity to determine whether the flexible pressure sensitive coil is in the contact phase, and obtaining the pressure and non-contact displacement by using calibration data. The method for measuring pressure and non-contact displacement by using the flexible pressure sensitive coil can improve the repeatability of the impedance of the flexible pressure sensitive coil with pressure and non-contact displacement, and can judge the stress state of the coil, thereby achieving measurement in the contact and non-contact phases, which is particularly suitable for is particularly suitable for the field of narrow inter-layer pressure and non-contact displacement measurement of modern large industrial equipment.

Owner:CENT SOUTH UNIV

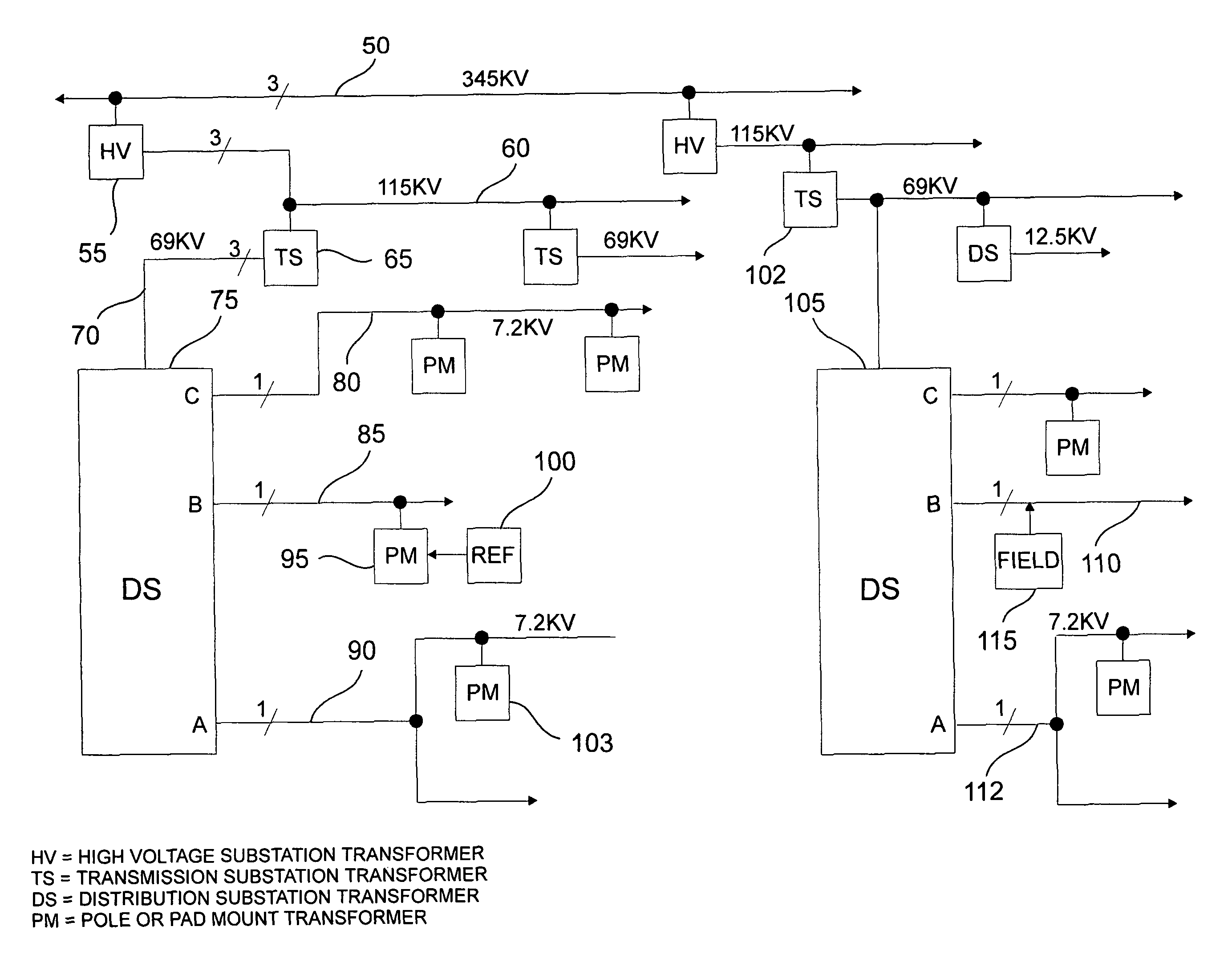

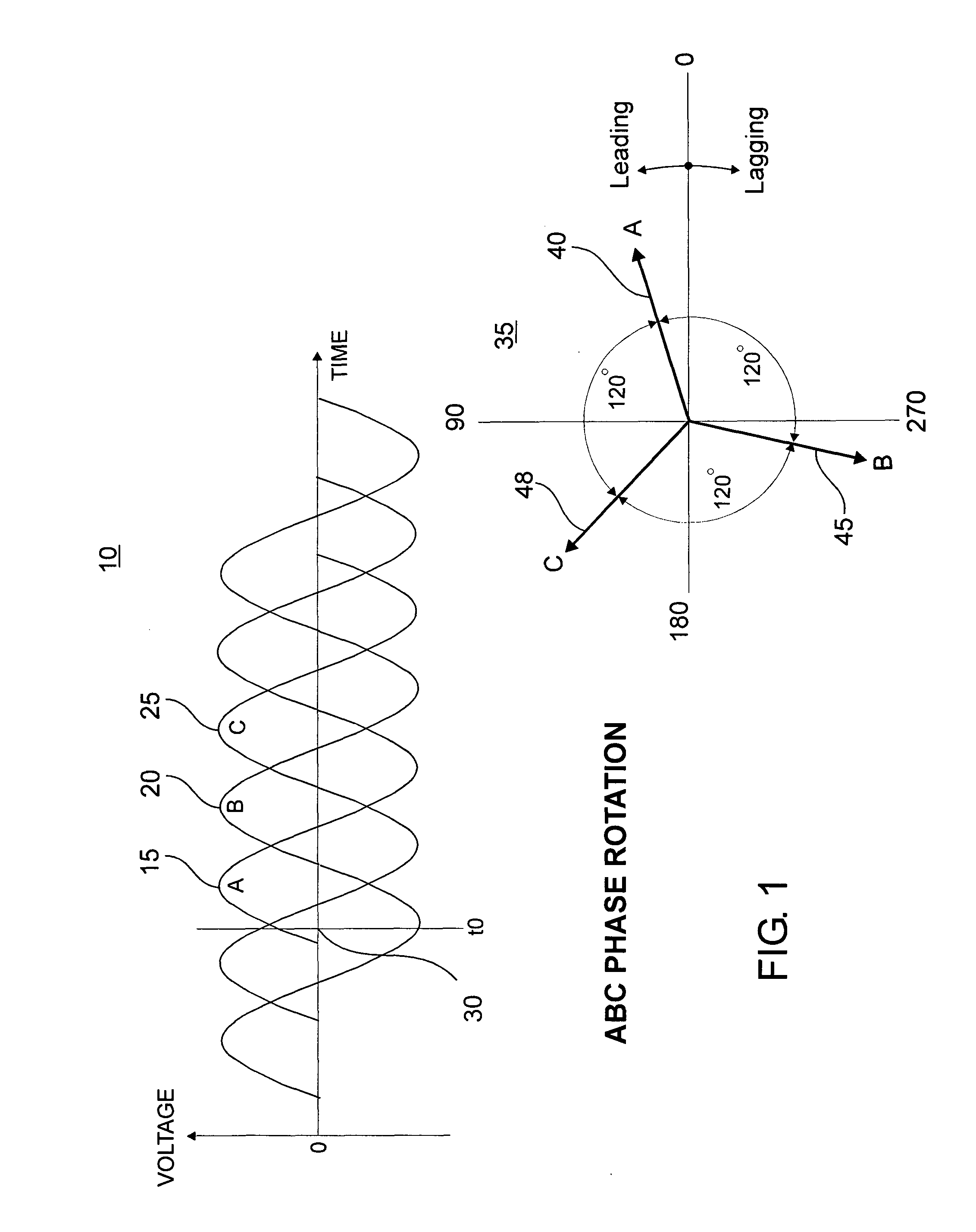

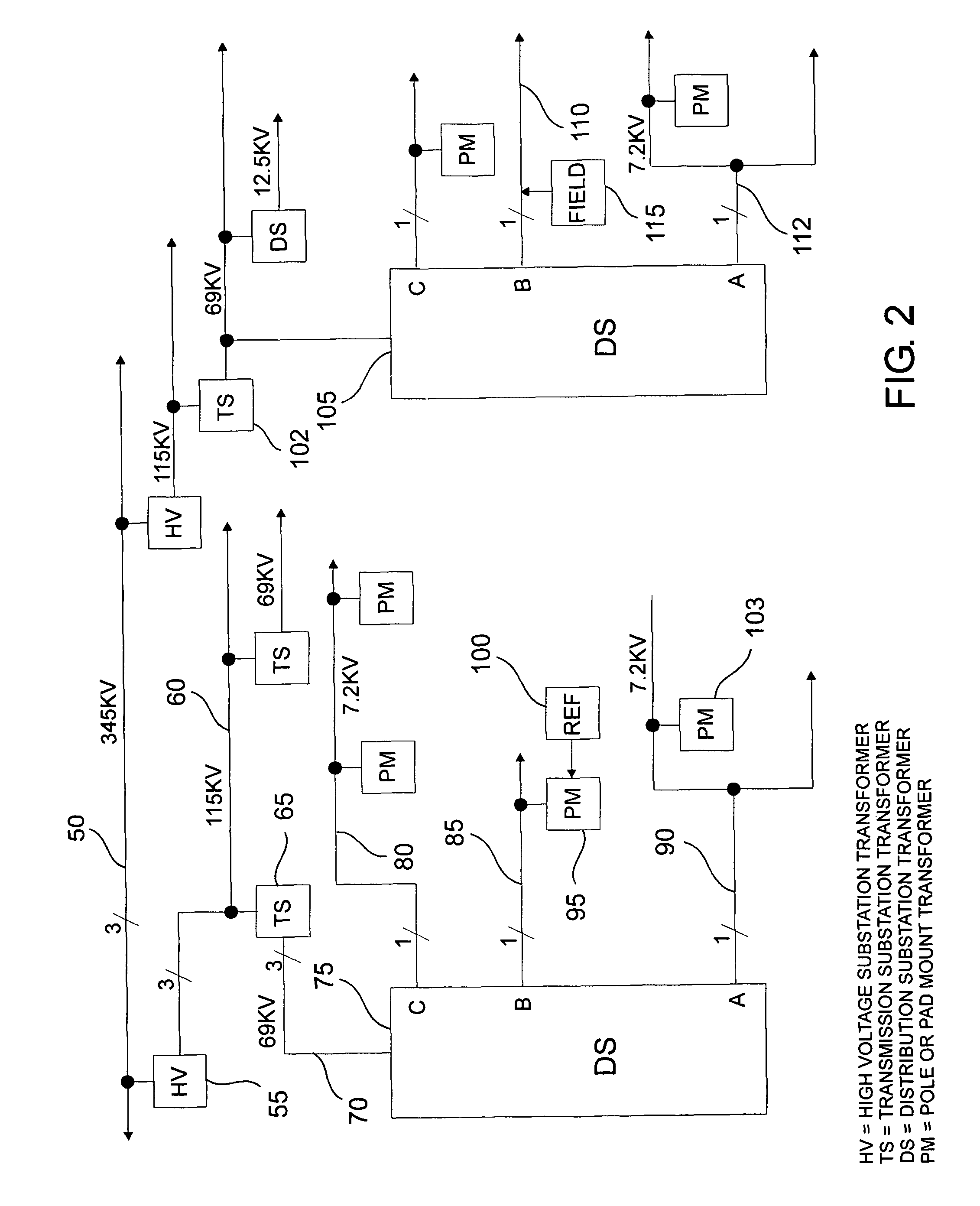

Non-contact phase identification method and apparatus

ActiveUS8570024B1Increase signal levelHigh sensitivityNoise figure or signal-to-noise ratio measurementCurrent/voltage measurementElectrical conductorThree-phase

A phase identification system identifies the unknown phase attribute of any energized conductor within a three-phase power distribution network by comparing remote location non-contact phase identification instrument phase measurements to phase measurements taken at a reference location. The vector sum of three-phase conductor voltages at the remote measurement location are used to determine the near, center, and far conductor phase attributes of the three-phase lines being measured. This allows phase attributes of high overhead conductors to be determined from ground level using a non-contact handheld instrument.

Owner:PIESINGER GREGORY HUBERT

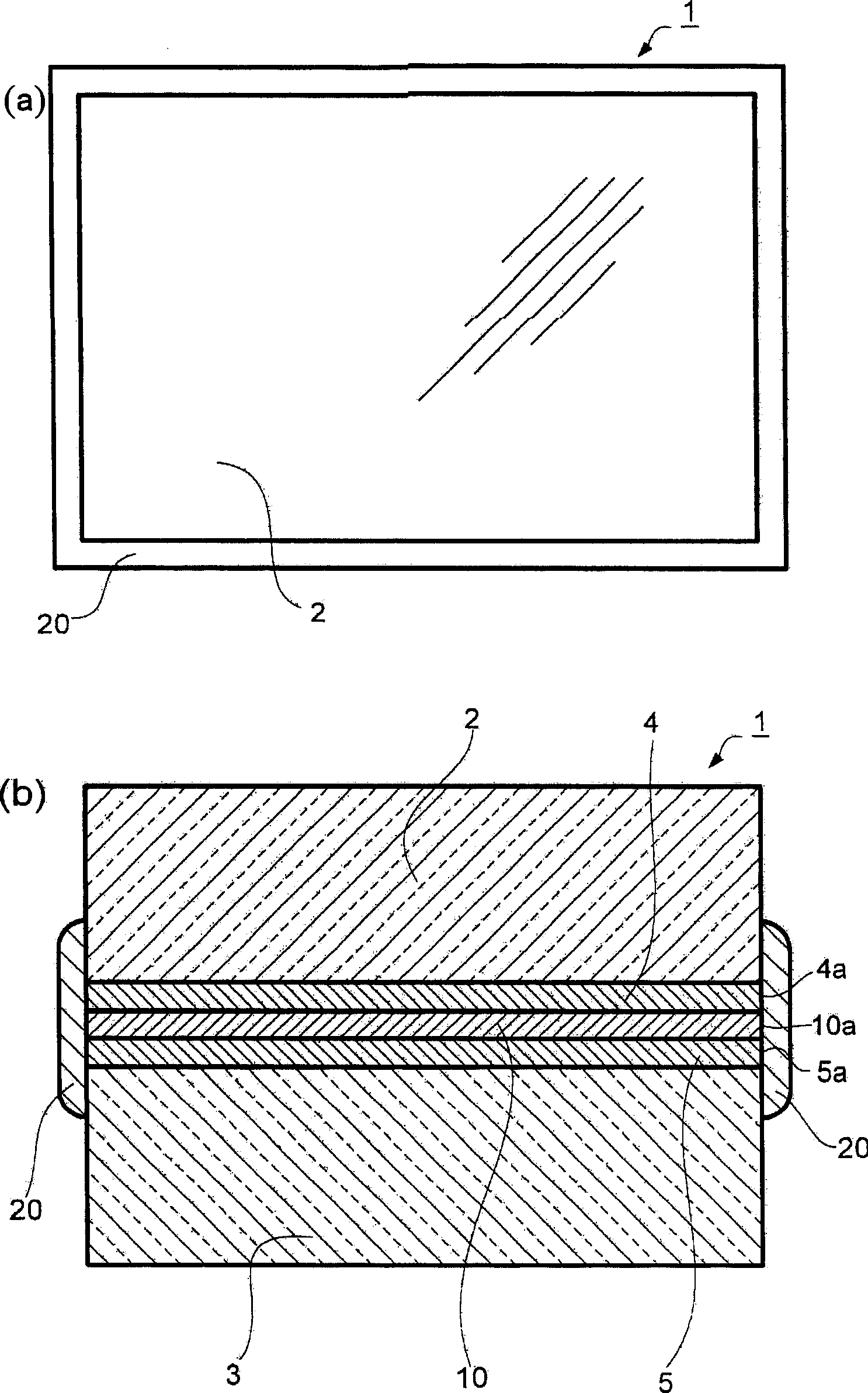

Optical low-pass filter

The invention relates to an optical low-pass filter, which is formed by using adhesive to contact phase difference film, to improve damp-proof property, wherein the phase difference film 10 formed by macromolecule film as 1 / 4 wavelength plate to be adhered with adhesives 4, 5 to be arranged between crystal plates 2, 3 as dual-reflective plates; in the areas of circumference 4a of adhesive layer 4, the circumference 5a of adhesive layer 5 and the circumference 10a of phase difference film, a sealing part 20 is formed, while it can be formed by physical filming layer, chemical filming layer, adhesive band and resin compound.

Owner:SEIKO EPSON CORP

Mixer-settler

ActiveCN109646996AMeet the needs of useGuaranteed contactLiquid solutions solvent extractionRefluxMixer-settler

The invention discloses a mixer-settler which comprises at least one settling tank. The settling tank comprises a mixing chamber, a settling chamber and a separation chamber which are sequentially arranged and communicated. The settling tank also comprises a submersible chamber which is arranged below the mixing chamber and communicated with the mixing chamber. The separation chamber comprises a heavy phase chamber, a light phase chamber, and the separation chamber also comprises a reflux chamber, wherein the heavy phase or the light phase in the separation chamber flows into the reflux chamber. One end of a reflux pipeline is connected with the submersible chamber and the other end of the reflux pipeline is connected with the reflux chamber. The reflux pipeline is used for refluxing the heavy phase or the light phase back to the submersible chamber. Under the condition that the two-phase flow of the heavy phase and the light phase in the mixer-settler is relatively large, a part of one phase with a smaller flow rate can be refluxed into the mixing chamber, so that the contact phase ratio of the two phases in the mixing chamber is close to 1, and the mass transfer efficiency is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Method for judging loading phase of flexible pressure sensitive coil

InactiveCN109341728AImmune to adverse effects of critical impedance driftConverting sensor output electrically/magneticallyInter layerMultiplexer

The invention relates to a method for judging the loading phase of a flexible pressure sensitive coil, which belongs to the technical filed of measuring. The method comprises the following steps: using a multiplexer to access an AC signal source and a DC signal source into a measurement circuit of the flexible pressure sensitive coil with time-division, so that a microprocessor can collect an AC response and a DC response of the flexible pressure sensitive coil with time-division. If there has a DC response, it indicates that the flexible pressure sensitive coil is in a contact phase, and thencompleting a pressure measurement by calibration data and a conversion algorithm of the AC response and the contact phase; if there has no DC response, it indicates that the flexible pressure sensitive coil is in a non-contact phase, and then completing a non-contact displacement measurement by calibration data and the conversion algorithm of the AC response and the non-contact phase. The methodfor judging the loading phase of the flexible pressure sensitive coil can prevent the judgment of the load phase of the flexible pressure sensitive coil from an adverse effect of a critical impedancedrift, and is particularly suitable for the field of narrow inter-layer pressure and non-contact displacement measurement of modern large industrial equipment.

Owner:CENT SOUTH UNIV

Method for back extraction of amine molybdenum-containing organic phase

InactiveCN109022831AHigh recovery rateReduce consumption costProcess efficiency improvementSingle stageDiluent

The invention relates to a method for back extraction of amine molybdenum-containing organic phase. The method adopts single stage back extraction or multi-stage back current back extraction, the amine molybdenum-containing organic phase comprises the following components by concentration: 1-20% of amine, 1-30 g / L of molybdenum, and the balance a phase improver and a diluent. The method comprisesthe following steps that 1, a back extraction agent is prepared, the back extraction agent is mixed solution of ammonia and hydrogen peroxide, the ammonia concentration range is 5-28%, the hydrogen peroxide addition is 1-15% of the ammonia addition, and the concentration range of the hydrogen peroxide is 10-50%; 2, the back extraction agent prepared by the step one and the amine containing-molybdenum organic phase are subjected to mixing and back extraction, the flow ratio of the organic phase to a water phase is 2:1-50:1, the back extraction time is 1-10 min, the back extraction temperature is 10-40 DEG C, and the contact phase ratio between the organic phase and the water phase is 4:1-1:4; and 3, and the mixed phase obtained in the step two is separated to obtain the containing-molybdenum back extraction fluid and a stripped organic phase. By means of the method, the interfacial dirt produced in the back extraction process of the amine containing-molybdenum organic phase can be reduced by more than 50%.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

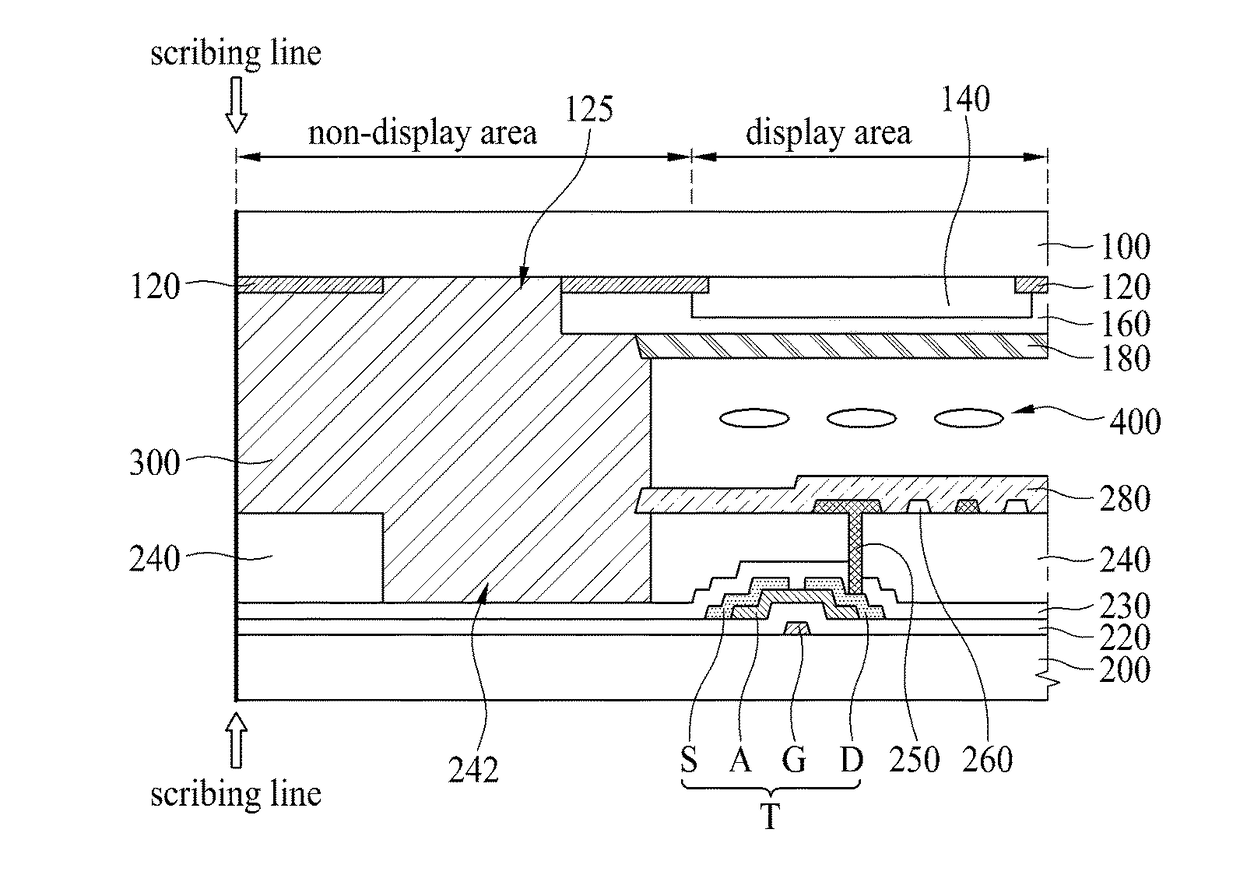

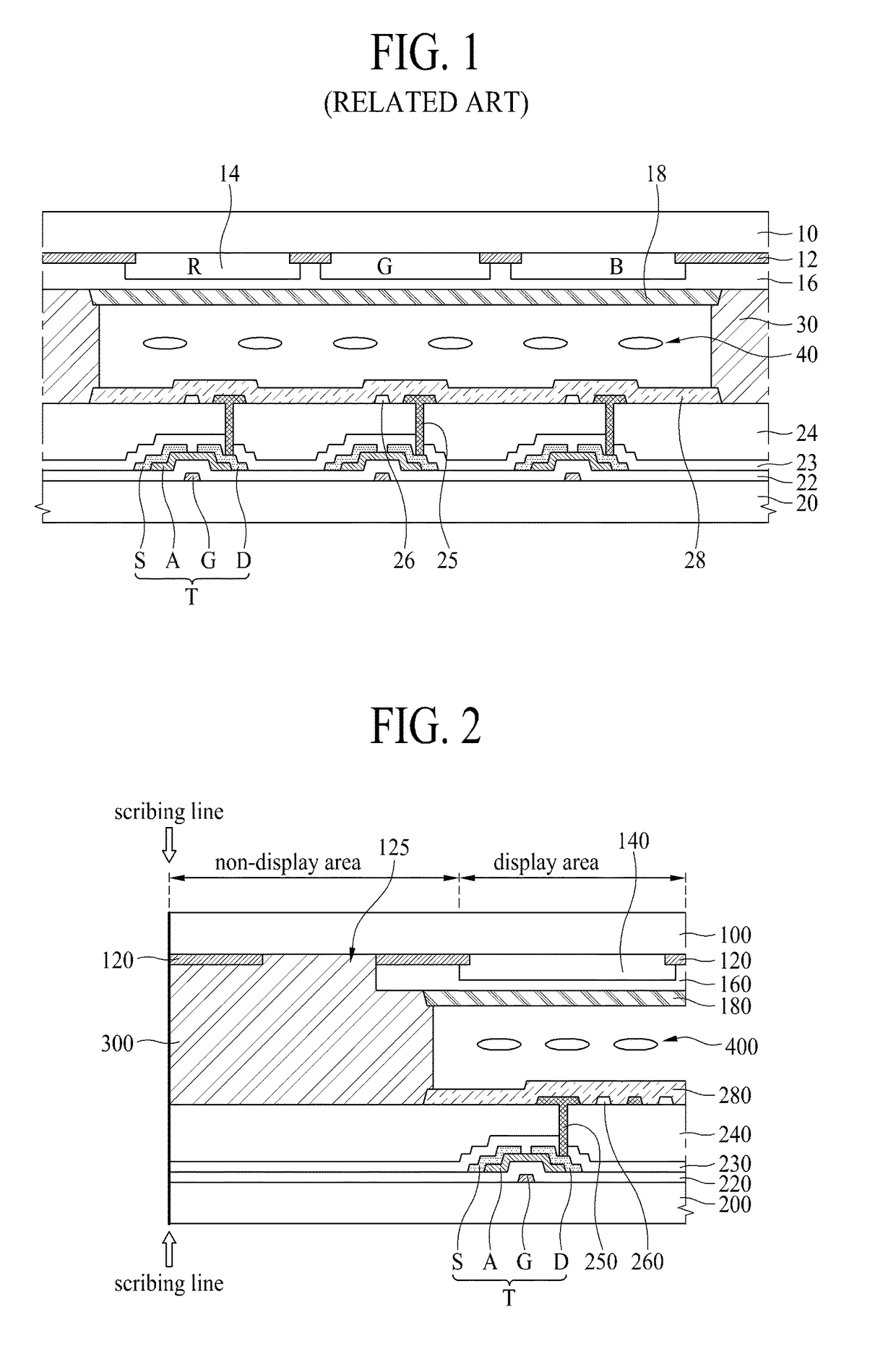

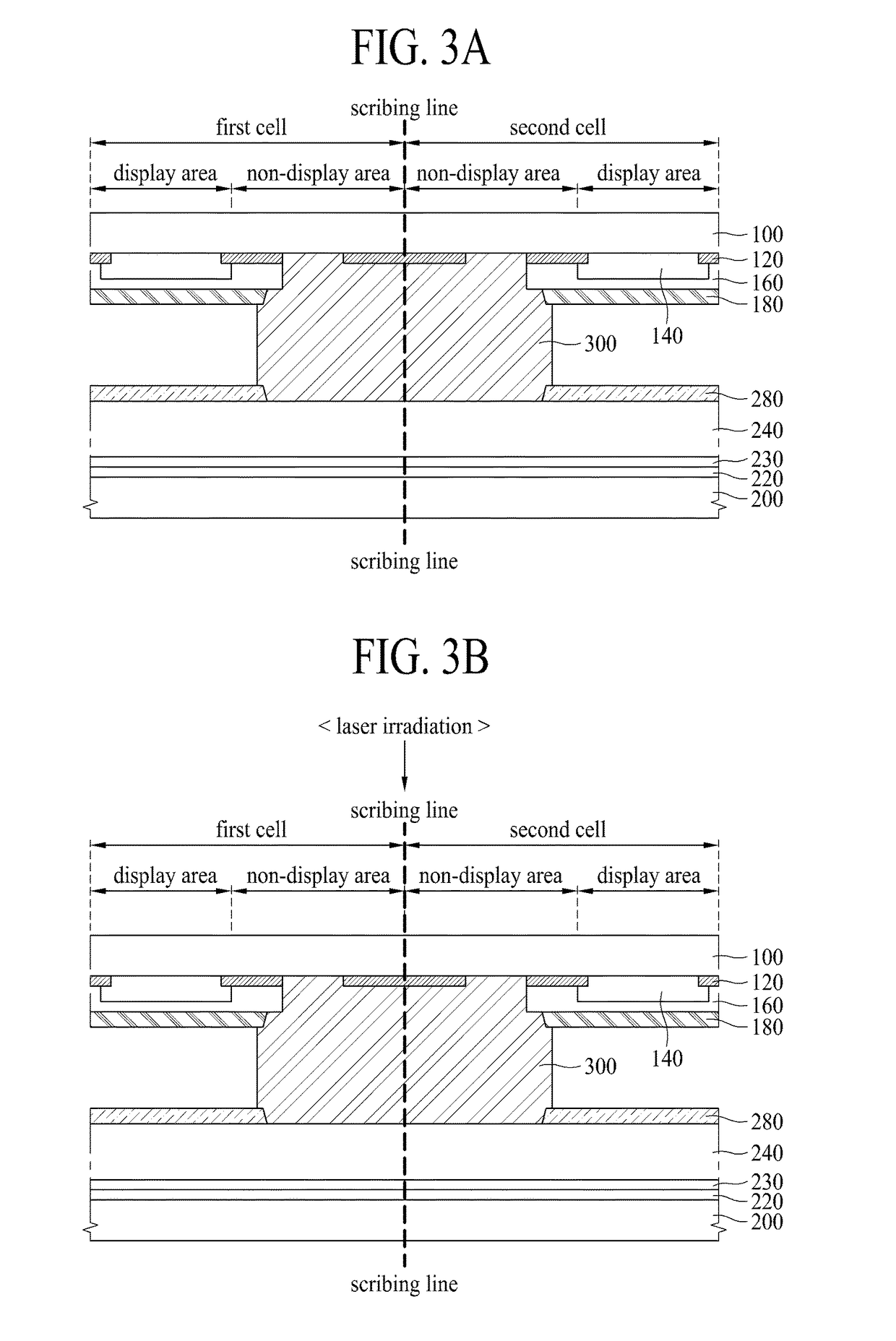

Liquid crystal display apparatus

Owner:LG DISPLAY CO LTD

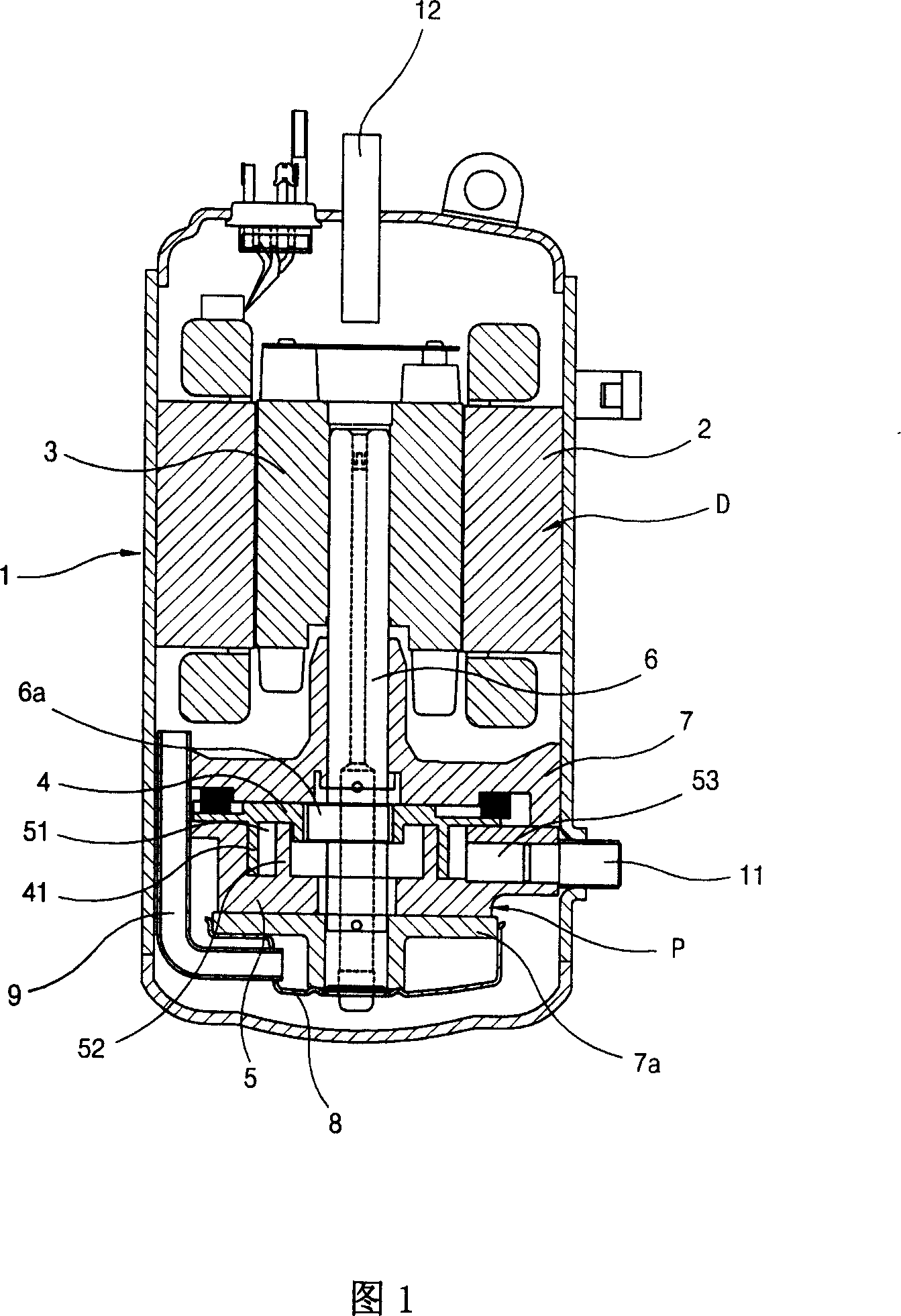

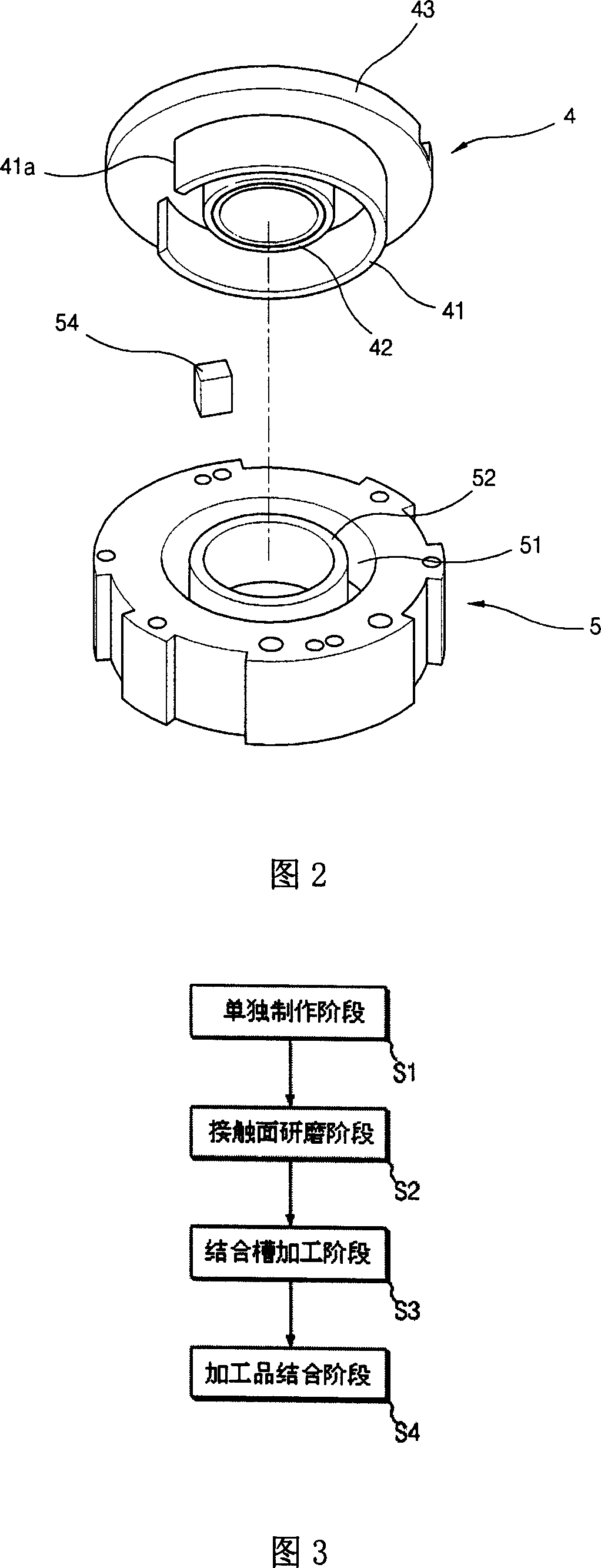

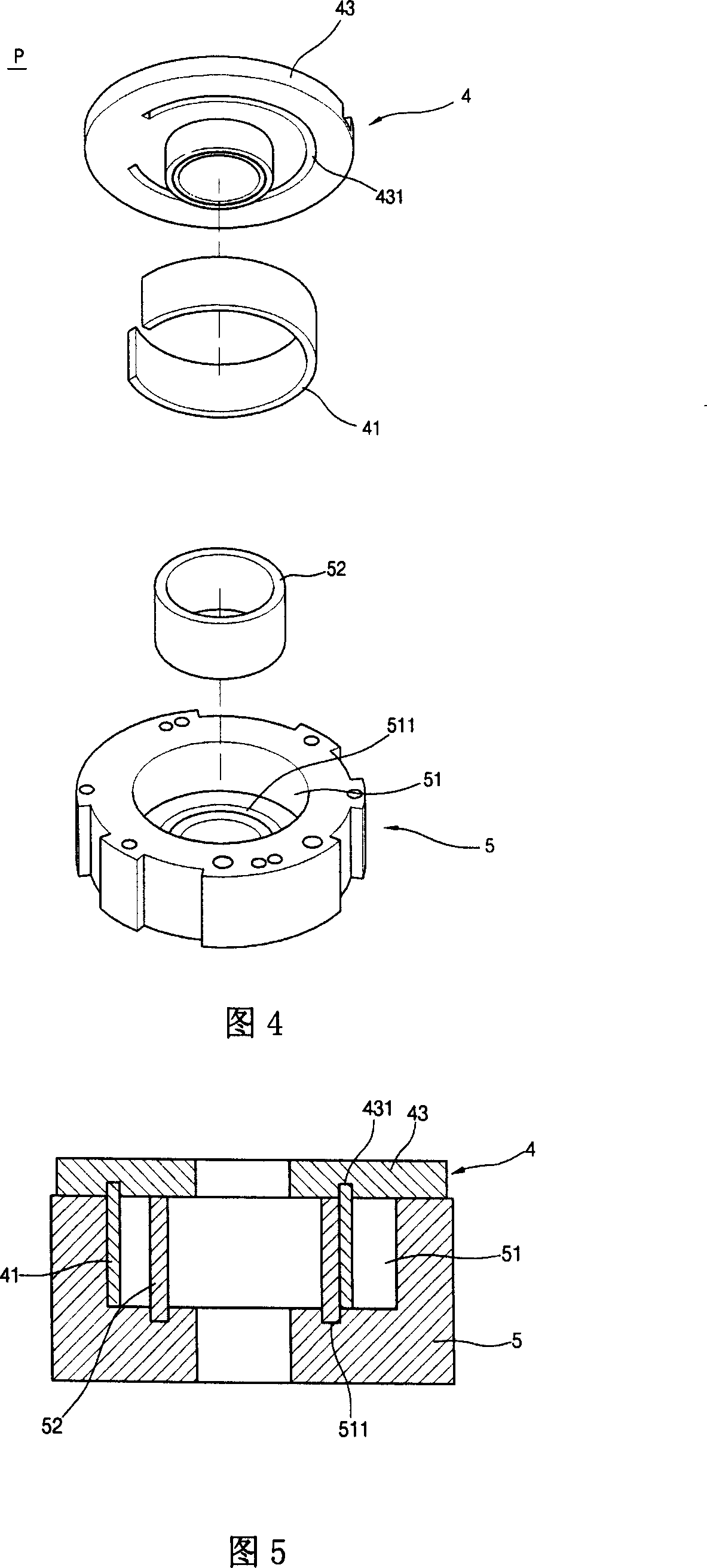

Method for making compression components for rotating blade type compressor

InactiveCN1963223AReduce leakageEasy to adjust toleranceRotary piston pumpsRotary piston liquid enginesContact phaseMechanical engineering

The compressing method for a rotary vane type compressor comprises the stage of making hard plates, round vanes, cylinders, and separate making of each inside rings, the contact grinding stage of the part under the hard plate and the round vane, above the inside of the ring space and inner ring, the jointing groove processing stage under the hard plate and above the inside of the ring space, and the combining stage of processed part by combining the top of the round vanes in the combining groove on the hard plate and combining the bottom of the inner rings in the combining groove of the ring space. While making the grinding process easier for the contact phase of the rotary vanes and other components touched with it, it can easily adjust the tolerance in the combining process.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Method for on-line measurement of MEMS membrane stress gradient

InactiveCN101403693BHigh precisionReduce the area occupied by the chipPhase-affecting property measurementsForce measurement by measuring optical property variationMembrane stressConductive materials

The invention discloses a method used for online measuring the stress gradient of MEMS film, comprising the steps as follows: a round film with center fixed is prepared on a structure layer film; after the round film is released, the round film generates deformation under the stress gradient inside the round film; the displacement of the edge of the round film in the vertical direction is measured by a non-contact phase-shifting typed Mirau interferometer, thus calculating the curvature radius of the round film; and the stress gradient of the film can be calculated by the young modulus and Poisson ratio of the film and the curvature radius of the round film. The measurement method is characterized in that a centrosymmetric round film with the center fixed is used as a testing structure and a choring area is fixedly clamped closely to an ideal state, thus improving the precision of the model; the non-contact optical interference method is used for measurement, thus not affecting testing structure and having good repeatability; the method is suitable for measuring the stress gradient of conductive material and non-conductive material simultaneously; and furthermore, the measurement method has the advantages of simple and convenient operation, high measurement precision, small chip occupying area and the like.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

Non-contact phase-difference type torque sensor

InactiveCN101907501BSimple structureLow costWork measurementTorque measurementInterference fitInvolute gear

The invention relates to a non-contact phase-difference type torque sensor which comprises an input sleeve, an output sleeve, a Hall sensor, a first involute gear and a second involute gear, wherein the input sleeve is connected with the output sleeve through a torsion bar, a hub bore of the first involute gear is in interference fit with the output sleeve, a hub bore of the second involute gear is in interference fit with the input sleeve, third sections of shaft segments of the input sleeve and the output sleeve are respectively matched with an inner ring of a corresponding bearing, an outer ring of the bearing is respectively matched with two groups of sensor shells which are arranged at two sides of the torsion bar, a magnetic circuit support is respectively fixed on the inner surfaceof each sensor shell, a magnetic circuit assembly and a circuit board are fixed on each magnetic circuit support, the Hall sensor is welded on the circuit board, and a detection surface of the Hall sensor is arranged in an air gap where the end surface of magnetic-conducting soft iron a just faces to a top addendum circle of the involute gear. The invention has the advantages of simple structure,accurate test, good stability, comparatively lower cost, and the like.

Owner:TONGJI UNIV

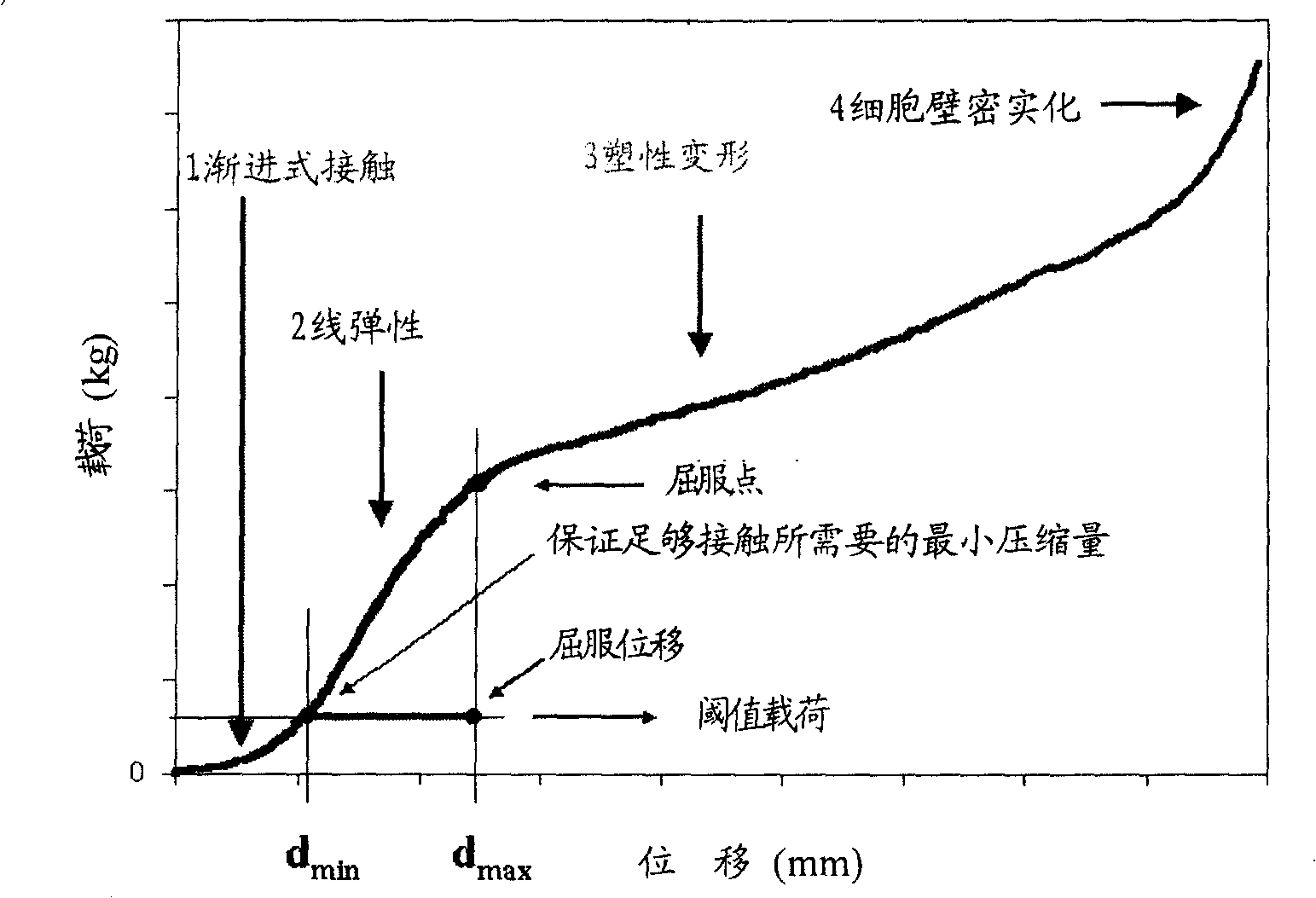

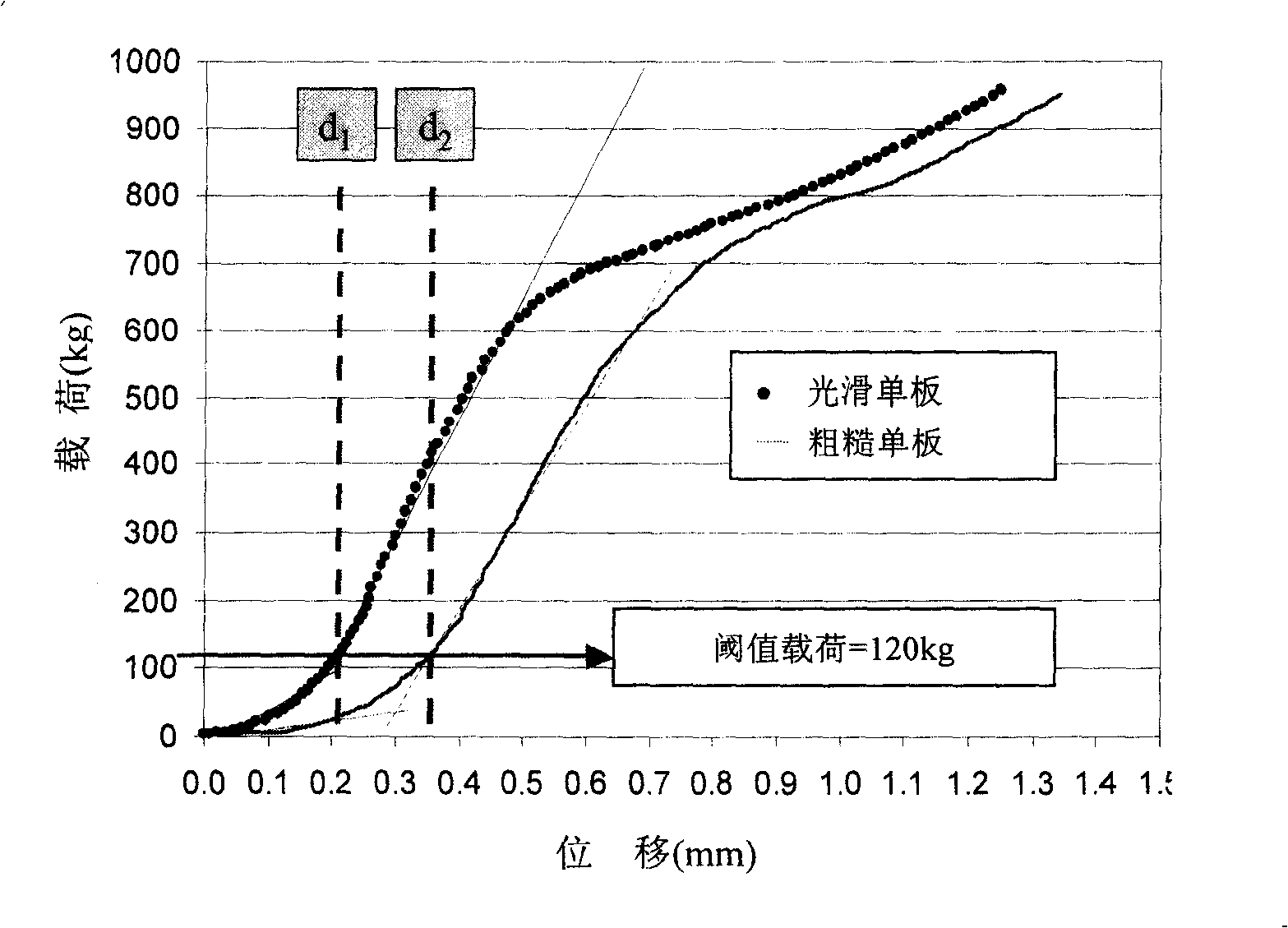

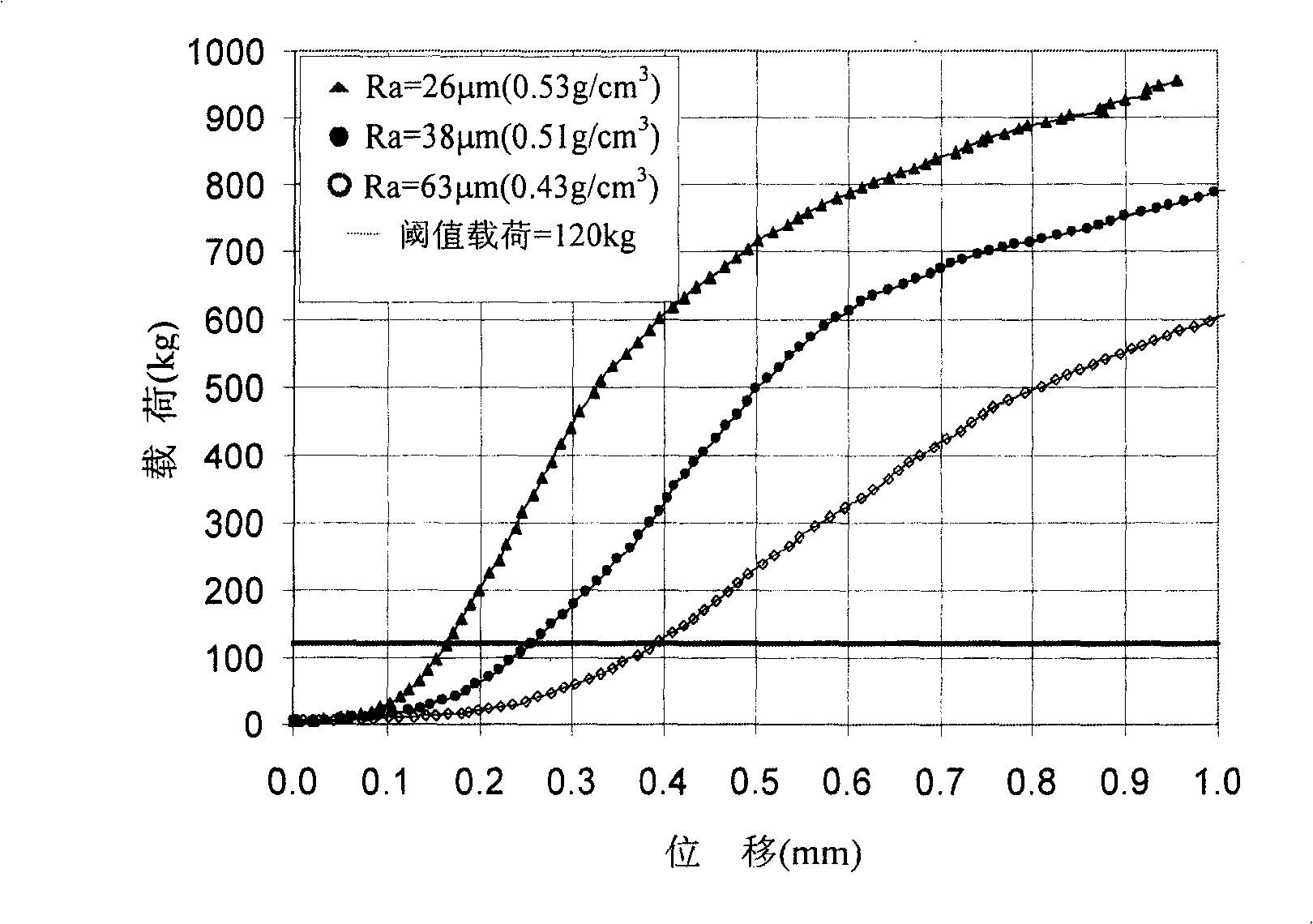

Veneer surface roughness and compressibility test method

The invention relates to a new measuring method for single-plate surface roughness and compressibility, belonging to the technology field of artificial plate, material processing and automation so on. According to relative theory of primary progressive contacting stage ignored in conventional method in radial compressing test of single plate, the invention provides the new method. When progressive contacting stage ends or linear elastic stage starts corresponding load is threshold load. The displacement under threshold load surface even roughness of single plate can be reflected well. So by measuring the displacement under threshold load surface roughness of single plate can be evaluated. When single plate is compressed in radius and load achieve threshold load, contacting area achieves 80% or more; here the influence of surface roughness can be eliminated basically and corresponding displacement can be used as the minimum compression amount needed by single plate. The invention can be used for measuring single-plate roughness and compressibility quickly and determine the minimum compression amount of single plate and glue consumption under special conditions. Single plate outturn rate and plate bonding quality are improved and it lays a foundation for realizing on-line intelligent decision.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com